SIBRE CB8-E Series Manual

Alterations reserved

Siegerland Bremsen –Emde GmbH & Co. KG –Auf der Stücke 1-5 –D-35708 Haiger, Germany

D:\Daten\dat_word\sibre\CB8\CB8-E-100 09-2010.doc

B06 20 243 E-EN

page 1 / 23

09. 2010

Installation and

Maintenance Manual

ABT 75 G / ABT 90

G

Installation and Maintenance

Manual

CB8-E

Alterations reserved

Siegerland Bremsen –Emde GmbH & Co. KG –Auf der Stücke 1-5 –D-35708 Haiger, Germany

D:\Daten\dat_word\sibre\CB8\CB8-E-100 09-2010.doc

B06 20 243 E-EN

page 2 / 23

09.2010

Installation and Maintenance Manual

CB8-E

Contents

page

1General Instructions 3

2Safety Directions 3

2.1 Safety Directions 3

2.2 Symbols used in the operating instructions 4

3Technical Data 5

3.1 Description 5

3.2 Dimensions 8

4Installation 9

4.1 Scope of supply 9

4.2 Transport 9

4.3 To be noted before installation 9

4.4 Lifting and Handling 9

4.5 Cleaning the brake disc 10

4.6 Cleaning the mounting surfaces 10

4.7 Handling of brake linings 10

4.8 Mounting of the brake –initial setup on site 11

4.9 Manual release 13

4.10 Adjustment of reserve stroke 14

4.11 Adjustment of brake torque 15

4.12 Limit switches 17

4.13 Removing the brake 17

5Maintenance 18

5.1 Replacing the brake linings 18

5.2 Replacing other components 20

5.3 Lubrication 20

5.4 Spare parts 21

6Trouble shooting 22

7Disposal 23

B06 20 243 E-EN

page 3 / 23

09.2010

Installation and Maintenance Manual

CB8-E

1 General Instructions

PLEASE NOTE

The present manual is only valid in connection with SIBRE document General Notes

B 06 20 176 E.

The present manual is an integral part of the brake as supplied.

It should always be kept near the brake.

Only precise knowledge of the manual can ensure trouble-free operation of the brake. It is therefore in

the interests of the customer that the manual is read, understood and complied with in all respects by

the personnel responsible for transport, assembly and operation.

PLEASE NOTE

We shall not be liable for any damage or any operating faults resulting from non-compliance

with the manual.

The brake described here corresponds to the state of the art at the date on which this manual went to

print. In the interests of design progress, we reserve the right to make modifications deemed beneficial

to increased efficiency and safety while preserving the main features.

2 Safety Directions

2.1 Safety Directions

The brake has been built to the state of the art and is supplied safe for operation. Unauthorized

modifications impairing operational safety are not permitted. This also applies to safety guards

fitted to prevent contact with moving parts.

The brake may only be used and operated within the limits of the conditions stipulated in the

scope of services and supply.

The customer must ensure that the personnel engaged in assembly, operation, care and

maintenance have read and understood the operating instructions and are complying with them

in every respect, in order to:

prevent risks to life and limb of the user and of third parties

to ensure operating safety of the brake and to rule out any loss of use and damage to the

environment as a result of incorrect handling.

During transport, assembly, dismantling, operation, care and maintenance, the relevant

regulations for working safety and for environmental protection must be complied with.

The brake may only be operated, maintained and repaired by authorized, trained and instructed

personnel.

All work must be performed with care and with a focus on the safety aspect.

B06 20 243 E-EN

page 4 / 23

09.2010

Installation and Maintenance Manual

CB8-E

Work on the brake may only be performed while it is stationary. The drive unit must be secured

against inadvertent switch-on (e.g. by locking of the key switch or by removing the fuses in the

power supply). At the switch-on point, a warning sign must be put up indicating that work is in

progress on the brake.

The drive unit must be stopped immediately if changes are detected in the brake during

operation, for example changes in operating noise.

The brake must be safeguarded against inadvertent contact by appropriate safety guards.

Before installation of the brake inside equipment or facilities, the manufacturers of the latter are

under an obligation to incorporate the regulations, directions and descriptions contained in these

operating instructions into their own operating instructions.

Any work carried out on the brake, which is not mentioned in this manual, should be regarded as

repair. In such cases, please contact your local SIBRE supplier.

2.2 Symbols used in the operating instructions

The important instructions contained in the operating instructions and relating to both safety and

protection are highlighted as follows:

WARNING

This symbol indicates safety measures that must be followed without fail to prevent injuries.

CAUTION

This symbol indicates safety measures that must be followed without fail to prevent damages.

PLEASE NOTE

This instruction refers to general operating directions which must be particularly noted.

B06 20 243 E-EN

page 5 / 23

09.2010

Installation and Maintenance Manual

CB8-E

3 Technical Data

3.1 Description

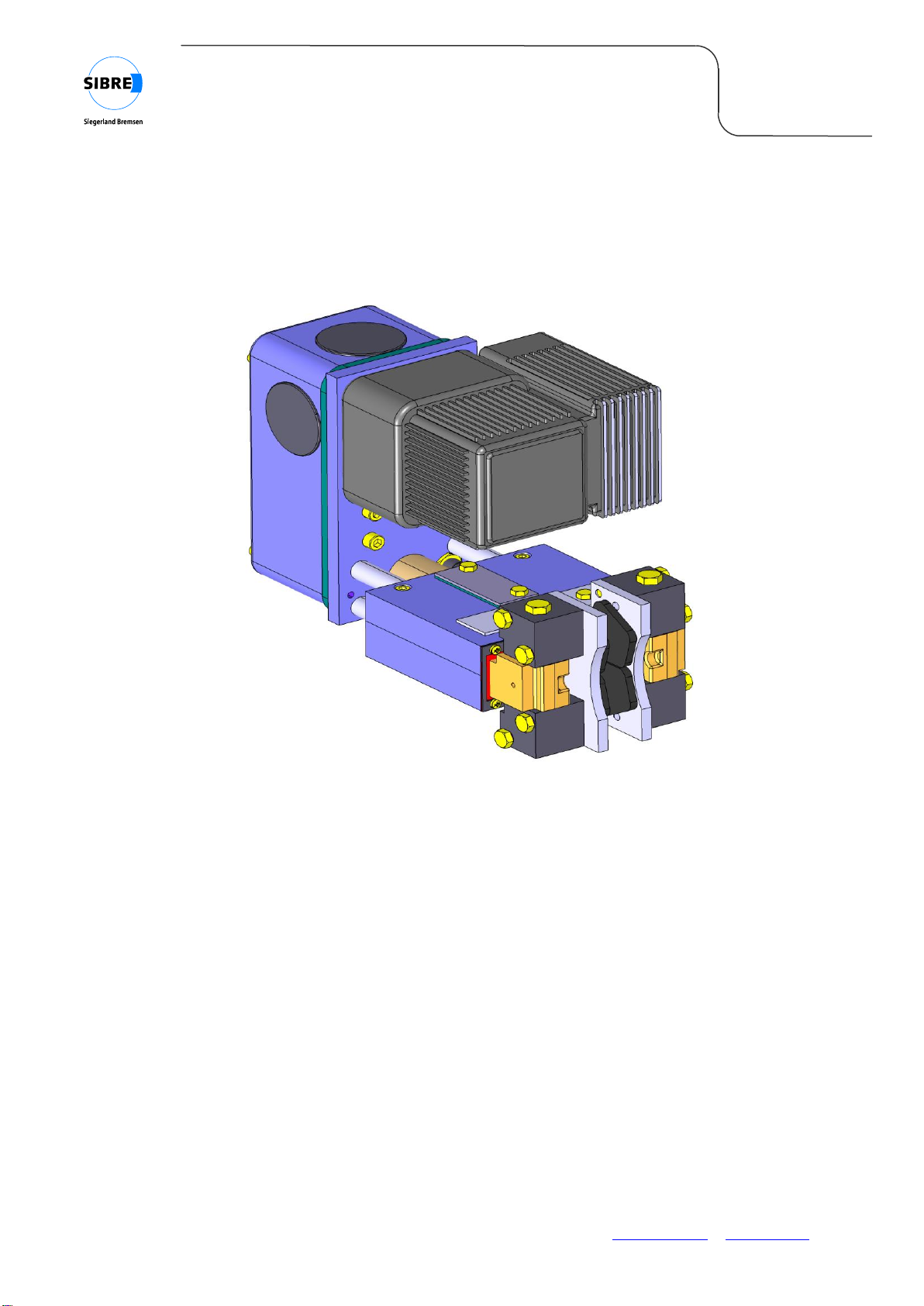

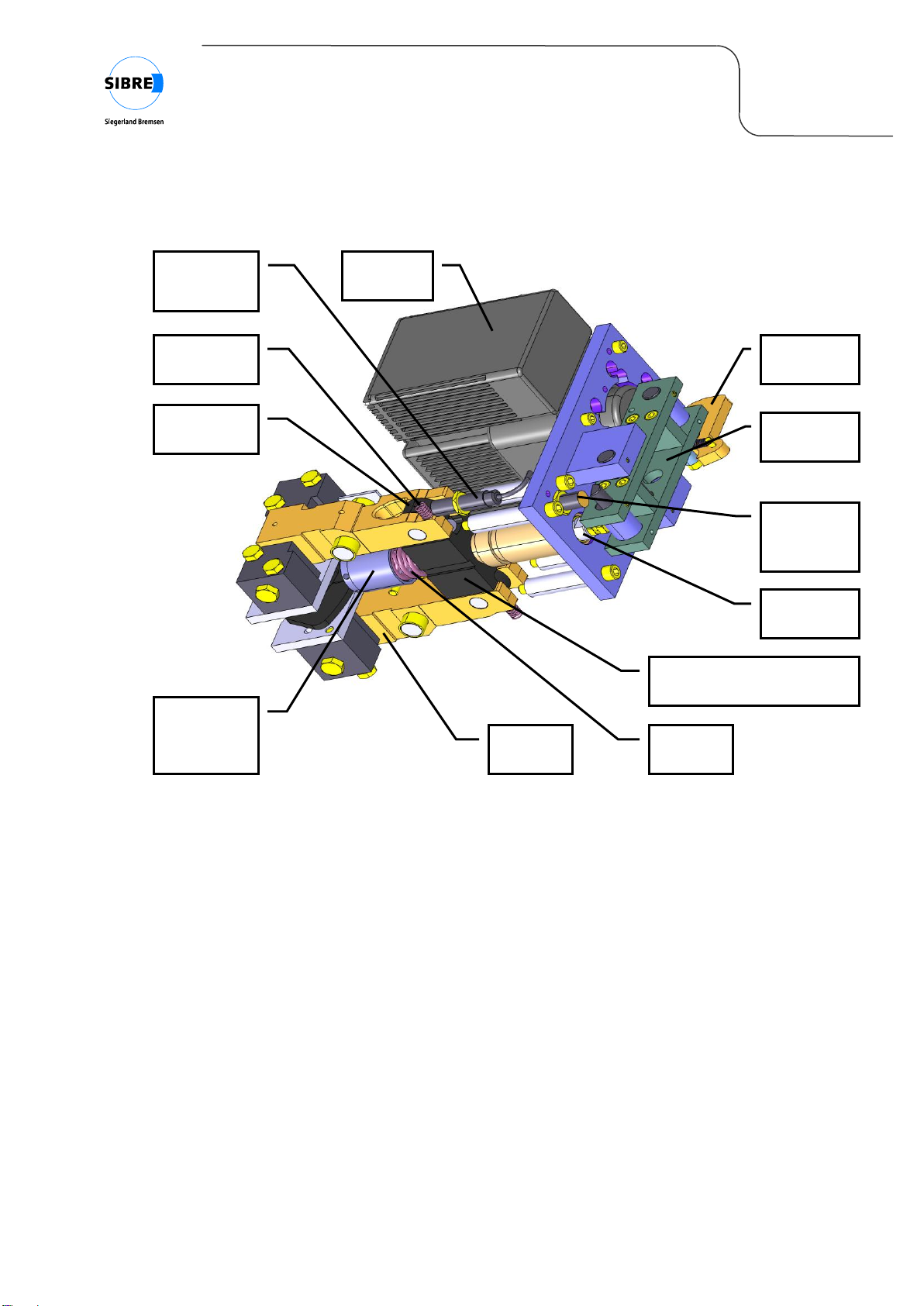

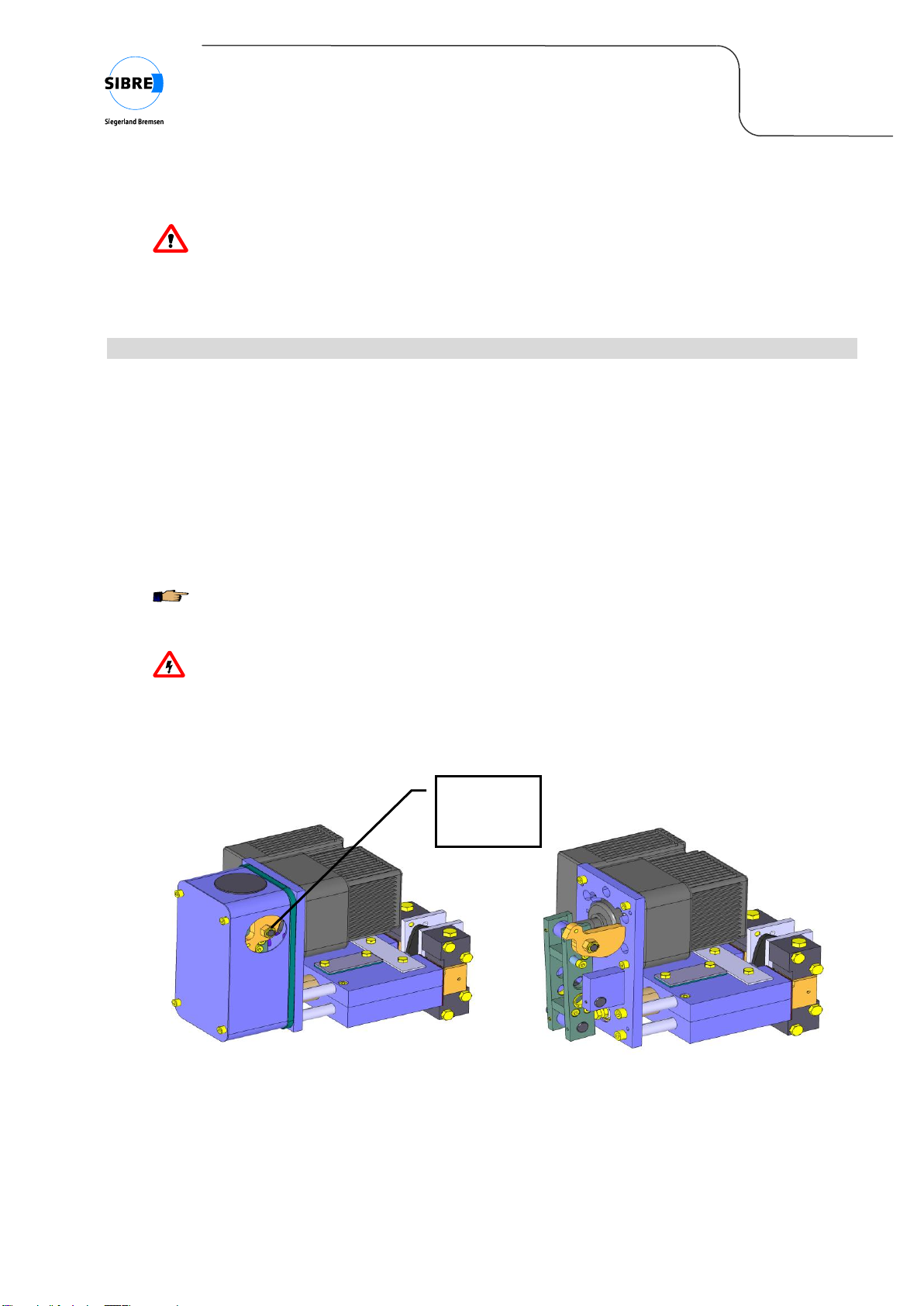

The CB8-E (see figure 1 and figure 2) is designed to transfer a braking torque to a brake disc in

order to stop the rotation of the brake disc or to prevent the brake disc from rotating when stopped

(parking brake). Any other use of the brake should be avoided.

CB8-E brakes are suitable for horizontal and vertical brake discs under any angular displacement.

The CB8-E is designed as a caliper brake which is activated / closed by the force of an integrated

helical compression spring. The clamping force and so the brake torque can be adjusted by adjusting

this spring force. An electro-hydraulic thrustor is used to open the brake.

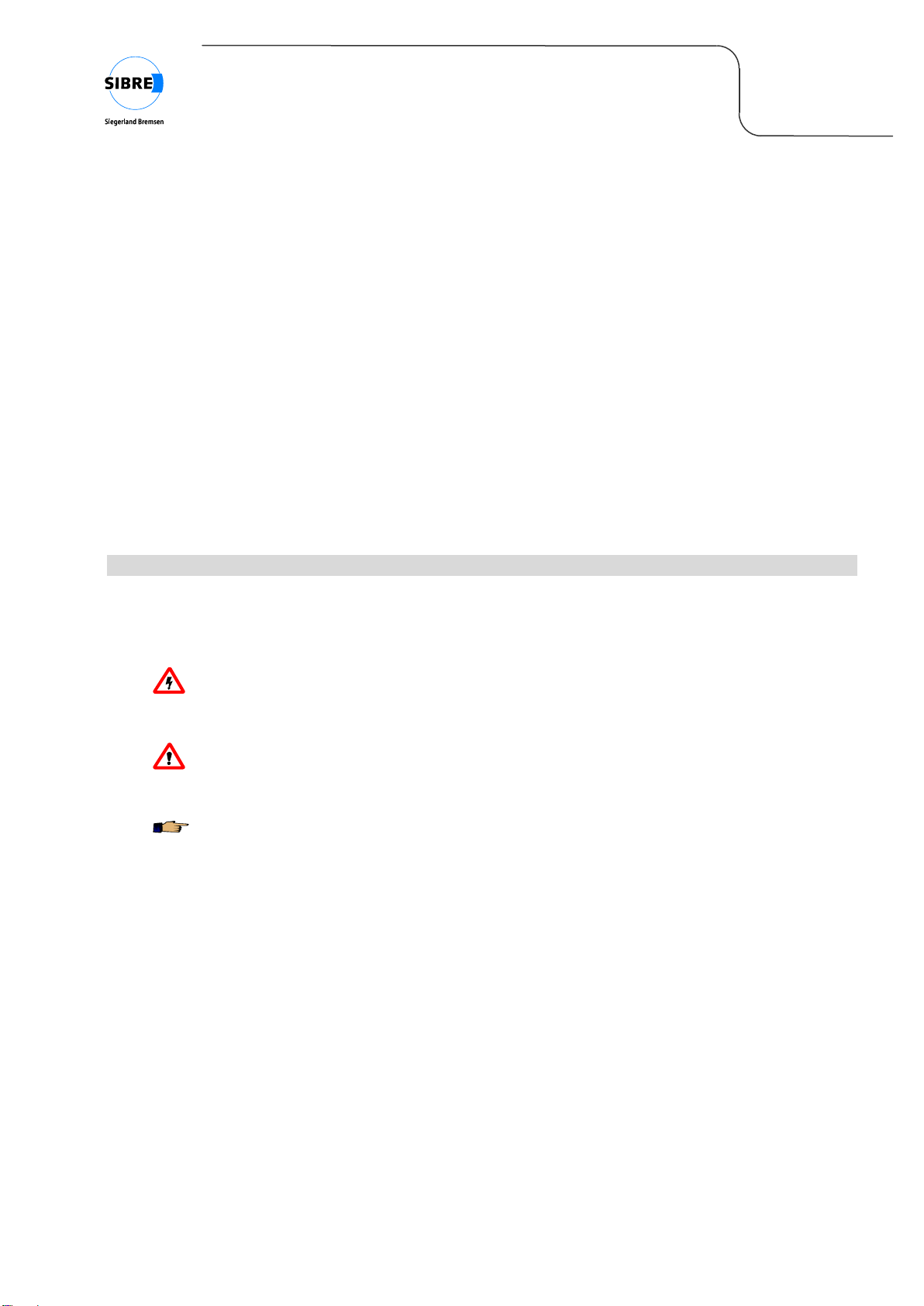

Fig. 1: CB8-E

brake lining

brake shoe

thrustor

protection

cover

housing

removable

cap

sensor

„pad wear”

B06 20 243 E-EN

page 6 / 23

09.2010

Installation and Maintenance Manual

CB8-E

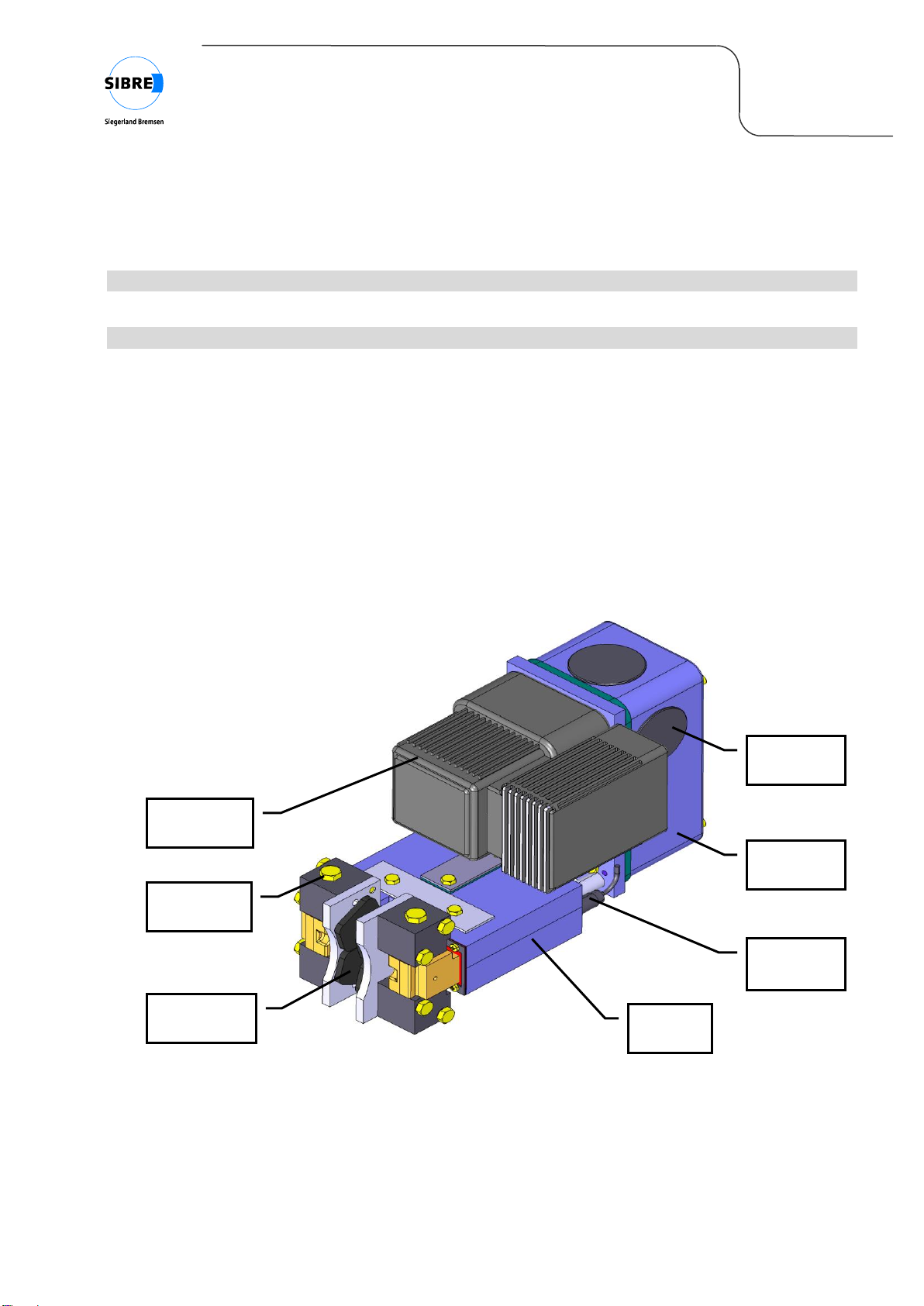

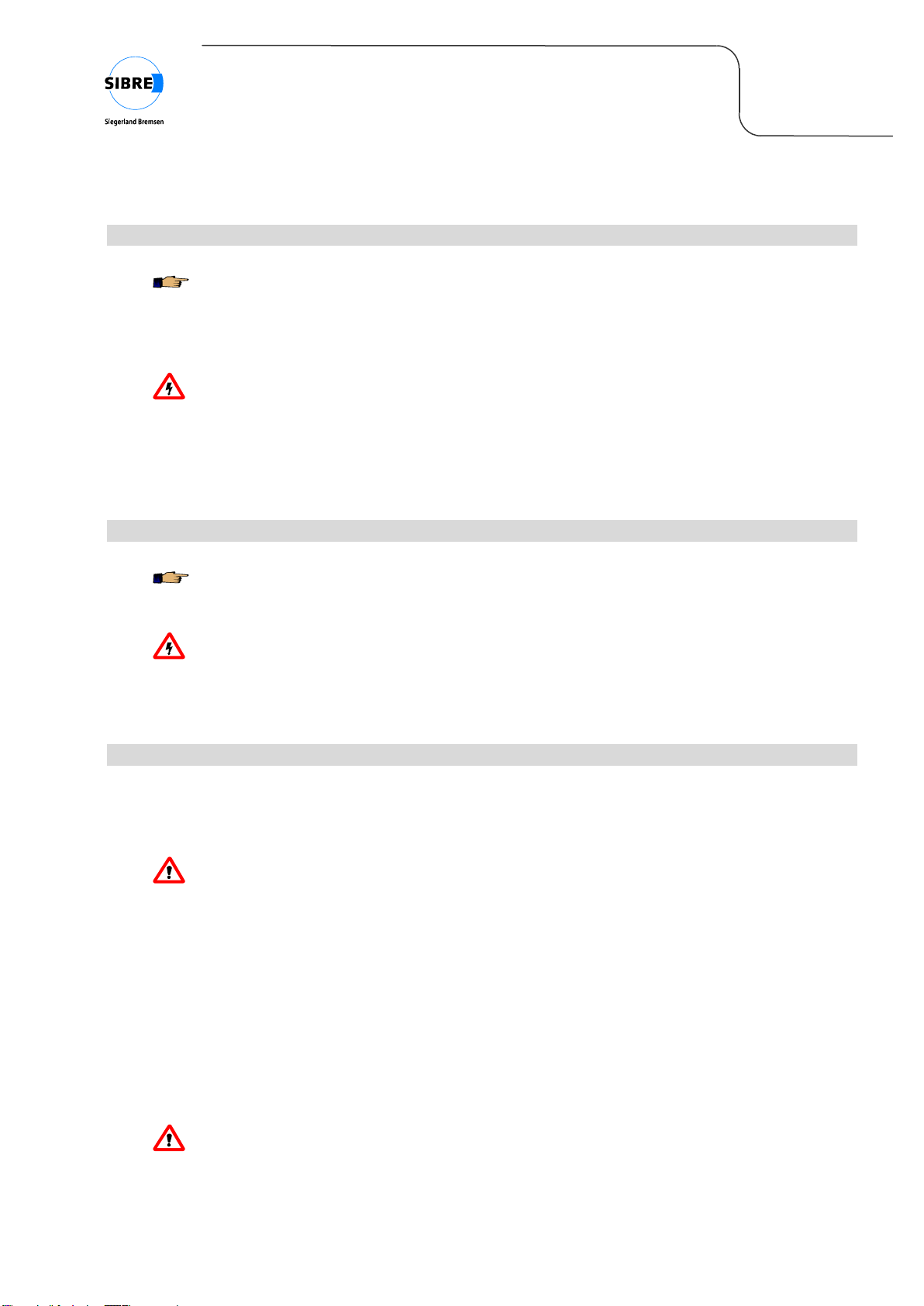

Fig. 2: CB8-E

The main components of the brake calliper are as follows:

Housing: The brake is mounted with three bolts M16 on a base frame or sub-construction.

Brake lever: Hinged with the brake shoes, they surround the brake disc and apply the braking

force. When releasing the brake, the embedded restoring springs lift the brake

shoes from the disc.

Thrustor: The thrustor is used to open the brake and is acting against the spring force. The

energy required for release is generated electro-hydraulically. The release force is

transmitted to the square part by the release lever and the stud.

Readjusting unit: The readjusting unit is used for compensation of lining wear, however its

compensating capacity per braking cycle is limited. Therefore an additional manual

wear compensation carried out by maintenance personnel is required according to

the specific application.

Spring: The helical compression spring generates the brake force and pushes the square

part back. The rollers transmit the brake force with low friction to the brake levers.

retension

spring

thrustor

square part with integrated

readjusting unit

spring

stud

sensor

„brake

open”

sensor

„pad wear”

release

lever

adjustable

spring

chamber

roller

manual

release

brake

lever

B06 20 243 E-EN

page 7 / 23

09.2010

Installation and Maintenance Manual

CB8-E

Spring chamber: Allows the continuous adjustment of spring torque, by adjusting the preload of the

spring.

Protection cover: The protection cover avoids the fouling of the release mechanism and guarantees

the operational reliability of the brake even under rough environmental conditions.

Removable caps allow the fast access to the manual release and enable the

maintenance personnel easily to control the reserve stroke.

Sensors: Sensors can be used to check the lining wear and to check if the brake is open.

B06 20 243 E-EN

page 8 / 23

09.2010

Installation and Maintenance Manual

CB8-E

3.2 Dimensions

dimensions depending on selected lining size

ØD1

ØD3

R

H

CB8-M3-50 with lining size 50

ØD2 –46

ØD2 –110

ØD2 /2 + 19.5

120

CB8-M4-100 with lining size 100

ØD2 –60

ØD2 –140

ØD2 /2 + 15

170

Braking torque in Nm (µ = 0,4) on disc-Ø D2,

adjustable from / to

Ø 200

Ø 250

Ø 315

Ø 400

Ø 500

CB8-M3-50

80-300

110-400

140-530

180-700

n.a.

CB8-M4-100

n.a.

350-680

460-910

620-1220

800-1580

Fig. 3: Dimensions of CB8-E

Options protective cover, manual release, limit switches „brake open“ & „pad wear“

thrustor mounting position selectable between “L”, “T” or “R”

B = disc thickness in mm, Standard = 20, optional: 12.7; 16; 25; 30

ØD2 = outer disc diameter in mm

linings: = organic, size 50 (suitable for circum. disc speed vmax= 35 m/sec)

= sinter, size 100 (available for disc diameter ØD2 250)

B06 20 243 E-EN

page 9 / 23

09.2010

Installation and Maintenance Manual

CB8-E

4 Installation

4.1 Scope of supply

The scope of supply is set out in the shipping documents. Completeness must be verified upon

receipt. Any damage incurred in transit and/or missing parts must be reported immediately in writing.

The CB8-E brake is supplied ready to install.

4.2 Transport

When leaving the factory the brake is always packed in such a way to guarantee maximum security

during transport.

4.3 To be noted before installation

During installation comply with the safety directions in §2.

All work must be performed with care and with a focus on the safety aspect.

WARNING

Non-compliance with these directions can lead to malfunction of the brake.

WARNING

Safeguard the disc against inadvertent rotation!

4.4 Lifting and Handling

The CB8-E brake is to be handled with care. The weight of the brake is approx. 42 kg including

thrustor.

CAUTION

Ensure use of suitable lifting gear.

To avoid damaging component parts or paintwork do not place chains or wire around the

caliper when lifting.

In order not to damage any parts on the brake do not fit any hook, rope, chain or strap around

indicators, linings, etc.

B06 20 243 E-EN

page 10 / 23

09.2010

Installation and Maintenance Manual

CB8-E

4.5 Cleaning the brake disc

PLEASE NOTE

Before installing the brake the disc must be washed clean with white spirit and thereafter with

thinners or tricolour ethylene. Any residual oil or anti-corrosion reparation will reduce the

friction coefficient markedly.

WARNING

Solvent cleaners can be flammable, poisonous and can cause burns. To avoid serious

personal injury, read the manufacturer’s instructions carefully before using a solvent cleaner

and follow these instructions. Also wear eye protection, protective clothing and work in well-

ventilated areas.

4.6 Cleaning the mounting surfaces

PLEASE NOTE

The mounting surface for the base plate should be cleaned in a similar way as the brake disc.

WARNING

Solvent cleaners can be flammable, poisonous and can cause burns. To avoid serious

personal injury, follow the manufacturer’s instructions and see §4.5.

4.7 Handling of brake linings

The brake linings are an essential part of the brake system. They should be handled carefully to avoid

damages or soiling of the friction material.

CAUTION

Brake linings should be kept as clean as possible especially from any kind of grease and oil.

Even a small amount of oil can reduce the friction coefficient and cause a malfunction of the

brake.

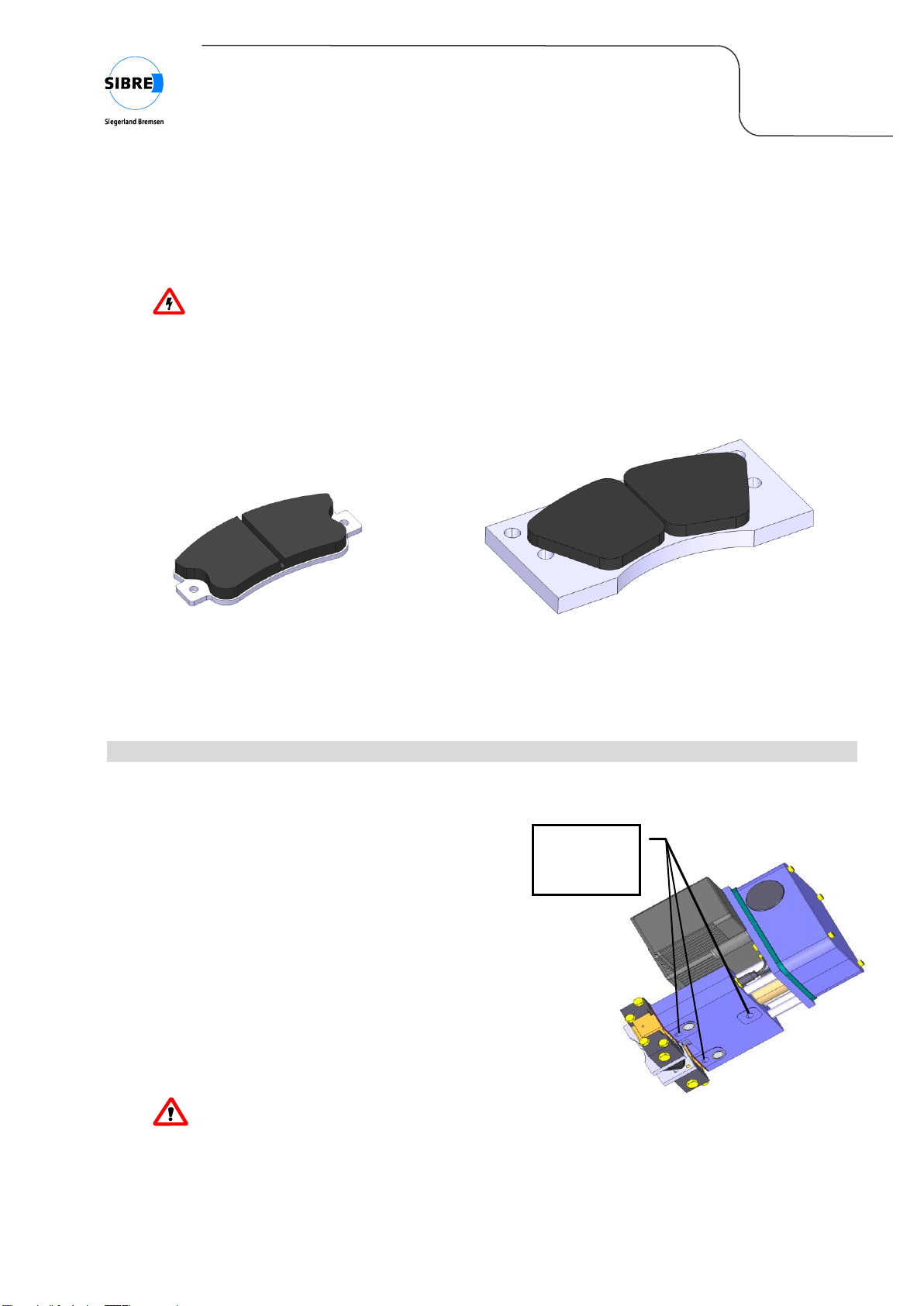

Brake linings can be supplied with several lining materials in two different types, depending on the

brake size and/or application. All brake linings supplied by SIBRE are asbestos free and free of lead.

In general two types of lining materials are available:

Organic brake linings size 50 for CB8-E-50

Sinter brake linings size 100 for CB8-E-100

CAUTION

Organic brake linings must be protected against grease and oil, which would significantly

decrease the friction coefficient. Cleaning of organic lining material is not possible. If any

grease or oil comes in contact with organic lining material, the lining must be discarded.

B06 20 243 E-EN

page 11 / 23

09.2010

Installation and Maintenance Manual

CB8-E

mounting

bolts

(3 x M16)

Sinter brake linings are less sensitive to dirt, grease and oil and can in some cases - where not fully

soaked up with oil - be cleaned with solvent and re-used.

WARNING

Solvent cleaners can be flammable, poisonous and can cause burns. To avoid serious

personal injury, follow the manufacturer’s instructions and see §4.5.

The different types of linings can be seen in figure 4.

a) organic lining size 50 for CB8-E-50 b) sinter lining size 100 for CB8-E-100

Fig. 4: Different types of brake linings for CB8

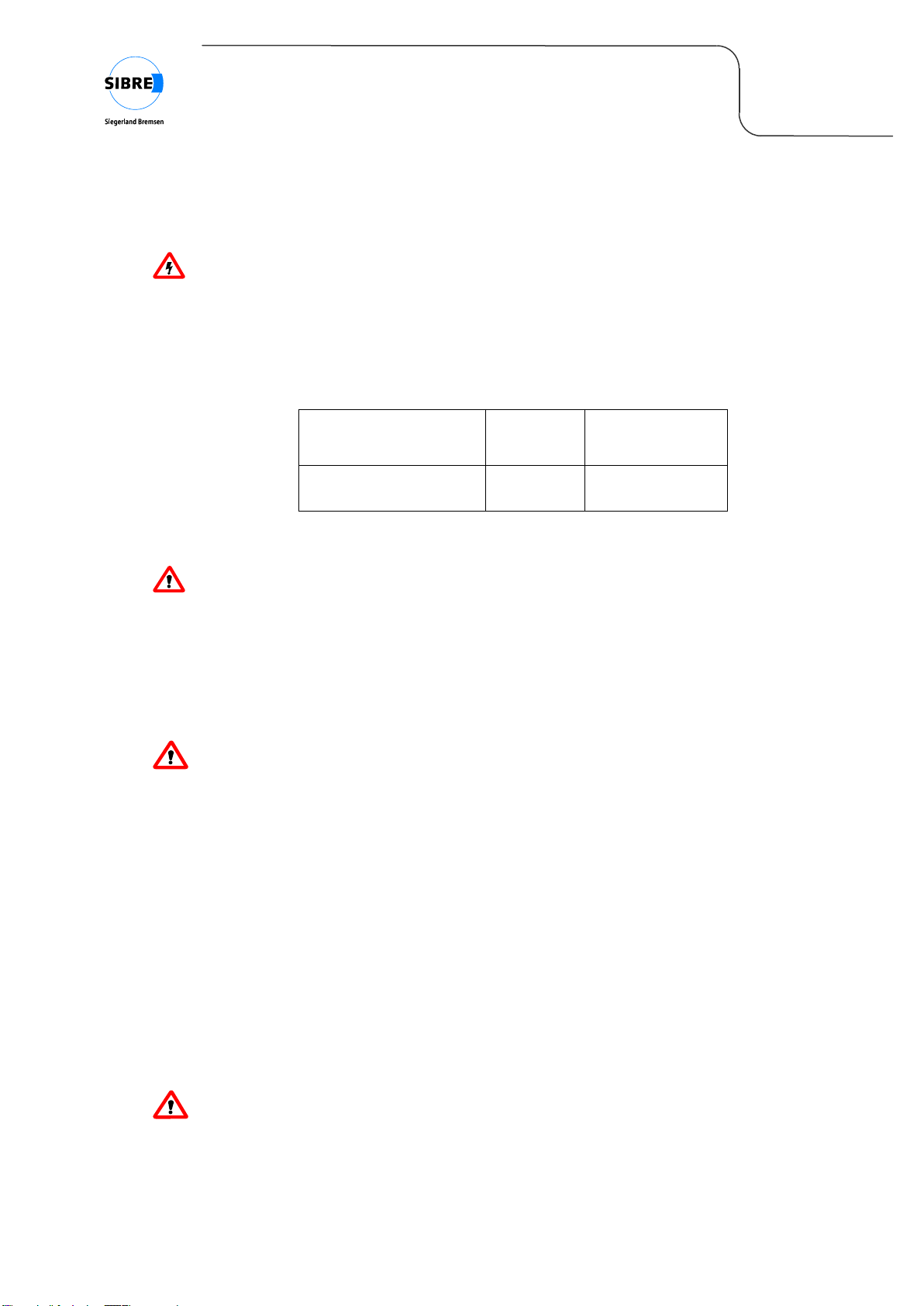

4.8 Mounting of the brake –initial setup on site

Ex works the gap between the lining surfaces is adjusted to the disc thickness the customer has

specified and fixed with a (wooden) distance piece.

The mounting of the brake should be done as

follows.

1. Open the brake with the help of the manual

release (see §4.9) and remove the distance

piece.

2. Put the brake on the sub-construction and

mount the three fastening bolts (figure 5).

Tighten the bolts only by hand in order to enable

the brake to centre itself when closing.

CAUTION

Choose bolt length so that bolts cannot jut inside

the housing and block the square part (max. overhang 14 mm).

3. Close the brake with the manual release. The brake will align automatically when closed.

Fig. 5: Mounting of CB8-E

B06 20 243 E-EN

page 12 / 23

09.2010

Installation and Maintenance Manual

CB8-E

WARNING

The manual release is spring biassed to realize an auto-kickback functionality. The activated

manual release will jump back in its initial position automatically by spring force, when the

brake is released by solenoid the next time.

4. Tighten fastening bolts when brake is closed.

Position of bolt

Bolt size

Tightening torque

(µG= 0.14)

Mounting bolts for

housing

M16 - 8.8

200 Nm

Fig. 6: Tightening torque for mounting bolts

CAUTION

The force transmission between the housing and the mounting surface should take place by

friction and not by the shear capacity of the mounting bolts. Therefore NO lubricant or other

compound must be applied between housing and mounting surface. The needed friction is

created by the clean, dry, lubricant free surface and by the accurate mounting of the bolts.

5. Connect the thrustor with the power supply.

CAUTION

Check the indications on the thrustor name plate before connecting it with the power supply.

6. Adjustment of brake torque:Check the installed brake torque. If necessary install the required

brake torque following the instructions in §4.11.

7. Adjustment of reserve stroke: The adjustment of the reserve stroke (see §4.10) is carried out

automatically by successive opening and closing the brake several times (approximately 40-50

cycles). Thus the readjusting unit sets the brake in working position.

8. Check by electronically opening of the brake, if the gap between brake linings and brake disc is

the same on both sides. Otherwise adjust the position of the brake. The permissible misalignment

for all brake axles is ± 0,1 mm

The brake is ready for operation now.

CAUTION

The brake linings and the disc must be free of oil and grease.

B06 20 243 E-EN

page 13 / 23

09.2010

Installation and Maintenance Manual

CB8-E

CAUTION

The full torque is only generated after bedding in of the linings. The contact pattern must be

minimum 70% for operation.

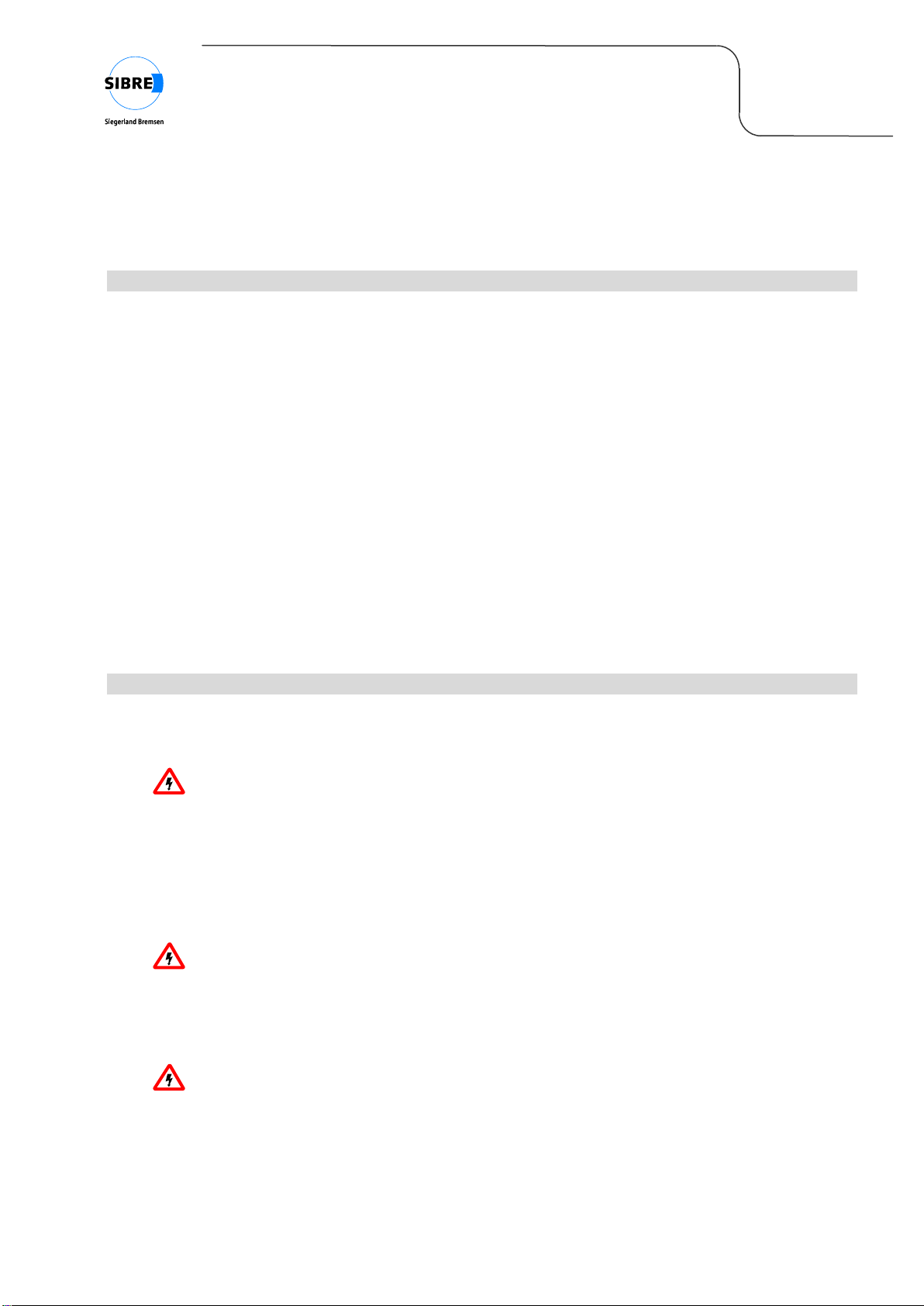

4.9 Manual release

The disc brake CB8 is provided with an eccentric manual release in series.

The handling of the manual release is carried out as follows:

1. Remove the sidewise cap (figure 7a)

2. Rotate the eccentric shaft clockwise until the indexed position is reached (figure 7b).

The brake is released now.

PLEASE NOTE

For the handling of the manual release a socket key wrench size 19 is recommended.

WARNING

The manual release is spring biassed to realize an auto-kickback functionality. The activated

manual release will jump back in its initial position automatically by spring force, when the

brake is released by solenoid the next time.

3. Push in sidewise cap.

a) Activating manual release b) Activated manual release, view without

protection cover

Fig. 7: Manual release

actuator for

manual

release

B06 20 243 E-EN

page 14 / 23

09.2010

Installation and Maintenance Manual

CB8-E

4.10 Adjustment of reserve stroke

The reserve stroke avoids, that the brake gets "on block" position and no more braking force is

transmitted to the disc any more. Without counteraction the reserve stroke would decrease with

increasing lining wear. Therefore the disc brake CB8-E is provided with an automatic readjusting unit

by default.

As the compensating capacity per braking cycle is limited, a regular inspection of the reserve stroke of

the closed brake is indispensable. Depending on the application a "manual" adjustment might be

necessary.

CAUTION

An insufficient or not existing reserve stroke may lead to a failure of the brake.

To check the reserve stroke remove the cap at the top of the protection cover. Push in the piston rod

of the thrustor manually against block. The reserve stroke can be measured between the roller of the

release lever and the piston rod with a feeler gauge or by eye (see figure 8). It must be approx. 7 mm.

Fig. 8: Checking the reserve stroke indirectly at the thrustor piston rod

Alternatively the reserve stroke can be controlled directly by removing the cover and the sealing at the

top of the brake housing. The distance between the square part and the housing can be measured

through the control window with a feeler gauge or by eye. It must be approx. 3 mm ( = 50% of control

window, see figure 9).

PLEASE NOTE

If the reserve stroke falls below, a "manual" adjustment has to be made by opening and

closing the brake against the stagnant disc until the required reserve stroke is reached again.

piston rod

roller

B06 20 243 E-EN

page 15 / 23

09.2010

Installation and Maintenance Manual

CB8-E

Fig. 9: Checking the reserve stroke directly at the square part

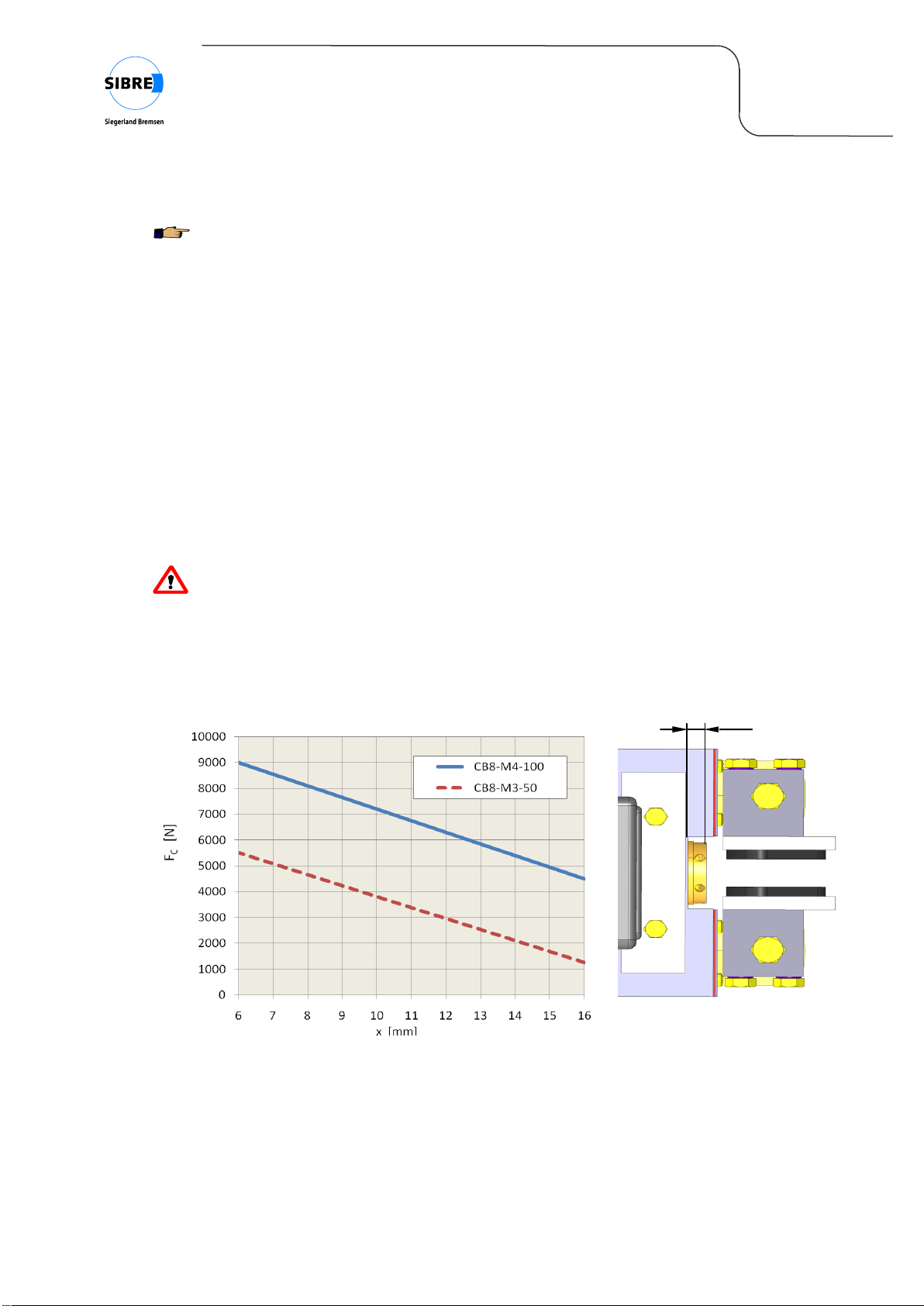

4.11 Adjustment of brake torque

The clamping force between the linings and the

disc and so the brake torque is created by a

helical compression spring.

The adjustment of the brake torque is done by

increasing or decreasing the spring preload

with the help of the adjustable spring chamber

(see figure 10 and figure 11).

Ex works the clamping force is already adjusted

to the brake torque the customer has specified

in his order. If there is no specification the

brake is adjusted to the minimum clamping

force. In this case the brake torque has to be

adjusted at site.

The adjustment of the brake torque is carried out as follows.

1. Calculate the braking torque MBr respectively the clamping force FC(see figure 3 for dimensions)

100-M4-CB8formm60-D

50-M3-CB8formm46-D

D0.4

D

M

FDFM 2

2

1

1

Br

C1CBr

2. Ascertain the required dimension x for the overhang of the adjustable spring chamber out of the

housing acc. to figure 11.

3. Turn around the spring chamber (figure 10 and figure 11) with a hexagon key Ø5 mm till the

ascertained overhang is reached.

cover with

sealing

control

window

square

part

adjustable

spring

chamber

Fig. 10: Adjustment of brake torque

B06 20 243 E-EN

page 16 / 23

09.2010

Installation and Maintenance Manual

CB8-E

PLEASE NOTE

Increasing the overhang will decrease the spring preload and so the clamping force / brake

torque.

Decreasing the overhang will increase the spring preload and so the clamping force / brake

torque.

4. Check and –if necessary –re-adjust the reserve stroke.

When the clamping force has been increased (overhang x has become smaller, figure 11) the

reserve stroke might have become too small for a safe functionality of the brake.

In this case the re-adjustment of the reserve stroke can be done by successive opening and

closing the brake several times (approximately 40-50 cycles). Thus the readjusting unit sets the

brake in working position.

When the clamping force has been decreased (overhang x has become bigger, figure 11) the

reserve stroke might have become too high. In this case proceed as described in §5.1 just

without replacement of the brake linings.

CAUTION

Changing the spring preload and so the clamping force might influence the existing reserve

stroke, too. Because of this a re-adjustment is absolutely necessary. An insufficient or not

existing reserve stroke may lead to a failure of the brake.

The brake is ready for operation now.

Fig. 11: Adjustment of brake torque

x

B06 20 243 E-EN

page 17 / 23

09.2010

Installation and Maintenance Manual

CB8-E

4.12 Limit switches

Optional the CB8 can be equipped with several kind of sensors.

“Pad wear”

An optional inductive limit switch (see figure 1 and figure 2) allows to detect lining wear. With

increasing lining wear the rotating angle of the two brake levers increases, too, when the brake is

closed. When the maximum allowed pad wear is reached, the brake lever will activate the limit switch

and a signal is send out. The sensor is chosen as “normally closed”, so that in case of a damage like

e. g. broken cable a signal is send out, too.

“Brake open”

An optional inductive limit switch (see figure 2) allows to control, if the brake is open. The sensor is

activated directly by the release lever. The sensor type “normally open” ensures, that in case of an

electronic or sensor defect there is no signal for “brake open”.

4.13 Removing the brake

1. Disconnect the thrustor from the power supply. Open the brake by using the manual release.

WARNING

The manual release is spring biassed to realize an auto-kickback functionality. The activated

manual release will jump back in its initial position automatically by spring force, when the

brake is released by solenoid the next time.

2. Unscrew the mounting bolts (3 x M16). The brake is now ready to be removed from the mounting

place.

WARNING

The weight of the brake is approx 42 kg including solenoid. Ensure use of suitable lifting gear.

3. Deactivate the manual release by hand.

WARNING

The manual release is spring biassed to realize an auto-kickback functionality.

B06 20 243 E-EN

page 18 / 23

09.2010

Installation and Maintenance Manual

CB8-E

5 Maintenance

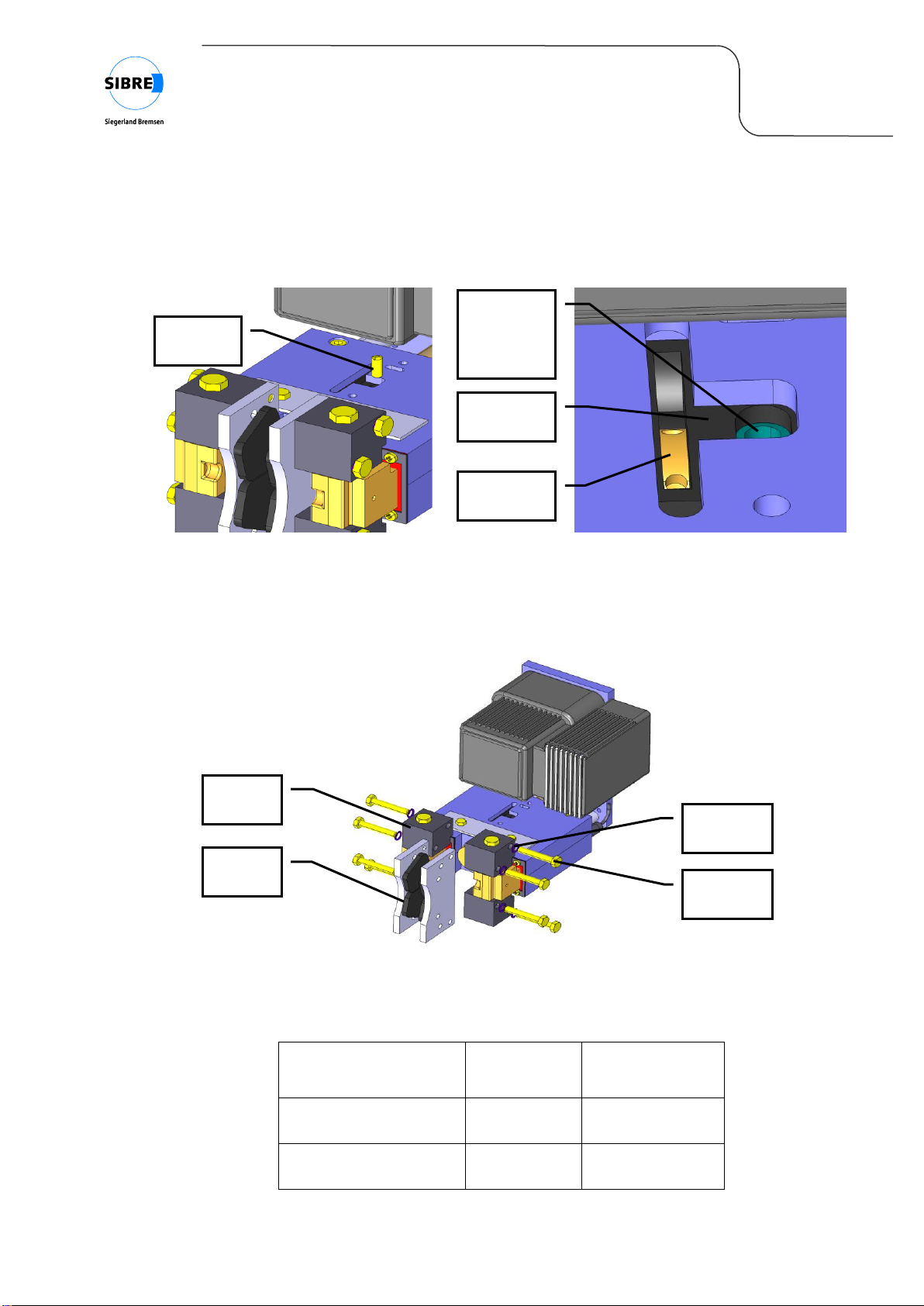

5.1 Replacing the brake linings

CAUTION

When the linings are worn, they must be replaced. Worn out linings can cause a failure of the

brake.

The maximum allowed lining wear of 5 mm per side is reached, when the remaining thickness of the

lining has reached a value of 2 mm for sinter linings or 7 mm for organic linings. The brake pad

thickness can always be checked with a gauge. All brake linings for the CB8 consist of a steel back

plate and the friction material. The linings have a total thickness of 17 mm, i.e. linings must be

replaced when the thickness of friction material + back plate is minimum 12 mm.

The brake linings can be replaced without dismounting of the brake.

CAUTION

See §4.7 for proper handling of brake linings.

To replace the linings follow the below mentioned steps.

1. Ensure that the whole drive system is secured against unintentional movement.

WARNING

Prior to commencing any repair or other work, the owner must guarantee for a standstill of the

whole drive system. Especially the drive motors must be locked against unintentional

switching. Further we draw your attention to the specific rules for prevention of accidents of

the plant.

WARNING

Never place your fingers between the brake linings and the brake disc.

2. Remove cover and sealing from topside of housing (figure 9).

3. Turn the threaded pin out of the free wheel ring (figure 12).

4. Open the brake with manual release (see §4.9).

5. Turn around the adjusting nut (figure 12) with a hexagon key Ø4 mm in direction of brake disc

until block or until the distance between brake shoes and disc is wide enough to mount new

linings.

B06 20 243 E-EN

page 19 / 23

09.2010

Installation and Maintenance Manual

CB8-E

6. Turn the threaded borehole inside the free wheel ring into the upper position by pumping the

adjusting nut with the hexagon key Ø4 mm. Mount threaded pin (figure 12).

Fig. 12: Handling of the readjusting unit

7. Loosen the bolts for the brake linings on the brake shoes. The linings can be removed upwards,

downwards or in front direction (figure 13).

Fig. 13: Replacing the brake linings

8. Put new linings on the brake shoes and fix them with bolts and locking washers .

Position of bolt

Bolt size

Tightening torque

(µG=0.14)

Mounting bolts for

linings CB8-M3-50

DIN961-

M8x1x55 - 8.8

25 Nm

Mounting bolts for

linings CB8-M4-100

DIN 933

M10x60 - 8.8

50 Nm

Fig. 14: Tightening torque for mounting bolts

threaded

pin

adjusting

nut

free wheel

ring with

threaded

borehole

square

piece

mounting

bolt

brake

lining

piece

locking

washer

brake

shoe

piece

B06 20 243 E-EN

page 20 / 23

09.2010

Installation and Maintenance Manual

CB8-E

CAUTION

The force transmission between brake shoes and linings should take place by friction and not

by the shear capacity of the mounting bolts. Therefore NO lubricant or other compound must

be applied between brake shoe and lining carrier plate. The needed friction is created by the

clean, dry, lubricant free surface and by the accurate mounting of the bolts.

9. Adjust reserve stroke by successive opening and closing of the brake several times

(approximately 40- 50 cycles). Control reserve stroke.

CAUTION

An insufficient or not existing reserve stroke may lead to a failure of the brake.

10. Mount cover and sealing on topside of housing.

11. Bed in the new linings. The brake is ready for operation again.

CAUTION

The full torque is only generated after bedding in of the linings. The contact pattern must be

minimum 70% for operation.

5.2 Replacing other components

Although some minor components might be replaced with the brake mounted on site, generally it is

highly recommended to take the brake to a SIBRE workshop for repairs. For removing the brake

follow the instructions given in §4.13.

5.3 Lubrication

Lubrication is not required for this type of brake. All bearings are equipped with self-lubricating

bushings and so virtually free of maintenance.

This manual suits for next models

2

Table of contents