Siemens-Allis Static Trip II User manual

.r

.

•

•

•

SIEMENS-ALLIS

Switchgear

INSTRUCTIONS

STATIC TRIP II

OVERCURRENT TRIP DEVICES

USED WITH

TYPE LA POWER

CIRCUIT

BREAKERS

18X4827-03

March,1978

. ,

•

•

•

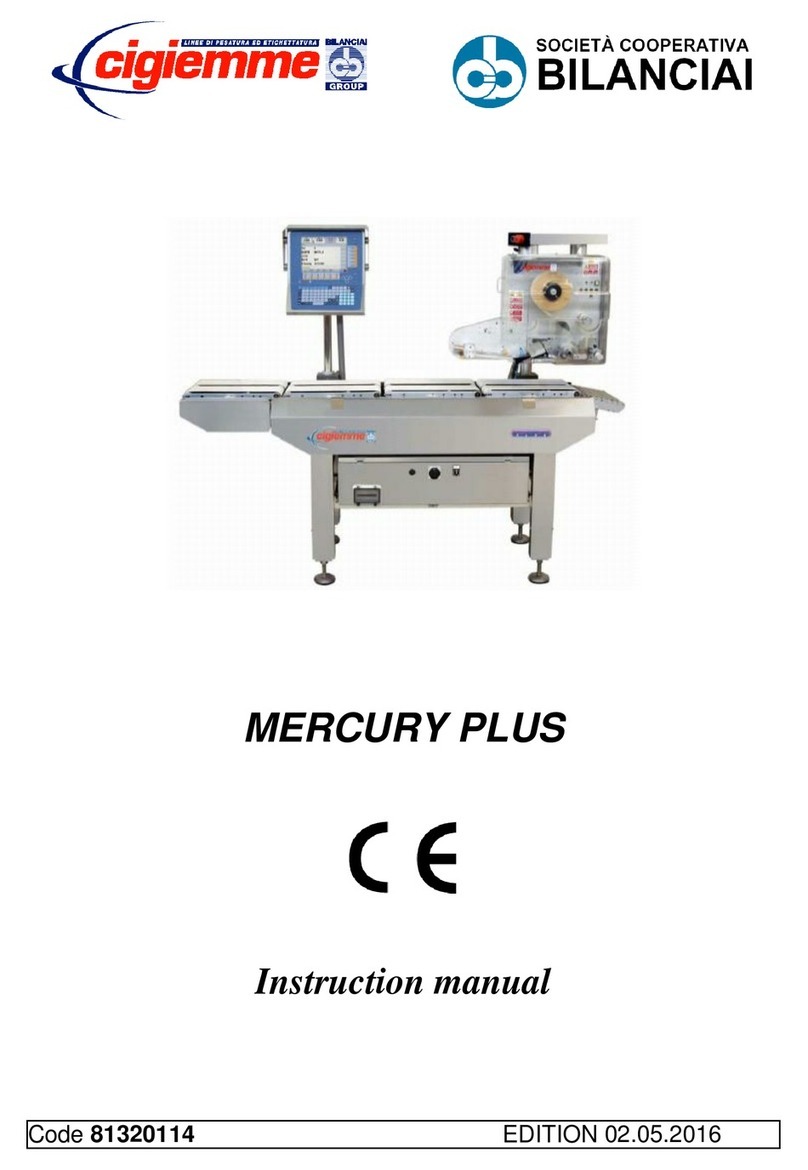

INTRODUCTION

This instruction manual contains descriptive, operating,

testing and maintenance information for SIalic

Trip

II

static overcurrent trip devices, several

of

which are

shown

in

Figure

I.

Static Trip

II

devices are used with

600-volt class, Type LA power circuit breakers. A com-

plete technical description

of

their circuits

and

how they

operate is contained in a separate instruction book,

18X4814 "Description of Operation -Static Trip

II

Overcurrent Trip Devices used with Type LA Power

Circuit Breakers",

WARRANTY

The

sales contract carries all information on warranty

coverage.

Figure J. - SIalic

Trip

II.

Sialic

Trip

Devices

11

DESCRIPTION

General

Sraric Trip

II

overcurrent trip devices

are

completely

static -there are

no

moving parts or contacts.

Com-

ponents used are semi-conductors, integrated circuits,

capacitors, transformers, etc.

The

circuits are desig

ned

for conservative loading

of

components for long life

and

little maintenance.

,

Static Trip

II

overcurrent trip devices

operate

to

"pen

the circuit brea

ker

when the circuit

current

exceeds a

preselected current·time relationship.

Depending

on

the

magnitude of the

overcur

rent

and

the selected settings,

tripping may be

in

stantaneous

or

time-delayed.

Energy

to

operate the tripping

sy

stem

is

obtained solely

from the circuit being protected. Batteries

or

other

power sources

are

not

ne

eded.

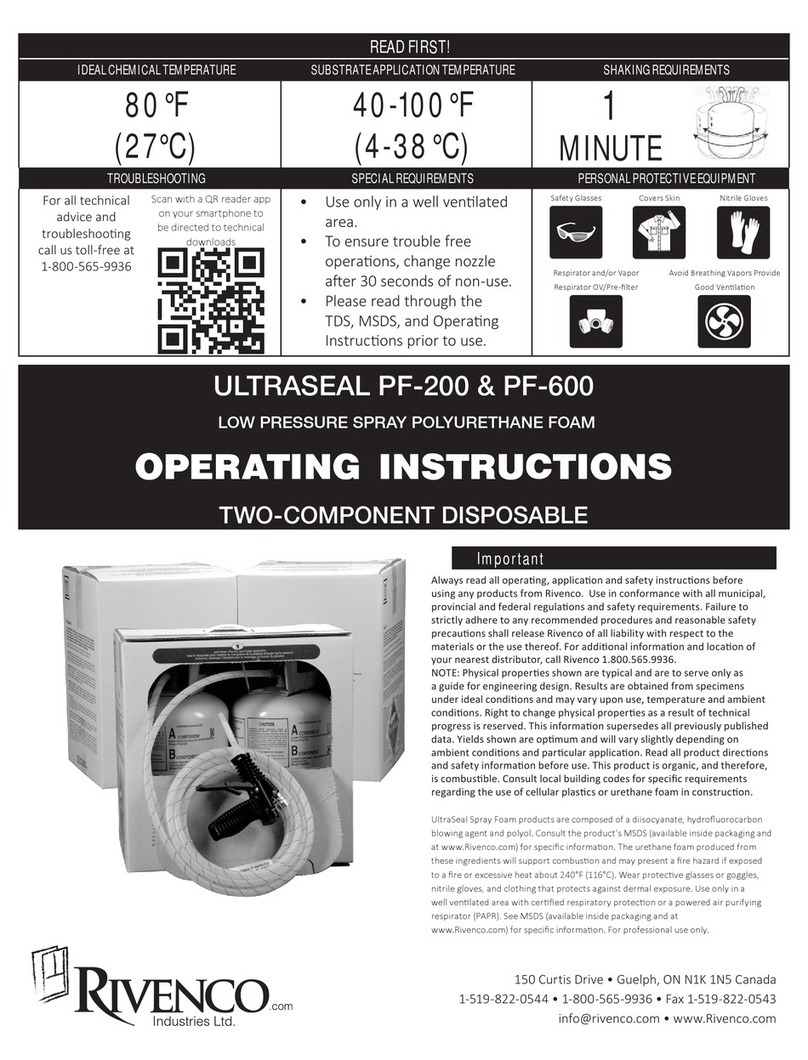

SERIAL

NO.

DATE

MFG.

VOLTAGE

MTR.

CLO.

TRP.

TRIP

XFMR

11A.

WIRED

PER

LONG

TIME

PICKUP

IN

AMPERES

A B C D

E F G

MAX

CONT

CURRENT

AMPS

SIEMENS-ALLIS

MILWAUKEE

,

Wi.

MADE

IN

US.

Figure 2. -Breaker Rating Plate

The

complete static overc

urrent

trip system consists

of

three

parts

-

(I)

primary circuit

current

transforme

rs

(2)

the Static Trip

II

device

(3)

a magnetically held

circuit

breaker

latch release device called the tripping

a

ctuator

.

Current

Transformers

Toroidal

current

transformer

s,

sim

il

ar to sta

nd

ard bush-

ing

current

transformers, are mounted, one-per-phase

on

the primary studs of the circuit breaker. Also called

trip

-

ping transformers, they provide a signal to the static trip

device

pr

opo

rtional

to

the primary

current

, a

nd

are used

o

nl

y for that

purpo

se.

The

tripping transfo

rm

ers selected

for a specific circuit breaker establish the maximum

con-

tinuous

curr

ent rating of that

breaker

and

the adjustment

range.

Each

tr

ansformer

pr

ovides a choice

of

seven con-

tinuous

current

settings which

are

listed on the br

eake

r

rating

pl

ate

(Figure

2).

The

highest setting

is

2V2

times

the lowest setting.

1

Static

Trip

II

Trip

Device

A metal enclosure, attached to the breaker, houses the

trip device and its electronic circuits.

The

static trip

device receives

the

signal from

the

tripping transformers.

It

monit

ors

the

signal, senses overloads

and

faults, a

nd

determines the requir

ed

action in

accordance

with

pr

e-

selected control knob settings.

On

the

front

of

the metal

enclos

ur

e

is

a calibration plate with

the

necessary ad-

justing knobs (Figure

1).

Tripping

Actuator

When the sta

ti

c trip devi

ce

senses a circuit condition

that

requires

the

circuit

br

eaker

to

open, it produces an

output

that

is fed to the tripping actuator.

The

actuator

then causes

the

circuit

breaker

contacts to open

and

isolate

the

circuit.

-

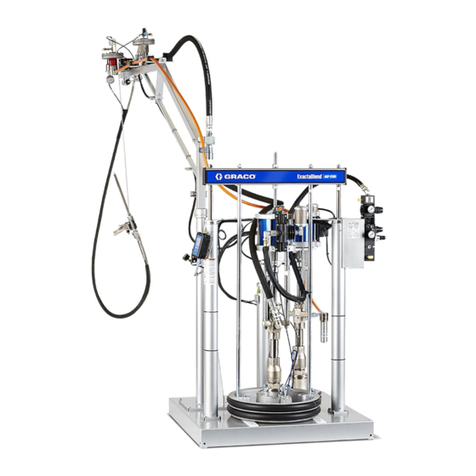

•

a.

Fi

gu

re 3. -Tripp

in

g Actuator

M

ounted

on

th

e circuit

breaker.

the

tripping

actuato

r

is held

in

a

cha

rged position by a permanent magnet.

It

contains

a coil that

is

energized by the

output

of

the

s

tat

ic trip dey ice. When energized, the coil

cau

ses the

magnetic flux

to

shift

to

a

new

path, releasing

the

stored

energy

of

a s

prin

g loca

ted

inside

the

tripping

act

uator.

The

spring provides

the

energy to trip the

breaker.

See

Figure

3.

Removing

Static

TripllFrom

The

Breaker

Stat

ic

Trip.II

units are easily removed from the circuit

breaker

for r

ep

lacement

or

for bench testing.

•

•

•

•

•

•

•

•

I.

Remove the two

SCrews

holding the terminal block

cover bearing the terminal numbers

1,2,3,4,7,8,9.

This exposes the terminal block that connects the

static trip device to the wiring on the breaker.

2.

Loosen the seven screws

in

the bottom row of the

terminal block (it

is

not necessary to remove the

screws completely) and slide

out

the connecting

strip from under the screws.

3. Removing

the

connecting strip exposes one screw

just above the name "Stalic TripII"'

on

the face plate.

Remove this screw and slide the static trip unit out

by

pulling it toward you.

4.

To

install a unit, reverse steps 1-3. Be sure to tighten

all screws.

It

is

important to replace the terminal

block cover because

it

guards against accidental con-

tact with the live terminals. Also, the terminal num-

bers on

it

arc helpful

in

testing.

Available Types

Nine types of SIalic Tripa devices are available. Similar

in

many respects, they differ only

in

their specific appli-

cation. All use identical tripping transformer inputs and

provide output

sign31s

to the tripping actuator. Several

types are shown in Figure I.

The type designation

is

coded to indicate the functional

elements: T

,-

LONG-TIME

delay element, S =

SHORT-TIME

delay element, I = INSTANTANEOUS

element, G

,=

GROUND

current element and

(T)

= a

TARGET

which indicates when tripping

is

initiated by

the ground clement.

For

each clement except INSTAN-

TANEOUS there are two adjustment knobs on the front

of the device. one for pick-up setting and one for delay

sctting. The instantaneous element has only one knob for

pick-up setting. See Figure

9.

Following are briefdescrip-

tions of the nine types:

TYPE

TI

-A dual trip device normally used for phase

overcurrent protection. The long time pick-up range

is

selected from the trip rating table and

is

continuously

adjustable from

"A"

thTU

"G"

in the field. The instan-

tancous element

is

continuously field adjustable from 3

to

12

mUltiples of the long time pick-up setting selected.

The long time delay

is

field adjustable with a choice of

six bands.

TYPE

T1G (optional) - A dual trip

dewice

which pro-

vides phase overcurrent protection same as Type

TI

plus

sensitive ground fault protection for 3-wlre and 4-wire

circuits on systems with either phase-to-phase

or

phase-

to-neutral loading. Ground current pick-up settings are

indcpendent of the phase pick-up settings; and continu-

ously adjustable

in

the field from

15%

through

100%

of the tripping transformer rating. When used on 4-wire

circuits. a fourth tripping transformer

is

required.

It

is

mounted

in

the cubicle, and wired to the breaker through

secondary disconnects.

TYPE

T1G(T)

(optional) -Same as Type TIG,

except a ground target

is

provided to give a visual indi-

cation of a trip initiated

by

a ground fault.

TYPE

TS (optional) - A selective trip device used for

phase overcurrent protection which provides time delay

tripping only.

It

allows complete field adjustment of the

long time band and pick-up plus the short time band

and pick-up.

The

short time pick-up

can

be adjusted

from 3 to 12 multiples of the long time pick-up setting.

Anyone

of the three short time bands can be chosen to

be

used with any of the six long time bands.

TYPE

TSG (optional) - A selective trip device which

provides phase overcurrent protection same as Type TS

plus sensitive ground fault protection for 3-wire and

4-wirc circuits on systems with either phase-to-phase or

phase-to-neutral loading. Ground current pick-up set-

tings arc independent of the phase pick-up settings, and

continuously adjustable

in

the field from

15%

through

100% of the tripping transformer rating. When used on

4-wire circuits, a fourth tripping transformer

is

required.

It

is

mounted

in

the cubicle, and wired to the breaker

through secondary disconnects.

TYPE

TSG(T)

(optional) -Same as Type TSG, ex-

cept a ground target

is

provided to give a visual indica-

tion of a trip initiated

by

a ground fault.

TYPE

TSI (optional) - A triple selective trip device

used for phase overcurrent protection which provides

long time delay, short time delay, and instantaneous

elements.

It

allows complete field adjustment of the long

time band and pick-up, the short time band and pick-up

and the instantaneous pick-up. Both the short time and

instantaneous clements

can

be adjusted to pick

up

at 3

to

12

multiples of the long time pick-up setting.

Anyone

of the three short time bands can be chosen to be used

with any of the six long time bands.

TYPE

TSIG (optional) - A triple selective trip device

which provides phase overcurrent protection same

as'

Type TSI plus sensitive ground fault protection for

3-wire and 4-wire circuits on systems with either phase-

to-phase

or

phase-to-neutral loading. Ground current

pick-up settings are independent of the phase pick-up set-

tings. and continuously adjustable in the field from IS%

through 100% of the tripping transformer rating. When

used

on

4-wire circuits, a fourth tripping transformer

is

required.

It

is

mounted

in

the cubicle, and wired to the

breaker through secondary disconnects.

TYPE

TSIG(T)

(optional) -Same as Type TSIG,

except a ground target

is

provided to give a visual indi-

cation of a trip initiated by a ground fault.

Time-Current Curves

";Figure 4

is

a set of curves for the Static Trip a devices.

'The

long-time element has a characteristic represented

by:

GROUND

CURRENT

IN

PERCENT

Of

TRiPPING

XFMR

RATING

IOOOP;~

I

.a

,4

~-l-I-++-

OF

TR

IP

PING XFMR RATING

•

\1\\

CURRENT

IN

MULTIPLES

OF

PICK-UP

2 4

LONG

TIME

CURVES

(1)

o

)Q

1'000

aoo

600

LONG

TlMf

PICK-UP

+

++1400

I

_~~

.

CONTI

NUOUS

LY AOJUSTA

BL~

_

._

14_+-tJlF'''''",::M~

0.5

TO

1.

25

TI~:S

~aR~PPINf.:

XfMR

RATING, WITH

POINlS PIC. n ,

aLI

.-~-++iTT

--,--+--+-+~+4

-HH200

++-+

+140

10

a

~

0

z

\\\\M

0

<.>

~

~

'"

l\\~

2

~

"

...

'IS

I

1,<

I

~

2 I

;0

100

CURRENT

IN

MULTIPLES

Of

PICK-UP

,~

'.

'

Figure 4,

--

SIalic Trip

II

Time-Current Curves

3

•

•

•

•

•

•

•

K 1 .

tn

= -

In

where

tn

=time delay, I = current expressed in multi-

ples

of

the long-time pick-up, n

is

a constant dependent

on the circuit design (slightly over 2 for

STATIC

TRIP

II),

and K

is

a constant depending

on

the delay band

sele"",d. In other words, the delay for a given band

setting varies approximately inversely as the square at"

the current. When plotted on log-paper this relationship

is

a straight line

as

shown

by

the sloping bands on Fignre

4.

Six

discrete long-time bands are available,

anyone

of

which may

be

selected

by

the band control switch on the

front. Each band has a delay exactly twice the delay

of

the next lower band.

~

The short-time element bas adefinite delaywhich

is

inde-

pendent of current as shown

by

the fact that the short-

time bands are horizontal on Figure

4.

There are three

calibrated short-time delay bands -MINIMUM, IN-

TERMJlDIATE, and MAXIMUM which have nominal

delayiof 0.1, 0.25, and 0.45 seconds, respectively. How-

ever, short time delay

is

continuouSly adjustable and can

be set at other values

if

suitable testing equipment

is

available.

,

The ground elementhas a definite delay characteristic

just like the short-time element and with the same cali-

brated points.

It

is

independently adjustable.

The width of the time bands on Fignre 4

is

due princi-

pally to differences between devices caused

by

normal

commercial tolerance of components in the circuits.

Repeated tests on

anyone

unit

will

fall in a much nar-

rower band.

The band width also includes breaker interrupting time.

The upper limit represents the total clearing time includ-

ing

breaker opening and arcing time, whereas tbe lower

limit

is

the "resettable time" -the maximum time that

the overload can persist without tripping the circuit

breaker. This representation, which

is

necessary to

demonstrate coordination between breakers set on

contiguous time bands, widens the SHORT TIME

bands significantly.

Performance In Service

Ambient conditions and length

of

service

",ill

have little

effect on the performance of static overcurrent trip

devices. The circuits are stable and will show ."itcellent

repeatability over long periods of time. Service involving

frequent operations

will

not cause the characteristics to

change

or

drift, since there are no moving mechanical

parts to wear or bearings to lubricate

.

Static Trip

II

devices are tolerant of dusty conditions and

4

will function properly in many areas that would affect

the performance of electro-mechanical trip devices.

The temperature

at

the static trip device does have some

effect onthe characteristics due to changes in response of

some of the components. However, the changes are

small and will not be a factor in most applications. Over

the range of

-40

C to 55 C

(-40

F to

131

F),

the

variation from performance at room temperature is very

small, amounting to less than 5%

of

LONG TIME,

INSTANTANEOUS and SHORT

TIME

PICK-UP

values, and 10% in timing of all time bands. Operation

is

not recommended beyond this range.

If

necessary,

control of the temperature should be provided

by

heat-

ers or ventilation.

Connection

Diagrams

Figures

5

through

8 show in

schematic form the pre-wired connections from the

breaker mounted tripping transformers to the static trip

device. This wiring varies with the application. The four

most commonly used schemes are shown, and the dia-

grams with their captions are self-explanatory.

NOTE

For

4 wire systems

with

ground

fault

tripping

the

neutral

busCT

or

ground

strap

CT

are

separate

from

the

breaker

and

are

connected

to

the

static

trip

through

secondary

drawout

contacts

on

the

breaker. . .

~',

.

SmlNGS

Static Trip

II

devices have a number of knobs and

switches that can be arranged to select specific load cur-

rent conditions that

will

cause the breaker

to

open. Selec-

tion of settings

is

usually made when the breaker

is

placed in service to match anticipated load conditions

and coordination requirements. Future changes are un-

necessary unless load conditions change

or

primary cir-

cuit changes are made.

POWER

TR

ANSFORM[R

~1J

.,

"

.'

03

1 ,

• •

1 2

-'

INTERNAL

TRANSFORMER

TRIPPING

TRANSFORMERS

r

BRKR.

MTD.

A'.

-

..

..

{"+

,+-

•

3

0-

.A

CIRCUIT_Go

BREAKER

,.

STATIC

TRIP

DEVICE

+>-

..

PHASE

CONN.

TO

LOAD

Figure

5.

-Breaker Wiring for Types Tl, TS, and

TSI (non ground)

I

1

I

>,

!

I

I

•

•

!

POWER

TRIPPING

TRANSFORMERS

(

BRI(R.

MTD.

TRANSFORMER

"

LA

~::t-;:-:N\:::I:-l~

C

IRC

U

IT

02

BREAKER

PHASE

CONN.

TO

LOAD

7f.

~

1:112

=

;==j'~3bttt:;~=~~

, 2 3 9

•• •

, 2 3

STATIC

TRIP

DEVICE

GNO

Figure

6.

-Breaker Wiring for Ground Protection

on

3-Wire Systems, Residual Sensing

POWER

TRANSFORMER

."

~

.~

2

'3

N

r -1

,,

.,

,

i

1..

-Gl2

,

T~E~

NG

BRI<R. M

TRIPPI

TRANSFO

RMERS

;;

;;

!l

••

,

STATIC

TRIP

I

, ,

1:

i•

DEVICE

,

LA

CIRCUIT

BREAKER

I I I

'l' 'l'

'l'

N

~

CONN.

TO

LOAD

,

: 4 GND I

I

L

___________

..J

NEUTRAL

BUS

TRIPPING

TRANSFORMER

Figure

7.

-Breaker Wiring for Ground Protection

on 4-Wire Systems, Residual Sensing.

POWER

TRANSFO

RMER

~

NO

GROU

ST.

AP-

'NG

TRIPP

TRANSFO

RMER

.'

.2

..

N

•

r

, 4

,

,

,

,

,

,

,

\~RKR.

MTO

"RIPPING

TRANSFORMERS

~

r:

- -

3 9

;-

I 2 3

GND.

6 ~

LA

.~

~

CIRCUIT

BREAKER

•

~

,

,

STATIC ,

,

TRIP ,

DEVICE

I

,

,

,

CONN.

TO

LOAD

L

________

-

--

_

__

.1

Figure 8. -Break1t( .wiring for Ground Protection

on

4-Wire Systems.

GJ:tJ/Uld

Strap Current Sensing.

5

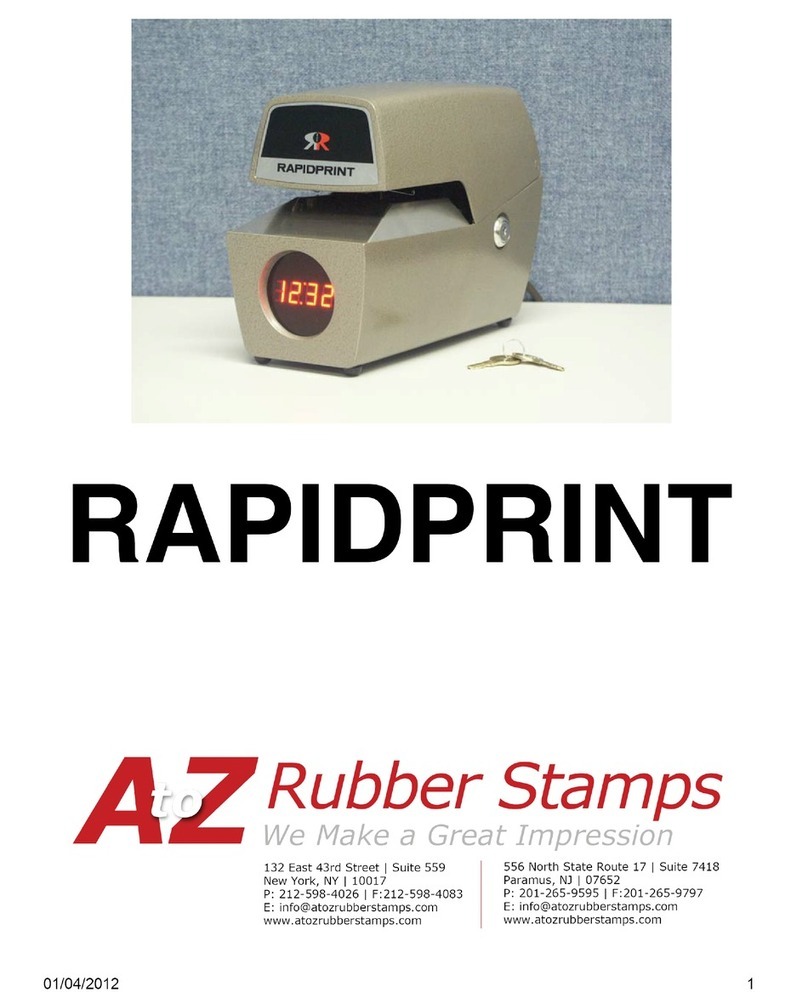

Figure 9

is

an illustration of the type

TSIG(T)

device

which contains all Static Trip

II

control options. The

following paragraphs discuss the calibration and use of

these controls.

LONG

TIME

PICK-UP has 7 calibration marks.

The

black reference dot on this and

aU

other knobs marks

the fully CCW (counter clockwise) position of the con-

trol and enables calibration to

be

restored if the knob

should inadvertently be turned on the shaft. (See the

section on Maintenance.)

When turning the knob in the clockwise (increase) direc-

tion from the black dot, the first red dot

is

setting"

A" in

the vertical column of letters A through G. The second

red dot

is

setting

"B",

etc.

The

values of the settings in

amperes depend upon the tripping transformer rating

and are shown on the breaker rating plate (Fig.

2)

just

above the static trip.

STATIC TRIP II

LONGTIME

DELAY

IN

SECS.

BAND

AT

6X

PICKUP

1 1.12

2

2.25

3

4.5

4 9

5 18

6 36

IU:'"

TO

l.rAIlEII:

RATI'"

~"Tr

'011

CU,.,.,.1

.,AWEI A

TO.

GROUND

TARGET

<.

TYPE TSIG(T)

LONGTIME

BAND

SEE

TA.LE

AT

Lm

,

..........

.,

....

D TIME BAND

Figure

9.

-Calibration Marks

DOT

1

•

•

•

•

•

•

Figure

lOis

a table

of

settings in amperes for all the

standard tripping transformer ratings.

The

tripping transformer rated secondary current

is

one

ampere. Because setting E, Figure 10 table corresponds

to rated tripping transformer current, one ampere input

to the static trip will cause it

to

pick

up

and start timing

if

LONG

TIME

pick-up setting is

on

HE".

Example: Suppose it

is

desired

that

the

breaker

shall trip

whenever sustained current exceeds

600

amperes,

and

suppose that the tripping transformer rating is

800

amperes.

The

LONG

TIME

pick-up setting should be

"C",

Figure 10 table. At

600

amperes,

current

input

to

the static trip will be

600

-:

800

= 0.75 ampere.

Long time pick-up control is continuous

and

other set-

tings between calibrated points may be used if suitable

test equipment is available.

INSTANTANEOUS

PICK-UP

has four calibrated

points,

3X,

5X,

8X, and 12X, calibrated in multiples of

the

LONG

TIME

pick-up setting. Again

the

black ref-

erence

dot

is

at

the fully counter-clockwise end of rota-

tion. Starting from the reference dot, the first red

dot

,

Br.aker Long Time Element

when rotating clockwise

(decrease)

is the

12X

point.

This control is also continuous, permitting field calibra-

tion of additional settings

if

suitable equipment

is

avail-

able.

For

special applications, settings as low as I.OX

can

be field calibrated.

Example: Referring to the previous example,

if

LONG

TIME

pickup is

on

"C"

and

INSTANTANEOUS

pick-

up

is

on

5X,

the breaker will trip instantaneously at

3000

amperes (5 x

600)

or

more.

SHORT

TIME

PICK-UP

is

calibrated just like instan-

taneous,

and

control

is

also continuous.

1t

can also

be

field calibrated as low as l.OX.

GROUND

PICK-UP

is

calibrated in percent of the

tripping transformer rating with four calibrated points,

and

is

also continuous.

Example:

If

the tripping transformer rating is

600

amperes and

GROUND

PICK-UP

is at 25

%,

a ground

current of 150 amperes will cause

the

ground circuit to

trigger.

If

the ground

current

persists as long as the

Ma.

Ground Element

TriPPi~g6

I)

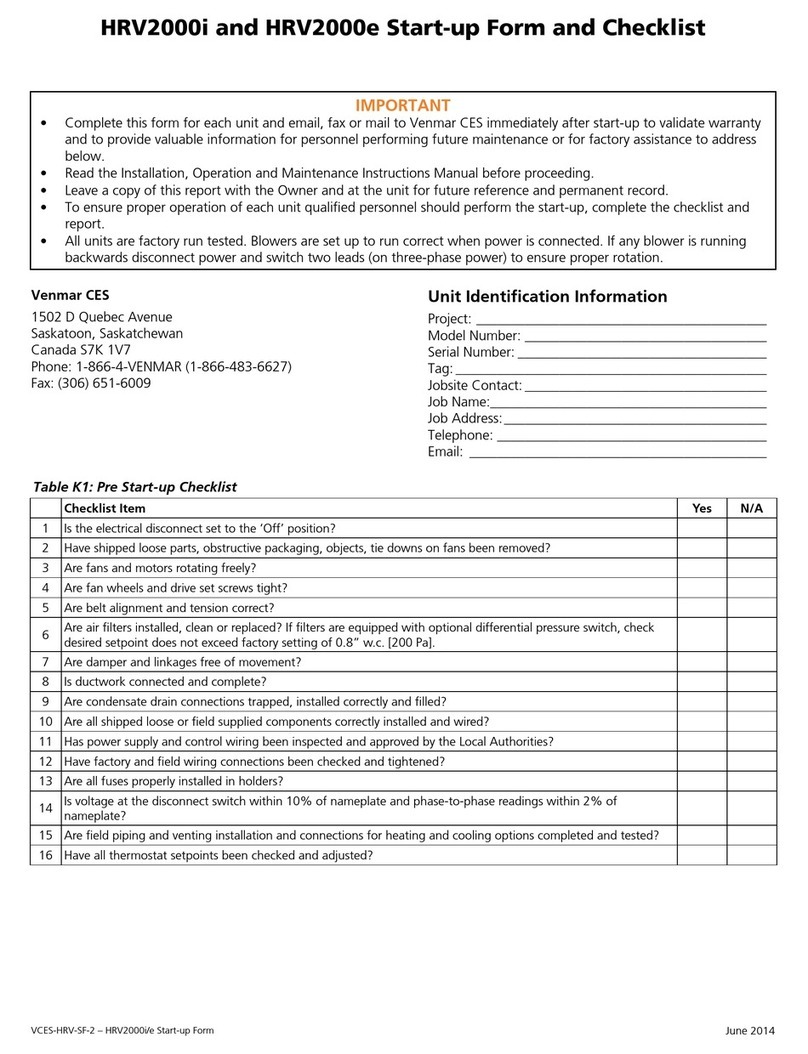

Type and

XFMR

Calibrated Pickup Settings Cont Calibrated Pickup

58"lng.

Rating

Frame

Si

..

(Primary) A B c D E F G

RaUng

15%

25%

50%

100%

80 40 50

60

70

80

90

100 100 --

40

80

LA-600 200 100 125 150 175 200

225

250 250 30 50 100 200

600 400 200 250 350 400 100 200 400

Amperes 300 450 500 500 60

600 300 375 450 525 600 675 750 600

90

150 300 600

200 100 125 150 175 200 225 250 250 -50 100 200

LA-1600 400 200 250 300 350 400 450 500 500 60 100 200 400

1600 800 400 500 600 800 1000 200 400 800

Amperes 700 900 1000 120

1600 800 1000 1200

i400

1600 1800 2000 1600 240 400 800

1600

LA-3000

2000 1000

1250

1500 1750 2000 2250 2500 2500 300 500 1000 2000

3000 3200

1600

2000 2400 2800 3200 3600 480 800 1600 3200

Amperes 4000 3000

LA-4000

4000 4000 2000 2500 3000 3500 4000 4500 5000 4000 600 1000 2000 4000

Amperes

Figure 10. -Static Trip

II

Rating Table -Amperes.

GENERAL

NOTES

1.

The

"Tripping

XFMR

Rating"

values

represent

the

primary value

of

the current transformer ratio in am-

peres.

The

secondary

value

is

one

ampere.

2.

The

pick-up settings

of

the

long

time

element

are

continuously

adjustable,

and

are calibrated

at

points

"A"

thru

"G"

as shown in

the

rating table.

3.

The

pick-up settings

of

the

instantaneous

and

short

time

delay

elements

are

continuously

adjustable,

and

are calibrated

at

3,

5,

8

and

12

multiples

of

the

long

time

pick-up setting.

4.

The

pick-up settings

of

the

ground

element

are

con-

tinuously

adjustable, and are

calibrated

in

percent

of

the

tripping

transformer

rating

as

shown

in

the

rating

table.

5. The

long

time

element

has 6

bands

that

are field selec-

6

table.

The

time

delay

at

6

multiples

of

pickup

is

as

follows:

Band 1 -1.12 seconds

Band 2 - 2.25 seconds

Band 3 -

4.5

seconds

Band

4 - 9 seconds

Band 5 - 18

seconds

Band 6 -

36

seconds

6. The

short

time

element

and

ground

element

have 3

time

delay

bands

which

are calibrated

at

minimum,

inter-

mediate

and

maximum,

but

are

continuously

adjustable.

7. The

maximum

interrupting

time

is

the

maximum

length

of

time

that

fault

current

flows,

including

arcing

time.

8.

Instantaneous

maximum

interrupting

time

may

be

greater

when

breakers are closed in

on

a fault

depending

on

aftual

fault

conditions.

The

maximum

potential

increase

for

a 3-phase fault is 0.01 seconds

and

for

a

single-phase

ground

fault is

0.02

seconds.

j

GROUN

0

TIME

BAND setting, the breaker will trip,

and

if

there

is

a ground target, the red plunger will pop

out.

The

target

is

reset

by

pushing it back in so that the

permanent magnet holds

it

in the reset position.

As explained previously, the tripping transformer sec-

ondary current rating

is

1.0 ampere

so

the

ground

CUf-

rent input currents to the static trip

device

at pick-up

are the same as the calibration value divided

by

100.

(E.G.:

when set on 25

%,

pick-up current

is

25%

of 1.0

ampere,

or

0.25 ampere.)

Time Bands

There arc six

LONG

TIME

BANDS numbered I

through 6, and three

SHORT

TIME

BANDS marked

MAXIMUM,

INTERMEDIATE,

and

MINIMUM.

The

GROUND

TIME

BANDS on devices with ground

trip are the same

as

the short time bands, but are inde-

pendently adjustable.

The

control for selecting the LONG

TIME

BAND

is

a

very small switch and the detent is not strong. There-

fore,

be

very careful that the white dot on the knob

lines

up

with

the desired number.

All the LONG

TIME,

SHORT

TIME

and

GROUND

TIME

bands are shown on the

TIME

CURRENT

CHARACTERISTICS

curve, Figure 4.

The

curve sheet

is

self-explanatory. In addition, a table printed on the

face plates of Slatic Trip

II

units lists the time delay at

six times pick-up current for each

LONG

TIME

band.

The

delay for each band is twice the delay of the next

lower band.

The

SHORT

TIME

and

GROUND

TIME

band con-

trols are continuous so that settings other than factory

calibrations may be used if suitable testing equipment

is available.

TESTING

General

STA

TIC

TRIP

n can be field tested either with primary

current through the breaker

or

with secondary current

applicd directly to the static trip device. The ease of

testing

with

secondary

current

is

onc of

the

advantages

of

static trip devices. With comparatively inexpensive

and readily available equipment, described

in

the fol-

lowin

g,

it

is

possible to demonstrate that the tripping sys-

tem will open the breaker, and to verify that the device

,

,

Figure 11. -Testing with Portable Test Set

7

conforms to the published time-current curves.

How-

ever field testing cannot be expected to

be

as accurate as

factory calibration. Therefore, slight discrepancies be-

tween

fie

ld tests and factory calibration marks can be

regarded as normal.

If

large deviations

or

improper oper-

ation should occur,

it

is recommended that the nearest

Allis-Chalmers office

be

contacted for advice.

S

econ

d

ary

Curre

nt

T

es

ting

A portable test

se

t

is

available for secondary testing that

is

designed to plug into a standard 115volt outlet,Figure

II

. With this test set, Static Trip

II

can be tested

by

itself

without a circuit breaker, or on a circuit breaker with

the breaker away from

th

e cubicle, or inside the cubicle

in

the

TEST

or

DISCONNECT

position.

CAUTION

The

static trip input

is

capacitively coupled to

the circuit breaker

frame

, through a surge

ca-

pacitor. Therefore to insure against electrical

shocks be sure to ground the

frame

when testing

with the circuit breaker

out

of

the cubicle.

There

is

a terminal block on the circuit breaker just

above the trip device. This terminal block accepts leads

with banana plugs when testing with the device on the

breaker. Such leads are furnished with portable test sets

purchased after March 1972.

•

•

•

•

•

•

Connections for the test set are shown in Figure 12.

If

test leads with banana plugs are not available, connec-

tionscan be made with small alligator clips after remov-

ing the terminal block cover bearing the numbers I,

2,

3,

4, 7, 8, 9.

CAUTION

Avoid even a momentary short circuit

between

terminals

4

and

7

or

terminals

8

and

9.

Such

a

short

cirCUit,

with

any

input

current

to

the

trip

device,

will

damage

it.

..

o

...

...

~cncncn..,

zOOOI-

...

-

I-I-I-

::I

=:I

~_NPl~!::

~

a:"'-a:-

I-~~::gc

1-1-

2

Octc(ctZ

u:::>

0

j:rrr=>o

i=c.:E

ctG..G..G..

<I-:E

GREEN

~<a:lU~

Ina

8

BANANA

,.......-=""=

.............

PLUG

'Wi

2

~

4 7 § 9 I

FROM

( .2.'i9 ?Y

'i'

TEST

SET

/

WHITE

BANANA

PLUG

-

TP3

TP,

TP'

:

TO

TEST

seT

TERM

8 -

RED

PLUG

TO

TEST

SET

TERM

7-

BLACK

PLUG

TO

VM

POSITIVE

FOR

LONG

TIME

TRIGGER

TO

VM

POSITIVE

fOR

SHORT

TIME

TRIGGER

"

::J

~

~

~

;:

~

TOVMNEG

FOR

TRIGG

TESTS

BLACK

TIP

ER

TP2

~

TO

VM

POSITIVE

FOR

~

GROUND

TRIGGER

TEST

~

PLUG

Figure 12. -Testing with Portable Test Set,

Connection Diagram

Be careful to make connections correctly

as

shown on

Figure

12.

There

is

a terminal

marker

strip above the

terminal block which can

be

seen although

it

is

partly

covered by wiring.

When

testing

with

the

Static

Trip

II

device

off

the

circuit

breaker

connections

must

be

made

to

the

spade

type

terminals

of

the

connecting

strip.

Mak-

ing

these

connections

with

clip leads involves

the

risk

of

shorting

between

clips

which

can

damage

the

trip

device. A

terminal

block

assembly,

18-657-506-585

and

special leads,

18-657-489-852

are

available

for

making

the

connections

to

old

model

test

sets.

The

terminal

block

assembly ac-

cepts

the

connecting

strip

just

like

the

one

on

the

circuit

breaker

and

the

leads

are

designed

to

make

connections

from

the

test

set

to

the

jacks

on

the

terminal

block.

8

Late

model

test

sets have a

terminal

block

on

them

just

like

the

one

on

the

circuit

breaker.

In

that

case

it

is

only

necessary

to

connect

the

static

trip

con-

necting

strip

to

this

terminal

block

and

make

con-

nections

with

the

banana

plugs

just

as

if

the

unit

were

mounted

on

a breaker.

Test

points,

TP1,

TP2, TP3,

and

TP4

are

on

the

Static Trip

II

face

plate.

They

are

for

connection

to

a

dc

voltmeter

of

25

to

50

volts full scale,

to

observe triggering (pick-up).

The

portable

test

set

contains

such

a

voltmeter.

TP1 is

common

nega-

tive, TP3 is

the

LONG

TIME trigger,

TP4

is

the

SHORT

TIME

TRIGGER,

and

TP2 is

the

GROUND

trigger.

These

test

points

are

designed

to

accept

standard

tip

plugs

which

are

furnished

with

the

portable

test

set.

However,

if

tip

plugs

are

not

available,

any

solid

metal

wire, nail,

or

pin

of

O.D.

.080

±

.002

inches

may

be

used

to

make

the

con-

nection.

A

number

46

or

47

twist

drill is satisfac-

tory.

See

Figure

12

for

connections.

Detailed

test

instructions

are

given

in

the

portable

test

set

instruction

book.

Instruction

books

for

test

sets

purchased

prior

to

1973

were

written

for

older

style

static

trip

devices,

not

for

STATIC

TRIP

II.

However,

with

the

information

contained

in

this

book,

the

necessary changes

in

test

procedure

when

testing

STATIC

TRIP

II

units

are easily

understood.

One

difference

that

should

be

noted

is

that

STATIC

TRIP

II has

two

more

LONG TIME

PICK-UP

points

than

older

static

trips.

The

LONG

TIME pick-up

current

values

for

secondary

testing

are

given

in

Table

I below.

TABLE I

LONG

TIME

PICK-UP

SF,rING

A H C D E F G

PICK-l!P

CURRENT.

AMPS

.50

.6~5

.75 .X75 1.00

1.

125 1.25

Testing

Without

a

Portable

Test

Set

The

portable

test

set

has

its

own

automatic

timer

which

permits

accurate

testing

of

all

time

delays.

If

the

test

set is

not

available, however,

it

is possible

to

perform

function

tests

and

some

timing

tests

if

the

following

equipment

is available.

I. One variable transformer (Variac)

115

or 120 volt,

60 Hertz. 2.5 amperes minimum.

2.

One air core reactor,

30

to

50

milli-Henries. 2

amperes minimum. Maximum dc resistance -20

Ohms.

3.

One ac ammeter,

0-1

or

0-2 amperes -necessary for

accurate checking of LONG TIME PICK-UP.

4.

One

ac

ammeter. 0-5 amperes, for LONG TIME

delay tests and

INSTANTANEOUS

and

SHORT

TIME

pick-ups.

5. One dc voltmeter, 0-25

or

0-50 volts, for trigger

indication.

6. One stop watch, desirable but

not

essential, for tim-

ing tests.

7. One single pole -single throw, snap action switch

rated 120 volts,S amperes ac

or

more.

TO

11511,60Hz

OUTLET

SWITCH

SPST

120

v.

AC

5'.

AIR

CORE

REACTOR

)

30

MH

MIN

-

VARIABLE

TRANSF.

12011.,

2,5A.

The

sudden appearance

of

this "trigger" voltage indi-

cates that the timed delay has started.

If

the current

drops slightly, causing the trigger voltage to disappear,

the timing circuit resets instantly and timing will restart

upon the next appearance

of

triggering.

Short

Time Pick-up Test

Use the 0-5 ampere

ammeter

and connect the voltmeter

to terminals

TPI

and

TP4

with

TPI

negative. Set

LONG

~

~ ~

~

~

~

..

~

~ ~

~

~

..

..

..

..

i ;0

~

~

~

i " ci

~ ~

~

..

.. ..

0 0

'"

0

4

'"

u " , + u

..

34

H?

o 0 0 0

J..

_.L-_J

.

t-r==~~~;;~~~~~

TO

11M

FOR

MM.

~}

TIMING

TESTS

W/O

BREAKER

STATIC

LFOR LONG

TIME

STRIP

n

TP3

TRIGGER

TEST

er---

--

.....

fOR

SHORT

TP4.l

I TIME TRIGGER

@-

__

~

___

""\

I TEST

, I

TPI

~

- + I

~

__________

L-

________________

~

TP2

I}-

VM I

,

___

,,

______

J

\...

--FOR

GROUND

TRIGGER

TEST

Figure 13. -Secondary Testing Without Test Set

Test Connections

Sec Figure

13

for test connections. Connect the input to

terminals I and 9 to test A phase,

to

2 and 9 for B

phase, 3 and 9 for C phase, and 4 and 9 to test the

ground circuit on devices with ground current tripping.

Long Time Pick-up Test

For

this test a circuit breaker

is

not needed.

'If

the static

trip is mounted

on

a breaker,

it

is

not necessary to close

the breaker.

Usc the 0-1

or

0-2

ampere ammeter. Connect the volt- !

meter to terminals

TP

I and TP3 with

TP

I negative.

Refer

to "Secondary

Current

Testing"

for tips and cau-

Lions

on making connections.

Set LONG

TIME

PICK-UP on

"A".

Raise the current

gradually until the voltmeter needle jumps suddenly to

15

volts

or

morc.

The

current at which this occurs should

be 0.5 ampere

~

10%.

Decreasing the

current

slightly

should cause the voltmeter reading to

drop

to a low

vallie. Repeat for the other

LONG

TIME

PICK-UP

settings

mId

compare with Table I.

9

TIME

PICK-UP

on A

and

SHORT

TIME

PICK-UP

on 3X. Raise the current until the voltmeter suddenly

jumps

up

as before. This should occur

at

1.5 amperes

(3 x

0.5).

Repeat for

SHORT

TIME

PICK-UP

settings

of

5X

and

8X

which should give readings of 2.5 and 4.0

amperes respectively,

(5

x 0.5 and 8 x

0.5).

You

may

not be able to get the 6.0 amperes for the 12X setting

even with the variable transformer

at

maximum output.

CAUTION

Do

not

allow

current

above

2

amperes

to

con-

tinue

more

than a

minute

or

so

at

a time

so

as

not

to

overheat

the

statiC trip, the

variable

trans-

former

and

the

reactor.

Ground Pick-up Test

Ground

pick-up cannot be checked accurately with this

equipment because of excessive current wave distortion

caused

by

the highly non-linear impedance of the static

trip ground circuit. However. it

is

possible to verify that

the circuit

is

operating and that pick-up

is

somewhere

near the right value.

•

•

•

·.

•

•

•

Use the 0-1 ampere ammeter and connect the

vo~ter

from

TP

I to TP2 with

TP

I negative. Set GR'OUND

PICK-UP on

15

% and gradually increase input current

until the voltmeter jumps up. Input current should be

somewhere near 0.15 ampere. Repeat for the other set-

tings. Each setting should give a reading in amperes

nearly equal

to

the calibration value divided by 100

(100%

= 1.0 ampere).

Instantaneous Trip Test

There

is

no trigger output for INSTANTANEOUS. but

tripping of the breaker will indicate operation when

testing with the static trip unit

on

a breaker. When test-

ing

wit~out

a circuit breaker, connect the voltmeter from

terminal 7 to terminal 8 with 7 negative to monitor the

trip device output.

Use the 0-5 ampere ammeter. Set LONG

TIME

PICK-

UP on

"A"

and INSTANTANEOUS on 3X. Gradually

increase current until the voltmeter indication jumps up

to

15

volts

or

more indicating that the instantaneous

cir~

cuit has caused a tripping output. This should occur at

about

1.5

amperes (3 x

0.5).

Repeat for the

5X

and

8X

INSTANTANEOUS PICK-UP settings which should

cause operation at 2.5 and 4.0 amperes respectively.

NOTE

Because of the load imposed

by

the actuator coil,

the voltmeter indication will be much less, perhaps

as

low

as

5 volts, if the static trip output,

(7-8)

is

connected to a circuit breaker.

Long Time Delay Test

For

currents less than 6 times pick-up setting and time

bands 2 and higher. the delay

is

long enough to be

checked fairly

well

with a stop watch or even an ordi-

nary watch having a sweep second hand.

Use the 0-5 ampere ammeter.

I. Close the switch and adjust current

to

the desired

value.

2.

Open the switch and close the circuit breaker.

3.

Without changing the variable transformer setting,

close the switch and measure the time interval from

switch closing to breaker tripping.

Example: Set LONG

TIME

PICK-UP on

"A,"

LONG

TIME

BAND on 5, input current at 3.0 amperes

(6

x

0.5).

Set

SHORT

TIME

and/or

INSTANTANEOUS

pick-up on 12X, above the input current value. The

timed interval should be between

14

and

22

seconds. See

the curves

on

Figure 4.

10

If the static trip

is

not mounted

on

a circuit breaker,

connect the voltmeter across terminals 7 and 8 of the

static trip and time the interval from switch closing to

voltmeter indication.

NOTE

While timing out at values of input current not

much above pick-up, normal fluctuations

in

supply

voltage may cause the device to de-trigger (see the

last paragraph under "Long Time Pick-Up Test")

and prevent the device from timing out properly.

To avoid this

it

is

desirable to monitor

LONG

TlME trigger output with a voltmeter throughout

the test.

Short Time

Delay

Test

The

SHORT

TIME

delays are too short (0.5 second

maximum) to be checked without a high speed auto-

matic timer, but

it

is

possible to perform a test to verify

that the short time circuit will trip the breaker. To do

this follow the instructions for testing INSTANTANE-

OUS

as

described previously, but set the INSTAN-

TANEOUS, if there

is

one, above the input current level

and the

SHORT

TIME

PICK-UP below the input cur-

rent level.

Example: Set

LONG

TIME

PICK-UP on

"A",

SHORT

TIME

PICK-UP at 3X

(J.5A.),

and INSTANTANE-

OUS (if applicable) on 12X

(6.0A.).

Close the breaker

and apply 2 to 5 amperes

by

closing the switch. The

breaker should trip

in

about

liz

second or less depending

on the

SHORT

TIME

BAND setting.

If

the static trip

is not on a breaker, the voltmeter may be used as before

to obtain an indication

of

the static trip output at termi-

nals 7 and

8.

Ground Time Delay Test

The

GROUND

time delay can

be

tested

in

the same way

as

the

SHORT

TIME

except current

is

applied to termi-

nals 4 and 9 instead of I, 2, or 3 and 9. When the trip-

ping output appears, the ground target should pop out.

Tripping Actuator Test

If

the static trip device fails

to

trip the breaker. the

question arises as to whether the trouble is

in

the static

trip or the actuator. Substitution

of

another static trip

may

supply a quick answer.

If

another static trip is not available, there is a simple

t~st

of the actuator. However. a dc power supply with

output adjustable from three to

12

volts minimum at 0.3

ampere minimum is required. Such a power supply is

contained

in

portable test sets built after late 1972.

Disconnect the static trip connecting strip from the ter-

minal block. With an ohmmeter or resistance bridge mea-

sure and record the resistance of the actuator coil from

terminal 7 to terminal 8 of the terminal block.

Disconnect the ohmmeter and connect the output of the

power supply to terminals 7 and 8 of the terminal block

with terminal 7 negative. Close the breaker and slowly

increase the de voltage from minimum. Note and record

the voltage atwhich the breaker trips.

There

are

two

types

of

actuators

which

have

dif-

ferent

coil

resistances.

If

coil

resistance

is

between

25

and

30

Ohms,

the

tripping

voltage

should

not

be

over

six

volts.

If

resistance

is

between

30

and

40

Ohms

tripping

voltage

should

not

be

over

10

volts.

Values

above

these

indicate

defective

trip-

ping

actuators.

CAUTION

Although

the

tripping

actuator can

be

easily

dis-

assembled, doing

so

may partially demagnetize

it,

and

remagnetizing requires special equipment.

Failure of the breaker to trip at any actuator voltage

even up to

12

volts may

be

due to the plunger of the

actuator not being reset fully so that the permanent mag-

net does not hold

it

in

the reset position. This can be

checked visually.

See

the circuit breaker instruction

book.

Tripping Transformer Tests

The tests described

in

the preceding verify performance

of the static trip device and the tripping actuator.

The third link in the STATIC

TRIP

IT protection sys-

tem

is

the breaker-moonted tripping current trans-

formers. When secondary current testing

is

done with

the static trip on the breaker. the tripping transformers

are subjected to approximately their normal excitation

so that a transformer with shorted turns would show

up

in

the form of pick-up values above tolerance. How-

ever, there would

be

no

way

of knowing whether the

problem was in the static trip or the transformers. More-

over,

an

open

circuit

in

the

transformer winding or

wiring would not show up at all. Therefore,

it

is

desirable

to test the tripping transformers as described

in

the

following:

Connections

If

the static trip device

is

on the breaker. disconnect

it

from the transformers

by

removing the connecting strip

from

the

lower row of terminal block connections. The

tripping transformers can now

be

tested

by

making con-

.~

11

nections to the banana jacks of the terminal block just

as before.

Continuity Check

An

ohmmeter

is

most suitable for checking continuity of

the transformer secondary windings and wiring. Con-

nect the ohmmeter to terminals 1 and 9 for A phase, 2

and 9 for B phase, and 3 and 9 for C phase. The value

of the resistance (which can fall within a wide range

depending on the transformer rating)

is

not important

for this test because the purpose

is

solely to verify con-

tinuity.

When ground protection

is

provided, the ground strap

transformer or neutral bus transformer, whichever

is

used,

is

mounted external to the circuit breaker and

wired to the static trip terminal block through secondary

draw-out contacts of the cubicle. Therefore, to check

continuity of this tripping transformer and its secondary

circuit, the breaker must be in the cubicle in the

TEST

or

CONNECTED

positions. Connect the ohmmeter be-

tween terminals 4 and 9 to check the ground strap

or

neutral

CT

continuity.

Excitation Test

The purpose of the excitation test

is

to reveal shorted

turns

in

the tripping transformer winding. Sixty-Hertz

ac voltage

is

applied to the secondary winding and the

exciting current

is

monitored. Short circuited turns will

be revealed by excessive exciting current and perhaps

by

overheating of the winding.

If

a portable test set

is

available,

it

may be used to furnish the applied voltage,

and

the ammeter

on

the set may be used to monitor

exciting current.

It

is

desirable, but not essential, to also

have an

ac

voltmeter of 0-150 volts scale to measure

the applied voltage. Many multitesters have such a volt-

meter range as well as an ohmmeter range for continuity

tests. In the absence of a voltmeter, the dial reading of

the variable transformer may be used as an approximate

voltage indicator. See Table IL

If

a portable test set

is

not available, the equipment listed under "Testing

Without a Portable Test Set" can be used.

Again, each phase must

be

tested in tum. Connect the ac

supply to terminals 1 and 9 for A phase, 2 and 9 for

B phase, and 3

and

9 for C phase.

To

test the ground

strap

or

neutral bus

CT

for ground protected systems,

it

is

necessary for

the

breaker to be

in

the

TEST

or

CONNECTED

position

in

the cubicle, as explained

before, and apply voltage

to

terminals 4 and 9.

Table

IT

gives applied voltage and test limits of exciting

current for all the standard tripping transformer ratings.

The figure .02 ampere

in

the table

is

used because that

is

about the lowest readable current on the test set am-

•

•

•

.-

•

•

•

meter, and transformers that meet this limit

will

give

satisfactory performance.

Normal

exciting current for

the 800: I and

up

ratings may be

well

below this value.

Therefore,

it

is

essential, for ratings of 1000: I and

higher,

to

perform

the

continuity check. On

the

lower

ratings the continuity

check

can be omitted since the

deflection

of

the ammeter verifies continuity.

TABLE

II

TRIPPING TRANSFORMER

EXCITING CURRENT TEST

APPROX.

I

RIPPING

VARIABLE

MAXIMUM

TRANSF.

APPLIED

TRANSF.

EXCITING

RATING

VOLTS

SF'nlNG

CURRENT

80: I 33.5 25 0.25

150: I 67

50

0.15

200: I 67

50

0.15

250: I 67

50

0.15

400: 1 67

50

.05

600: I 134 100 .05

800: 1 134 100 .03

1000 and

Up

134 100

<.02

Primary Current Testing

Testing with primary

current

applied

to

the

circuit

breaker requires a low voltage, high

current

supply

that

can

deliver

currents

up

to

4

or

6 times

the

sen-

sor

transformer

rated

current.

Available high

current,

low

voltage

test

sets are

single phase, so

that

tests

must

be

made

one

break-

er

pole

at

a

time

as

shown

in Figure

14.

When test-

ing a

breaker

having

ground

current

protection

(Le.

equipped

with

any

STATIC

TRIP

II

with

the

letter

G in its

type

designation) this single phase in-

put

wiII

appear

to

the

static

trip

device

to

be

ground

current.

Therefore,

when

testing

the

LONG

TIME,

SHORT

TIME,

and

INSTANTANEOUS cir-

cuits,

it

is necessary

to

by-pass

the

ground

trip

ele-

ment

by

placing a

jumper

from

terminal 4

to

ter-

minal 9

of

the

static trip.

To

test

the

G

RO

UND

trip

circuit

this

jumper

should

be

removed.

Primary

current

testing

can

provide

the

ultimate

as-

surance

that

the

entire

protective

system is func-

tioning

properly since

the

entire

system

is

tested

at

one

time. However,

primary

current

testing

may

present

additional problems.

One

major

difficultly

arises

from

the

non-linear

impedance

of

the

static

trip

power

supply circuit.

The

transformers

that

supply

power

to

the

static

trip

circuit

are designed

to

saturate

to

limit

the

input

to

an

acceptable level.

12

( A

-

TRIPPING

TR.SF.'S

)

1

B

)

-

)

TO

HIGH

CUR. SOURCE

C

-

-)

Figure 14. -Primary Current Testing

When supplied from a

low

voltage

source

that

can-

not

provide a

pure

sine wave

of

current,

the

wave·

shape supplied

to

the

static

trip

will be· altered.

This results

in

either

insufficient

power

to

prop-

erly

operate

the

static

trip

device

or

it

may

effect

the

indication

of

the

source

ammeter,

depending

on

the

ammeter

design, leading

to

the

erroneous

assumption

that

the

trip

device calibration is in-

correct.

One

other

major

difficulty

with

primary

current

testing

is

related

to

the

duty

cycle

limitation

of

the

circuit

breaker

and

sensor

transformers.

A

properly

operating

tripping

system will

be

self

protecting

from

thermal

damage

up

to

the

circuit

breaker

short

time

and

interruption

rating

provided

that

the

duty

cycle applicable

for

each rating is

not

ex-

ceeded.

The

standard

duty

cycle

for

the

short

time

rating as

demonstrated

per

ANSI

C37.50

is

0.5

sec-

onds ON,

15

seconds

OFF

followed

by

a

second

ON time

of

0.5

seconds.

The

ON intervals generally

are

too

short

in

time

to

read

the

ammeter

for

the

current

source.

For

the

instantaneous

interruption

rating,

the

ON times are

reduced

to

50

milli-

seconds. Because

of

this, calibration

of

the

trip

device high range settings

cannot

be

accurately

done

with

primary

current.

The

calibration

can

be

verified safely

at

the

lower

settings

and

operation

only

verified

at

the

higher

set

points.

If

the

duty

cycle limits are exceeded during testing,

the

circuit

breaker

or

sensing

transformers

may

be

damaged. Between tests,

the

unit

must

remain

OFF

long enough

to

allow

the

sensor transformers

to

cool.

In

addition,

if

there

were a

fault

in

the

trip-

ping system

and

the

breaker

could

not

trip

within

its

rated

time limits,

the

system

would

not

be

self

protecting.

Therefore

to

properly

protect

the

tripping system

from

potential

damage and still assure

operation,

the

following procedure

is

recommended.

1. Apply

to

one

phase

of

the

circuit

breaker

an

in-

put

current

of

one-half sensor

transformer

rating

and

measure

the

trip device

power

supply volt-

age. This voltage

is

across

the

filter

capacitor

from its negative terminal

to

the

red

actuator

lead.

If

this voltage exceeds

18

volts,

the

distor-

tion

of

the

input

current

can

be

disregarded ex-

cept

for

its

effect

on

the

ammeter

reading.

Test

all

three

poles

of

the

circuit

breaker

in

the

same

manner. This establishes

that

the

device

power

circuits are operating.

2.

Set

the

long time pick-up

control

to

the

"A"

po-

sition, slowly increase

the

current

from zero

while watching

the

long

time

trigger

output.

Pick-up should

occur

at

one-half

the

sensor

transformer

rating plus

or

minus

10%

not

in-

cluding

ammeter

error. Pick-up is indicated

by

a

sudden

increase in

the

trigger voltage.

Repeat

for all

three

poles

of

the

circuit breaker. When

the

trigger is present,

the

long

time

circuit tim-

ing oscillator

is

released

and

the

device will

time

out

on

long time.

Repeat

calibration

check

on

the

other

long time pick-up calibration points

if

desired.

3.

Set

long

time

pick-up on

"A",

long

time

band

control

on Band

one

(if adjustable), instantan-

eous

and

short

time pick-up

on

12X,

and

the

in-

put

current

equal

to

the

sensor

transformer

rat-

ing. Remove and reapply power. Allow

the

de-

vice

to

time

out

and trip

the

breaker. The

time

to

trip

should

meet

the

published curves

for

the

device being tested.

Repeat

for

all long

time

bands.

Note

that

if

the

input

current

waveshape

is

distorted,

the

time delay

may

be

less

than

ex-

pected.

Some

newer

primary

current

test

sets

have

peak

responding

ammeter

circuits

that

will

properly

indicate

current

magnitude

when

wave-

shape

distortion

is

present.

.13

4.

Set

instantaneous

at

3X,

short

time

at

12X,

long

time

band

on

its

maximum

(if adjustable).

The

breaker

should

trip

instantaneously

at

1.5

times

the

sensor

rated

current.

Repeat

for

all

three

poles

of

the

breaker.

5.

Set

short

time pick-up

at

3X,

instantaneous

at

12X,

long time

band

on

its

maximum

(if adjust-

able), and

short

time

band

on

minimum. Slowly

increase current.

The

breaker

should

trip

on

short

time

at

1.5

times

the

sensor

rated

current.

The

short

time

"time

delay"

can allow

the

cur-

rent

to

increase

after

tripping has

been

initi-

ated,

so

the

rate

at

which

the

current

is

increas-

ed

must

be

limited

to

prevent

"over

shoot".

6. With

the

same settings as

in

Step

5, adjust

the

supply

current

to

3 times

the

sensor

transformer

rating. Apply

the

current

and observe

the

break-

er

tripping time.

Test

all

three

short

time

bands

and

verify

that

the

short

time

delay matches

the

published curves.

7. Increase

the

instantaneous

and

short

time

pick-

up

controls

to

their

maximum

and

set

the

long

time

band

on

minimum

(if adjustable). Adjust

the

supply

current

to

twice

the

sensing trans-

former

rating. Apply

the

current

and

observe

the

breaker tripping time.

Test

at

the

same cur-

rent

for

all time bands,

if

bands

are adjustable,

and

verify

that

the

long

time

delay matches

the

published curves.

Other

values

of

current

can

be

tested

if

over

heating

is

prevented.

8.

To

demonstrate

operation

at

normal

control

setting, reset all

controls

to

their

desired condi-

tion,

set

current

to

a value high

enough

to

de-

finitely cause tripping, apply

current,

and verify

that

tripping occurs.

•

•

•

•

•

•

•

REPAIR

B

eca

use of the

co

mplexity

of

so

me

of

the semi

-co

ndu

c-

tor components, for example, (he integrated circuit

s.

we

do not recommend field repair of

STATIC

TR

IP

IT

unit

s.

Mo

re

ove

r.

component fa

ilur

e usually docs

not

sh

ow

up

as

vis

ual

dama

ge

~

md

l

ocat

in

g

the

defective

compo

n

cnr

or

components

requ

ire

s specia

li

zed t

ech-

niques. Therefore. if the tests

de~cribcd

in

the preceding

section indicate that a

STAT

IC

TR

IP

II

device

is

defec-

tive. contact yo

ur

Allis-Chalmers

repr

ese

nt

a

ti

ve

for

in-

"tructions

on

returning the unit 10

th

e factory for repair.

MAINTENANCE

Each

trip device is adjusted.

ca

librated, and tested

before shipment. It

is

ready for use after the appropriate

settings have been

se

lected.

Bec

ause there a

re

no m

ov

ing parts.

no

readjusting, lub-

ric

a

tin

g,

et

c.

is

req

uir

ed. The o

nly

maintenance th

at

is

required

is

periodic verification that

the

device

is

func-

tionin

g.

This may be sup

pl

emented

as

desired

by

check-

in

g

th

e calibration, inspecting for l

oose

or

br

oken

c

~ter

nal wiring. restoring l

ost

calibralion, and where unusu-

a

ll

y dusty conditions ex

is

t, pe

ri

odic cleaning.

Rest

or

ing Lost Calib

ration

Calibra

ti

on of the trip device depends on the knobs

being properly oriented on their shaft

s.

If the knobs are

forced

by

turning past the s

top

s,

ca

li

bration

will

be lost

but

can readily be restored.

A knob

wi

ll

be

in

proper calibration

if

, when

tumed

counterclo

ckwise

as far as

it

ca

n

go,

th

e pointer lines up