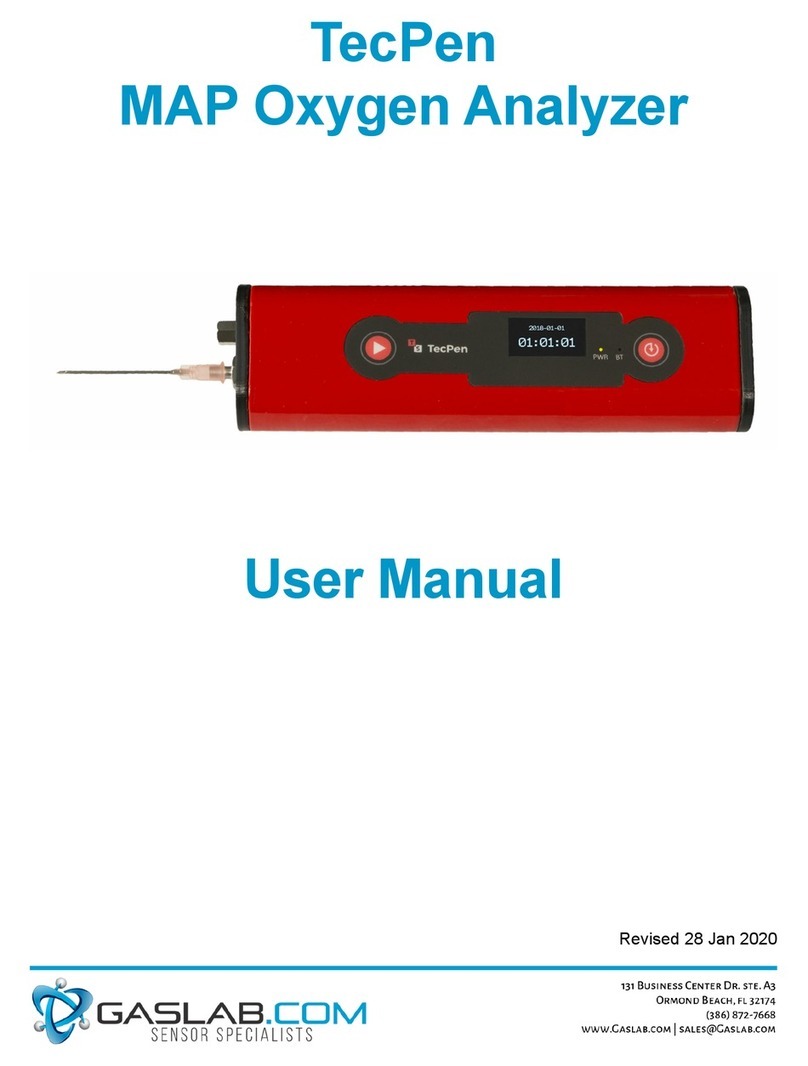

Siebe Climate Controls EWLP 120 User manual

GENERAL DESCRIPTION

The EWLP 120 data recorder is an elec-

tronic device designed to measure temper-

ature, humidity or pressure from two

different locations.

Due to the use of a microprocessor it can

store up to 1600 reading points, with user

programmable storage intervals. Stored

data can be printed with messages in sev-

eral languages.

The instrument can be connected to PTC

or Pt100 probes; alternatively the current

input port can be used for pressure or hu-

midity. It is available in a 161x192 mm ABS

plastic case, 94 mm deep.

COMMANDS ON FRONT PANEL

(response to key pressure is delayed by

approximately 0.5 seconds).

RECORDING 1

The pressure of this key starts recording

related to sensor n. 1; the related led turns

on and the display indicates the value read

by probe 1.

A further key pressure stops recording re-

lated to sensor 1; the related led turns off

and the display indicates the value read by

the probe of sensor 2, when enabled, oth-

erwise the OFF message is displayed.

RECORDING 2

The pressure of this key starts recording

related to sensor n. 2; the related led turns

on and the display indicates the value read

by probe 2.

A further key pressure stops recording re-

lated to sensor 2; the related led turns off.

When the two probes are set to STAND BY

(disabled data recording) the display indi-

cates the OFF message.

When both probes are enabled (enabled

data recording) the led on indicates the

zone whose value is displayed, the blinking

reminds that the related zone is enabled for

recording.

CLEAR

The key pressure after print clears from

memory the recordings related to the re-

port printed and enables the recording

again.

PRG

When held pressed for 3 seconds in

STAND BY (OFF message displayed) with

no stored data it allows to enter or exit pa-

rameters programming mode. In case

stored data are present, the display shows

the ErPr alarm code.

MUTE

The key pressure in data recording allows

to silence the alarm by disabling the relat-

ed relay; the code on the display will con-

tinue to show the alarm presence.

▲(UP)

When pressed in programming mode it al-

lows to skip to the following parameter or

increase its value. In recording mode it se-

lects to display the value related either to

sensor 1 or sensor 2.

▼(DOWN)

When pressed in programming mode it al-

lows to skip to the following parameter or

increase its value. In temperature recording

mode it selects to display the current time.

LABEL/VALUE

When pressed in parameters programming

mode it allows to switch from the parame-

ter label display to its value, and vice-ver-

sa.

PRINT

The key pressure starts the printing of

recorded data; while printing the display

shows letter P (print), recording is sus-

pended and all keys are disabled.

HOW IT IS MADE

WHAT IT IS

EWLP 120 is a data recorder capa-

ble to measure temperature, humid-

ity or pressure from two different

locations.

It is provided with a micro gate in-

put and a relay for alarm signal con-

trol.

EWLP 120 rel. 5/99 ing

temperature recorder

• Size: 161x192 mm, depth 94 mm

• Housing: ABS plastic

• Mount: wall mount through special

fixing holes

• Protection grade: IP65

• Connections: screw terminal block

• Storage: on non-volatile memory -

capacity 1.600 readings

• Printer type: 24 columns with 7x5

matrix on thermal non-photo sen-

sitive paper, paper width 57 mm

• Outputs: on relay (in exchange) for

external alarm repetition

• Inputs: 2 PTC or PT100 tempera-

ture probes; the second input can

be matched with a humidity or

pressure input. One input for micro

gate and one for backup battery

• Resolution: 0.5 °C, 0.5 Bar and

0.5 %RH

• Accuracy: 0.5 °C, 0.5 Bar and

0.5 %RH

• Power supply: 230 Vac

At the end of print the display shows the

messages OFF and “Prnt” (print) alterna-

tively; a further key pressure repeats the

print while the pressure of key CLEAR rubs

all data from memory and restarts data

recording.

FEED

The pressure of this key allows to move the

paper forward.

PARAMETERS PROGRAMMING

Hold the “PRG” key pressed for 3 seconds

in STAND BY mode (OFF message dis-

played) and no data stored; the display

shows the first parameter (Po1). The pres-

sure of the “UP” (or “DOWN”) key while in

programming mode allows to skip to the

following (previous) parameter or increase

(decrease) its value. The pressure of key

“Label/Value” while in parameters pro-

gramming mode allows to switch from pa-

rameters label display to value display and

vice-versa. Hold button “PRG” pressed for

3 seconds to exit programming mode.

WARNING: new values are only stored

when programming mode is exited. Check

time indicated by parameters Po1 and Po2

to control the clock.

PARAMETERS DESCRIPTION

Po1: minutes setting (01…59).

Po2: hours setting (00…23).

Po3: weekday setting:

1 = Monday;

2 = Tuesday;

3 = Wednesday;

4 = Thursday;

5 = Friday;

6 = Saturday;

7 = Sunday.

Po4: month day setting (01…31).

Po5: month setting (01…12).

Po6: year setting.

Po7: setting of the instrument recognition

code (4 digits maximum); this code ap-

pears as heading on every report.

Po8: data storage interval setting; values

from 1…240 minutes (default 30 minutes).

Po9: maximum alarm value setting for sen-

sor n. 1; when the threshold is exceeded

after the delay time set through parameter

Po14, the alarm relay is triggered and the

alarm value related to letter P is printed if

the print is enabled through parameter

Po13.

Po10: minimum alarm value setting for

sensor n. 1; when the threshold is exceed-

ed after the delay time set through para-

meter Po14, the alarm relay is triggered

and the alarm value related to letter N is

printed if the print is enabled through para-

meter Po13. The value of this parameter

shall be lower than or equal to P9; other-

wise the negative set will be set to P9

when programming mode is exited.

Po11: maximum alarm value setting for

sensor n. 2; when the threshold is exceed-

ed after the delay time set through para-

meter Po14, the alarm relay is triggered

and the alarm value related to letter P is

printed if the print is enabled through para-

meter Po13.

Po12: minimum alarm value setting for

sensor n. 2; when the threshold is exceed-

ed after the delay time set through para-

meter Po14, the alarm relay is triggered

and the alarm value related to a symbol is

printed if the print is enabled through para-

meter Po13.

The value of this parameter shall be lower

than or equal to P11; otherwise the nega-

tive set will be set to P11 when program-

ming mode is exited.

Po13: print enabled in case of alarm (de-

fault 0) where:

0 = alarm print disabled;

1 = print enabled for maximum alarms only

(Po9 - Po11);

2 = print enabled for minimum alarms

only(Po10 - Po12);

3 = print enabled for minimum and maxi-

mum alarms (Po9 - Po10 - Po11 - Po12).

Po14: alarm delay time and open door set-

ting; values from 1…60 minutes (default 30

minutes).

Po15: allows to change the value read by

probe n. 1; values from –5…5 (default 0).

Po16: allows to change the value read by

probe n. 2; values from –5…5 (default 0).

Po17: language selection for printed mes-

sages (default 1):

1 = Italian;

2 = English;

3 = French;

4 = German;

5 = Spanish.

NOTE: the measurement unit related to

probe n. 2 is automatically selected (°F or

%RH or Bar) according to the configuration

of dip switch KD1.

ALARM CODES

EE01: memory error - possible loss of all

set data, alarm relay triggered and data

recording stopped. After this alarm print

the recorded data - that could be wrong -

and at the end of the report the message

“LOST RECORDS - CHECK PARAME-

TERS” will be printed.

Device check procedure: enter program-

ming mode and check the set parameters;

if they correspond to those previously set,

change one parameter; in case the alarm is

still present when exiting programming

mode, contact an authorised servicing

centre otherwise re-enter programming

mode and correct previously changed

data.

FULL: full memory. The alarm relay is trig-

gered. The recorded data need to be print-

ed. 100 more recordings are available in

the device since the alarm appears. When

the memory is full recording continue over-

writing the first recorded data. At the end

of print the message “PARTIAL RECORD-

INGS DUE TO FULL MEMORY” will be

printed.

EndP: paper missing: slightly open the

side pads, extract the paper support. To in-

sert a new paper roll fit the support be-

tween the two pads with a light pressure.

Then insert the paper into the upper slot

and load it using the FEED button.

If this alarm occurred while printing, press

the PRINT key to restart the report, that will

begin from day on which it was interrupted.

ALP1: alarm related to probe n. 1 and

alarm relay triggering. On the report the

alarm occurrence will be indicated by the

following symbols:

Z (zone 1 or 2), SET, * to indicate the alarm,

NEG (negative) and POS (positive).

When the measured temperature exceeds

the range defined through parameters Po9

and Po10 for more than the time set

through parameter Po14, the alarm code is

displayed. Such code is automatically re-

called as the temperature returns within the

range.

ALP2: alarm related to probe n. 2 and

alarm relay triggering. On the report the

alarm occurrence will be indicated by the

following symbols:

Z (zone 1 or 2), SET, * to indicate the alarm,

NEG (negative) and POS (positive).

When the measured temperature exceeds

the range defined through parameters

Po11 and Po12 for more than the time set

through parameter Po14, the alarm code is

displayed. Such code is automatically re-

called as the temperature returns within the

range.

ErP1: probe n. 1 faulty and alarm relay trig-

gering; replace the faulty probe; instead of

the value message “--.-” will be printed,

while the display will show message ErP1

and “--.-” alternatively.

ErP2: probe n. 2 faulty and alarm relay trig-

gering; replace the faulty probe; instead of

the value message “--.-” will be printed,

while the display will show message ErP2

and “--.-” alternatively.

ErCL: clock module faulty, alarm relay trig-

gering, the instrument is automatically set

to OFF and recordings interrupted; the dis-

play shows alarm information ErCL and

OFF alternatively; if the ▼key is pressed to

display the current time the display indi-

cates “- -”. After this alarm print the record-

ed data; at the end of the report the

message “CHECK PARAMETERS FOR

CLOCK ERROR” will be printed. Device

check procedure: enter programming

mode and check the parameters set by

Po1 to Po6; if they correspond to those

previously set, change one parameter; in

case the alarm is still present when exiting

programming mode, contact an authorised

servicing centre otherwise re-enter pro-

gramming mode and correct previously

changed data.

Erdr: door open for a time exceeding pa-

rameter Po14; alarm relay triggering. The

alarm stops automatically as the door is

closed.

ErPr: alarm code informing that no new

value can be set for parameters as data are

already stored in memory. The following

process shall be performed to change pa-

rameters: put the instrument in place and

2EWLP 120 5/99 ing

set both inputs to OFF, print data through

the PRINT key and press CLEAR to clear

memories; access parameters program-

ming mode through the PRG button.

ErFd: alarm code informing the printer pa-

per tray is blocked.

Use the FEED key to feed the paper and

check its proper position; if the alarm code

disappears the print restarts automatically,

if the alarm code is still present contact a

servicing centre to replace the printer unit.

ErPE: faulty sensor for paper detection;

contact a servicing centre to replace the

printer unit.

WARNING: if message “RECORDING ER-

ROR” is printed on the “time and tempera-

ture” line, the data recorded at that time

was not correct and is not reported.

MECHANICAL MOUNT

The instrument is designed for wall mount,

through the special fixing holes provided.

The operating temperature for correct op-

eration is 0…50 °C.

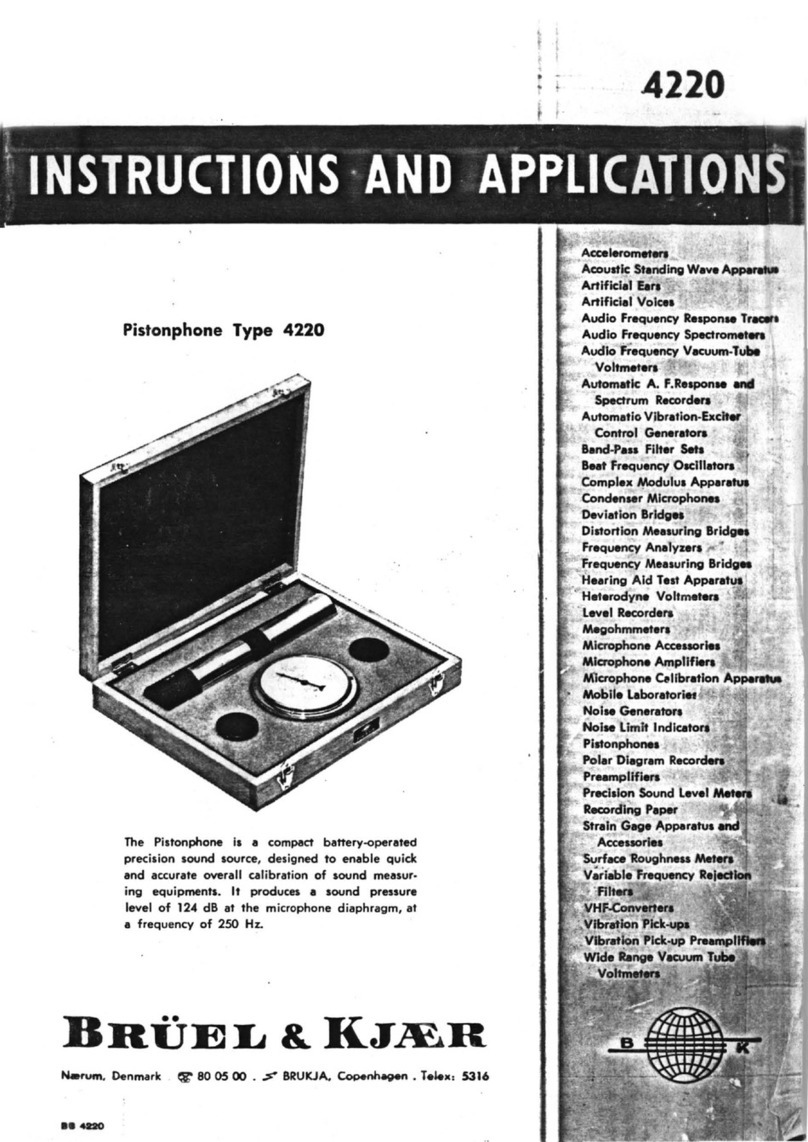

ELECTRICAL CONNECTIONS

Remove the terminal block cover and

make connections according to the dia-

gram inside the cover.

List of operations to be performed.

WARNING: connection to mains shall be

performed as last operation from an exter-

nally accessible point.

1) Select the probe type and operating

mode through the configuration dip

switches.

DIP SWITCH KD1

- terminal n. 1 in ON = input n. 1 and 2

enabled to recording;

- terminal n. 1 in OFF = input n. 1 only

enabled to recording;

- terminal n. 2 in ON = input n. 2 set to

temperature measurement;

- terminal n. 2 in OFF = input n. 2 set for

4...20 mA (humidity or pressure) elec-

tronic transducer;

- terminal n. 3 in ON = input n. 2 con-

nected to a 0...99 %RH humidity elec-

tronic transducer;

- terminal n. 3 in OFF = input n. 2 con-

nected to a 0...30 Bar pressure elec-

tronic transducer;

- terminal n. 4 = not used.

DIP SWITCH KD2

- position 1 = PT100 (RTD) temperature

probe;

- position 2 = PTC temperature probe.

WARNING: do not turn switch KD2 when

the instrument is on.

2) Connect temperature probes supplied:

- for zone n. 1 to terminals: 12-13-14

(see connection diagram referred to the

probe type);

- for zone n. 2 to terminals: 15-16-17

(see connection diagram referred to the

probe type);

- the humidity or pressure transducer al-

ternatively to zone 2 probe to terminals:

10-11 (see connection diagram and

check the transducer power supply is

14 …18 Vdc).

3) When connecting the open door input

remove the jumper and connect wires

to terminals n. 8-9.

4) Connect the alarm relay output to termi-

nals n. 3-4-5, maximum current 8(2)A

250V AC.

5) In case the “external backup battery kit”

was purchased connect to terminals n.

6-7 paying attention to the wire polarity.

In case of power failure the device will

turn display and leds off and disable the

printer to continue recording while limit-

ing power consumption.

6) Connect the power supply cable to ter-

minals 1/2, checking the cable plug is

accessible as the instrument is not pro-

vided with an ON-OFF power switch

(but do not insert the power supply

plug).

7) Close the terminal block cover using

screws “A”.

8) First connect the instrument power plug

then, if purchased, the Backup Battery

Key plug and proceed to the parame-

ters programming.

9) When the instrument is started the dis-

play shows the three central dashes for

about 1 second.

NOTE: probes, transducer and micro gate

cables shall be placed in other raceways

than power cables.

HINTS

1) Once the instrument has been config-

ured the operations to be performed

are:

a) enable or disable zone recordings

through button RECORDING 1 and 2.

Regardless the selected reading range

the zone disable or enable time is print-

ed on the report; when one of the two

zones is set to OFF the print reports

OFF;

b) with both zones in STAND BY (disabled)

the display shows OFF, with both zones

in ON, enabled recording, the led on in-

dicates the zone whose temperature is

displayed while the blinking led indi-

cates the zone is enabled;

c) to get a printed report of recorded data

and continue recordings:

- press the PRINT button;

- the data print begins, the display shows

message P; recordings, open door in-

put and buttons are disabled; at the end

of print the display shows messages

OFF and “Prnt” (print) alternatively. In

this condition prints can be repeated

through the PRINT button, in case the

previously printed report was not read-

able;

- press key CLEAR to clear memories re-

lated to the last report and restart

recordings;

- at the end of the report the message

“RECORDING STOP” is printed;

d) to get a printed report of recorded data

switch the instrument OFF:

- press buttons RECORDING 1 and 2 -

the display shows OFF;

- press button PRINT;

- the data print begins, the display shows

message P; recordings, open door in-

put and buttons are disabled; at the end

of print the display shows messages

OFF and “Prnt” (print) alternatively. In

this condition prints can be repeated

through the PRINT button, in case the

previously printed report was not read-

able;

- press key CLEAR to clear memories re-

lated to the last report;

- at the end of the report the message

“RECORDING STOP BY OPERATOR”

is printed;

e) print example:

at the beginning of every print the fol-

lowing data will appear: reference code

of the temperature recorder (EWCode

N:), code number assigned to the in-

strument, set values, recording interval,

date of recording start and date of print

request;

- in case of power failure during recording

the message “RECORDING STOP DUE

TO POWER OFF” is printed so that the

power failure time can be calculated by

comparing the time of the last recording

before power failure and the time of the

first recording after power restore;

- in case of no alarm the message

“RECORDING STOP BY OPERATOR”

is printed at the end of the report, in

3EWLP 120 5/99 ing

EWLP 120

4…20 mA input door switch backup battery

POWER SUPPLY

5 4 317 16 15 14 13 12 1267891011

–+

alarm

14 13 1217 16 15

14 13 1217 16 15

PTC PTC

Pt100 Pt100

input

12 Vdc output

CONNECTIONS

case of alarms the alarm cause is print-

ed and the “BY OPERATOR” message

is not reported.

2) The recorded cover shall be open dur-

ing print. Check the paper does not

touch the floor during print, as wet can

damage the paper.

3) In case the alarm output is not connect-

ed it is advisable to daily check the de-

vice operation to ensure no alarm codes

are present.

4) The time interval between two print re-

quests is determined by the set reading

interval (parameter Po8). The instru-

ment memory can store about 1600

temperature recordings; by multiplying

this figure by the set time the time with-

in which the next print shall be per-

formed can be calculated.

Example of calculation with a recording

interval set to 30 minutes: in 24 hours

with 30 minutes reading, 48 recordings

are performed, 1600: 48 = 33,3 record-

ing days. To prevent the FULL condition

(almost full memory) the print interval

shall be lower than 10% the memory

capacity.

5) The printed reports shall be stored far

from heat sources, no plastic folders

and with no copying paper.

6) For good print use non photo sensitive

thermal paper supplied by ELIWELL or

one of the following paper types (width

57 mm):

- Jojo paper “TP50KS-A” or “TF50KS-

E2”;

- Honshu paper “FH65BX-14N” or

“FH65BU-2”;

- Mitsubishi paper “F-200 U7N5” or “F

200 U9W3”;

- Hokuetsu paper “MFHB-31”.

TECHNICAL DATA

Housing: ABS plastic.

Size: 161x192 mm, depth 94 mm.

Mount: wall mount through special fixing

holes.

Protection: IP40 protection grade when

the cover is open, IP65 with closed cover.

Insulation class: II.

Connections: screw terminal block.

Operating temperature: 0…50 °C.

Storage temperature: –10…70 °C.

Display: data and parameters through 4

7-segment red displays and 2 leds.

Parameters setting: through buttons on

front panel.

Storage: on non-volatile memory - capac-

ity 1.600 readings.

Number of channels: 2 channels.

Inputs: two inputs available for PTC,

Pt100 or current (for humidity or pressure),

user selectable through Dip Switch.

Reading range: IP55 temperature probes

with sensor:

- PTC: –40…70 °C resolution 0.5 °C and

accuracy ±0,5 °C;

- Pt100: –80…350 °C resolution 0.5 °C

and accuracy ±0.5 °C;

- pressure transducer: 0…30 Bar resolu-

tion 0.5 Bar and accuracy ±0.5 Bar;

- humidity transducer: 0…99 %RH reso-

lution 0.5 %RH and accuracy ±0.5

%RH.

Digital input: input to detect open door.

Input for battery kit: n. 1 backup to en-

sure 6-hour continuos recording without

power, for connection of temperature

probes only.

Clock module: accuracy 0.1% and not-

rechargeable backup battery with electric

life longer than 10 years.

Alarm output: on relay (in exchange)

8(2)A 250V AC for external alarm repeti-

tion.

Programmable parameters:

- year - month - day - hour - minutes;

- instrument code number (4 digits maxi-

mum);

- temperature reading interval from 1 to

240 minutes;

- positive and negative alarm set for each

analogue channel;

- delay for alarm acquisition of positive,

negative and open door sets from 1 to

60 minutes;

- language selection for printed mes-

sages (I-GB-FR-D-S).

Button on front panel: for manual print

command.

Printer type: 24 columns with 7x5 matrix

on thermal non-photo sensitive paper, pa-

per width 57 mm.

Resolution: 0.5 °C, 0.5 Bar and 0.5 %RH.

Accuracy: 0.5 °C, 0.5 Bar and 0.5 %RH.

Consumption: 25 mA (50 mA while print-

ing).

Power supply: 230 Vac ±10%, 50/60 Hz.

Fuse: PTC self-resetting by disconnecting

the current plug and leaving the deivce

disconnected for about 5 minutes.

Siebe Climate Controls Italia s.p.a.

via dell’Artigianato, 65

Zona Industriale Paludi

32010 Pieve d’Alpago (BL)

Italy

Telephone +39 0437 986111

Facsimile +39 0437 989066

An Invensys company

4EWLP 120 5/99 ing

Popular Measuring Instrument manuals by other brands

ACI Laser

ACI Laser DFL Ventus Marker operating instructions

DNT

DNT Grabstar Audio user manual

Molecular Devices

Molecular Devices SPECTRAmax PLUS 384 Operator's manual

Endress+Hauser

Endress+Hauser Levelflex FMP50 operating instructions

Bender

Bender RCMA426H manual

Sekonic

Sekonic DUAL MASTER L-558 Opearting manual