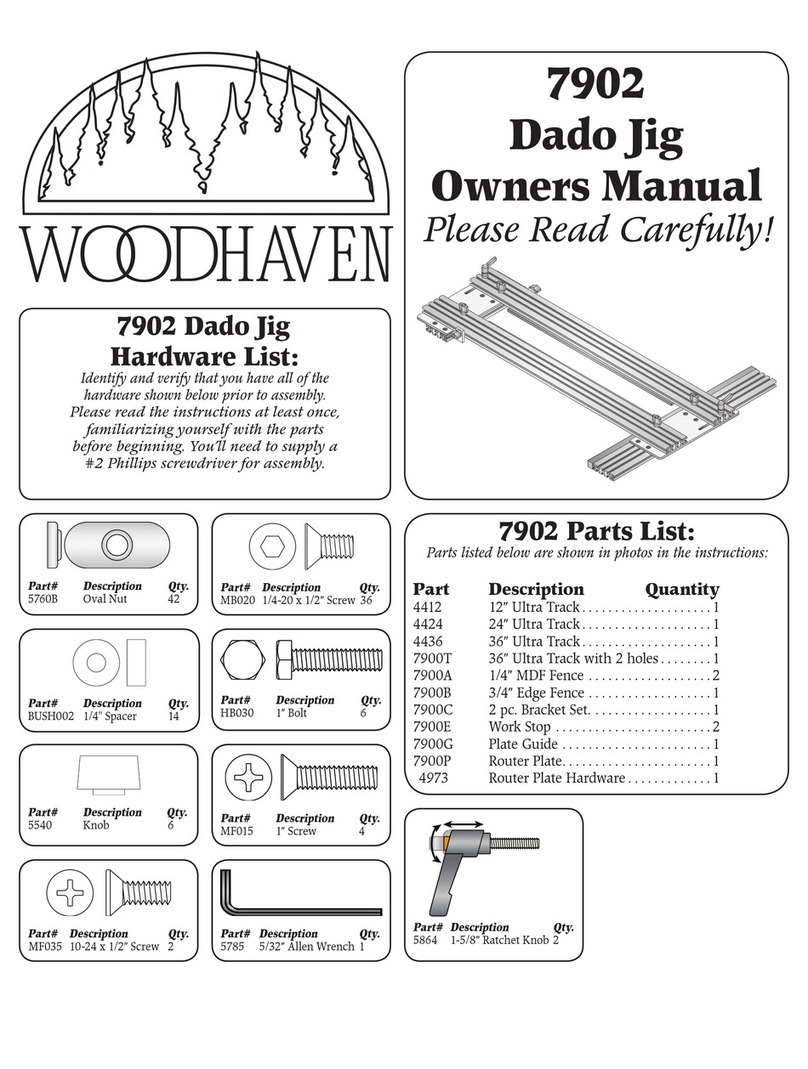

10

STOCK SPECS

This jig is designed for 3/8" to 1" thick stock. 1/2"

stock is the most common thickness used for drawers. The

stock used for the fronts & backs can be a different thick-

ness then the stock used for the sides All stock should be

flat and straight.

Stock thinner than 1/2" may be used for the backs and

fronts, but the ends of the pins (dovetails) will show. Using

thinner stock for the sides will not effect the look of the

joint like it will on the fronts and backs.

We recommend a 1/64" overhang on each end of the

fronts and backs. Cut them 1/32" longer than the desired

finished width of the drawer. See fig. 33, pg. 9 & 38, pg.

12. Cut the sides approximately 9/16" longer (this will

depend on the final cutting depth of the router bit) than the

desired inside length of the drawer.

The width of the stock will depend on the height of the

drawer opening, desired drawer depth and the dovetail pat-

tern selected.

STOP SPECS

The Stops have two offsets on them, a small offset on

one side and a larger offset on the opposite side. See 7500S

Stop part drawing, pg. 2. If you use the 3/4" spacing on the

Template, you also need to use the 3/4" spacing on the

Stops.

The position of the Stops control the dovetail margins

at both edges of the work and also control the inside drawer

depth. Since one effects the other, it is usually best to focus

on the drawer depth you want to achieve. We recommend at

least 1/2" of material on the bottom edge of the drawer. See

fig. 38, pg. 12. After the initial setup, the only time you

need to adjust the Stop position is when you have half a pin

(or less) at the top of the drawer. Then you need to either

re-adjust the Stop position or cut the drawer sides narrower.

The location of the Stop has an effect on the eventual

groove placement for the drawer bottom. The drawer bot-

tom groove normally falls within the first full dovetail pin so

it is hidden after assembly. See fig. 38, pg. 12. Changing

the Stop position effects the groove position, which effects

the inside depth of the drawer.

ACCESSORIES

We have several accessories that expand the capabili-

ties of this jig. See the photos to the right.

The 7507K Keller Dovetail Kit is for cutting through dove-

tails with a 1-1/8" spacing using our dovetail jig. Includes the tem-

plate and a pair of 1/4" shank carbide tipped bits (one for pins and

one for tails) with shank mounted bearings. Stock capacity is 12"

wide x 1/8" to 3/4" thick.

The 7506K Box Joint Kit is for 1/2" & 3/4" box joints and

works on stock up to 3/4" thick. Includes the template (1/2" phe-

nolic) and a 1/2" diameter x 1/4" shank carbide tipped bit with a

shank mounted bearing.

The 7508K Small Dovetail Kit is for 1/4" & 3/8" half-blind

dovetails and works on 3/8" or thicker stock. Includes the template

(1/2" phenolic), 1/4" dovetail bit, 5/16" guide bushing and nut.

The 6104 Kamtite Clamps replace the wing knobs and speed

up the clamping process. Continued

7506K

For 1/2" & 3/4"

Box Joints

7508K

For 1/4" & 3/8"

Half-Blind

Dovetails

7507K

Keller template & bits for

Through Dovetail Joints