- 8 -

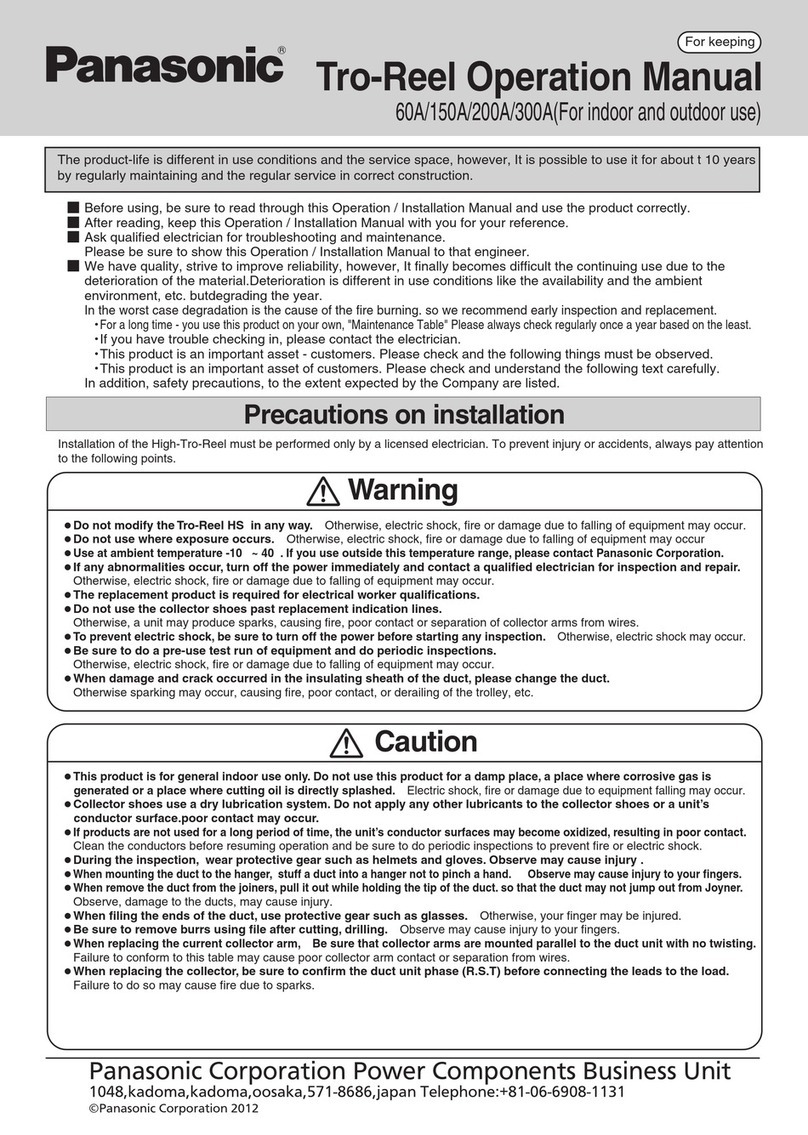

Usage Precautions

Warranty

Products and specifications described in this document are subject to change without notice for product improvement and so forth

(including specification changes and discontinued production). Upon considering using these products or placing orders, please check

whether the information provided in this document is up to date by contacting our inquiry desk as necessary.

Though we make utmost efforts on quality control of this product,

1. we would like to ask you to consult our inquiry desk and exchange specification documentation in the case that the application

may entail usage beyond the range of specifications, environments and conditions provided in this document or in the case of

applications requiring especially high reliability such as usage under conditions and environments not prescribed or safety

devices and control systems such as railways, aviation and medical use.

2. In order to prevent the occurrence of unexpected troubles regarding matters not provided in this document, please consult

about the specifications of your product, its customers, usage condition for this product, details on the area this product is

mounted, etc.

3. Take external safety measures such as a redundant circuit so that a fail-safe mechanism will work for the entire system in the

case of product failures or errors caused by external factors. Please use this product with a margin against the values of its

guaranteed characteristics and performance as provided in this document.

4. Please perform acceptance inspection with purchased or delivered articles in a timely manner and also carry out the handling

of this product before and during the acceptance inspection with sufficient consideration on controlled maintenance.

Warranty period

In the case of failures for which we are to be held responsible within 1 year from technical acceptance, we will perform the repair or

provide the parts free of charge.

However, warranty period shall be 1 year from accounting acceptance in the case that technical acceptance is not performed within 15

days from accounting acceptance due to reasons on your side or that the article about deeming accounting acceptance as technical

acceptance out of articles concerning accounting acceptance prescribed on product specification sheet is to be applied.

Warranty coverage

In the case of failure or flaw with this product revealed during the warranty period for which we are to be held responsible, we will provide

substitute articles or required replacement parts or replace or repair the flawed part free of charge.

However, failures and flaws corresponding to the following will be excluded from the scope of this warranty.

1. If it is due to the specifications, standards, handling methods, etc. ordered by you.

2. If it is caused by modifications on the structure, performance, specifications, etc. performed after purchase or after delivery

without any involvement from us.

3. If it is due to a phenomenon that cannot possibly be foreseen by the technology made available at the time of the purchase or

contract.

4. If the usage deviated from the range of conditions and environments prescribed in the catalog, specification sheet, and user’s

manual.

5. In the case of damages that could be avoided if your devices, into which this product is integrated for use, retain functions and

structures that should naturally be equipped by common sense in the industry.

6. If it is due to natural disasters, infliction by a third party, or an act of God.

7. If the failure is due to specifications deviating from power source specification recommended by us or the power source.

8. Other cases where our responsibility is not clarified through failure analysis.

9. If the device is damaged due to corrosion caused by poisonous gases in the vicinity.

10. In the case of occurrence due to use of products not designated or recommended by us.

11. In the case of occurrence due to usage with disassembly and modification.

12. If it is caused by relocation from the original position at the time of technical acceptance.

13. If it is due to scratches, damages, erroneous connection, or erroneous setup upon assembling the apparatus.

14. If it is used without performing appropriate maintenance.

15. In the case of minor performance change that can be compensated by output adjustment and so forth.

16. Concerning consumables and secondary materials such as filter.

17. Other cases where free warranty is not granted based on our judgment.

The warranty as mentioned herein is limited to the warranty on the sole unit of this purchased or delivered product, and damages brought

about due to failures or flaws of this product will be excluded.

This warranty is applied to the application at the time of purchase. Please contact us when changing the application or relocating abroad.

Location to which free services are applicable

Final delivery address in Japan designated at the time of order or location of your staff in charge of this device in Japan.