Bilanciai Cigiemme MERCURY PLUS User manual

MERCURY PLUS

Instruction manual

Code 81320114 EDITION 02.05.2016

January 2007

MERCURY PLUS

1-3

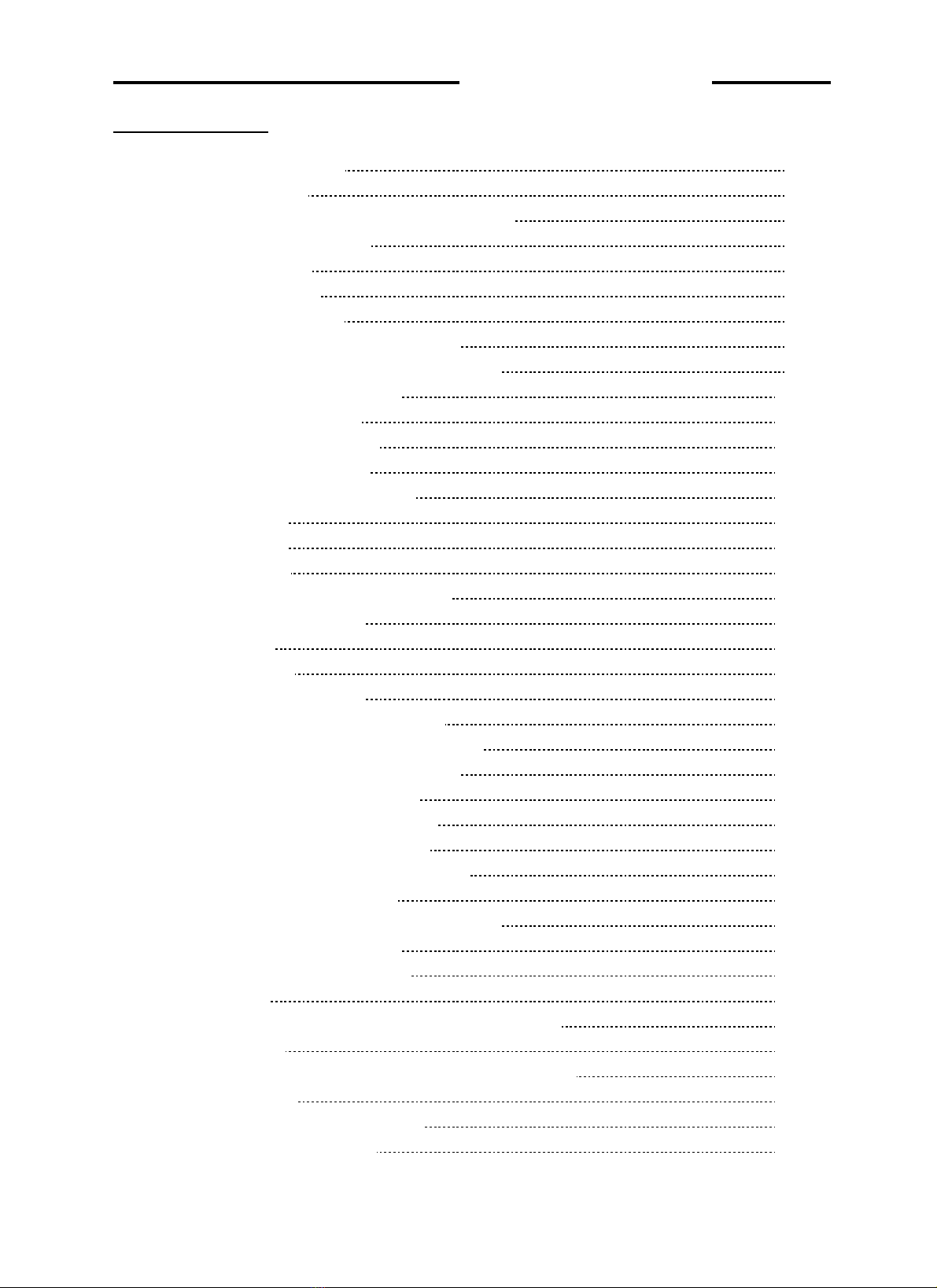

Table of Contents

1. GENERAL INFORMATION 1-13

1.1 Declaration of conformity 1-13

1.2 Foreword 1-14

1.3 Symbols 1-16

1.4 How to care for the manual 1-17

1.5 How to consult the manual 1-17

1.5.1 General information 1-18

1.5.2 Safety instructions 1-18

1.5.3 Testing, delivery and installation 1-18

1.5.4 Controls and indications 1-18

1.5.5 Use of the line - programming 1-18

1.5.6 Use of the line - process 1-18

1.5.7 Maintenance 1-18

1.5.8 Options 1-18

1.5.9 Troubleshooting 1-18

1.5.10 Glossary 1-18

1.6 Description of the system - general notes 1-20

1.7 Types and overall dimensions 1-22

1.7.1 Mercury Plus basic stainless steel MX130 1-22

1.7.2 Mercury Plus basic stainless steel with additional belt MX130 4N 1-23

1.7.3 Mercury Plus high speed stainless steel MX130HS 1-24

1.7.4 Mercury Plus high speed stainless steel with additional belt MX130HS

4N 1-25

1.7.5 Mercury Plus stainless steel with label underneath MX130ES 1-26

1.7.6 Mercury Plus stainless steel with additional belt and label underneath

MX130ES 4N 1-27

1.7.7 Mercury Plus double head stainless steel MX130TB 1-28

1.7.8 Mercury Plus double head stainless steel with additional belt MX130

4N 1-29

1.8 Electrical specifications 1-30

1.8.1 Electrical connections 1-30

1.8.2 Table of electrical values 1-31

1.9 Mechanical specifications 1-33

1.9.1 Compressed air connections 1-33

1.9.2 Conveying speed 1-33

1.9.3 Conveying system 1-33

1.9.4 Conveyor belt 1-34

1.9.5 Roller conveyor 1-34

1.9.6 Strap conveyor 1-34

1.9.7 Entry (or loading) conveyor 1-34

1.9.8 Separator conveyor 1-35

1.9.9 Weighing conveyor 1-35

1.9.10 Labelling conveyor 1-35

1.9.11 Printing system 1-36

1.10 How to obtain technical assistance 1-39

1.10.1 Identification data 1-39

1.10.2 Identification plates 1-40

1.11 Warranty 1-40

MERCURY PLUS

1-4

2. SAFETY INSTRUCTIONS 1-41

2.1 Prohibited uses 1-41

2.2 Prescriptions for use 1-42

2.3 General safety recommendations 1-43

2.3.1 Personal protective equipment 1-43

2.3.2 Definitions 1-44

2.4 Regulations 1-44

2.5 Professional profiles 1-45

3. TESTING, DELIVERY AND INSTALLATION 1-47

3.1 Testing 1-47

3.2 Delivery of the line 1-47

3.3 Dimensions and weight of the pack 1-48

3.4 List of materials supplied 1-48

3.5 How to handle the line 1-48

3.6 Positioning 1-50

3.6.1 Environmental specifications 1-50

3.6.2 Clear zones 1-51

3.6.3 How to open the pack 1-52

3.7 Connection to the user line 1-55

3.7.1 Electrical connections 1-55

3.7.2 Compressed air connections 1-55

3.7.3 COM1 - COM2 - COM3 serial output connection 1-55

3.7.4 Fast Ethernet connection 1-57

3.7.5 Printer connection 1-57

3.8 Switching the terminal on and off 1-58

3.8.1 Powering 1-58

3.8.2 Starting phase 1-59

3.8.3 Switching off 1-59

3.9 Decommissioning 1-60

3.9.1 Temporary 1-60

3.9.2 Definitive (dismantling) 1-61

4. CONTROLS AND INDICATIONS 1-63

1-63

4.1 Front part (display and

keyboard) 4.2 Display 1-64

4.2.1 Pathway area 1-65

4.2.2 Tare area 1-65

4.2.3 Weight area 1-65

4.2.4 Metrological data area 1-66

4.2.5 Price area 1-66

4.2.6 Message area 1-66

4.2.7 Functions area 1-67

4.2.8 Date, time and level area 1-67

4.2.9 Settings area 1-67

4.3 Keyboard 1-68

4.3.1 Groups of keys 1-68

4.3.2 Function keys (orange background) 1-69

4.3.3 Date keys (purple background) 1-69

4.3.4 Summing keys (purple background) 1-69

4.3.5 Alphanumerical keys (light blue and grey background) 1-70

4.3.6 Editing keys (black background) 1-71

MERCURY PLUS

1-5

5. USE OF THE LINE - PROGRAMMING 1-73

5.1 Convention 1-73

5.2 Initial range 1-74

5.3 Operating levels 1-75

5.3.1 Introduction 1-75

5.3.2 List of levels 1-76

5.3.3 Level changes 1-77

5.3.4 Change Password 1-77

5.3.5 Access level changes on powering 1-78

5.4 Macro area 1-79

5.4.1 Foreword: difference between macro and global field 1-79

5.4.2 Introduction 1-79

5.4.3 How to program a macro function 1-80

5.4.4 Start Macro 1-81

5.4.5 How to erase a macro function 1-81

5.4.6 Macro display 1-82

5.5 Global fields 1-83

5.6 Soft keys 1-86

5.6.1 Introduction 1-86

5.6.2 Programming 1-87

5.6.3 Cancellation 1-90

5.7 Key combinations with ALT 1-91

5.8 Use of the TAB key during process 1-93

5.9 List of menus 1-94

5.10 Common notes about archive programming 1-97

5.10.1 SAVE 1-98

5.10.2 NEW 1-98

5.10.3 COPY 1-98

5.10.4 CANCEL 1-98

5.11 Texts 1-99

5.11.1 Introduction 1-99

5.11.2 Text archive properties 1-100

5.11.3 How to find a text 1-100

5.11.4 Preset texts 1-100

5.12 Barcodes 1-105

5.12.1 Introduction to the barcodes 1-105

5.12.2 EAN 13 / EAN 8 1-106

5.12.3 UPC A / UPC E 1-108

5.12.4 CODE 39 / CODE 32 Pharmaceutical Ita 1-110

5.12.5 Interleaved 2 of 5 / ITF 14 1-112

5.12.6 CODE 128 / EAN 128 1-114

5.12.7 Monarch Codabar 1-116

5.12.8 PDF 417 1-117

5.12.9 Barcode archive properties 1-118

5.13 Images 1-128

5.13.1 Introduction 1-128

5.13.2 Images archive properties 1-130

5.13.3 Memorize in PTR 1-131

5.14 Labels 1-132

5.14.1 Introduction 1-132

5.14.2 Label archive properties 1-135

MERCURY PLUS

1-6

5.14.3 Label archive field properties 1-139

5.15 PLU 1-144

5.15.1 Introduction 1-144

5.15.2 Plu archive properties 1-145

5.16 Barcode reading 1-158

5.16.1 Introduction 1-158

5.16.2 Store 1-160

5.16.3 Crate weigher - Note for the installers 1-160

5.16.4 Single product - Note for the installers 1-161

5.16.5 Properties of the BC Read archive 1-161

5.17 Traceability (optional) 1-164

5.17.1 Introduction and properties of the traceability archive 1-164

5.17.2 Error messages 1-166

5.18 Packing list (optional) 1-167

5.18.1 Introduction 1-167

5.19 CTRL weight control (optional) 1-168

5.19.1 Limitations established by the standards and introduction 1-168

5.19.2 Properties of the weight monitoring archive 1-169

5.20 Weight Bounding (optional) 1-171

5.20.1 Introduction and properties 1-171

5.21 General Totals 1-173

5.21.1 Introduction and properties 1-173

5.21.2 General Totals management 1-174

5.22 Menus accessible at 5th level 1-175

5.22.1 Introduction 1-175

5.22.2 Network settings 1-176

5.22.3 Transmission of Weights, Rejected Weights and application

errors 1-177

5.22.4 Password entry 1-179

5.22.5 Time/date setting 1-179

5.22.6 Miscellaneous settings 1-180

5.22.7 Logger settings 1-181

5.22.8 I/O Test 1-182

5.22.9 Input table 1-184

5.22.10 Table of inputs only if board 57130001 is installed 1-185

5.22.11 Output table 1-186

5.22.12 Table of outputs only if board 57130001 is installed 1-188

5.22.13 PTR Test 1-189

5.22.14 Counter setting 1-190

5.22.15 Backup/Restore 1-192

5.22.16 Old Cigiemme serial link 1-193

6. USE OF THE LINE - PROCESS 1-195

6.1 Combinations available 1-195

6.2 Type of process 1-197

6.2.1 PLU 1-197

6.2.2 Remote mode 1-197

6.3 Type of operation 1-197

6.3.1 Single product 1-197

6.3.2 Crate weigher/Multiproduct 1-197

6.4 Operating modes 1-198

6.4.1 CTRL - Operation 1-198

MERCURY PLUS

1-7

6.4.2 CTRL - Process example 1-199

6.4.3 CTRL - Lot closing 1-199

6.4.4 Weight Bounding (weight classes) - Operation 1-200

6.4.5 W.B. - Standard single product 1-201

6.4.6 W.B. - Single product with CTRL enabled 1-201

6.4.7 W.B. - Crate weigher 1-202

6.5 Double head mode 1-203

6.5.1 Additional head 1-203

6.5.2 Alternative head 1-204

6.6 Labelling machine mode 1-206

6.7 How to prepare and power the line 1-208

6.8 Modify data 1-211

6.9 Reverse entry management 1-211

6.10 Totals management (Advanced closing) 1-211

6.11 List of open PLU 1-211

6.12 Conveyor belt 1-212

6.13 Scale reset 1-212

7. MAINTENANCE 1-213

7.1 Foreword 1-213

7.2 Inspections conducted in the factory 1-214

7.3 Inspections to be conducted on installation 1-214

7.4 Routine inspections 1-215

7.5 How to replace the conveyor belts 1-216

7.6 How to tighten the conveyor belts 1-217

7.7 How to check the weighing system 1-219

7.8 How to calibrate the weighing system 1-221

7.9 How to clean the thermal head 1-222

7.10 How to clean the paper tractor roller 1-224

7.11 How to clean the paper photosensor 1-226

7.12 How to clean the accessory parts of the printer 1-227

7.13 How to replace the thermal head 1-228

7.14 How to replace the belts 1-230

7.15 How to replace the motor 1-231

7.16 How to clean the conveyor belts 1-232

7.17 How to clean the compressed air filter 1-233

7.18 How to clean the photocells 1-233

8. TROUBLESHOOTING 1-235

8.1 Foreword 1-235

8.2 List of errors 1-236

9. GLOSSARY 1-251

MERCURY PLUS

1-8

Index of the figures

Figure 1.1 - MX130 1-22

Figure 1.2 - MX130 4N 1-23

Figure 1.3 - MX130HS 1-24

Figure 1.4 - MX130HS 4N 1-25

Figure 1.5 - MX130ES 1-26

Figure 1.6 - MX130ES 4N 1-27

Figure 1.7 - MX130TB 1-28

Figure 1.8 - MX130TB 4N 1-29

Figure 1.9 - Metrologic data plate 1-40

Figure 1.10 - Identification plate of the weighing platform 1-40

Figure 3.1 - Position of main switch 1-59

Figure 4.1 - Front part of terminal 1-63

Figure 4.2 - LCD Display 1-64

Figure 4.3 - Detail of price area 1-66

Figure 4.4 - Keyboard 1-68

Figure 5.1 - Initial mask 1-74

Figure 5.2 - 1/3 menu list 1-94

Figure 5.3 - 2/3 menu list 1-95

Figure 5.4 - 3/3 menu list 1-96

Figure 5.5 - Texts archive 1-99

Figure 5.6 - Barcode archive 1-118

Figure 5.7 - Images archive 1-129

Figure 5.8 - Labels archive 1-133

Figure 5.9 - Entry and editing of labels fields 1-134

Figure 5.10 - Heading 1-138

Figure 5.11 - Plu archive 1-144

Figure 5.12 - BCRead archive 1-159

Figure 5.13 - Traceability archive 1-165

Figure 5.14 - Weight Bounding archive 1-172

Figure 5.15 - General Totals archive 1-174

Figure 5.16 - 5th level configuration 1-175

Figure 5.17 - I/O test 1-182

Figure 5.18 - PTR test 1-189

Figure 6.1 - Permit combinations 1-196

Figure 7.1 - Flat belt (motor view) 1-216

Figure 7.2 - Flat belt (belt tightening) 1-217

Figure 7.3 - Thermal head and lifting components 1-222

Figure 7.4 - Paper feed roller and lifting components 1-224

Figure 7.5 - Paper feeding photosensor 1-226

Figure 7.6 - How to remove the head from the dissipator 1-228

MERCURY PLUS

1-10

Index of the table

Table 1.1 - Electrical values 1-31

Table 1.2 - Power input 1-31

Table 3.1 - List of weights of the various models 1-48

Table 3.2 - Serial output pinout 1-55

Table 5.1 - List of levels 1-76

Table 5.2 - Password list 1-77

Table 5.3 - Soft-key options 1-87

Table 5.4 - Combinations with the ALT ke 1-91

Table 5.5 - Use of the TAB key during process 1-93

Table 5.6 - Texts archive propertie 1-100

Table 5.7 - List of preset texts 1-101

Table 5.8 - EAN 13 fixed weight 1-106

Table 5.9 - EAN 8 fixed weight 1-106

Table 5.10 - EAN 13 variable weight 1-106

Table 5.11 - UPC - A 1-108

Table 5.12 - UPC - E 1-108

Table 5.13 - Code 39 1-110

Table 5.14 - Code 32 Pharmaceutical Ita 1-110

Table 5.15 - Interleaved 2 of 5 1-112

Table 5.16 - ITF 14 1-112

Table 5.17 - EAN 128 1-114

Table 5.18 - Types of barcode 1-119

Table 5.19 - Barcode archive properties 1-121

Table 5.20 - Barcode process variable fields 1-122

Table 5.21 - Barcode totals variable fields 1-125

Table 5.22 - Barcode field properties 1-126

Table 5.23 - Images archive properties 1-130

Table 5.24 - Labels archive properties 1-135

Table 5.25 - Labels archive field properties 1-139

Table 5.26 - Plu field explanations 1-145

Table 5.27 - Reference table for weight control 1-169

Table 5.28 - Network configuration 1-176

Table 5.29 - Miscellaneous settings 1-180

Table 5.30 - Inputs 1-184

Table 5.31 - Inputs only if board 57130001 is installed 1-185

Table 5.32 - Outputs 1-186

Table 5.33 - Outputs only if board 57130001 is installed 1-188

Table 5.34 - Counters 1-190

Table 5.35 - Old Cigiemme serial link 1-193

Table 7.1 - Periodic inspections 1-215

MERCURY PLUS

1-12

1-13

1 GENERAL INFORMATION

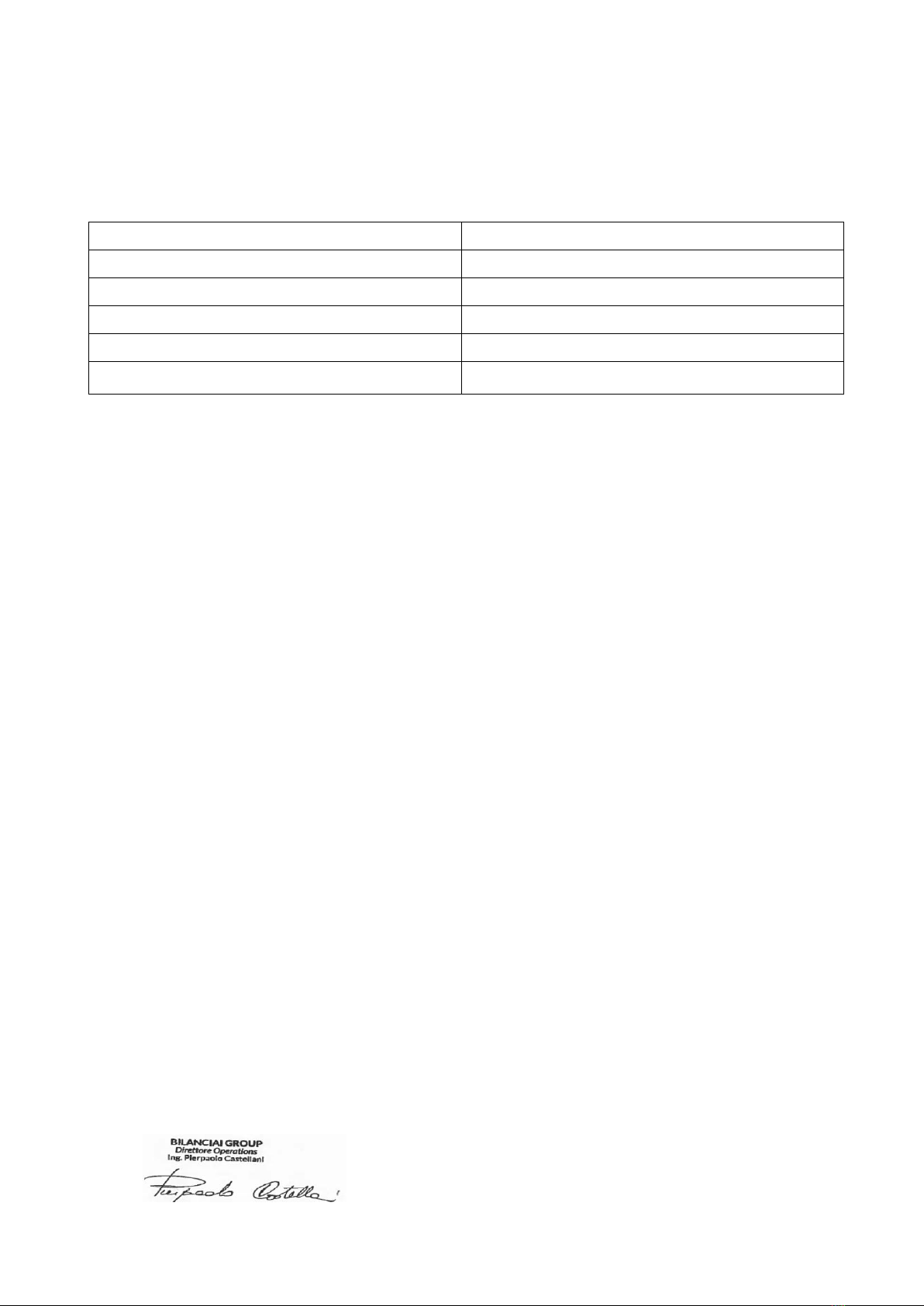

1.1 EU Declaration of conformity

1. THE AUTOMATIC WEIGHING INSTRUMENT

TYPE

MERCURY PLUS

Serial number

------

Capacity (Max

6.0 kg

interval (e)

0.002 kg

Accuracy class

R51 XIII (1) / Y(a)

N° of the EC type-approval certificate

………

2.

Manufacturer: SOCIETÀCOOPERATIVA BILANCIAI CAMPOGALLIANO

Via S. Ferrari, 16 - 41011 Campogalliano MO ITALIA)

3.

This declaration of conformity is issued under the sole responsibility of the manufacturer.

Object of the declaration: see 1.

4.

The object of the declaration described above is in conformity with the relevant Union

harmonisation legislation:

2014/32/EU (MID): Recommendation OIML R51-1:2006

2014/35/EU (LVD): Norm EN 60950-1:2006

2014/30/EU (EMC): Norm EN 61000-6-3:2007 61000-6-4:2007

2006/42/EC (MD): Norm EN 12100:2010

5.

The Notified Body Kiwa Cermet Italia N°0476 has carried out the conformity of the

Production quality assurance assessment and issued the certificate:MID_7_D_1.

6.

Additional information:

All the instructions given in the Use and maintenance handbook supplied with the

instrument must be followed during the utilization, as well as the safety and accident-

preventing norms in force in the country of installation.

The CE mark has been applied on the product.

The terminal is also suitable for the creation of automatic weighing instruments

approved with the “CE Type Approval Certificate” in conformance with the

requirements of Directive 2014/32/EU (MID).

If the instrument is installed in a system, it is PROHIBITED commissioning before the

plant, in which the instrument is intended to be incorporated, It is placed in a safe

condition and to comply with the requirements.

In addition we declare that the authorized person to set up the technical file of this

machine is: Mirco Ing. Valmori

Signed for and on behalf of: Place and Date of issue:

Campogalliano,02/05/2016

MERCURY PLUS

1-14

Foreword

✔The aim of this manual is to provide the operator, through the use of

text and illustrations, with essential information regarding the

installation, safe operation and maintenance of the weighing system.

✔This manual must be kept in a safe place where it is readily available

for consultation! Always observe the instructions contained in the

manual!

✔Safe operation of the system is the responsibility of the operator, who

must be fully familiar with it.

✔The user is responsible for ensuring that the installation conforms to

the applicable regulations.

✔The equipment must only be installed by specialised personnel who

have read and understood this manual.

✔The term "specialised personnel" means any personnel who, by

virture of the training they have received and their professional

experience, have been explicitly authorised by the "System safety

supervisor" to install, operate and service the system.

✔Contact your nearest Service Centre if problems occur.

✔Any attempt on the part of unauthorised personnel to dismantle or

modify the terminal is prohibited. Any such attempt shall invalidate the

warranty and relieve the manufacturer from all liability for any damage

or injury to persons or property.

✔It is also forbidden to alter or remove the data plates and seals on the

terminal. Make sure that all plates and seals are present and legible,

if not contact the After-Sales Service.

✔The manufacturer shall not be liable for any damages caused by

incorrect handling of the terminal.

✔The information and illustrations contained in this manual were up to

date at the time of publication.

✔The manufacturer is committed to a policy of continuous product

improvement and parts of the system may therefore be subject to

modification.

✔All the technical information contained in this manual remains the

exclusive property of the manufacturer and may not be disclosed to

third parties.

✔No part of this document may be reproduced or transmitted in any

form, including publication in computerised form or on the World Wide

MERCURY PLUS

1-15

WEB, without the explicit written permission of the manufacturer.

✔This manual may not be used for purposes other than those directly

related to installation, operation and maintenance of the terminal.

✔In order to more clearly describe certain maintenance or adjustment

operations, some of the illustrations in this manual show the weighing

system with the safety guards removed. Under no circumstances may

the system be operated in these conditions. The safety guards may

only be removed for the time strictly required to carry out the required

repairs or maintenance work after which they must be fitted back in

place.

MERCURY PLUS

1-16

1.2 Symbols

Below is a list of the symbols used in this manual to alert the reader to

the various hazards associated with the operation and maintenance of

the instrument.

DANGER

Information or procedure where failure to observe the

instructions will result in death or serious personal injury.

ATTENTION

Information or procedure where failure to observe the

instructions could cause death or serious personal injury.

WARNING

Information or instructions on how the system is to be

operated correctly in order to maximise its service life or

prevent loss or damage of programmed data or to optimise

operation with regard to metrological standards.

Text and messages displayed on the terminal are printed in this manual

using special characters.

Messages:

Display messages appear like this.

Menu pathways:

Home\Process\Data Modification\Product

The "\" character indicates the transition from one menu option to the

next.

1-17

MERCURY PLUS

1.3 How to care for the manual

Take care to prevent the pages, drawings and annexes from being spoilt

when the manual is consulted. You are advised to procure a spare copy

of the original and to keep it in a safe and protected place.

WARNING

The contents of this document in their unabridged form and

only when the copy is to be exclusively used within the

proprietor company.

It is forbidden to disclose the contents of this manual without

prior written authorization from the manufacturer.

This manual is supplied with a CD-ROM containing information about

how to program the archives as well as operating, setting up and

servicing instructions for the weighing-pricing machine.

1.4 How to consult the manual

The way this manual has been compiled makes it easy for the user to

find the information he needs.

It has been divided into chapters as described below.

ATTENTION

The user must read this manual carefully before proceeding

with any operation.

Ask the manufacturer for another copy if the manual is lost,

is incomplete or becomes damaged.

1-18

MERCURY PLUS

1.4.1 General information

Contains important reference matter and descriptions about the

machine, its identification and the manufacturer. Summarizes the basic

characteristics of the line.

1.4.2 Safety instructions

Contains information about rules of conduct in relation to safety.

1.4.3 Testing, delivery and installation

Contains information about how to handle and install the line.

1.4.4 Controls and indications

Description of the display-keyboard unit and the user interface.

1.4.5 Use of the line - programming

Detailed description of the data entry mode.

1.4.6 Use of the line - process

Detailed description of the operating modes of the line and the various

possible configurations.

1.4.7 Maintenance

Describes the procedures and frequencies with which the routine

maintenance operations must be carried out.

1.4.8 Options

Description of non-standard options.

1.4.9 Troubleshooting

Simple instructions about how to resolve the most probable faults.

1-19

MERCURY PLUS

1.4.10 Glossary

Gives the meanings of the technical terms used in this manual.

MERCURY PLUS

1-20

1.6 Description of the system - general notes

Automatic high-performance weighing-pricing lines suitable for the most

different fields of use.

Created with latest generation electronics and controlled by the very

highest level, flexible software allowing the users to operate by means of

the keyboard and 10.4" graphic display in a simple and intuitive way in

order to achieve operating rates of up to 120 weighing

operations/minute.

Thanks to their modular design, the Mercury Plus lines are able to

comply with any weight, product shape, frequency and size requirement.

The different types of belt (flat, "V" shaped, mobile), the different

application systems (arm, air-jet) and the choice of weighing modes

(static or dynamic) make this an absolutely versatile machine.

A series of optional functions and devices such as ejectors, the

metal-detector and totalizers complete the range.

A list of the main technical features is given below:

✔Conveyor with 3 or 4 flat or "V" shaped belts.

✔Static or dynamic weighing with frequencies of up to 120 packages

per minute according to the dimensions, weight and shape of the

package and the length of the labels.

✔Alphanumeric-functional keyboard with 99 keys

✔Ethernet network with TCP/IP protocol

✔Printing width up to 102 mm

✔Air-jet application system or with motorized arm

✔Structure made of AISI 304 stainless steel

✔Labelling "on top" or "underneath", in front or at the side

The mod. MERCURY PLUS automatic weighing line is a system that

handles, weighs, labels and unloads the product in a fully automatic

way.

Cigiemme machines are equipped with systems that receive and

transmit signals to enable the actual line and prior machines to operate.

When the enabling signals are disabled by the machines downstream,

the weighing system stops after having concluded its weighing and

labelling cycle. A package may therefore be unloaded after the signal

has been disabled.

The line comprises a series of conveyors (belt types, roller types, etc...)

This manual suits for next models

4

Table of contents

Other Bilanciai Industrial Equipment manuals