Siecor 5000 Series User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Operating Instructions

for Fusion Splicer M90/Series 5000

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

The pages of these Operating Instructions will not be exchanged.

Modifications will be provided in the form of supplementary sheets.

Products subject to availability. Technical modifications reserved.

Edition 02/97

Published by

Siecor Corporation

489 Siecor Park

P.O Box 489

Hickory, NC 28603-0489

For US and Canada 1-800-743-2673

International 704-327-5000

FAX 704-327-5973

Printed in Germany

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents 1 Getting to Know the M90 Splicer

2 Preparations

3 Parameters and Programs

4 Splicing

5 Attenuation Splice

6 Taking Out of Service

7 Troubleshooting and Maintenance

8 Accessories

9 Supplement / Modifications

Index

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Notes on these Operating Instructions

Please read these Operating Instructions carefully and note the recommendations they

contain. This will ensure your splicer remains free of fault. Use the information set out in

the Operating Instructions to perform the necessary regular care and maintenance of

your splicer. Avoid damage by using extreme care.

If you are in doubt about any points, contact the relevant service center. The trained

experts available at these centers should be able to assist.

Incorrect or incomplete maintenance can impair the operation of your splicer.

The manufacturer's warranty obligations for the splicer shall be rendered null and void if

the unit has been tampered with by unauthorized persons.

Warranty The Siecor M90 Fusion Splicer is warranted against defects in material and

workmanship for a period of one year from date of shipment. Any M90 found to be

defective during the warranty period may be returned, transportation prepaid, to the

factory for repair without charge.

This warranty does not apply to units which have been repaired or altered by an

unauthorized person, or which have been subject to misuse, negligence or accident.

A complete explanation of Siecor corporation´s warranties, and terms and conditions of

sale may be found on the reverse side of Siecor´s Quotations, Order Acknowledgement

and/or invoice forms and only the Warranty appearing thereon is to be considered

Siecor´s Warranty.

All inquiries regarding repairs or replacement parts should be directed to the Customer

Service Department, SIECOR CORPORATION, 489 Siecor Park, Hickory,

NC 28603-0489; (704) 327-5000. This will assure you the fastest possible service.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Definition of Warning Terms

Danger Within the scope of these Operating Instructions and the warning notices on the

products themselves, death, serious injury or substantial damage to property will occur

if the relevant precautionary steps are not taken.

Warning Within the scope of these Operating Instructions and the warning notices on the

products themselves, death, serious injury or substantial damage to property can occur

if the relevant precautionary steps are not taken.

Caution Within the scope of these Operating Instructions and the warning notices on the

products themselves, minor injury or damage to property can occur if the relevant

precautionary steps are not taken.

Note Within the scope of these Operating Instructions, important information on the product

or the relevant part of the Operating Instructions to which particular attention should be

paid.

Qualified

personnel Within the scope of these Operating Instructions, persons familiar with the

commissioning, operation and maintenance of electrical devices and possessing the

qualifications relevant for their work.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Password Request

The splicer must be opened in order to activate or deactivate the password request.

Danger

The fusion splicer or electrically operated accessories must not be opened except by

suitably qualified personal. Switch off fusion splicer. Pull power supply plug and 12-V

lead.

Open the front

panel see section 7.

Activating the

password re-

quest

The PC board which is now visible (see figure) contains a switch for activation or deac-

tivation of the password. If the password request is deactivated, the stored password is

deleted when the equipment is switched on again. However, the old password is re-

tained if you reactivate the password request before the equipment is switched on and

off. On renewed activation of the request there is no password stored. It is therefore

necessary to define a new password first (Parameter “Password”, see below).

M=23%

Switch “off”:

request acti-

vated.

Entering the

password A password consists of an arbitrary sequence of five input keys. If you try to change a

parameter while the password request is activated, the message “Enter password” ap-

pears. If an incorrect password is entered, the change of parameter is rejected. This

applies also to a change of password, i.e. a new password cannot be defined unless the

current password is known. To redefine the password, activate the parameter menu,

select the parameter “Password” and proceed according to the following flow chart:

Change password? Enter password?

Only if password already exists

Enter new password

Confirm password Password wrong

Operator menu

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operating Instructions 1-1 M90 Fusion Splicer

Issue 02/97 Getting to Know the M90 Fusion Splicer

Getting to Know the M90 Splicer

Contents Page

Scope of Delivery.......................................................................................................................................1-2

General......................................................................................................................................................1-3

Fiber diameter.......................................................................................................................................1-3

Automatic fiber positioning....................................................................................................................1-3

Automatic fusion time control................................................................................................................1-3

Flexible software...................................................................................................................................1-3

Splicer shutdown...................................................................................................................................1-3

Accessories ..........................................................................................................................................1-3

Definition of X, Y, Z directions..............................................................................................................1-4

Overview of Modular Units.........................................................................................................................1-4

Modular units........................................................................................................................................1-4

Power Supply.............................................................................................................................................1-5

Overview...............................................................................................................................................1-5

Splicing Unit...............................................................................................................................................1-6

Overview...............................................................................................................................................1-6

LID system............................................................................................................................................1-6

Pigtail adapters.....................................................................................................................................1-7

Monitor and Control Panel..........................................................................................................................1-8

Monitor .................................................................................................................................................1-8

Control panel ........................................................................................................................................1-8

Inputs / Outputs.........................................................................................................................................1-9

Overview...............................................................................................................................................1-9

RS 232 interface...................................................................................................................................1-9

External video output ............................................................................................................................1-9

External LID input ...............................................................................................................................1-10

Case Lid ..................................................................................................................................................1-11

Overview.............................................................................................................................................1-11

Tool bag..............................................................................................................................................1-11

Technical Specifications...........................................................................................................................1-14

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

M90 Fusion Splicer 1-2 Operating Instructions

Getting to Know the M90 Fusion Splicer Issue 02/97

Scope of Delivery

Basic unit With LID system

Fiber guides Fiber guide 250-900 µm:

for clamping fiber on glass, for coatings

from 250 µm to 900-µm diameter. 2 x

Fiber guide 250 µm:

for clamping fiber on coatings

with 250-µm diameter 2 x

AC power cord Stored in case lid 1 x

Working light Stored in case lid 1 x

Tool bag Consisting of:

Tool roll 1 x

Syringe with index-matching fluid 1 x

Hexagon socket head wrench, size 2.5 1 x

Cleaning tips 1 x

Electrode cleaning tool 1 x

Emery paper strip for

electrode cleaning tool 10 x

Cleaning tool for LID system 1 x

Groove cleaner for LID system 10 x

Leather cloth for swab holder 10 x

Leather cloth for monitor 1 x

Dusting brush 1 x

Nylon tweezers 1 x

Hexagon socket head wrench, size 1.5 1 x

Hexagon socket head wrench, size 5 1 x

Open-end wrench 6 x 7 1 x

Spare electrodes 2 x

AC power fuse, medium time-lag 2.5 A 1 x

Battery fuse 10 A 1 x

Screwdriver, size 3 1 x

Hexagon socket head wrench, size 2 1 x

Wrench for splicing case 2 x

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operating Instructions 1-3 M90 Fusion Splicer

Issue 02/97 Getting to Know the M90 Fusion Splicer

General

The microprocessor-controlled fusion splicer is employed to produce mechanically

strong, durable and low-loss connections between optical fibers.

Fiber diameter It is possible to connect single-mode fibers, dispersion-shifted single-mode fibers and

multimode fibers up to a maximum coating diameter of 900 µm. The splicer is designed

for the standard fiber outside diameter 125 µm (without coating). If you want to fuse

other fiber diameters, please contact the manufacturer.

Automatic fiber

positioning The fibers are positioned and fused automatically. This ensures consistently good re-

sults irrespective of the operator. Two mutually independent processes for positioning

and automatic splice loss calculation are incorporated into the splicer. The proven LID

system (LID = Local Injection and Detection) allows the user to perform exact core-to-

core positioning of the fiber ends so that usable splice results can also be obtained in

the case of single-mode fibers with eccentric cores. It also allows the user to measure

the splice loss at the operating wavelength of 1300 nm. If the LID system cannot be

used (e.g. in the case of tight buffered fibers), the finished splice is analyzed with the

L-PAS video system (Lens Profile Alignment System) and the splice loss likewise

given in dB.

Automatic

fusion time con-

trol

The LID programs with automatic fusion time control measure the light transmitted

through the fusion point during the fusion process. The optimum fusion time for each

individual splice is thus selected automatically.

Flexible

software The splicer is equipped with a flexible software package that allows the user to adapt it

to all conceivable applications:

The following programs are provided:

- LID programs with automatic fusion-time control for minimum splice loss

- L-PAS programs for special fiber types

- Special programs with preselectable fusion time and programmable fusion current

profile

- Attenuation splice program for making attenuators up to 10 dB

Splicer

shutdown The splicer shuts down automatically 30 minutes after the last operation in AC power

mode. In battery mode, the operator can select the shutdown time himself.

Accessories At the customer's request, the splicer can be equipped with various accessories such

as a battery, cleaver and splice tray holder. For accessories, see section 7.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

M90 Fusion Splicer 1-4 Operating Instructions

Getting to Know the M90 Fusion Splicer Issue 02/97

Definition of

X, Y, Z

directions

Y

X

X

Z

Z

Y

Fiber Direction

Overview of Modular Units

Modular

units The splicer is made up of service-friendly modular units.

M=23%

5

1

1

2

34

Overview of the Fusion Splicer Modules

1 Power supply

2 Fusion unit

3 Monitor and

control panel

4 Input/output

5 Case lid

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operating Instructions 1-5 M90 Fusion Splicer

Issue 02/97 Getting to Know the M90 Fusion Splicer

The mechanical and electronic systems are housed in a sturdy aluminum case.

The splicer can be powered by connecting it to mains voltages of 95 V to 260 V and

50 Hz to 60 Hz, the integral AC-line adapter selecting the correct voltage/frequency

range automatically.

If the splicer cannot be powered from the mains, it can be operated by a battery instead

(accessories). If the lead-acid battery is fully charged, operation can be sustained for 3-

4 hours if no additional load (e.g. working light or heatshrink oven) is connected. When

the battery is run down it can be recharged by means of the integral charger even if the

fusion splicer is switched off. The splicer can still be used while charging is in progress.

The splicer can also be operated from an external 12-V power supply.

Power Supply

Overview The terminal panel is located in the rear third of the splicer and features the sockets for

the power supply, charging indicator and mains switch ("I").

M=23%

1

2

3

4

5

6

Overview of Power Supply

1 AC power connec-

tor

2 Connection for

working light

3 Connection for

heatshrink oven

4 Input, 12-VDC

(red +, black -)

5 Charging indicator

6 Mains switch

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

M90 Fusion Splicer 1-6 Operating Instructions

Getting to Know the M90 Fusion Splicer Issue 02/97

Splicing Unit

Overview

Overview of Fusion Unit

Fusion unit

1 Electrode flap

with illumination

2 Electrodes

3 Fiber guides

4 Holder flap

LID system

5 Transmitter

6 Receiver

LID system The LID system allows exact core-to-core positioning. It consists of a transmitter and a

receiver. The optical fibers that are to be connected are inserted into the transmitter

and receiver. Located in the LID flaps there are the mandrels for bending the optical

fibers.

Principle Light can normally be launched into the core of a straight fiber only at its end face. If the

fiber is bent around a sufficiently small radius, however, such as occurs here at the

mandrels of the holder flaps, light can be launched into or extracted from the fiber

through the primary coating.

Y

X

2

3

4

4

5

Z

1

1

Principle of the LID System

X X axis

Y Y axis

Z Z axis

1 Mandrel

2 Receiver

(photodiode)

3 Microprocessor

4 Positioning ele-

ments

5 Transmitter (LED)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operating Instructions 1-7 M90 Fusion Splicer

Issue 02/97 Getting to Know the M90 Fusion Splicer

Launching/

extracting the

light

At the radius of the mandrel on the transmitter side, the light from an LED is radiated

into the optical fiber at a wavelength of 1300 nm. Part of this light is transferred into the

core of the second optical fiber at the splice point. The light emerges again at the re-

ceiver's mandrel and strikes a photodiode.

Optical power

as an electrical

signal

The extracted optical power is proportional to the transmission at the splice point. Fol-

lowing conversion to an electrical signal it can be used for automatic alignment of the

fiber ends and for automatic control of the splicing process itself.

Coating diameter Your splicer is equipped with a LID system for coating diameters of 250 µm.

The following options are available for fusing fibers of diameters 400, 500 and 900 µm:

- You can align and fuse the fibers fully automatically by selecting the "Fixed parame-

ters (video)" program group in the Parameter menu. This program aligns the ends of

the fibers using the video camera, the LID system not being required.

- Align the optical fiber manually.

- Use an external optical attenuation test set, the test set being connected to the

splicer's external LID input. In this case, you can perform fully automatic fusion by

selecting the "Fixed parameters (LID)" or "Variable fusion curve" program group in

the Parameter menu and switching there to an external LID system (see section 3).

Note

When using the internal LID system, use only optical fibers with the correct diameter

(250-µm coating)

Pigtail

adapters To fuse pigtails to fibers, pigtail adapters are available for various connector types, al-

lowing the LID system to be used (see section 8).

Pigtail adapter

Pigtail adapters

e.g. for:

D4 plugs

LSA plugs

ST/II plugs

SC plugs

DIN plugs

FC plugs

E2000 plugs

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

M90 Fusion Splicer 1-8 Operating Instructions

Getting to Know the M90 Fusion Splicer Issue 02/97

Monitor and Control Panel

Monitor The monitor used is an LCD (Liquid Crystal Display) screen subdivided into three

areas.

Subdivision The upper third and middle third of the monitor show the fiber pair in the X plane and

Y plane respectively, unmirrored in each case.

The bottom third contains two lines of text for displaying the current program step

and message texts.

During the self-test at switch-on and during parameter setting, the monitor switches

to full-page text display mode.

Reference line Located in the middle of the monitor and at right angles to the X and Y observation

directions are two dashed lines. The inside edges of these lines indicate the ap-

proximate required position of the fiber ends for manual positioning.

Auto-XYZ, clean,

fuse?

X plane

Y plane

Image Area with Reference Line and Monitor Display

Control panel

0

Control Panel Buttons

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operating Instructions 1-9 M90 Fusion Splicer

Issue 02/97 Getting to Know the M90 Fusion Splicer

Inputs / Outputs

Overview

M=23%

1

2

3

Inputs and Outputs

1 RS 232

interface

2 External

video output

3 External

LID input

RS 232

interface The RS 232 interface can be used to print out the splice values and splicing parameters

or to transfer these to a computer with appropriate terminal software.

Pin assignment

PIN 5

PIN 3

PIN 2

RS 232 Interface

PIN 2: RXD

PIN 3: TXD

PIN 5: Ground

External

video output An external monitor of European standard CCIR (625 lines, 50 Hz) with an input imped-

ance of 75 Ωor higher can be connected to the video output.

RF cable A cinch plug and an RF cable (75 Ω) must be used to connect the external monitor.

Cinch Plug

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

M90 Fusion Splicer 1-10 Operating Instructions

Getting to Know the M90 Fusion Splicer Issue 02/97

External LID

input The LID system cannot be employed for optical fibers of diameter > 250 µm over the

coating or for optical fibers with a color coating impermeable to light.

If you have an external attenuation test set, you can nevertheless still perform fully

automatic fusion by selecting the "Fixed parameters (LID)" or "Variable fusion curve"

program group in the Parameter menu.

The external attenuation test set must have the following features:

Permissible output voltage Uout 0 V ≤Uout ≤10V

Voltage level Variable DC voltage

Wavelength 800 - 1600 nm *

Settling time (rise or fall time of output

voltage) 10 ms - 500 ms *

Signal-to-noise ratio of output voltage >20 dB

Recommended output voltage range for

automatic mode 1 V ≤Uout ≤10 V

* can be set in Parameter menu

Jack plug A two-pin or three-pin plug of diameter 3.5 mm and a shielded cable must be used for

connecting the external analog attenuation test system.

+-

Connecting the Plug

The "-" and "Ground" connections are interconnected in the splicer.

If your external attenuation test set has a settling time of 10 ms, the splicer functions

automatically at the original speed. If the settling time is very long, e.g. 200 ms, the

positioning procedure can take significantly longer.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operating Instructions 1-11 M90 Fusion Splicer

Issue 02/97 Getting to Know the M90 Fusion Splicer

Case Lid

Overview The case lid houses as standard the working light, the AC power cord, the tool bag and

the 250-µm fiber guides (two items).

1

2

3

4

Overview of Case Lid

1 Tool bag

2 AC power cord

3 Working light

4 Storage container

for fiber guides

Tool bag The tool bag houses all the tools required for care and maintenance.

Overview of Tool Bag

Caution

The AC power cord and tool bag must not project out of the holders!

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

1

Table of contents

Popular Tools manuals by other brands

MSW

MSW MSW-ETT-VW-120 user manual

Samoa

Samoa 160 100 Parts and technical service guide

Woodhaven

Woodhaven 7500 owner's manual

EINHELL

EINHELL 41.327.20 Original operating instructions

Accles & Shelvoke

Accles & Shelvoke CASH Small Animal Tool Original instruction manual

Niigata seiki

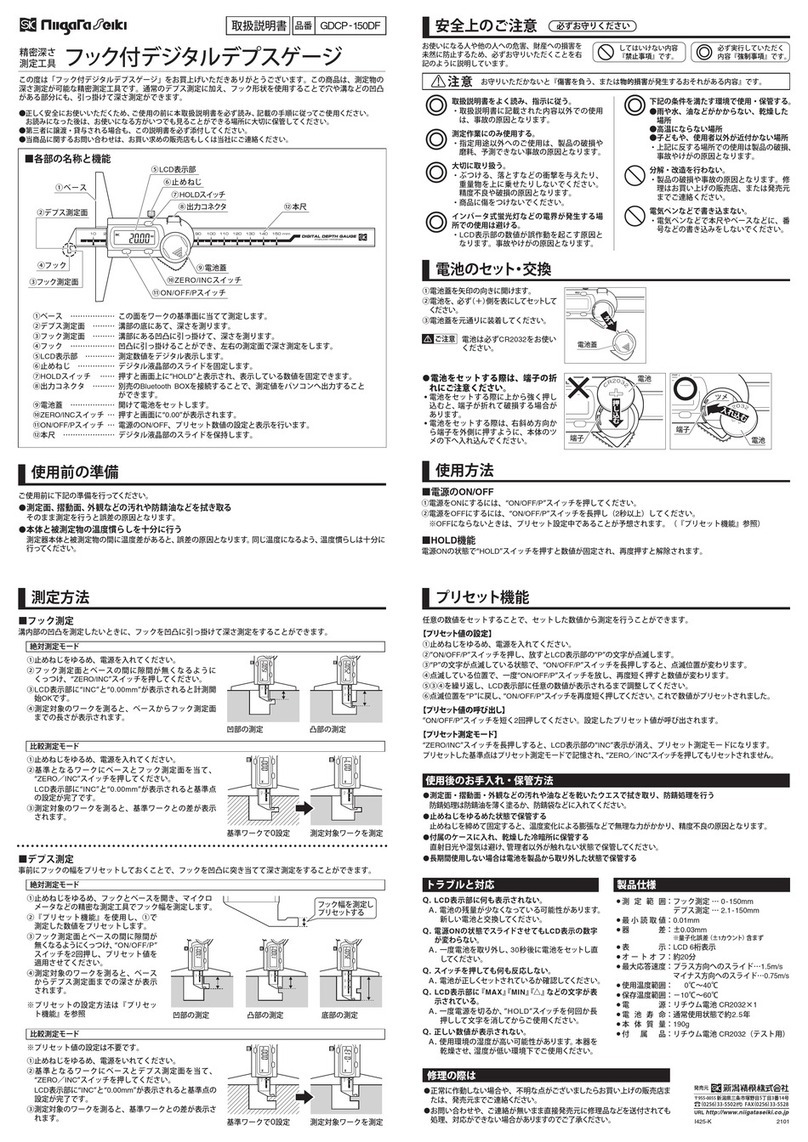

Niigata seiki GDCP-150DF instruction manual