Page 2 For technical questions, please call 1-800-444-3353. Item 61163

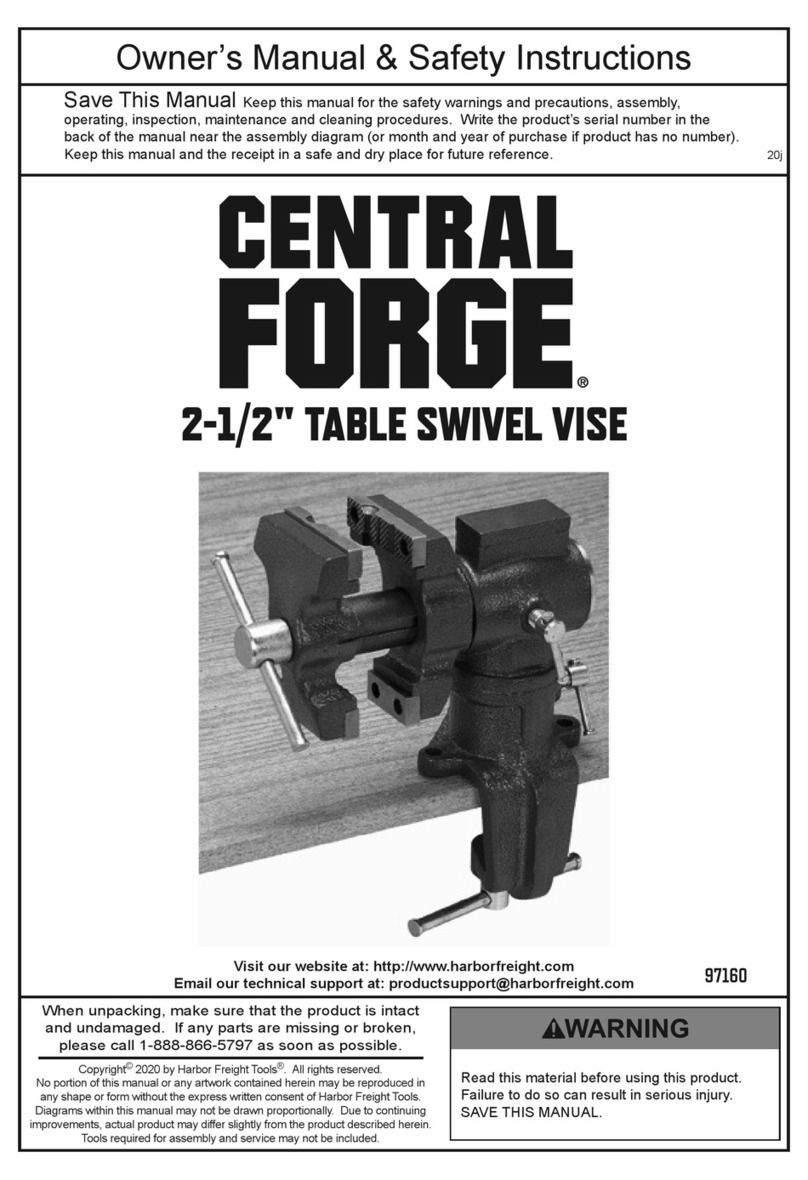

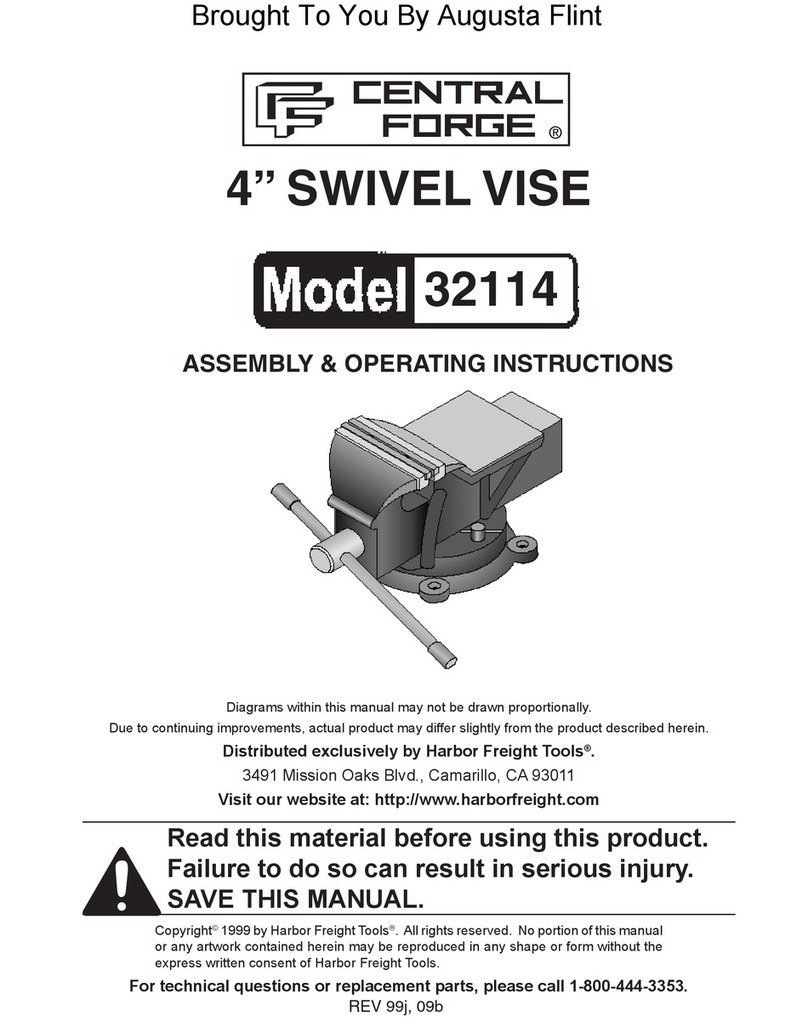

Specifications

Jaw Throat Depth 3"

Pipe Jaw Capacity 2"

Swivel Capacity 360°

Important Safety Information

1. Mount according to these instructions

before use. Improper mounting

can create hazards.

2. Wear ANSI-approved safety goggles

and heavy-duty work gloves

during mounting and use.

3. Keep hands clear of Jaws.

4. Do not use additional leverage

for tightening jaw grip.

If required, use a larger vise.

5. Do not strike Vise with hardened tool.

Inspect before use; discard if chipped.

6. Keep work area clean and well lit.

7. Keep bystanders out of the work area.

8. Do not use when tired or when

under the influence of alcohol,

drugs or medication.

9. This product is not a toy. Do not allow

children to play with or near this item.

10. Use as intended only.

11. Inspect before every use; do not use

if parts are loose or damaged.

12. Maintain product labels and

nameplates. These carry

important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

13. The warnings, precautions, and

instructions discussed in this instruction

manual cannot cover all possible

conditions and situations that may occur.

It must be understood by the

operator that common sense and

caution are factors which cannot

be built into this product, but must

be supplied by the operator.

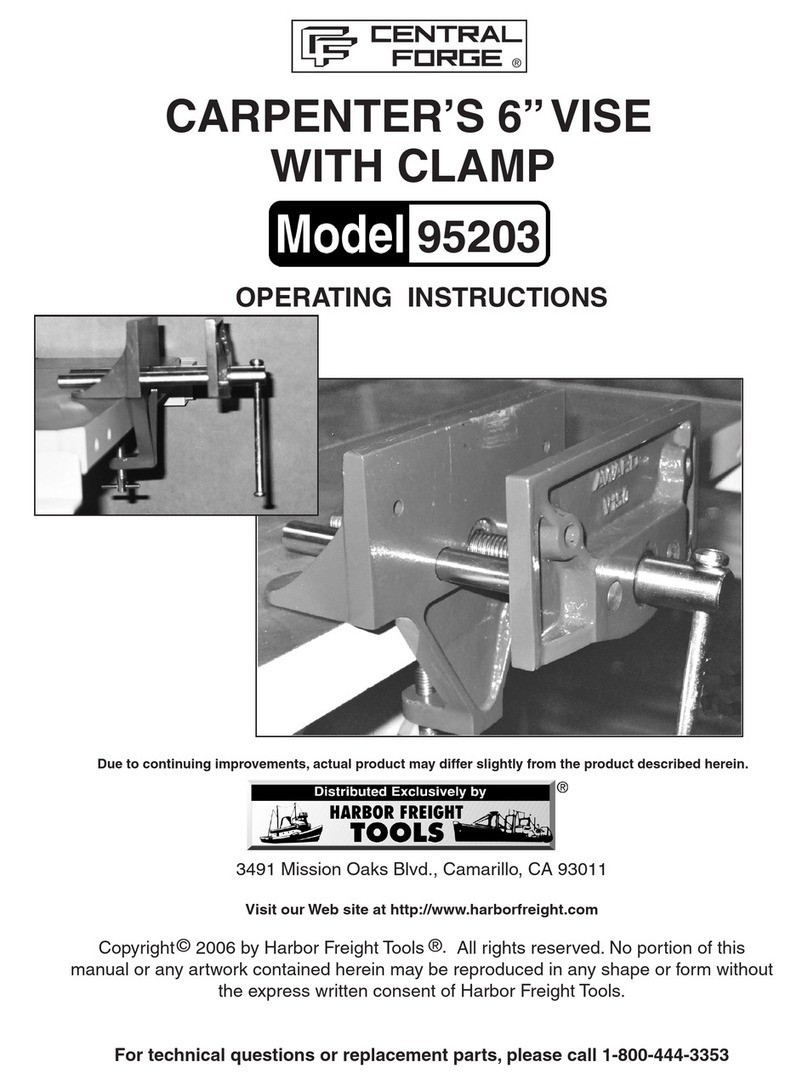

Mounting Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the

beginning of this document including all text under subheadings therein

before set up or use of this product.

1. Vise must be mounted on a solid,

level surface capable of supporting

combined weight of Vise, workpieces,

and applicable forces.

2. Use the holes in the base of the Vise as

a template to mark the bench surface.

WARNING! Verify that the installation

surface has no hidden utility lines

before drilling or driving screws.

3. Drill holes and attach the Vise

firmly to the work surface with

appropriate hardware (1/2" hex bolts,

flat washers, and nylon insert nuts,

all sold separately).