Siebe Group Company EWPX 195 User manual

GENERAL DESCRIPTION

EWPX 195(/E) is a single point temperature

controller designed for applications in the

field of commercial refrigeration.

The instrument provides two input probes:

one for temperature control, the other for

defrost control and speed control of the

evaporator’s fans. Three output relays are

provided for the compressor, the defrost

system, the alarm management, plus an

output to control the evaporator’s fans

through special power modules.

As a standard feature it can be connected

to the TELEVIS system (through its appro-

priate interface module). The “/E” version

can also be connected to the EWPX

ECHO data repeater, which allows remote

display of the temperature measured by

the instrument.

The instrument can be configured accord-

ing to the application through a series of

parameters - it is supplied in the new

32x74 mm cabinet (ELIWELL Standard).

COMMANDS ON FRONT PANEL

The instrument is provided with two keys:

“UP” and “SET/DOWN”.

SET/DOWN: by pressing and releasing it

the Setpoint is displayed, the “SET” led is

turned on.

To change the Setpoint value use the “UP”

and “SET/DOWN” keys within 5 seconds.

If no operation is performed for more than

5 seconds normal mode is restored and

the new value is automatically acquired.

The same button is used to increase val-

ues during Setpoint change or parameters

programming. When held pressed a fast

increase is performed.

UP: button used for value increase, used

to change both the Setpoint and the para-

meters. A fast increase is obtained by

holding it pressed.

This key also allows manual start of the de-

frost cycle, by holding it pressed for more

than 5 seconds (this function is not en-

abled during Setpoint or parameter pro-

gramming).

During the manual defrost cycle the “DE-

FROST” led will blink.

“COMPRESSOR” Led: led related to the

compressor relay; it is on when the com-

pressor works.

“SET” Led: it is on during Setpoint display

and programming; it blinks during parame-

ter programming.

“DEF” Led: status light of the defrost. It is

on during automatic defrost; it blinks dur-

ing manual defrost.

“ALARM” Led: led related to the alarm. It

is on when the alarm is active or disabled

due to the exclusion time (see parameters

“PAO”, “dAo” and “tAo”); it blinks when the

alarm is silenced.

DISPLAYING AND SETTING THE

SETPOINT

To display the Setpoint value press and re-

lease “SET/DOWN”; the Setpoint value is

displayed and the “SET” led is turned on.

To change the Setpoint value operate on

keys “UP” and “SET/DOWN” within 5 sec-

onds; after such time normal mode will be

restored.

CONTROLLING THE SPEED OF THE

EVAPORATOR’S FANS

A phase choking and a filtered TRIAC al-

low the instrument to control the speed of

single-phase motors which are generally

used to operate the evaporator’s fans in a

refrigerating system.

The instrument provides a probe to mea-

sure the evaporation temperature and an

output to drive special power modules di-

rectly connected to the fans (modules CF

series).

A range of parameters allows to set the

Setpoint temperature, the width of the op-

eration band and the minimum speed for

the fans of the evaporator.

The controller delivers null power for a

temperature above the Setpoint, maxi-

mum power for a temperature exceeding

the Setpoint minus the band width and a

choked power for a temperature between

the Setpoint minus the band width and the

minimum speed. After a stop the fans will

restart (at minimum speed) when the

Setpoint temperature is exceeded.

MANUAL ACTIVATION OF THE

DEFROST CYCLE

The manual activation of the defrost cycle

starts by holding the “UP” key pressed for

more than 7 seconds (the key is not active

during Setpoint or parameter program-

ming). In case the defrost conditions are

not suitable (e.g. the temperature of the

evaporator probe exceeds the end defrost

temperature) the display will show the

blinking “dFu” (deFrost unable) label.

During manual defrost the “DEFROST” led

blinks.

SILENCING THE ALARM

An alarm condition is signalled by the

“ALARM” led and the activation of the re-

lated relay on the terminal block.

The alarm can be silenced by pressing any

HOW IT IS MADE

• Housing: plastic resin PC+ABS ex-

tinguishing grade V0

• Size: front panel 76x34 mm, depth

58 mm

• Mount: panel mount on 71x29 mm

hole

• Protection: front IP65

• Connections: on screw terminal

block for wires max 2.5 mm2(one

wire only per block in compliance

with VDE regulations)

• Remote connection: serial con-

nection to the EWPX ECHO re-

peater (version /E only)

• Serial connection: TTL port for the

connection to the EWRS 485 inter-

face for TELEVIS system linking

• Display: 3 digit plus “-“ sign; digit

height 12.5 mm

• Main outputs: 1 on N.O. relay

8(3)A 250V AC for the compressor

and 1 on N.O. relay output 5(2)A

250V AC for defrost system

• Alarm output: 1 on N.C. relay 8(3)A

250V AC

• Evaporator fans output: 1 output

to drive special power modules

• Analogue inputs: two NTC

probes, one to control tempera-

ture, the other for defrost and

evaporator fans speed

• Power supply: 12 Vac/dc ±15%

WHAT IT IS

EWPX 195(/E) is a single point tem-

perature controller designed for ap-

plications in the field of commercial

refrigeration.

The instrument provides two input

probes: one for temperature con-

trol, the other for defrost control

and speed control of the evapora-

tor’s fans. Three output relays are

provided for the compressor, the

defrost system, the alarm manage-

ment, plus an output to control the

evaporator’s fans through special

power modules.

EWPX 195(/E) rel. 6/97 ing

controller for “forced air” refrigerating units

with evaporator fans speed control

2EWPX 195(/E) 6/97 ing

key on the front panel; the relay will be dis-

abled and the led will blink until the end of

the alarm condition.

DISPLAYING PROBE VALUES

The instrument provides two probe inputs:

temperature control and defrost manage-

ment.

The pressure and release of the “UP” and

“SET/DOWN” keys simultaneously causes

the label “CPr” (Compressor Probe) to be

displayed; by pressing and releasing the

“SET/DOWN” key the display shows the

value on the control probe.

By pressing the “UP” key the display will

show label “EPr” (Evaporator Probe); by

pressing and releasing the “SET/DOWN”

key the display shows the value of the

probe for control of the evaporator fans.

KEYBOARD LOCKING

A special programming of the “Loc” para-

meter allows to disable the keyboard in or-

der to avoid unauthorised operations or

parameter changes.

When the keyboard is disabled the

Setpoint and the parameters can only be

displayed (not changed), except parameter

“Loc” to allow keyboard release.

PASSWORD TO ACCESS

PARAMETER PROGRAMMING

A password can be set to allow access to

the parameter programming phase. To set

(or change) the password access parame-

ter “PAS” and type a number from 1 to 15

(0 to disable the password). The password

will be enabled when exiting from the pa-

rameter programming phase.

In case the password is enabled, when re-

questing access to the parameter pro-

gramming phase the label “PAS” is

displayed. Press the “SET/DOWN” key to

access password programming and

change it using keys “UP” and

“SET/DOWN”. If the password is correct

the pressure of keys “SET/DOWN” and

then “UP” enables access to the program-

ming phase, otherwise it will automatically

quit.

PARAMETERS PROGRAMMING

The programming phase can be accessed

pressing the “UP” and “SET/DOWN” keys

simultaneously for more than 7 seconds.

The first label is displayed and the “SET”

led starts blinking. To access other para-

meters press “UP” or “SET/DOWN”; to

display the value of the parameter shown

on the display press “UP” and

“SET/DOWN” simultaneously. To change

its value press “UP” or “SET/DOWN”.

The storage of new values takes place au-

tomatically when exiting the programming

mode (no key pressed for some seconds).

PARAMETERS DESCRIPTION

diF: diFferential.

Setpoint intervention differential.

For applications in the field of refrigeration

the differential shall be set to positive val-

ues; the compressor will stop when the

Setpoint is reached (according to the con-

trol probe) and start again when the tem-

perature reaches the Setpoint plus the

differential.

LSE: Lower Set.

Minimum value that can be assigned to

Setpoint.

Usually set to the minimum value measur-

able by the probe.

HSE: Higher Set.

Maximum value that can be assigned to

Setpoint.

dty: defrost type.

EL = electric defrost;

in = cycle inversion defrost (hot gas).

dit: defrost interval type.

Defrost interval in hours or minutes.

dct: defrost counting type.

Counting mode for the defrost interval.

dF = digifrost Feature (DIGIFROST®

method; only the operation time of the

compressor is counted).

rt = real time (the count is based on the op-

erating time of the instrument).

SC = Stop Compressor (the defrost takes

place whenever the compressor stops).

Fr = Free (the compressor relay has no re-

lation with the defrost functions and con-

tinues to regulate on Setpoint).

doh: defrost offeset hour.

Defrost start delay time; in minutes.

dEt: defrost Endurance time.

Defrost time-out; in minutes or seconds.

dSt: defrost Stop temperature.

Fdt: Fan delay time.

Delay for fan start after defrost; in minutes.

dt: drainage time.

Dripping time in minutes.

dPo: defrost (at) Power-on.

y = yes; n = no

ddL: defrost display Lock.

n = no; during defrost the display will show

the temperature measured by the room

probe.

y = yes; during defrost the display will

show the last value measured by the room

probe before defrost.

Lb = Label (“defrost”); during defrost the

display will show the “dEF” (dEFrost) label

to indicate defrost is in progress.

Lg = Label (“degivrage”); during defrost the

display will show the “dEg” (“dEgivrage”)

label to indicate defrost is in progress.

NOTE: in case “n” or “lb” is selected the

display will be locked until the Setpoint on

the room probe is reached.

dFd: defrost Fan disable.

Allows the selection of fan evaporator ex-

clusion during defrost.

y = yes; n = no.

Att: Alarm temperature type.

Decoding mode for parameters “HAL” and

“LAL”.

Ab = Absolute; re = relative.

HAL: High Alarm.

Maximum temperature alarm.

LAL: Low ALarm.

Minimum temperature alarm.

AFd: Alarm (Fan) differential.

Operating differential for temperature

alarms.

PAO: Power-on Alarm Override.

Alarm exclusion after instrument start-up;

in hours.

dAo: defrost Alarm override.

Alarm exclusion after defrost; in minutes.

tAo: temperature Alarm override.

Delay for temperature alarm signalling; in

minutes.

Fco: Fan compressor off.

Allows to disable or enable the fan lock

when the compressor is OFF.

cPP: compressor Probe Protection.

Allows the selection of the output state in

case of faulty probe.

oF = relay OFF in case of faulty probe.

on = relay ON in case of faulty probe.

dc = duty cycle; the ON and OFF times for

the relay are defined by parameters “Ont”

and “OFt”.

Ont: On time (compressor).

ON time for the compressor (when CPP =

dc); in minutes.

OFt: OFF time (compressor).

OFF time for the compressor (when CPP =

dc); in minutes.

ctP: compressor type Protection.

Allows the selection of the protection type

to prevent close startups of the output

(time is set through the following parame-

ter).

nP = no Protection.

don = delay on start. Delay on relay activa-

tion.

doF = delay at switching oFf. Minimum

time for relay cut off.

dbl = delay between two successive

starts.

cdP: compressor delay Protection.

Time referred to the previous parameter; in

minutes.

odo: output delay (at) on.

Delay for the activation of outputs at start-

up; in minutes.

PrP: Presence Probe.

Allows to select the presence of the

Evaporator probe.

nP = Evaporator probe not present;

EP = Evaporator probe present;

AP = not usable;

EAP = not usable.

CAL: CALibration.

Allows the calibration of the value mea-

sured by the control probe in case it is dif-

ferent from a sample value.

Default set to “0”.

FPS: Fan Probe Setpoint

Allows the selection of the holding temper-

ature (Setpoint) of the speed regulator.

Fpd: Fan probe differential.

Allows the selection of the operating band

width for the speed regulator. Shall be set

to negative values to operate in “evapora-

tion” mode.

FLS: Fan Low Speed.

Allows to select the minimum speed for the

evaporator fans.

0…9 = minimum speed allowed values (0

3EWPX 195(/E) 6/97 ing

= 0%, 9 = 100%).

dEA: dEvice Address.

Allows the selection of the device address

in the remote control network.

FAA: Family Address.

Allows the selection of the device family in

the remote control network.

AOP: Alarm Output Polarity.

di = direct; in = inverted.

CLO: CLOck frequency.

Reading double the mains frequency.

ndt: number of digits.

Type of display.

Int = reading without decimal point;

dEc = reading with decimal point, resolu-

tion 0.1 °C;

hFn = reading with decimal point, resolu-

tion 0.5 °C.

Loc: keyboard Lock.

Allows to disable the keyboard to prevent

unauthorised operations. When the key-

board is disabled only display (not modifi-

cation) of Setpoint and parameters is al-

lowed. Only the “Loc” parameter can be

modified to permit keyboard unlock.

y = yes ; n = no.

PAS: PASsword.

Allows to set a password (see paragraph

“Password to access parameter program-

ming”).

0 = no password required to access para-

meter programming;

1…15 = available values for the password.

rEL: rELease firmware.

Read-only parameter showing the release

code of the product.

tAb: tAble of parameters.

Summary of factory set parameters; can-

not be modified by the user.

MECHANICAL MOUNT

The instrument is designed for panel

mount. Drill a 29x71 mm hole and intro-

duce the instrument, then fix it with the

special bracket (included).

The operating temperature range for cor-

rect operation is from –5 to 65 °C. Do not

install the instrument in moist and/or dirty

places; it is suitable for operation in envi-

ronments with an ordinary pollution level.

Leave enough room for air circulation by

the cooling holes of the instrument.

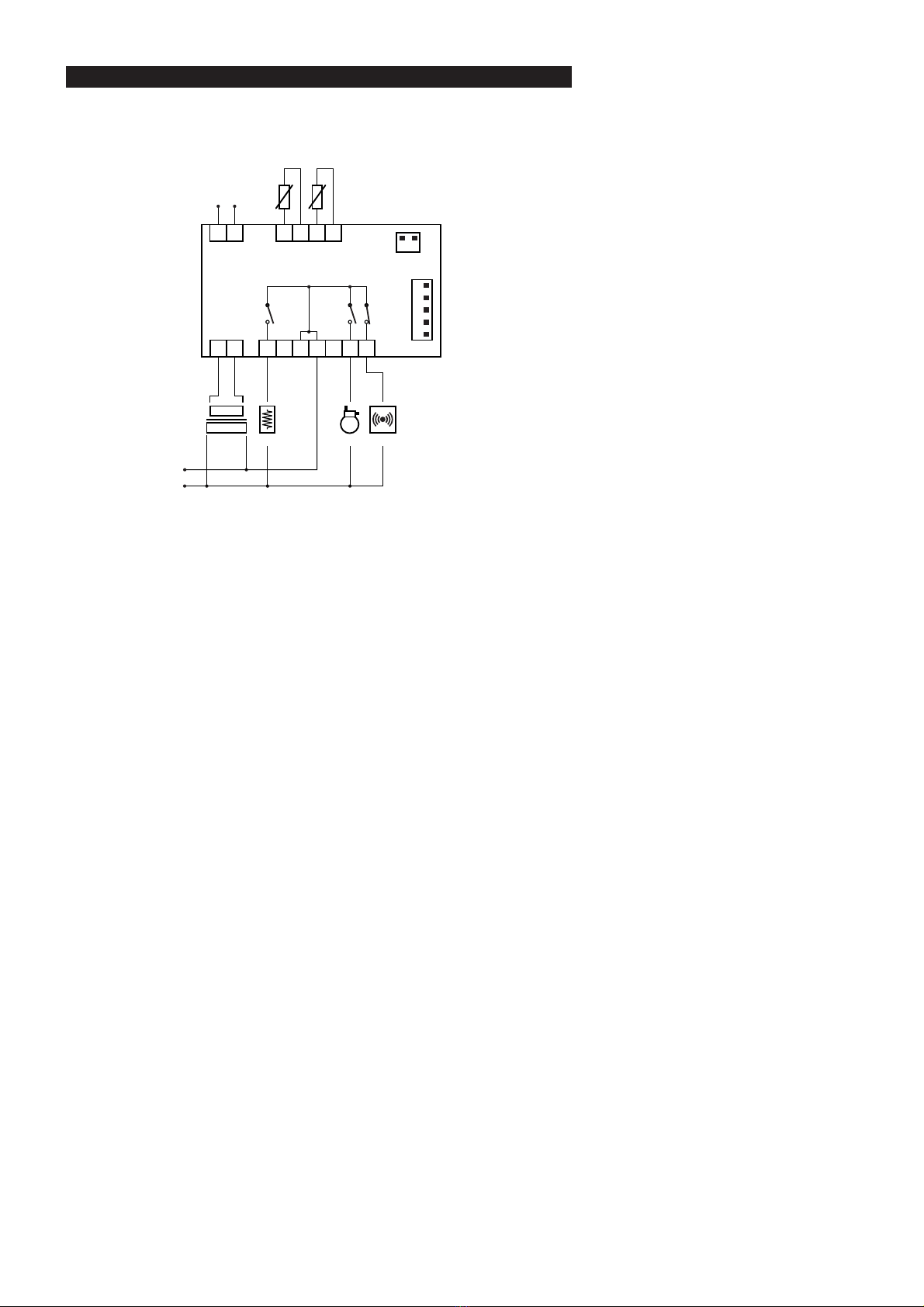

ELECTRICAL CONNECTIONS

EWPX 195(/E) is provided with three relay

outputs, one serial output for the connec-

tion to the TELEVIS system and another

serial output for the EWPX ECHO repeater

(version /E only).

The instrument includes a screw terminal

block for the connection of electrical ca-

bles with a maximum 2.5 mm2section

(one wire only for each block, according to

VDE regulations).

Relay outputs, connected through two

common terminal blocks, are free from

voltage. Do not exceed the maximum al-

lowed current (alarm and compressor:

8(3)A 250V AC; defrost system: 5(2)A

250V AC). In case of heavier loads use a

suitable power contactor.

Check the power voltage complies with

the instrument requirements: 12 Vca/cc

±15% (very low safety voltage).

The NTC probe has no insertion polarity

and can be lengthened using a common

bipolar cable (bearing in mind that a very

long probe implies worse instrument per-

formances referred to the EMC).

Outputs for the connection of the EWPX

ECHO repeater (version /E only) and the

EWRS 485 interface module of the TELE-

VIS system require connections according

to the indicated polarity.

The probe cable, the connection cable for

the EWPX ECHO repeater (version /E only),

the connection cable for the EWRS 485 in-

terface module shall be kept far from the

relay cables both for EMC and safety rea-

sons. The coordinated European safety

regulations state that the relay contacts

(and generally speaking, all parts subject

DEFAULT SETTINGS - STANDARD MODELS

Parameter

diF

LSE

HSE

dty

dit

dct

doh

dEt

dSt

Fdt

dt

dPo

ddL

dFd

Att

HAL

LAL

AFd

PAO

dAo

tAo

Fco

cPP

Ont

OFt

ctP

cdP

odo

PrP

CAL

FPS

FPd

FLS

dEA

FAA

AOP

CLO

ndt

Loc

PAS

rEL

tAb

Description

diFferential

Lower SEt

Higher SEt

defrost type

defrost interval time

defrost counting type

defrost offset hour

defrost Endurance time

defrost Stop temperature

Fan delay time

drainage time

defrost (at) Power-on

defrost display Lock

defrost Fan disable

Alarm temperature type

High ALarm

Low ALarm

Alarm (Fan) differential

Power-on Alarm Override

defrost Alarm override

temperat. Alarm override

Fan compressor off

compressor Probe Prot.

On time (compressor)

OFF time (compressor)

compr. type Protection

compr. delay Protection

output delay (at) on

Presence Probe

CALibration

Fasec Probe Setpoint

Fasec Proportional diff.

Fasec Low Setting

dEvice Address

FAmily Address

Alarm Output Polariry

CLOck frequency

number display type

(keyboard) Lock

PASsword

rELease firmware

tAble of parameters

Range

–12…12

–999…HSE

LSE…999

EL / in

0…31

dF / rt / SC / Fr

0…59

1…250

–999…999

0…250

0…250

n / y

n / y / Lb / Lg

n / y

Ab / re

–999…999

–999…999

1…50

0…10

0…999

0…250

oF / on

oF / on / dc

0…250

0…250

nP/don/doF/dbi

0…15

0…99

nP / EP / AP / EAP

–12…12

–999…999

–99…99

0…10

0…14

0…14

di / in

/

int / dEc / hFn

n / y

0…15

/

/

Unit

°C / °F

°C / °F

°C / °F

flag

hours

flag

minutes

minutes

°C / °F

minutes

minutes

flag

flag

flag

flag

°C / °F

°C / °F

°C / °F

hours

minutes

minutes

flag

flag

minutes

minutes

flag

minutes

minutes

flag

°C / °F

°C / °F

°C / °F

number

number

number

flag

Hertz

flag

flag

number

/

/

Default

2

–50

40

EL

6

dF

0

30

8

0

0

n

n

y

re

50

–50

2

2

60

0

on

on

10

10

doF

0

0

EAP

0

2

–1

0

0

0

in

/

int

n

0

/

/

4EWPX 195(/E) 6/97 ing

to dangerous voltage) shall be kept away

from the very low safety voltage connec-

tions (probe, Televis serial, power supply)

using insulation systems and distances

providing at least a double or reinforced in-

sulation.

However EMC requirements for correct

operation suggest/impose better accuracy

in such separation by using separated in-

sulating pipes and special cable fixing sys-

tems.

EWPX ECHO (version /E only) operates at

very low safety voltage and shall be in-

stalled respecting the same insulation/sep-

aration conditions from the parts bearing

voltage and the wires of the relay contacts.

ERROR MESSAGES

In case of shorted, interrupted or discon-

nected probe the instrument displays error

message “E1” for the regulation probe and

“E2” for the defrost/evaporator fans control

probe. The same message will appear in

case of “under range”, i.e. in case the val-

ue is below the minimum readable mea-

surement, or “over range” (value exceeding

the upper limit).

Before replacing the probe always check

its connections.

TECHNICAL DATA

Housing: plastic resin PC+ABS extin-

guishing grade V0.

Size: front panel 76x34 mm, depth

58 mm.

Mount: panel mount on 71x29 mm hole.

Protection: front IP65.

Connections: on screw terminal block for

wires max 2.5 mm2(one wire only per

block in compliance with VDE regulations).

Remote connection: serial connection to

the EWPX ECHO repeater (version /E only).

Serial connection: TTL port for the con-

nection to the EWRS 485 interface for

Display: 3 digit plus “-“ sign; digit height

12.5 mm.

Commands: all located on front panel.

Data storage: on non-volatile memory

(EEPROM).

Operating temperature: –5…65 °C;

(23…149 °F).

Storage temperature: –30…75 °C;

(–22…167 °F).

Main outputs: 1 on N.O. relay 8(3)A 250V

AC for the compressor and 1 on N.O. relay

output 5(2)A 250V AC for defrost system.

Alarm output: 1 on N.C. relay 8(3)A 250V

AC.

Evaporator fans output: 1 output to dri-

ve special power modules (CF05, CF15,

CF22).

Analogue inputs: two NTC probes, one

to control temperature, the other for de-

frost and evaporator fans speed.

Range: –50…100 °C (–58…212 °F).

Resolution: 1 °C, 0.1 °C, or 0.5 °C, se-

lectable through parameters.

Accuracy: better than 0.5% on full range.

Consumption: 3VA (5 VA in the “/E” ver-

sion with the EWPX ECHO module con-

nected).

Power supply: 12 Vac/dc ±15%.

Eliwell S.p.A.

via dell’Artigianato, 65

Zona Industriale

32010 Pieve d’Alpago (BL)

Italy

Telephone +39 (0)437 986111

Facsimile +39 (0)437 989066

A Siebe Group Company

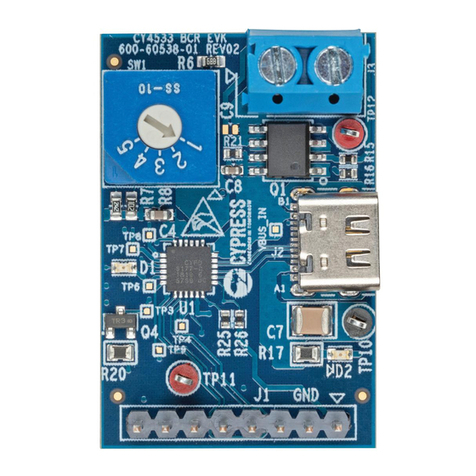

EWPX 195/E

11 12 15 16 17 18

TTL output

to the interface module

to TELEVIS system

thermostat

probe

defrost

probe

4 5 6 7 8 9 10

comp.

defrost

POWER SUPPLY

output to

the EWPX ECHO

signal repeater

–+

–

+

alarm

output evaporator

fans control

–

+

1 2

CONNECTIONS

This manual suits for next models

1

Other Siebe Group Company Controllers manuals

Popular Controllers manuals by other brands

cashco

cashco 1000HP Installation, operation & maintenance instructions

Novy

Novy 990030 operating instructions

Lipidex

Lipidex AirCycler SmartExhaust FV-WCPT1-W quick start guide

roco

roco ROCOMOTION 10785 quick start guide

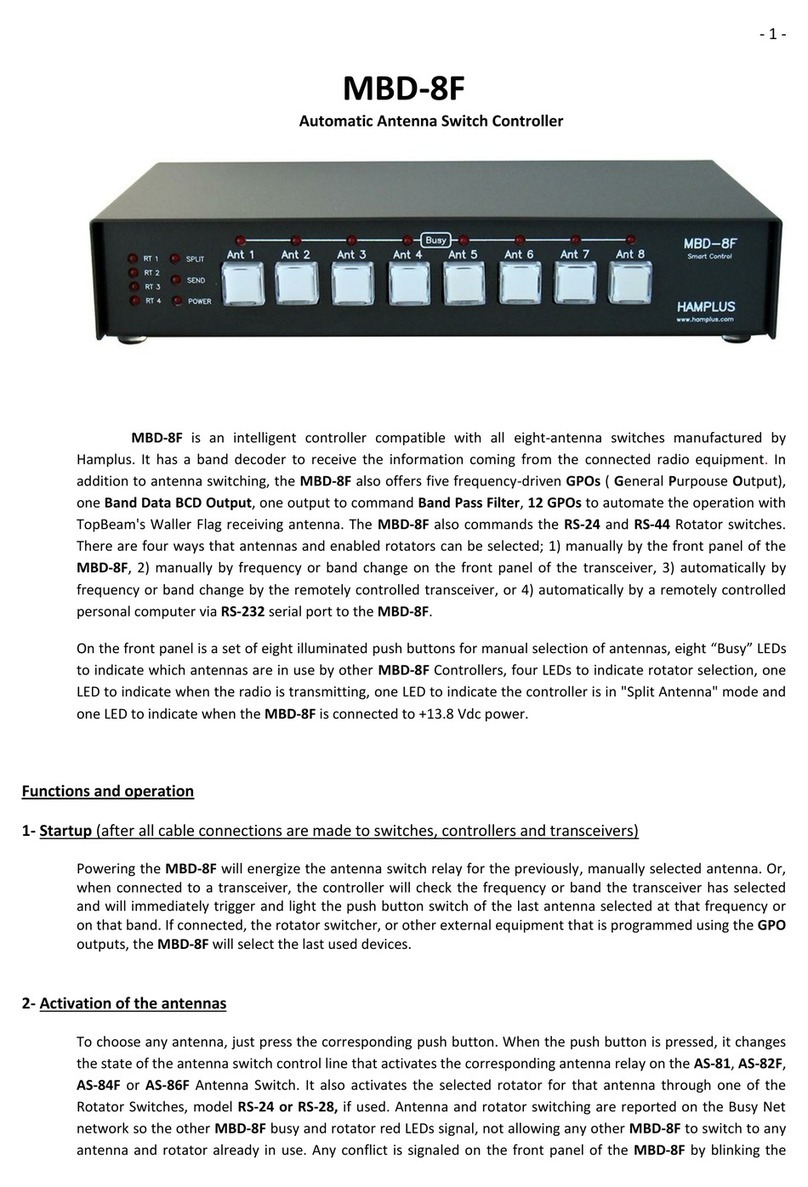

Hamplus

Hamplus MBD-8F Operation manual

Johnson Controls

Johnson Controls VA-9070 Series Technical bulletin