triOS OSCAR G2 User manual

OSCAR G2

Online hyperspectral integrating cavity absorption meter

Manual preliminary

release: 17.10.2018

TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D-26180 Rastede

Germany

fon: +49 (0) 4402 69670-0

fax: +49 (0) 4402 69670-20

www.trios.de

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

2 / 62

Content

1General notes................................................................................................................ 5

1.1 Health and environment......................................................................................... 6

1.2 Warning notices..................................................................................................... 7

1.3 Target group and user skills................................................................................... 8

1.4 Intended use.......................................................................................................... 9

1.5 Purchased parts package ...................................................................................... 9

1.6 Proper disposal.....................................................................................................10

2Introduction...................................................................................................................11

2.1 Measuring principle...............................................................................................11

2.1.1 Measurement setup ..........................................................................................12

2.1.2 Theoretical considerations ................................................................................13

2.1.3 Calibration.........................................................................................................15

2.1.4 Calibration procedure in short ...........................................................................16

2.1.5 Measurement of the absorption coefficient of a sample.....................................17

2.1.6 Temperature and salinity correction for pure water absorption..........................17

2.1.7 References........................................................................................................18

2.2 Basic measuring arrangement of the OSCAR.......................................................19

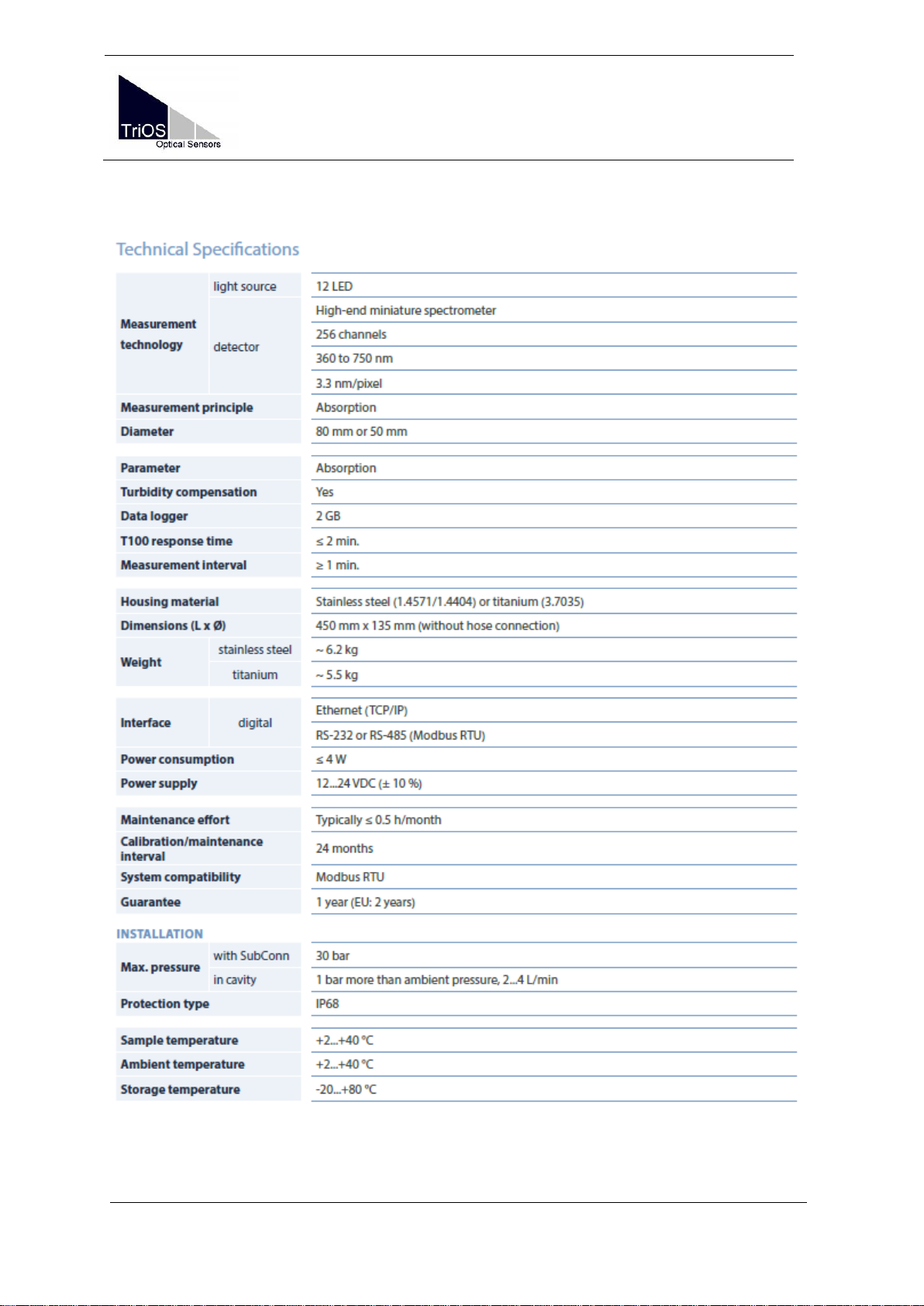

2.3 Technical specifications........................................................................................20

3Installation....................................................................................................................21

3.1 Electrical installation .............................................................................................21

3.1.1 Power supply ....................................................................................................21

3.1.2 EIA 232 / 485....................................................................................................22

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

3 / 62

3.1.3 Ethernet............................................................................................................23

3.2 Mechanical installation..........................................................................................25

3.2.1 Submerged use.................................................................................................25

3.2.2 Operation on-site...............................................................................................26

4Operation......................................................................................................................28

4.1 Web Interface –configuration of the sensor..........................................................28

4.1.1 Overview...........................................................................................................30

4.1.2 Data logger .......................................................................................................30

4.1.3 Measurement....................................................................................................32

4.1.4 Peripherals........................................................................................................39

4.1.5 System..............................................................................................................41

4.1.6 Calibration.........................................................................................................43

4.2 Data calculation with MSDA_XE...........................................................................48

4.2.1 Calculation of the reflectivity..............................................................................48

4.2.2 Calculation of absorption spectra with reflectivity ..............................................52

4.3 Operation in practice.............................................................................................54

5Cleaning and servicing .................................................................................................55

5.1 Sensor housing cleaning.......................................................................................55

5.2 Cavity cleaning .....................................................................................................56

6Calibration....................................................................................................................58

6.1 Factory calibration.................................................................................................58

6.2 Procedure of the factory calibration.......................................................................58

6.3 Reference spectrum of Nigrosin............................................................................59

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

4 / 62

7Warranty.......................................................................................................................60

8Support.........................................................................................................................61

8.1 Fast functional test................................................................................................61

9Contact information.......................................................................................................62

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

5 / 62

1 General notes

OSCAR is an innovative sensor applying the principle of the integrating sphere providing

absorption measurements literally free of scattering influence. Please read this manual

carefully and follow its recommendations to make the maximum use of it. Please notice that it

is in the user responsibility to follow the local governmental rules for the installation of

electronic devices. Any damages caused due to misuse or unprofessional installations are

not covered by warranty. While operation requires opening the cavity, it is not foreseen to

open the main housing of the sensor. Please note that warranty is lost due to open the main

housing. OSCAR and any accessories, delivered from TriOS Mess- und Datentechnik

GmbH, should only be installed and operated following the instructions of the manufacturer.

Please use only original accessories and cables of TriOS Mess- und Datentechnik GmbH

for a professional use of the sensor.

This device is designed for use in science. The intended use of the OSCAR is to measure

the absorption of water or aqueous fluids e.g. river water, sea water, ground water in a

temperature range from 2 °C to 40 °C. It has to be operated and powered according to the

specifications. All parts have been designed and are tested to fulfil the international rules for

electronic instrumentations. The unit is complying with the international EMC rules.

Make sure that you have read and understood the safety precautions described below before

using the sensor. Always make sure that the sensor is operated correctly.

This manual is made on basis of OSCAR software version V.1.1.6.

The safety precautions noted on the following pages are intended to provide a simple and

correct operation of the instrument and all its accessories to prevent you, other people or

devices from harm.

Copyright Notice

All contents of this document, including text, photographs and graphics are copyrighted. The

copyright is, unless otherwise expressly indicated, at the TriOS Mess- und Datentechnik

GmbH. Anyone who violates the copyright, is liable to prosecution under the German

Copyright Act §106 et seq. He will also be warned with costs and must pay compensation.

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

6 / 62

1.1 Health and environment

This manual contains important information about health and safety rules. This information

will be marked as follows and must be followed.

Important hint for safe and professional approach to the measurement

system.

Electromagnetic waves

Electromagnetic waves in the UV range can affect the skin or eyes.

Never look directly into the light source.

The emitted radiation can cause injury to the eyes.

Reagents

In use of reagents follow the safety and operating instructions of the manufacturer. Observe

the valid Ordinance on Hazardous Substances used for any reagents!

Biological Safety

Possibly liquid waste can be biologically hazardous. You should therefore always wear

gloves when handling such materials. Observe the currently valid biological agents

regulation!

Waste

When dealing with liquid waste, the regulations concerning water pollution, drainage and

waste disposal must be observed.

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

7 / 62

1.2 Warning notices

This sensor is designed for use in science. It should only be used for measuring

aqueous solutions, e.g. river water or sea water.

Sensors made of stainless steel are not made for use in sea water

(corrosion). Only sensors of titanium can be used in sea water.

Sensors which are made of stainless steel have to be cleaned immediately after

exposure to salt water or other corrosion-causing substances (e.g. acids, alkalis,

chlorine-based compounds).

Even Titanium will be affected for example by bromine, hydrofluoric acid and hot

acids. Do not use sensors of titanium in these media.

The sensor OSCAR has seals of NBR (nitrile butadiene rubber). On custom request

sealing rings of other materials can possibly be used. Before operation take care that

the assay medium does not damage the seals.

Before operating check the power supply. OSCAR has to be operated with voltages

between 12 and 24 VDC.

Don’t use alcohol, benzene, dilutor or other flammable substances to clean or

maintain the equipment. The use of these substances may lead to fire.

Exception: cleaning of the optical windows with a few drops of acetone and optical

paper from TriOS Mess- und Datentechnik GmbH or a lint-free tissue and cleaning

of the cavity with ethanol.

Do not cut, damage nor modify any of the cables. Make sure that no heavy objects

are located on the cable or that the cables are kinked.

Make sure that the cable does not run near hot surfaces.

If the power cable is damaged, it must be replaced only by TriOS Mess- und

Datentechnik GmbH or an authorized TriOS workshop with an original replacement.

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

8 / 62

Do not cover any other items not provided for this purpose in the optical path, as long

as the instrument measures, as this may cause damage to the sensor or incorrect

measurement results.

The optical windows should be cleaned with special optical paper to avoid the risk of

false results. Make sure that there is no dirt around the optical path. It is

recommended to wear gloves during cleaning.

Stop the usage of the sensor immediately if it emits smoke, noxious fumes or

excessive heat production (i.e. more than lukewarm). Turn off the sensor

immediately, remove the cable from the power supply and unplug the power cord

from the outlet. Make sure that smoke or fume emissions have ceased. Please

contact your dealer or TriOS Mess- und Datentechnik GmbH customer service.

Never attempt to disassemble or alter any part of it to make changes that are not

expressly described in this guide. Internal inspections, alterations and repairs should

be performed by the equipment dealer or the TriOS Mess- und Datentechnik GmbH

authorized and qualified professionals.

Devices from TriOS Mess- und Datentechnik GmbH meet the highest safety

standards. Repairs of equipment (which includes the replacement of the connecting

cable) must be conducted by TriOS Mess- und Datentechnik GmbH or an

authorized TriOS workshop. Defective, improper repairs can lead to accidents and

injuries.

1.3 Target group and user skills

The absorption meter OSCAR was developed for use in science. The implementation of

photometric determinations with test sets often requires the handling of hazardous

substances.

We assume that the operator is familiar due to the professional training and experience in

dealing with hazardous materials. The operator must in particular be able to understand

safety signs and safety instructions on the packaging and the package inserts of the test sets

and to apply them.

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

9 / 62

1.4 Intended use

The intended use of the absorption meter consists exclusively in the implementation of

photometric measurements in accordance with these instructions. The sensor is a

submersible absorption meter, which can be used immersed in water or in laboratory use.

Any other use is improper. Use this appliance only for measuring the absorbance of aqueous

fluids. Other media can lead to accidents. For the use of the sensor OSCAR in media other

than the specified please contact support of TriOS Mess- und Datentechnik GmbH

CAUTION

Avoid every contact with the glass and plastic components in the cavity, because they

can be scratched or get dirty. This will change the functionality of the sensor;

correctness of the measured values is no longer ensured.

Only touch the sensor on the housing. Do not lift the sensor on the cord.

Install the sensor and it cables away from hot surfaces.

According to the current scientific knowledge, the appliance is safe to use, if it is handled

properly and according to the instructions in this manual.

1.5 Purchased parts package

Sensor

Manual

Accessory (if applicable)(e.g. G2 Interface Box)

Preserve the original packing material for a possible return of the unit for maintenance or

repair purposes.

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

10 / 62

1.6 Proper disposal

At the end of lifetime, the device and its accessories may be returned for environmentally

friendly disposal. The previous professional decontamination must be proven by a certificate.

Please contact us before you send the device to the manufacturer. This will tell you more

details.

Shipping address:

TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede

Germany

fon: +49 (0) 4402 69670 - 0

fax: +49 (0) 4402 69670 –20

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

11 / 62

2 Introduction

OSCAR is an independent measuring instrument. For the operation nothing more than a

power supply of 12 - 24 VDC is required. The sensor is equipped with a configurable digital

serial interface. It supports EIA-232 and EIA-485 as well as various protocols, such as

Modbus RTU.

The sensor can be configured via the web interface. This is a graphical user interface that

can be opened by a web browser.

Like all TriOS Mess- und Datentechnik GmbH sensors, OSCAR is shipped pre-calibrated

so that OSCAR is ready for immediate use.

This manual provides information about the specifications, the installation and the operation

of OSCAR.

2.1 Measuring principle

The measurements of particulate light absorption in natural waters, i.e. that of suspended

phytoplankton algae, sediment, detritus etc., remains a difficult issue because with most

measurement technique the light scattering of those particles deteriorates the signal and the

absorption is strongly overestimated. The observed light attenuation has often to be

corrected to receive the correct absorption by subtracting the scattering signal. Furthermore

the generally low concentration of particles in natural water makes it necessary for most

common techniques to concentrate the particles before their absorption can be measured. A

typical technique is to concentrate particles on a glass fibre filter and measure the filter in a

spectrophotometer (QFT, quantitative filter technique). However, this requires

comprehensive sample handling, like filtration, preservation, storage etc. One possibility to

overcome these problems is to measure the original sample inside an integrating sphere,

that would reduce/avoid scattering problems and sample handling, and increase sensitivity

by a rather long optical path length (up to several meters). To reduce scattering effects to an

insignificant level the light distribution inside the sphere has to be homogeneous and

isotropic, such that any additional scattering inside the sphere does not change the light field.

A simple way to do this is to use a central isotropic light source, as proposed and

theoretically described by Kirk (1995, 1997), a point-source integrating-cavity absorption

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

12 / 62

meter (PSICAM). Another, more complex set-up was e.g. used to determine pure water

absorption (Pope & Fry 1997, Pope et al. 2000). The PSICAM concept was further

investigated by Leathers et al. (2002) and Lerebourg et al. (2002) and successfully tested by

Röttgers et al. (2005). First results with natural sample are shown in Röttgers et al. (2007)

and Röttgers & Doerffer (2007). First results from a flow-through system are shown in

Wollschlaeger et al. (2013).

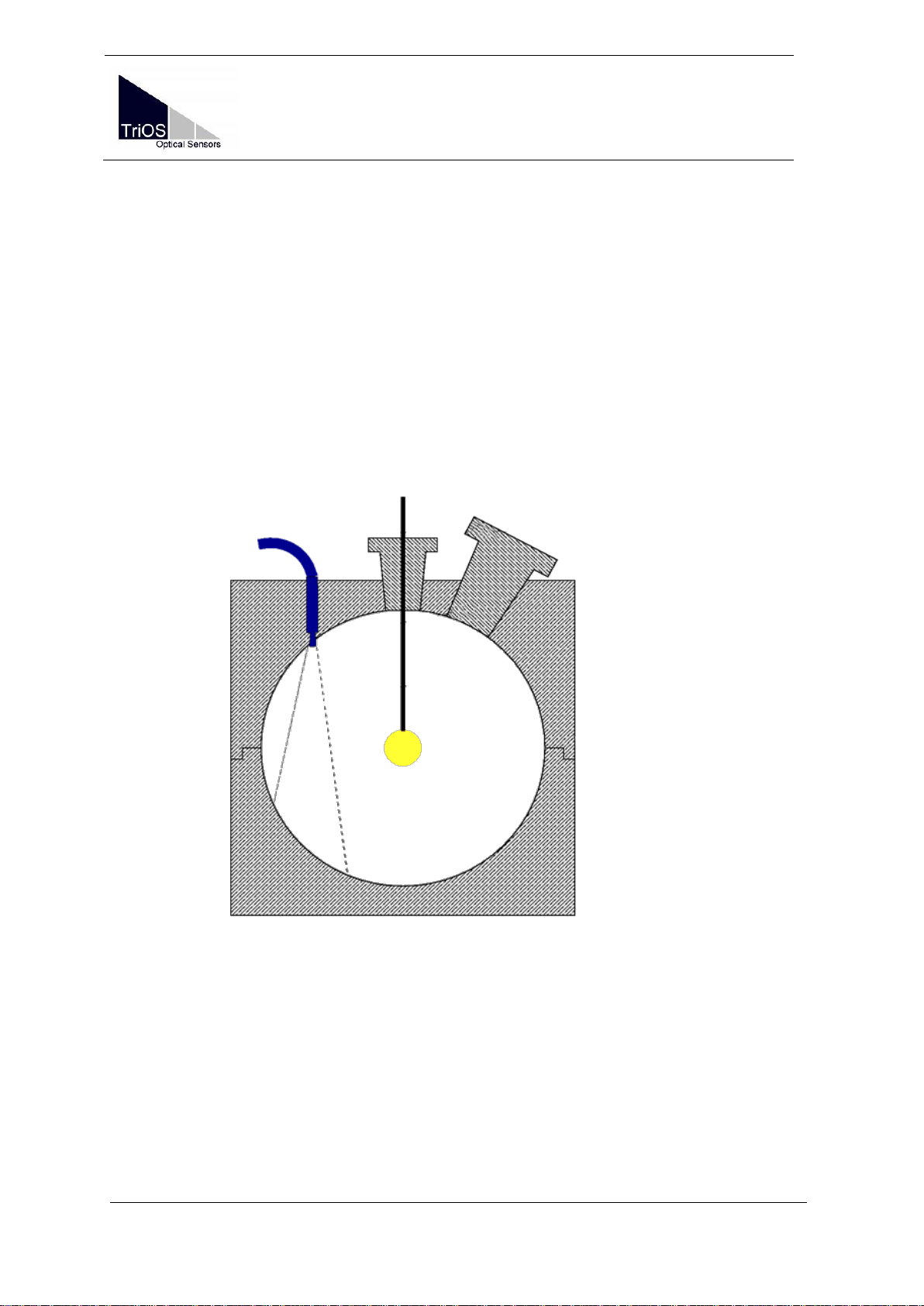

2.1.1 Measurement setup

Fig. 1. Schematic cross section of the OSCAR showing the central light source (yellow), the

light detector (blue) and the inner cavity (white). The light detector is a tip of a fiber optic which

other end is connected to a spectrometer. The central light source is a sphere made from a

diffuse quartz-glass sitting on the tip of a fiber optic connected to the light source.

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

13 / 62

The integrating cavity of the OSCAR (Fig. 1) has an inner diameter of 8.0 cm or 5.0 cm

(depending on the ordered version) and is made out of a diffuse reflective plastic material

(PTFE). The reflectivity of this material is depending on the material thickness, and

between ~ 94 and 97 % for a thickness of 10 mm. The surface is water-repellent to

avoid/mitigate problems with contamination. Particulate matter is easily washed out of

the cavity. The central light source consists of a small scattering sphere made out of a

diffuse quartz-glass with an outer diameter of approx. 10 mm. The light beam from the

lamp is guided to the central diffuse emission sphere by a quartz-glass rod. Similarly the

light from the cavity to the detector is guided by a second quartz-glass rod. The rod has

only a narrow field of view and, thus, does not collect any light coming from the central

light source directly. It measures the light reflected at the cavity wall opposite to the

collector as well as the path radiance, i.e. the light scattered into the receiving cone of

the collector.

2.1.2 Theoretical considerations

According to Kirk (1997) and Leathers et al. (2000), the “transmission”, TAB, measured in a

PSICAM is the ratio of the diffuse reflected irradiance F0at the inner wall when the cavity is

filled with either the sample A or B (Eq. 1). Each irradiance is proportional to the number of

times a photon is reflected by the wall NC, before it is absorbed either by the wall or by the

sample fluid. Hence,

B

C

A

C

B

A

AB N

N

F

F

T

0

0

(1)

NCis the fraction of photons reaching the wall directly and indirectly by reflection on the wall

for one, or more times (Eq. 2). It depends (1) on the probability P0that a photon, coming from

the central light source, reaches the wall directly, (2) on the reflectivity of the wall

, and (3)

on the probability Psthat a photon, which is reflected, will return to the wall. In the PSICAM

set-up used here the detector does not collect light that comes directly from the light source,

thus, for NCthis gives

S

S

n

S

n

SSC P

PP

PPPPPPN

1

)(... 0

1

0

22

00

(2)

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

14 / 62

Therefore,

)1(

)1(

0

0A

S

B

S

B

B

S

A

S

A

AB PPP

PPP

T

(3)

P0and Psare related to the radii of the PSICAM r0= r - rsand r, respectively, where r is the

inner radius of the cavity and rsthe radius of the central light source and to the absorption

coefficient a in the following way (see Kirk 1997 for details):

)exp(),( 000 arraP

(4)

)12)(2exp(1

21

),( 22 arar

ra

raPS

. (5)

Finally the transmission in the PSICAM is related to the absorption coefficients aAand aBof

the two solutions as

01 ( , ) ( , )

exp( ( )) 1 ( , ) ( , )

S B S A

AB A B S A S B

P a r P a r

T r a a P a r P a r

. (6)

When using Eq. (5) and (6), TAB is a function of the light absorption of the samples aAand aB,

the radii rand r0, and the reflectivity

. Solving Eq. (6) for the reflectivity gives

),(),()exp(),(),()exp( ),()exp(),()exp(

00

00 raPraPraraPraPraT raPraraPraT

ASBSABSASBAB

ASABSBAB

(7)

Hence, if

is not known, it can be determined by measuring the “transmission” induces by

two solutions with known absorption coefficients using Eq. (7) and (5).

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

15 / 62

2.1.3 Calibration

The error for absorption determination in a PSICAM is related mainly to the error in

determining the inner radius r, the reflectivity of the PSICAM

, and to the “transmission”

determination in the PSICAM. The “transmission” measurement is further influenced by the

stability of the light source and the spectroradiometer response. From these errors the error

related to

has the strongest influence: a 1 % error in

leads to >10 % error in the

absorption determination. Hence,

has to be known with a high accuracy. It is determined

using Eq. (7), by measuring the “transmission” induced by two solutions with known

absorption coefficients.

Determining

in this way has the advantage that it will eliminate errors associated with the

true

of the wall material, and with r0, aA, aB, and the known water absorption. However, the

error of the necessary determination of the absorption coefficient with a photometer directly

influences the error of the absorption determination with the PSICAM.

Practically

is determined following the suggestion by and description in Leathers et al.

(2000). Therefore the transmission TAB is determined from a sample solution A with an

absorption coefficient aAmeasured against a reference solution B with an absorption

coefficient aBin the PSICAM. The reference solution Bconsists simply of purified water. The

assumed absorption coefficient spectrum of this purified water aw, is taken from published

pure water absorption coefficients, whose were adjusted and smoothed to have a complete

spectrum for the considered wavelengths range. As discussed above any error in this pure

water absorption is compensated by the calibration procedure described here, the exact pure

water absorption is of less significance.

The sample solution Ais prepared from the coloured stain Nigrosine (see

www.sigmaaldrich.com product nr. 198285 or Certistain, Merck, Germany), following

suggestions of Kirk (1997). Compared to other dye solutions Nigrosine has the advantage of

having a considerably high absorption coefficient at all required wavelengths.

A Nigrosine stock solution is prepared by dissolving a few crystals of Nigrosine in 100 ml

purified water. The optical density of this solution is roughly determined photometrically in a

1 cm cuvette at 578 nm, to be able to calculate the necessary volume of this stock solution

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

16 / 62

when later preparing the calibration solutions. Calibration solutions with an absorption

coefficient (a578nm) between 0.5 and 2 m-1(on the lognscale) are prepared by diluting a few

milliliters of the stock solution in ca. 2000 ml purified water. The exact spectral absorption

coefficients of this Nigrosine in solution is determined photometrically in the range of ca. 350

to 800 nm using a 10 cm cuvette and purified water as the reference.

The transmission measurements in the PSICAM are conducted by determining the light

intensity inside the cavity when the cavity is first filled with purified water Fw, and second with

the calibration solution Fnig. In each case the temperature of the fluid (twand tnig) inside the

cavity should be recorded for a later temperature correction of the pure water absorption. For

field applications the parallel application of a CTD probe is recommended.

After the calibration solution has been measured, the PSICAM has to be cleaned as the stain

adsorbs considerably fast on the cavity wall of the PSICAM. Therefore the PSICAM is

bleached for 15 min with a 0.1 % sodium hypochlorite solution (NaOCl). Afterward the bleach

is removed from the PSICAM by washing the cavity several times with purified water.

The reflectivity is calculated for the pair of pure water/calibration solution using the pure

water absorption as aB, and the sum of absorptions of pure water and Nigrosine as aA. The

pure water absorption is calculated beforehand for each fluid using the specific fluid

temperature.

2.1.4 Calibration procedure in short

1) preparation of approx. 100 ml Nigrosine stock solution (a580nm1cm ca. 3 OD)

2) preparation of 2000 ml Nigrosine calibration solution a580nm = 0.5 –2 m-1

3) determination of Nigrosine absorption, anig, of the calibration solution (10 cm cuvette

in spectrophotometer or using a LWCC system (liquid waveguide capillary cell), 3x)

4) determination of “transmission” (nigrosine solution vs. purified water) in the PSICAM,

5) cleaning and bleaching of the cavity after the measurement of the nigrosine solution

6) calculation of reflectivity (after temperature correction of pure water absorption),

where

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

17 / 62

aA= aw (tnig°C) + anig

aB= aw (tw°C)

TAB =

nig

w

F

F

r= inner radius of the cavity

rs = radius of the central light source

r0=r-rs

a = Absorption coefficient on the lognscale

Fw = light intensity inside the cavity when the cavity is filled with purified water

Fnig = light intensity inside the cavity when the cavity is filled with the calibration

solution nigrosine

2.1.5 Measurement of the absorption coefficient of a sample

A regular measurement is done by measuring the light intensity inside the cavity when it is

filled with either purified water or the sample. For each measurement the fluid temperature

and the sample salinity need to be recorded for a later temperature and salinity correction of

the pure water absorption (see below). For each sample measurement, TAB can be

calculated by using the reference measurement taken before the sample measurement.

There is no analytical solution for the absorption coefficient a(λ) in Eq. (6). When

is known,

a(λ) is determined by solving this equation numerically. This is done by minimizing the least

square function G(a(λ)) for the measured transmission, Texp(λ) using a numerically calculated

transmission Tnum(λ):

2

exp

()( ) ( ( ) ( ))

num

yG a T T

(8)

2.1.6 Temperature and salinity correction for pure water absorption

The absorption of pure water, aw, is dependent on temperature and salinity. Any difference in

temperature and salinity of the sample or the reference to that of the theoretical pure water

absorption reference (i.e. 20°C and 0 PSU) has to be corrected using instrument-specific

temperature and salinity correction coefficients,

Tand

Sas

)()(),(),( 00

Tww TTTaTa

(9)

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

18 / 62

and

)()(),(),( 00

Sww SSSaSa

(10)

where Tis the specific temperature, Sthe specific salinity, and T0and S0the values at which

the pure water absorption had been measured, i.e. 20 °C and 0 PSU.

As a simplified approach the sample and reference can be tempered at 20 °C e.g. with a

water bath.

2.1.7 References

J. T. O. Kirk, Modeling the performance of an integrating-cavity absorption meter. Theory and

calculations for a spherical cavity, Appl. Opt. 34, 4397-4408 (1995).

J. T. O. Kirk, Point-source integrating-cavity absorption meter: theoretical principles and numerical

modeling, Appl. Opt. 36, 6123-6128 (1997).

R. A. Leathers, T. V. Downes, and C. O. Davis, Analysis of a point-source integrating-cavity

absorption meter, Appl. Opt. 39, 6118-6127 (2000).

C. J.-Y. Lerebourg, D. A. Pilgrim, G. D. Ludbrook, and R. Neal, Development of a point source

integrating cavity absorption meter, J. Opt. A: Pure Appl. Opt. 4, S56-S65 (2002).

R. M Pope, and E. S. Fry, Absorption spectrum (380–700 nm) of pure water: II. Integrating cavity

measurements. (1997) Appl. Opt. 36 33, pp. 8710–8723

R. M. Pope, A. D. Weidemann and E. S. Fry, Integrating Cavity Absorption Meter measurements of

dissolved substances and suspended particles in ocean water. (2000) Dynamics of Atmospheres and

Oceans 31: 307-320.

R. Röttgers, R., Doerffer, Measurements of optical absorption by chromophoric dissolved organic

matter using a point-source integrating-cavity absorption meter, Limnol. Oceanogr.: Methods (2007)

5:126-135.

R. Röttgers, C. Häse, and R. Doerffer. Determination of the particulate absorption of microalgae using

a point-source integrating-cavity absorption meter: verification with a photometric technique,

improvements for pigment bleaching and correction for chlorophyll fluorescence. (2007). Limnol.

Oceanogr. Methods. 5: 1-12

R. Röttgers, W. Schönfeld, P.-R. Kipp, and R. Doerffer, Practical test of a point-source integrating

cavity absorption meter: the performance of different collector assemblies, (2005), Appl. Opt. 44:

5549-5560.

J. Wollschläger, M. Grunwald, R. Röttgers, and W. Petersen, Flow-through-PSICAM: A new approach

for determining water constituents absorption continuously, (2013), Ocean Dynamics 63: 761-775.

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

19 / 62

2.2 Basic measuring arrangement of the OSCAR

The OSCAR sensor consists of a multi-LED light source that emits a defined radiation in the

visible range, a lens system, the cavity and a miniature spectrometer. The cavity contains the

liquid sample to be measured. The TriOS Mess- und Datentechnik GmbH absorption meter

can be purchased in two different cavity diameters (50 mm and 80 mm).

Fig. 2. Illustration of the OSCAR sensor with 80 mm cavity

OSCAR G2

Manual

D01-44en201810

Software V.1.1.6

(C)TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D- 26180 Rastede/Germany

20 / 62

2.3 Technical specifications

Table of contents

Other triOS Measuring Instrument manuals