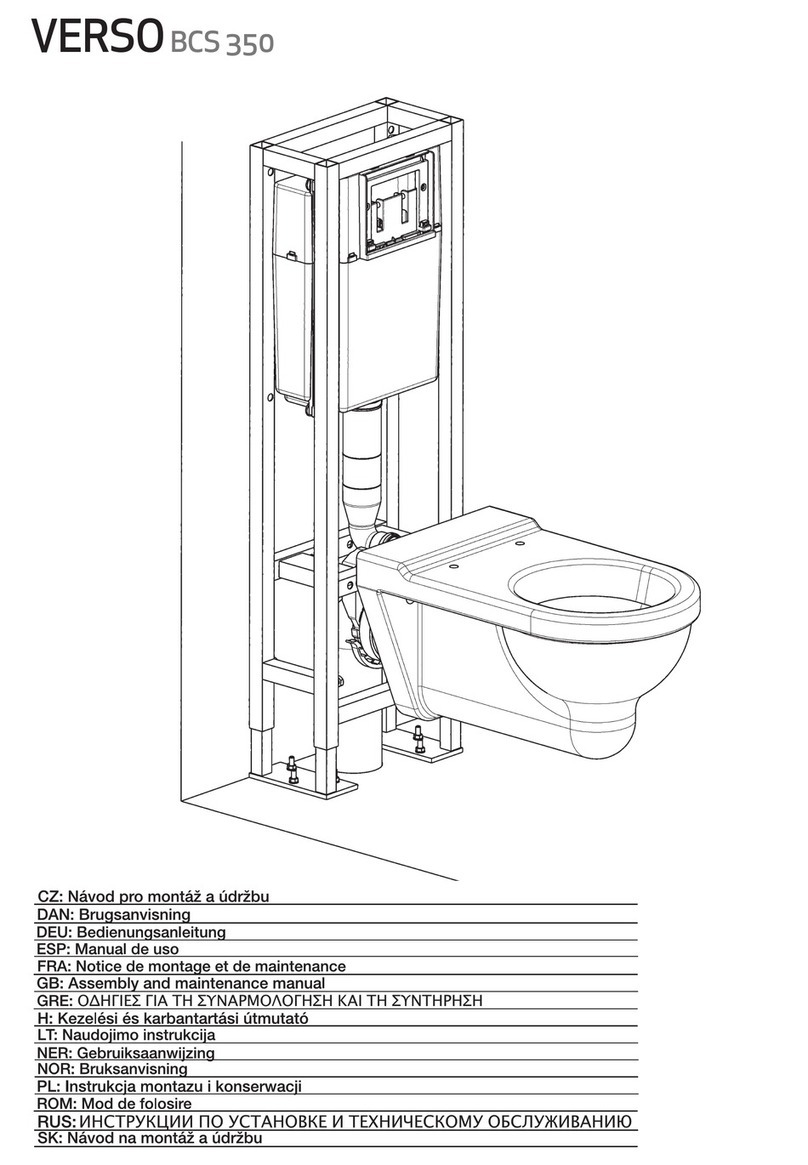

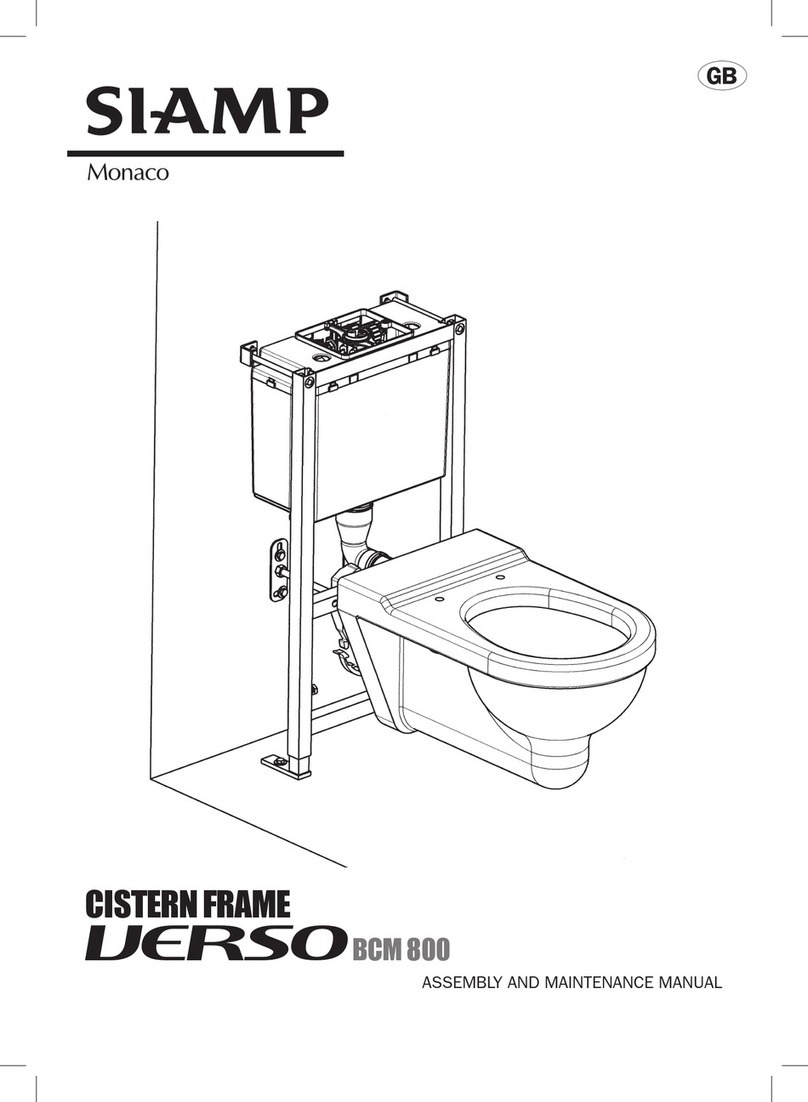

Siamp 50 6189 00 User manual

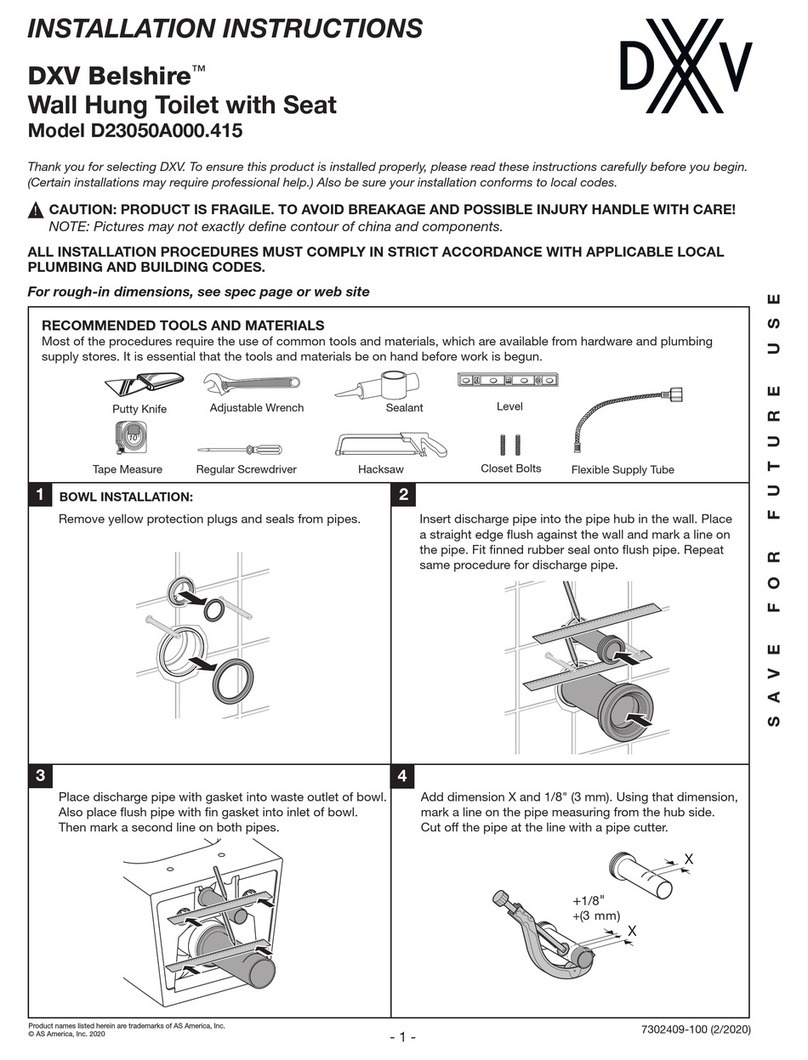

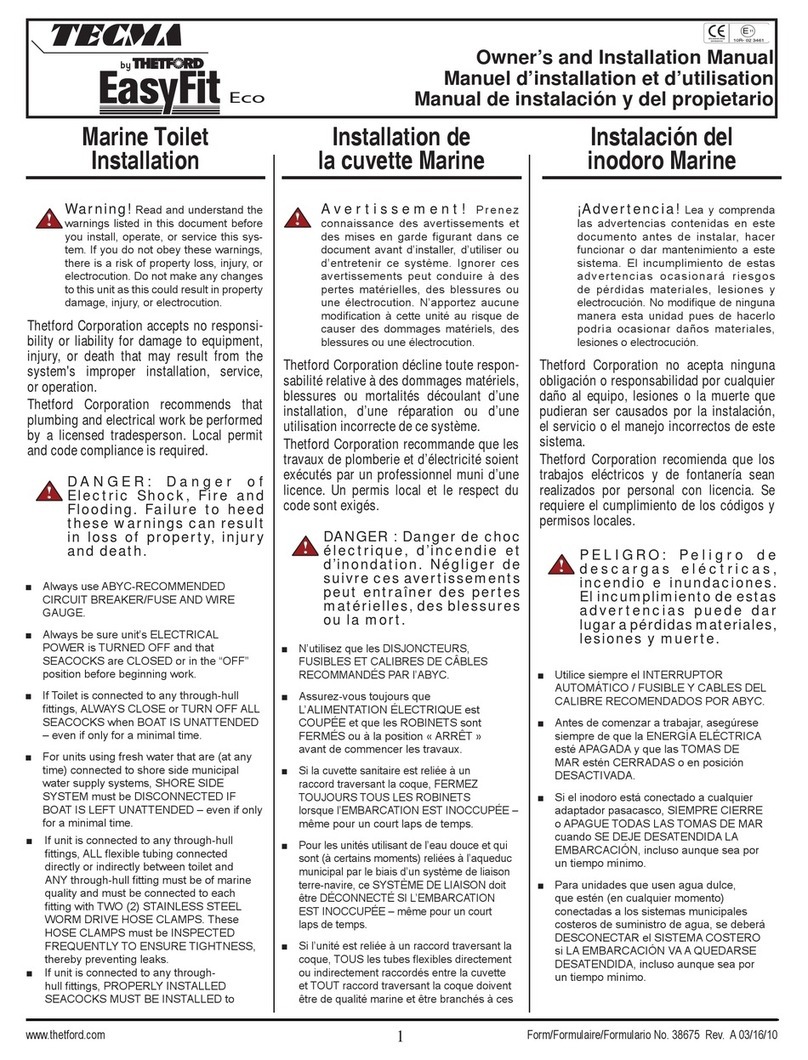

ASSEMBLY

INSTRUCTIONS

N 50N 100

Asean

Adjusting screw

Backnut

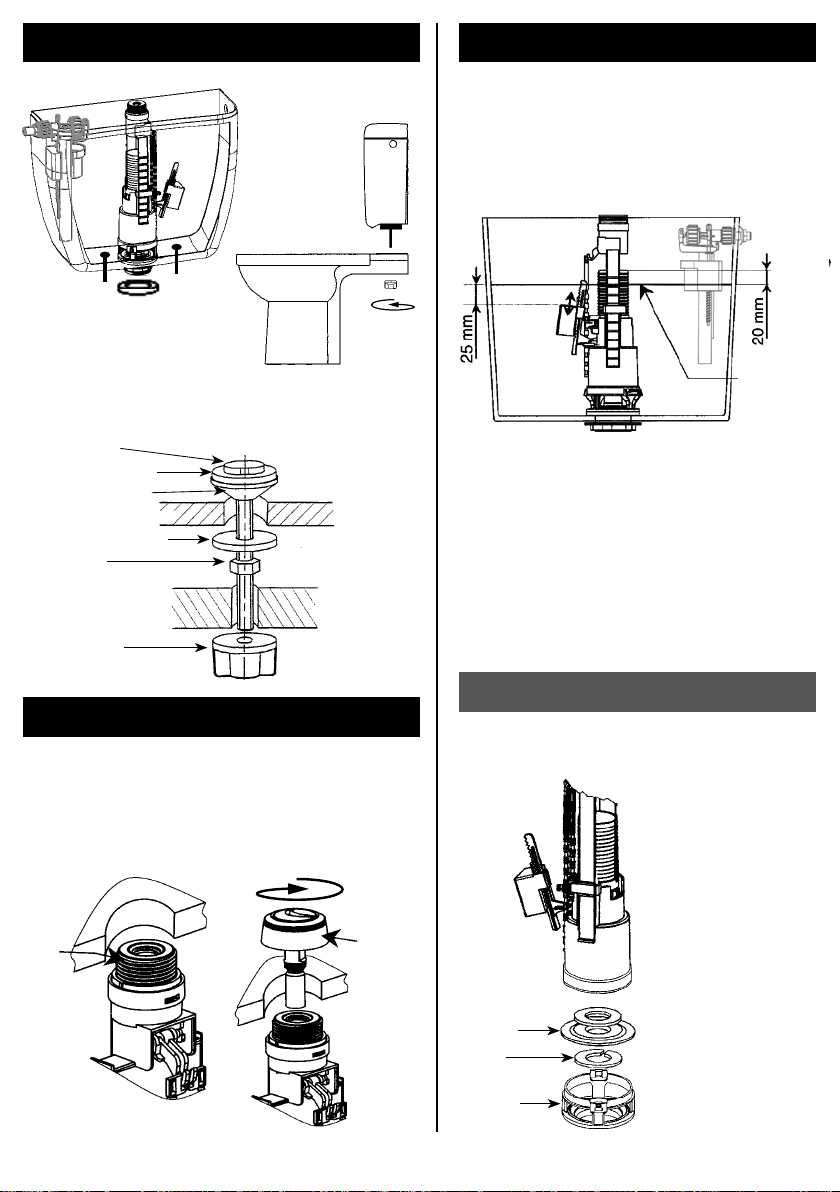

COMPACT 99B / 93B

➊Place inlet valve through inlet hole with inlet

rubber washer inside the cistern

➋Secure with backnut

➌Connect the supply

➍Adjust water level

with grey adjusting screw.

N.B. Ensure tightness of connection to cistern with filter

gasket.

WARNINGS:

1 - Do not overtight in any case.

2 - Do not use any sealing paste and/or compound in any case

3 - Do not use connector handling the internal part of the

inlet valve.

SIAMP will be not responsible in case these warnings are

not respected.

Seal

Inlet

rubber

washer

COMPACT 99T WITH TELESCOPIC TUBE

➊Adjust telescopic tube

(a) raise the grey blocking ring

(b) screw or unscrew the gradiated tube

in way so that the inlet top not exceed

the top of the tank

(c) position back the grey ring

➋Place inlet valve through inlet hole with inlet

rubber washer inside the cistern

➌Secure with backnut

➍Connect the supply

➎Adjust water level

with grey adjusting screw.

N.B. Ensure tightness of connection to cistern with filter

gasket.

WARNINGS:

1 - Do not overtight in

any case.

2 - Do not use any

sealing paste and/

or compound in any

case

3 - Do not use connector

handling the internal

part of the inlet valve.

SIAMP will be not responsible in case these warnings are

not respected.

Adjusting screw

Backnut

Filter seal

Inlet

rubber

washer

MAINTENANCE

Membrane

Blocking ring

(b)

(a)

(c)

2

HANDY 93T WITH TELESCOPIC TUBE

➊Adjust telescopic tube

(a) raise the grey blocking ring

(b) screw or unscrew the gradiated tube

in way so that the inlet top not exceed

the top of the tank

(c) position back the grey ring

➋Place inlet valve through inlet hole with

inlet rubber washer inside the cistern

➌Secure with backnut

➍Connect the supply

➎Adjust water level

with grey adjusting screw.

N.B. : Make connecting tightness

with fibre seal other than any

corrosive joint compound

Adjusting screw

Backnut

Fibre seal

Inlet

rubber

washer

Blocking ring

(b)

(a)

(c)

HANDY 93L

➊Place inlet valve through inlet

hole

➋Secure with backnut

➌Connect the supply

➍Adjust water level

with grey adjusting screw.

N.B. : Make connecting tightness

with fibre seal other than any

corrosive joint compound

Adjusting screw

Backnut

Fibre seal

3

H

D

➍

➊

➌

➎

➏➐

➋

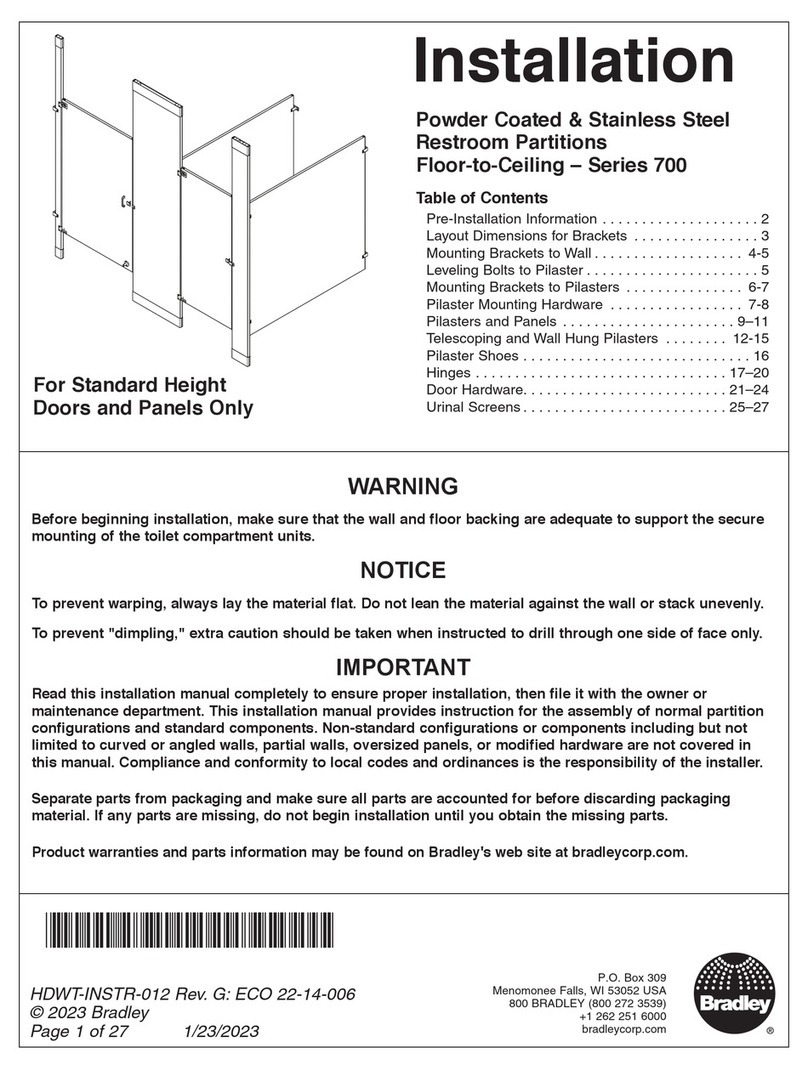

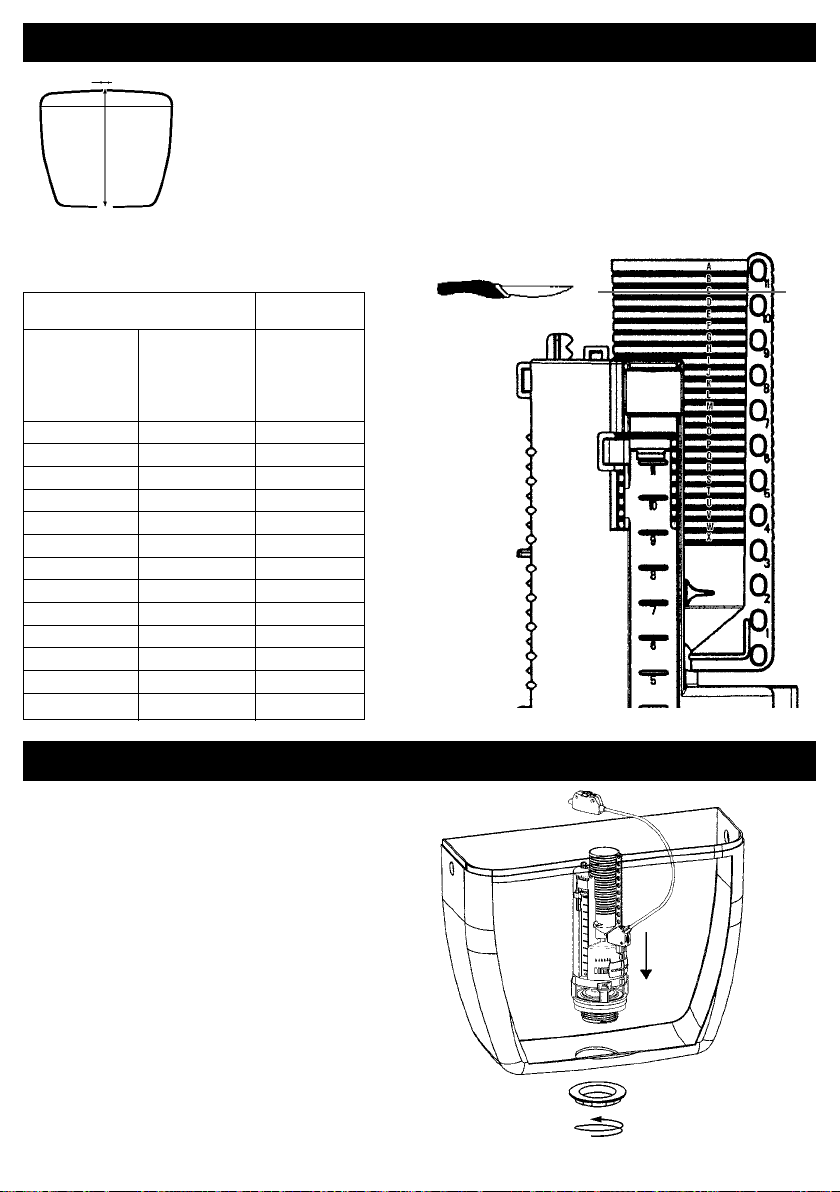

I - PREPARATION OF THE MECHANISM 33A/22A

Measure the cistern:

- H (from top of lid to inside bottom of cistern)

- D (diameter of hole in lid)

Check the positioning of the stirrup

if the stirrup is positioned correctly with

reference to the table below, move on

to step ➑; otherwise, go through all the

following steps in order:

➊Unclip the pulls

➋Remove the pins

➌If necessary, cut the overflow as shown in

the table

➍Squeeze the stirrup and then move it to

defined podition (P)

➎Relax the stirrup and ensure the clipping

into the strap

➏Clip on the lift rod

➐Block the stirrup with the 2 grey blocking

clips

➑Unscrew the nut

Height of cistern H

Diameter D Diameter D

of hole of hole

in lid from in lid from

16 to 36 mm &

37 to 42 mm

43 to 50 mm

1* 307 to 325 325 to 343

2* 326 to 340 344 to 358

3 341 to 355 359 to 373

4 356 to 370 374 to 388

5 371 to 385 389 to 403

6 386 to 400 404 to 418

Position (P)

Stirrup notch Overflow

1 Cut between E and F

2 Cut between B and C

II - INSTALLATION

Position the mechanism in the

cistern and attach

it with the nut.

4

5

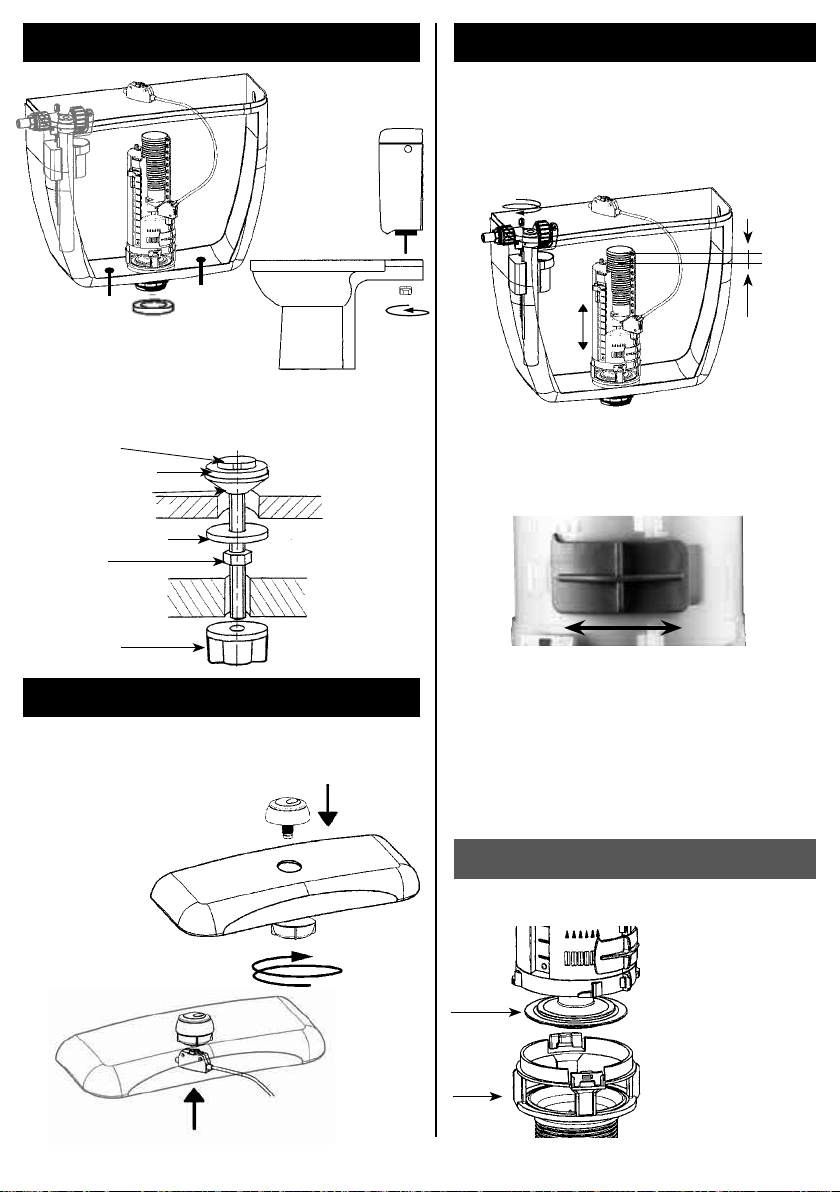

III - ASSEMBLY OF CISTERN TANK

➊Attach the screws to the

bottom of the cistern (see

stack of parts indicated

below

➋Position the foam seal on

the nut

➌Position the cistern

on the toilet bowl and

attach it with the wing

nuts

IV - ADJUSTMENT OF WATER LEVEL

First connect your float valve to the water system,

open the stop valve and adjust the water level using

the float valve (see page 2 or 3).

Note: The max. water level should be 20 mm lower

than the overflow tube.

Overflow

Maximum

water level

20 mm

V - INSTALLING THE BUTTON

➊Once you have finished adjusting, fit the lid.

➋If the lid hole (D) is < 37 mm and > 42,

remove the rose

➌Position the button on the lid and screw down

(without pushing the central part) until it locks

NB : For the model

SWITCH 22A push once

to flush. Pussh again to

interrupt.

VI - MAINTENANCE

Replacement of the seal

➊Open the cistern and turn the mechanism a

quarter turn to separate it from the plug

➋Remove the seal attaching clip

➌Replace the seal

➍Fit the clip then relocate the mechanism,

locking it on the plug

➎Close the cistern making sure that the control

button is correctly assembled (see § V)

Seal

Clip

Plug

Bottom of tank

Cistern wall

Screw M6x78

Tapered joint

Hexagonal nut

Washer

Wing nut

Washer

6

I - PREPARATION OF THE MECHANISM 36A

II - INSTALLATION

Check the positioning of the stirrup

if the stirrup is positioned correctly with

reference to the table below (pin clipped

into the right notch), move on to step ➒;

otherwise, go through all the following

steps in order:

➊Unclip the pulls

➋Remove the pins

➌Remove the stirrup

➍If necessary, cut the overflow as shown in

the table

➎If necessary, cut the pulls

➏Set the stirrup in the suitable notch - see

table

➐Attach the stirrup again using the pins

➑Clip the pulls back in place

➒Clip the small float in place

➓Unscrew the nut

Measure the cistern:

- H (from top of lid to inside

bottom of cistern)

- D (diameter of hole in lid)

Height of cistern H

Diameter D Diameter D

of hole of hole

in lid from in lid from

18 to 38 mm &

38 to 44 mm

45 to 50 mm

10* 293 to 310 312 to 329

9* 309 to 325 328 to 344

8* 324 to 341 343 to 360

7 340 to 356 359 to 375

6 355 to 371 374 to 391

5 370 to 387 390 to 406

4 386 to 402 405 to 422

3 401 to 417 421 to 437

2 416 to 432 436 to 453

1 431 to 447 452 to 468

Stirrup adjusting notch

H

D

➋

➐

➌

➏

➊

➑

➒

➍

Stirrup notch Overflow Pulls

10 Cut between I and J Cut

9 Cut between F and G at 50 mm

8 Cut between C and D from base

Position the mechanism in the cistern and attach

it with the nut.

NB: The small float should

be on the opposite side

to the water inlet.

➓

Position the mechanism in the cistern and attach

it with the nut.

NB: The small float should

be on the opposite side

to the water inlet.

7

Bottom of tank

Cistern wall

Screw M6x78

Tapered joint

Hexagonal nut

Washer

Wing nut

Washer

IV - ADJUSTMENT OF HALF FLUSH

III - ASSEMBLY OF CISTERN TANK

V - INSTALLING THE BUTTON

VI - MAINTENANCE

➊Attach the screws to the

bottom of the cistern (see

stack of parts indicated

below

➋Position the foam seal on

the nut ➌Position the cistern

on the toilet bowl and

attach it with the wing

nuts

Replacement of the seal

➊Open the cistern and

turn the mechanism

a quarter turn to

separate it from the

plug

➋Remove the seal

attaching clip

➌Replace the seal

➍Fit the clip then

relocate the

mechanism, locking it

on the plug

➎Close the cistern

making sure that

the control button is

correctly assembled

(see § V)

Seal

Clip

Plug

First connect your float valve to the water system, open

the stop valve and adjust the Full flush level using the

float valve (see page 2 or 3).

NB: the maximum water level should be 20 mm below

the overflow.

➊Fill the cistern to the maximum level (as

indicated above)

➋Slide the small float along the gray rocker so that

it is 25 mm at least below the water level.

NB: The more you depress the small float, the more

flushing water you will have (minimum possible

3 liters).

➊Once you have finished adjusting, make sure that

the gray collar (C) is unscrewed entirely.

➋Fit the lid

➌If the lid hole (D) is < 38 mm and > 44, remove the

rose (B)

➍Position the button on the lid and screw down until

it locks.

B

C

Overflow

Maximum

water level

8

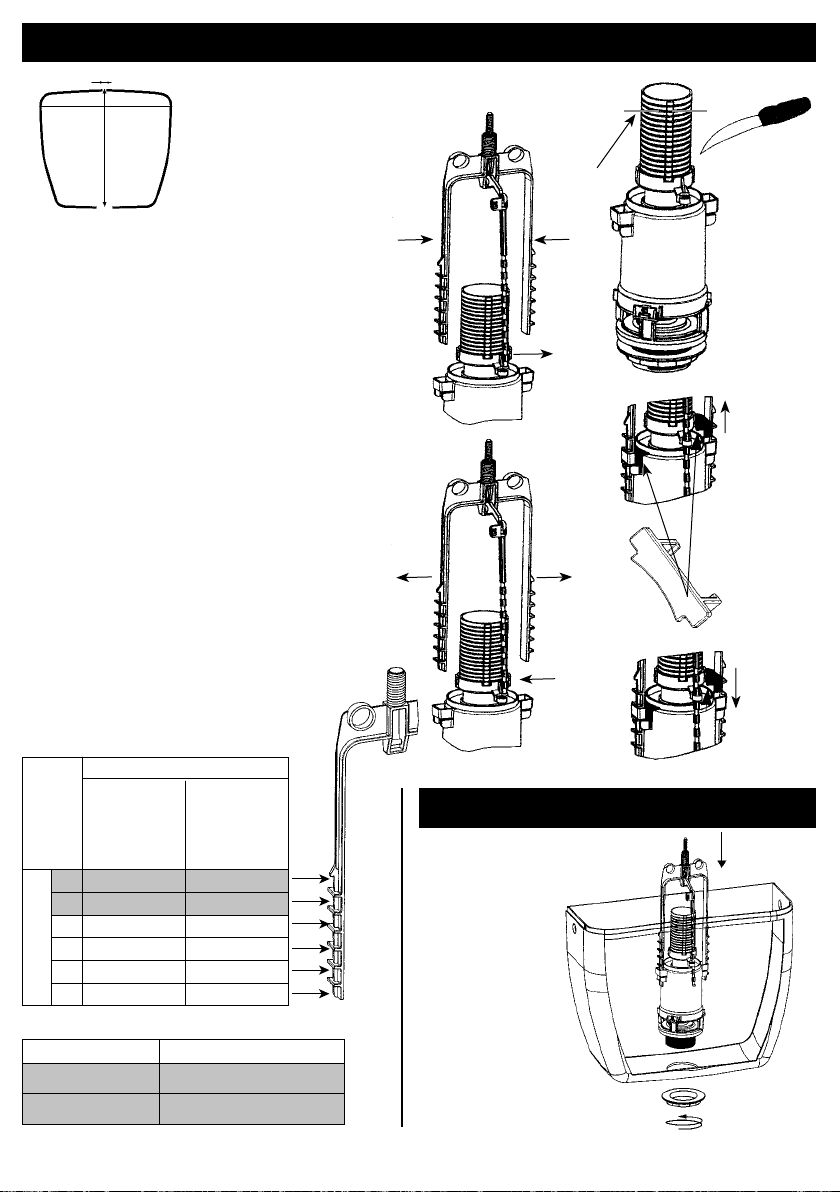

I - PREPARING THE MECHANISM 49

II - INSTALLATION

Check the position of the stirrup

If the stirrup is correctly positioned on

the basis of the below table, proceed to

step ➏. Otherwise, carry out all of the

following steps:

➊Unclip the lift rod

➋Remove the stirrup (m) , by pressing on

the two catch clips

➌Cut the overflow if necessary according to

the table

➍Reposition the stirrup in its seat and slide

it to the required position (desired setting

notch number visible)

➎Clip lift rod back into the hole of the

overflow which has the same number as

that of the setting notch

➏Unscrew the strainer nut

Measure the cistern

-H (from the top of the lid to the inside base of the cistern)

-D (diameter of the hole in the lid)

Height Hof cistern

Diameter D Diameter D

of hole in lid of hole

18 to 38 mm in lid

and 38 to

45 to 50 mm 44 mm

11 430 to 417 448 to 435

10 416 to 405 434 to 423

9 404 to 393 422 to 411

8 392 to 381 410 to 399

7 380 to 369 398 to 387

6 368 to 357 386 to 375

5 356 to 345 374 to 363

4 344 to 333 362 to 351

3 332 to 321 350 to 339

2 320 to 309 338 to 327

1 308 to 297 326 to 315

Mini

296 to 282 314 to 300

No. of notch visible on lift rod

H

D

➌

➍

Stirrup notch Cut on overflow tube

3 C mark visible

2 F mark visible

1 I mark visible

Mini L mark visible

Position the mechanism

in the cistern and secure

it in place with the nut

➊

➋

➊+ ➋=

Visible stirrup notch

no. 4 = position of lift rod no. 4

➎

9

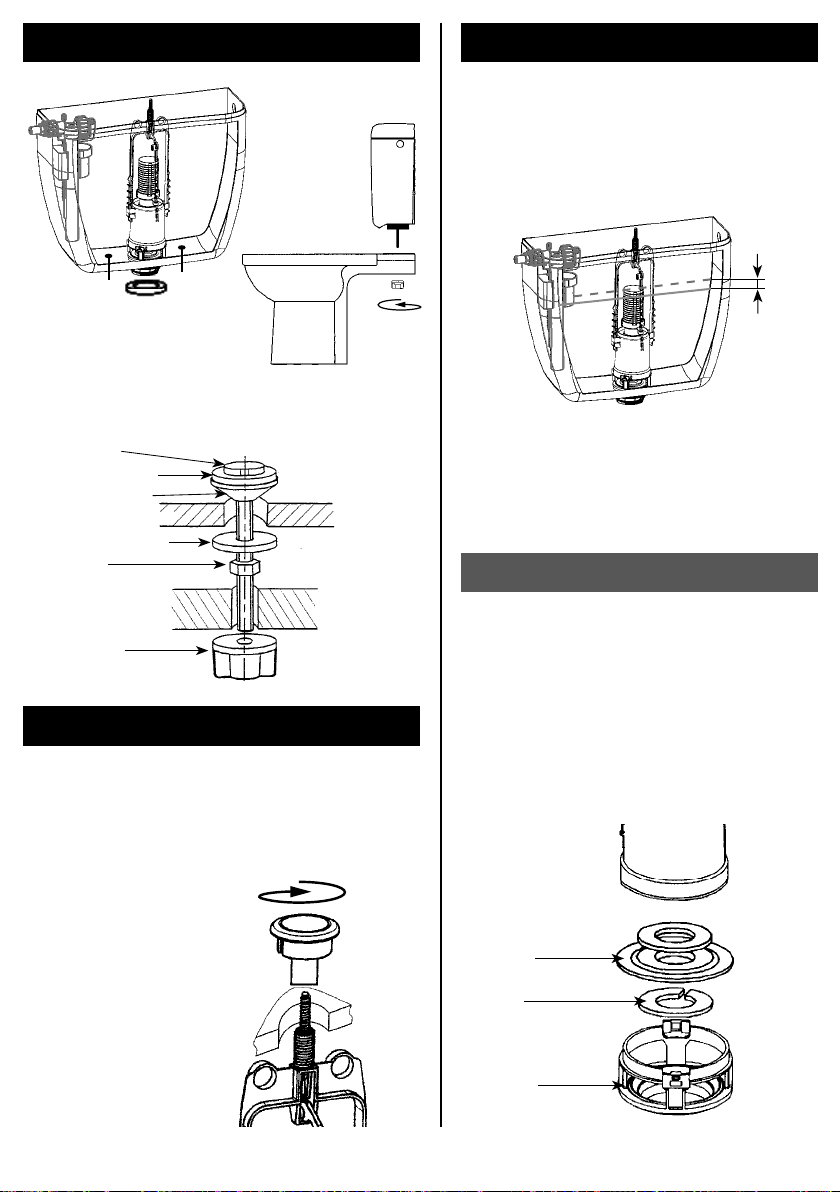

IV - SETTING WATER LEVEL

III -

ASSEMBLING BOWL AND CISTERN

V - INSTALLATION OF BUTTON

VI - MAINTENANCE

Bottom of cistern

Wall of bowl

Conical seal

Hexagon nut

Washer

Wing nut

Washer

➊Fix screws at the bottom

of the cistern (see order of

parts below)

➋Position the latex foam

gasket on the nut

➌Position the cistern on

the bowl and secure it

with wing nuts

Changing the valve gasket

➊After having opened

the cistern, turn the

mechanism 90° to

separate it from its

strainer

➋Change the valve

gasket

➌Reposition the

mechanism, locking

it into the strainer

➍Close the cistern

again.

Valve gasket

Strainer

After having connected your ballcock to the water

supply, open the tap and set the level of the long flush

using the ballcock (see overleaf).

Note: The max. water level should be 20 mm lower

than the overflow tube.

To adjust the water level of the short flush, slide the

cursor along.

Note : The closer the cursor is to 18, the more

water will be flushed.

➊Once the set-up has been completed, put on the lid

on the cistern

➋If the hole in the lid (D) is > 38 mm and < 45 mm,

remove the escutcheon

➌Position the button on the lid and screw until tight.

20 mm

Overflow

Max.

water level

In some (rare) cases, the residual water level

(amount of water remaining after the long flush)

must be increased to ensure more efficient

cleaning. To do this, move the sliding valve to the

left (the more it is open, the more the residual water

increases).

Note: Increasing the residual water reduces the

volume of water flushed. If necessary, readjust the

max. water level using the ballcock.

M6x78 screw

10

I - PREPARING THE MECHANISM 50

II - INSTALLATION

➊In the table below, choose the right level

for the overflow shortening

➋Unscrew the strainer nut

Measure the cistern

-H (from the top of the lid to the inside base of the cistern)

-D (diameter of the hole in the lid)

H

D

Position the mechanism in the cistern

and secure it in place with the nut

Height H Overflow tube

of cistern shortening

Diameter D Diameter D

of hole in lid of hole

18 to 38 mm in lid Cut between

and 38 to

45 to 50 mm 44 mm

> 332 mm > 350 mm No cut

327 to 332 345 to 350 A and B

322 to 326 340 to 344 B and C

317 to 321 335 to 339 C and D

312 to 316 330 to 334 D and E

307 to 311 325 to 329 E and F

302 to 306 320 to 324 F and G

297 to 301 315 to 319 G and H

292 to 296 310 to 314 H and I

287 to 291 305 to 309 I and J

282 to 286 300 to 304 J and K

277 to 281 295 to 299 K and L

272 to 276 290 to 294 L and M

11

IV - SETTING WATER LEVELIII -

ASSEMBLING BOWL AND CISTERN

V - INSTALLATION OF BUTTON

VI - MAINTENANCE

Bottom of cistern

Wall of bowl

Conical seal

Hexagon nut

Washer

Wing nut

Washer

➊Fix screws at the bottom

of the cistern (see order of

parts below)

➋Position the latex foam

gasket on the nut ➌Position the cistern on

the bowl and secure it

with wing nuts

Changing the valve gasket

➊After having opened

the cistern, turn the

mechanism 90° to

separate it from its

strainer

➋Change the valve

gasket

➌Reposition the

mechanism, locking

it into the strainer

➍Close the cistern

again.

Valve gasket

Strainer

After having connected your ballcock to the water

supply, open the tap and set the level of the long flush

using the ballcock (see overleaf).

Note: The max. water level should be 20 mm lower

than the overflow tube.

To adjust the water level of the short flush, slide the

cursor along.

Note : The closer the cursor is to 18, the more

water will be flushed.

➊Once the set-up has been completed, place button

on lid and screw button nut, (if the hole in the lid (D)

is > 38 mm and < 45 mm, remove the escutcheon)

➋Clip cable case

➌Place lid back on top of cistern

In some (rare) cases, the dead water level (amount

of water remaining after the long flush) must be

increased to ensure more efficient cleaning. To do

this, move the sliding valve to the left (the more it is

open, the more the residual water increases).

Note: Increasing the dead water reduces the

volume of water flushed. If necessary, readjust the

max. water level using the ballcock.

M6x78 screw

20 mm

Overflow

Max.

water level

(k)

Ref. 50 6189 00 A

12

➊Position the mechanism in the cistern and attach it with the nut.

I - INSTALLATION 41

II - ASSEMBLY OF CISTERN TANK

➊Attach the screws to the bottom of the cistern

(see stack of parts indicated below

➋Position the foam seal on the nut

➌Position the cistern on the

toilet bowl and attach it

with the wing nuts

Bottom of tank

Cistern wall

Screw M6x78

Tapered joint

Hexagonal nut

Washer

Wing nut

Washer

III - INSTALLATION OF CONTROL SYSTEM

➊➋

➌

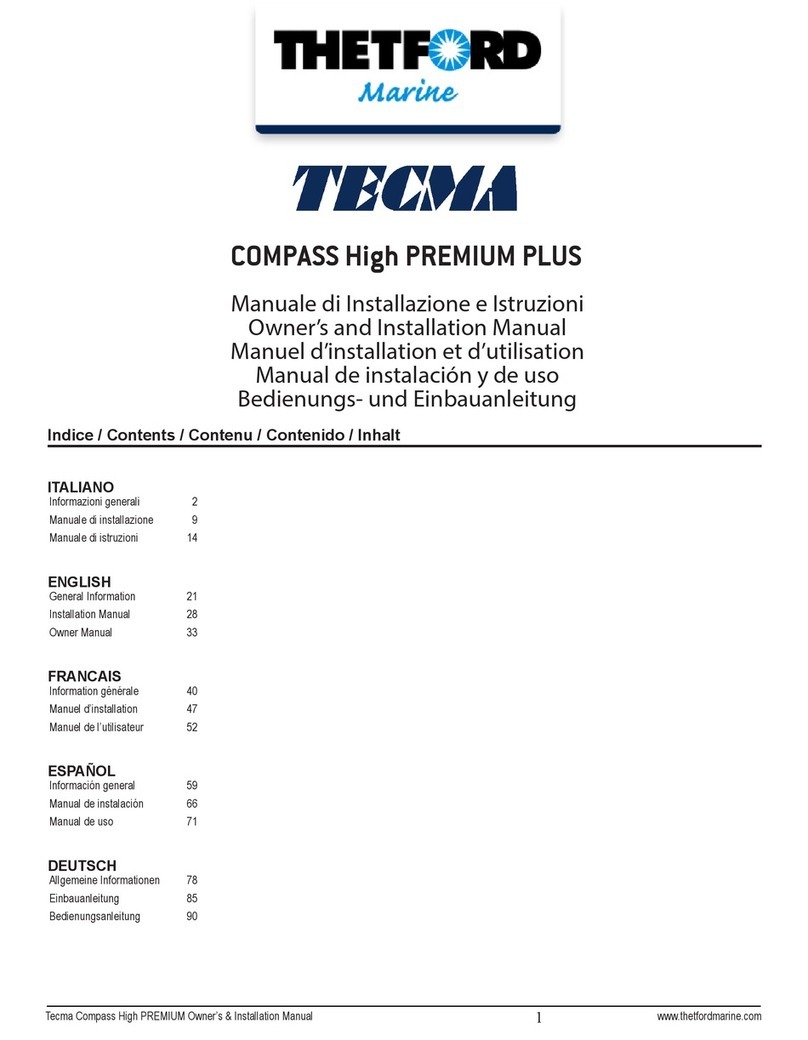

Table of contents

Other Siamp Toilet manuals

Popular Toilet manuals by other brands

JABSCO

JABSCO 37010 Series quick start guide

Dometic

Dometic SeaLand MasterFlush 8900 Series installation instructions

DURAVIT

DURAVIT SENSOWASH 610001 operating instructions

SFA-SANIFLO

SFA-SANIFLO SANIGRIND Installation and maintenance instructions

Geberit

Geberit AQUACLEAN CAMA user manual

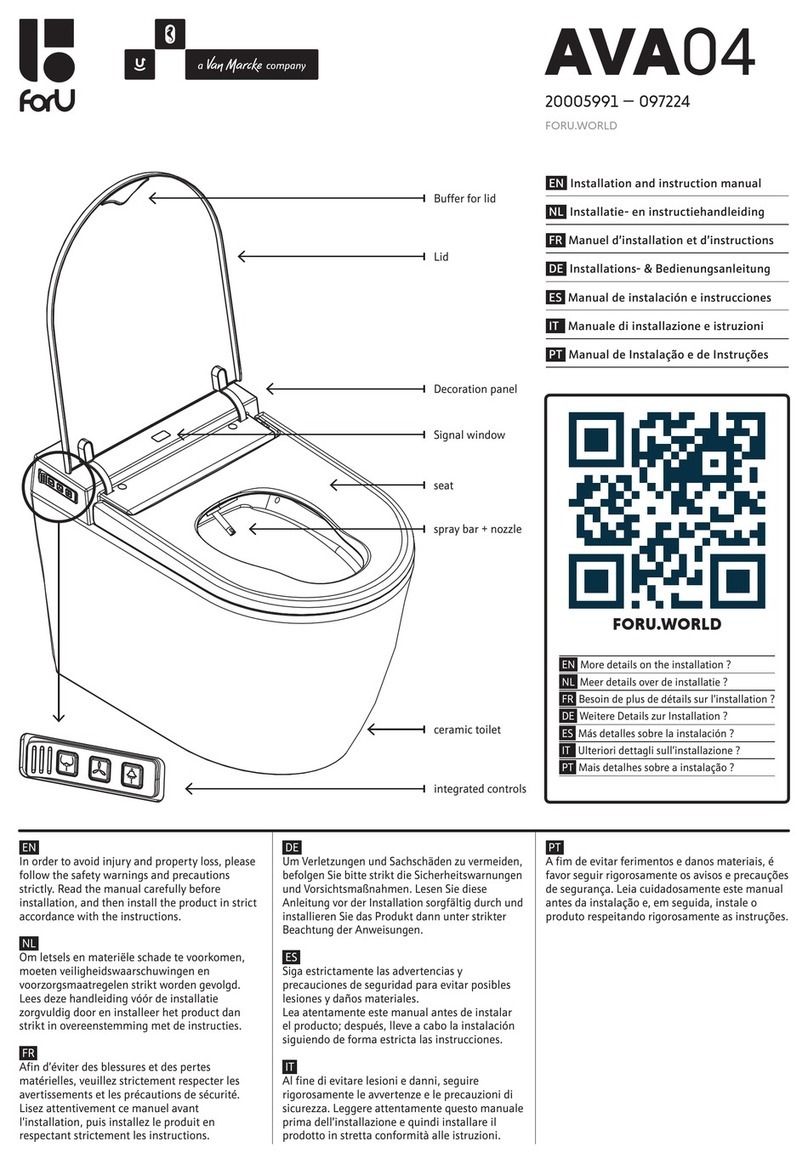

ForU

ForU AVA04 Installation and instruction manual