Siemens Energy DigiTRON Retrievable Electrical Distribution... User manual

Document No:

Template

Issue Date:

dd/mm/yyyy

Revision:

1

Page:

1 of 35

Unrestricted

Siemens Energy is a registered trademark licensed by Siemens AG

DigiTRON Retrievable Electrical Distribution

Unit (REDU), 1st generation - Installation,

Operations and Maintenance Manual

Protection, Storage, Shipment, Unpacking, Deployment

& Maintenance Instructions

Document No: IOM-006

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

2 of 35

Unrestricted

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

3 of 35

Unrestricted

Foreword

Thank you for purchasing a Siemens Energy Subsea product. The information contained in this

document is an overview including the protection, storage, shipment, unpacking, deployment and

maintenance for 1st generation ‘TC3A’ DigiTRON Retrievable Electrical Distribution Unit (REDU) and

mounting plate.

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

Revision Summary

This page records the revision status of the entire document and its authorisation for issue.

Copyright © 2020 Siemens Energy Subsea Connectors, (a division of Siemens Energy plc),

Subsea Excellence Centre, Ulverston, Cumbria, LA12 9EE, England.

Rev

Compiled

by

Date

Approved

by

Issue Date

Page(s) Affected/Remarks

3

R Wyatt

16/11/2020

Eric Chaize

16/11/2020

Updated onto new IOM template with product

safety advice clearly identified. Harmonised with

IOM-005.

2

A.Ellis

28/10/2020

J. Pridmore

28/10/2020

Fig 1 added showing REDU lifting points. Section

7 updated with max. deployment/retrieval speed

and reference to IOM-002 added

1

T. Archer

JP Smith

11/02/2020

First issue

Contents

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

4 of 35

Unrestricted

1PRODUCTS COVERED BY THIS MANUAL....................................................6

2BASIC INFORMATION & QUICK REFERENCE..............................................7

2.1 Product overview.....................................................................................7

2.2 Product specification and certification .................................................7

2.3 Contact details and feedback.................................................................8

2.4 Product advice label................................................................................8

2.5 Product marking ......................................................................................9

2.6 CE label/marking......................................................................................9

2.7 Product example....................................................................................10

3PRODUCT SAFETY........................................................................................11

3.1 Action-related warnings........................................................................11

3.2 Intended use...........................................................................................11

3.3 General safety information...................................................................12

3.4 Related documents................................................................................15

3.5 Control of substances hazardous to health (COSHH) .......................15

4ABBREVIATIONS...........................................................................................16

5SPECIFICATIONS...........................................................................................17

5.1 ROV operated Connector Specification ..............................................17

6PREPARING PRODUCT FOR USE OR STORAGE......................................18

6.1 Product protection and packaging ......................................................18

6.2 Lifting......................................................................................................18

6.3 Unpacking...............................................................................................19

6.4 Storage, protection, and end of life .....................................................19

7INSTALLATION AND ASSEMBLY ................................................................21

7.1 Cathodic protection...............................................................................21

7.2 REDU.......................................................................................................21

7.3 Base plate installation...........................................................................23

7.4 Mate/de-mate of REDU box to Base plate ...........................................23

8USER INFORMATION DURING NORMAL OPERATION AND FAULT

CONDITIONS..................................................................................................28

8.1 Visible/audible signals ..........................................................................28

8.2 Normal and faulty/dangerous operation..............................................28

8.3 Troubleshooting.....................................................................................28

9PRODUCT OPERATION AND MAINTENANCE............................................29

9.1 Safety precautions.................................................................................29

9.2 Product maintenance and servicing....................................................29

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

5 of 35

Unrestricted

9.3 Subsea protection of receptacle contact pins....................................29

9.4 Product protection; caps and dummy connectors.............................29

9.5 Live Mate / De-mate ...............................................................................31

9.6 Removal of marine growth and calcareous deposits.........................31

9.7 Testing of product .................................................................................32

9.8 Checks before mating the connectors ................................................32

9.9 ROV connectors mating and de-mating..............................................32

10 CUSTOMER COMMENTS/FEEDBACK.........................................................35

Tables

Table 1 List of other Installation, Operation and Maintenance manuals related to

DigiTRON product range.................................................................................6

Table 2 DigiTRON product specification and certification .......................................7

Table 3 DigiTRON product contact details.................................................................8

Table 4 DigiTRON ROV connector specification .....................................................17

Table 5 Maximum misalignment values REDU box to Base plate..........................24

Table 6 Troubleshooting product contact details....................................................28

Illustrations

Figure 1 Product advice label........................................................................................8

Figure 2 Product marking on DigiTRON product ........................................................9

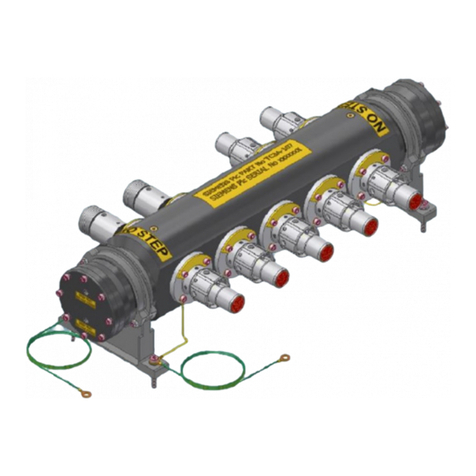

Figure 3 Typical REDU Box Assembly and Base Plate Assembly...........................10

Figure 4 REDU lifting points........................................................................................18

Figure 5 Dry (topside) test connectors, ROV, Diver and Stab-plate type................22

Figure 7 Markings on guideposts ...............................................................................24

Figure 8 a) Allowable Horizontal Misalignment, b) End View Allowable

Misalignment..................................................................................................25

Figure 9 Secondary Pin Capture Misalignment.........................................................26

Figure 10 Allowable Cone to Pin Concentric Misalignment.......................................27

Figure 11 23mm (0.905”) diameter through hole .........................................................27

Figure 12 ROV-type Transport Caps (left) and Topside Protective Caps .................30

Figure 13 ROV-type Subsea Caps.................................................................................30

Figure 14 ROV-type Subsea Environmental Cap and Dummy Connectors, flying

and flanged types.................................................................................................................30

Figure 15 Alignment marks and lip seal mating indicator..........................................33

Figure 16 ROV de-mate tool, part number BQ-30090-00.............................................34

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

6 of 35

Unrestricted

1 PRODUCTS COVERED BY THIS MANUAL

This document is an overview of the protection, storage, shipment, unpacking, deployment, and

maintenance instructions for the 1st generation ‘TC3A’-type Retrievable Electrical Distribution Unit

(REDU).

Products covered by this IOM can be readily identified visually, all looking very similar to the

examples given section 2.7.

Part numbers for these REDU products all begin with:

TC3A-xxx -where xxx are part numbers for specific variants of REDU, differences mainly being

quantity of connectors, and connector types.

Installation, Operation and Maintenance manuals for other DigiTRON products not covered by this

document can be found on Siemens Subsea website https://www.siemens-energy.com /search

Subsea, as follows:

DOC. No.

PRODUCT

IOM-001

DigiTRON electrical flying leads, Jumper and Sensor Harnesses

IOM-002

DigiTRON single connectors

IOM-003

Obsoleted, replaced by IOM-002.

IOM-004

Not used

IOM-005

Retrievable Electrical Distribution unit (REDU), 2nd generation

IOM-007

Disconnectable junction boxes type TC3A-107 and similar Electrical

distribution Units (EDUs).

IOM-008

DigiTRONffiber optic flying leads and harness assemblies

IOM-009

DigiTRONffiber optic single connectors

00003075

Subsea PT/TT sensors

00007464

Differential Pressure sensors SDP-6 / SDP-8

Table 1 List of other Installation, Operation and Maintenance manuals related to DigiTRON

product range

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

7 of 35

Unrestricted

2 BASIC INFORMATION & QUICK REFERENCE

2.1 Product overview

DigiTRON REDUs intended use is communication and distribution of low voltage between pieces of

electrical equipment that are submerged in water, e.g. subsea. The REDUs utilizes DigiTRON

connectors. The DigiTRON range of connectors have been developed for long term reliable

communications and low voltage power control system applications associated with offshore

installations. The underwater mating capacity of these connectors is achieved using pressure

compensated electrical inserts employing the CE principle.

An example is shown in section 2.7 to help identify the REDU product.

2.2 Product specification and certification

Basic specifications relating to all products covered by this manual are below in Table 2. Additional

specifications can be found in section 5.

Design Life:

30 years in subsea environment

Rated voltage

1,000Vac pin-ground, 2,000Vac pin-pin

Rated current

In water: 4-way 35-40A 7-way 22-32A 12-way 20-28A

In air: 4-way 18A 7-way 14A 12-way 11A

Over-current

100A for 5 seconds, no more than 2 per hour

Rated number of

operations

1000 (750dry/250wet) mate / de-mate cycles (Power off)

Water depth

3,000 m (9,843 ft)

Deployment and

retrieval rate

Max. 350m/min (1,150ft/min)

Storage temperature

-40°C +70°C (-40°F +158°F) (upper limit is surface temperature of the

product and includes solar gain from bright sunlight)

Operational temp

Subsea: -5°C +60°C (+23°F +140°F)

In air: -20°C +50°C (-4°F +122°F)

Weight

Up to 170kg (374 lb), depending on product configuration

(see shipping note, or specific product datasheet)

Product Certification:

Standard

Description

EU Directive

2001/95/EC

General Product Safety

EU Directive

2014/35/EU

Low Voltage Directive

IEC 61984

Connectors - Safety requirements and tests

API-17F

Standard for Subsea Production Control Systems

Note: Self-certified via in-house testing.

Table 2 DigiTRON product specification and certification

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

8 of 35

Unrestricted

2.3 Contact details and feedback

For additional information or questions regarding the products visit the Siemens website

www.siemens-energy.com /search Subsea, or contact the following:

Department

E-mail address

Product Safety Officer

subsea.connectors.productsafety.gb@siemens-

energy.com

Technical Support

connectortechnicalsupport.gb@siemens-energy.com

Service (Site Team)

susultlcmsupport.gb@siemens-energy.com

Sales

connectorsales.gb@siemens-energy.com

Table 3 DigiTRON product contact details

Any information, records, or Health and Safety feedback that needs to be detailed can be recorded

in section 10 of this document and sent to the relevant department in Table 3.

2.4 Product advice label

The following product advice label is supplied with all Siemens Energy subsea products.

Figure 1 Product advice label

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

9 of 35

Unrestricted

2.5 Product marking

Siemens Energy REDU products are marked with the Siemens Energy part number and unique

serial number. Also, the voltage, temperature and water depth ratings are indicated.

Typically these are etched on a yellow-coloured label permanently attached to the product (refer to

Figure 3)

Also, similar information relating to each connector is etched onto the connector metal body, refer

to Figure 2.

Figure 2 Product marking on DigiTRON product

2.6 CE label/marking

The CE label/marking where applicable shows that the products comply with the requirements of the

applicable directives as follows:

•2014/35/EU –Low Voltage Directive

Declaration of Conformity will be supplied with the goods.

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

10 of 35

Unrestricted

2.7 Product example

Figure 3 Typical REDU Box Assembly and Base Plate Assembly

Product identification label

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

11 of 35

Unrestricted

3 PRODUCT SAFETY

Siemens Energy Subsea recommends that the termination of all equipment shall only be undertaken

by trained, suitably qualified and experienced personnel (SQEP) i.e. competent person.

Following installation, commissioning or deployment of product, if you have any feedback please

complete and return the Customer Comments/Feedback form (Section 10). Please e-mail completed

form to the Product Safety Officer at subsea.connectors.productsafety.gb@siemens-energy.com

3.1 Action-related warnings

Classification of action-related warnings

The action related warnings are classified in accordance with the severity of the possible danger

using the following warning signs and signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental damage

3.2 Intended use

The product is intended as a Low Voltage electrical connection and distribution system for subsea

use. There is a risk of injury or death to the user or others, or of damage to the product and other

property in the event of improper use or use for which it is not intended.

Intended use includes the following:

- observance of the installation and operating instructions included for the product and any other

system components.

- compliance with all inspection and maintenance conditions listed in the instructions.

- use of all recommended tooling appropriate for specific tasks.

- all activities to be undertaken by a competent person (see 3.3.1 for definition).

Any other use that is not specified in this document or covered in installation and operating

instructions, or beyond that specified in this document shall be considered improper use.

Caution. Risk of material or environmental damage, improper use of any kind is prohibited.

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

12 of 35

Unrestricted

3.3 General safety information

Installation by competent persons only

The installation, inspection, maintenance and repair of the product shall be undertaken by trained,

suitably qualified and experienced personnel (SQEP) i.e. competent person, to carry out a specified

activity. Installation, inspection, maintenance and repair of products by untrained and deemed non-

competent persons could invalidate the product warranty. For further information contact Siemens

Personal protective equipment (PPE)

Personal Protective Equipment (PPE) is legally defined as ‘all equipment (including clothing affording

protection against the weather) which is intended to be worn or held by a person at work and which

protects the user against one or more risks to their health or safety’.

In the hierarchy of risk control, PPE is considered to rank lowest and represent the option of last

resort. PPE is only appropriate where the hazard in question cannot be totally removed or controlled

in such a way that harm is unlikely (for example by isolating the hazard or reducing the risk at source

to an acceptable level).

All company personnel and operators should wear appropriate Personal Protective Equipment (PPE)

defined as a result of relevant risk assessments in accordance with the Personal Protective

Equipment (PPE) Regulations.

Wear appropriate PPE according to the product safety advice given in this document

Danger caused by improper operation and foreseeable misuse

Improper operation and foreseeable misuse may present a danger to you and others and cause

material damage. Carefully read the enclosed instructions and all other applicable documents,

particularly the “Safety” section and the warnings.

Danger! Risk of death from electric shock if shuttle pins (on the plug connector) are

depressed e.g. with a screwdriver when plug is live (foreseeable misuse).

- Testing activities must only be carried out by a competent person.

- Correct test connector shall always be fitted for electrical testing.

Danger! Risk of imminent danger to life, risk of severe personal injury caused by a shuttle

pin projectile due to damage caused to shuttle pins e.g. with a screwdriver (foreseeable

misuse).

- Maintenance and testing activities must only be carried out by a competent person.

- Correct tools must always be used.

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

13 of 35

Unrestricted

Risk of death due to electrocution

Danger! Risk of death from electric shock due to exposed live pins, e.g. factory or top-side

system test and unmated receptacle is energised.

- Never energise a receptacle connector when not mated to a plug.

- Ensure all test procedures are followed.

- Communication channels and protocols are observed.

Danger! Risk of death from electric shock due to unscreened cables.

- Do not touch electrical wires while energised. Ensure all test procedures are followed.

Danger! Risk of death from electric shock from any exposed conductors due to stored

electrical energy, e.g. capacitance of cable or elsewhere in the system.

- Ground all electrical conductors after testing and do not touch conductors until

electrical system is fully discharged. Ensure all procedures are followed.

Danger! Risk of death from electric shock, if product is terminated incorrectly e.g. loose

conductor touching metal box or terminated to metal box in error.

- Installation/termination activities must be carried out by a competent person.

- Always electrically ground metal bodies prior to electrically energising a connector.

- Never hold the product when live.

Danger! Risk of death from electric shock or severe personal injury through burning from

de-mating live conductors by hand.

- Do not de-mate the product while live

- Never hold the product while live

- Ensure all procedures are followed for mating/de-mating connectors.

Risk of injury and material damage due to testing, maintenance and

repairs carried out incorrectly or not at all

The REDUs are non-serviceable by the user. In case of suspected faults with the product (refer to

section 8.2), do not use the product and contact Siemens Energy Technical Support or Siemens

Energy Product Safety for advice. Never attempt to carry out maintenance work or repairs on the

product yourself.

Danger! Risk of death from electric shock if user dismantles / incorrectly re-assembles /

incorrectly terminates product (foreseeable misuse).

- There are no parts of the product that require maintenance or inspection. The product

should not be disassembled.

- Termination of electrical wires to the product must only be carried out by a competent

person.

Danger! Risk of death from electric shock from improper use of test connector

(foreseeable misuse). In particular, removal of the rubber termination sleeves placed over

the joint between the cable and the test connector is prohibited, as this will expose live

parts to the user.

Never disassemble a test connector

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

14 of 35

Unrestricted

Warning. Risk of minor personal injury from high temperature of the product due to ohmic

heating in short-circuit condition or high over-currents.

- In the event of a high over-current, allow the connectors to cool before touching.

- Ensure all testing of products both factory and deployed in-field have been completed

by competent persons.

Danger! Risk of severe personal eye injury due to pressurised oil squirting out of damaged

hose or removal of fill/vent screw.

- Ensure all testing of products both factory and deployed in-field have been completed

by competent persons.

Warning. Risk of eye/bodily injury caused by released pressure during product

disassembly, in the event of retrieval from subsea with a fault that causes depth pressure

to be trapped inside the product.

- Ensure all product disassembly activities are completed by competent persons in

accordance with relevant procedures and using relevant personal protective

equipment (PPE).

Warning. Risk of bodily injury caused by pressure retaining parts becoming projectile due

to user over-pressurising the system, e.g. during Site Installation Test (SIT).

- Ensure all product SIT activities are completed by competent persons in accordance

with relevant procedures.

Risk of injury and material damage due to manual handling

Manual handling, lifting and carrying are known to be one of the largest contributors to occupational

ill-health. Ensure mechanical handling aids are used wherever possible to avoid manual handling.

Where manual handling is considered appropriate for the task, safe lifting guidelines must be

followed, e.g. adopt correct posture, consider team lifting, employ safe lifting technique, etc. Only

competent persons are permitted to perform tasks without supervision, if in doubt ask.

Warning. Risk of musculoskeletal injury from mating or de-mating connectors by hand.

- Referring to the mate / de-mate forces specified herein, ensure suitable manual

handling precautions are taken.

Ensure all product testing activities are completed by competent persons in accordance

with relevant procedures.

- Warning. Risk of musculoskeletal injury from manual handling of heavy products.

Refer to section 2.2 (Table 2) or shipping information or product datasheet for weights

of the product.

- Ensure mechanical handling aids are used wherever possible to avoid manual

handling.

- Where manual handling is considered appropriate for the task, safe lifting guidelines

must be followed, e.g. adopt correct posture, consider team lifting, employ safe lifting

technique, etc.

Only competent persons are permitted to perform tasks without supervision, if in doubt

ask.

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

15 of 35

Unrestricted

Warning. Risk of bodily injury from heavy product falling during lift with machinery.

- Ensure machinery/slings used have been tested and are within their expiry date.

- Safe lifting guidelines must be followed, e.g. lifting plan, banksman, etc.

- Correct lifting points must be identified and used.

Only competent persons are permitted to perform tasks without supervision, if in doubt

ask.

Warning. Risk of minor personal injury to persons with sensitivities to silicone or mineral

based oils.

There is a small risk that oil could leak from the product if faulty. Wear appropriate hand

protection when handling products or mineral or synthetic based oils in case oils leak

from the connector due to a fault.

Warning. Risk of minor personal injury and material damage due to slips, trips and falls.

Good housekeeping avoids slips, trips and falls, keep all work areas clean and tidy.

3.4 Related documents

Installers shall carry out a full site risk assessment and put into place all necessary steps and

procedures to comply with applicable area, regional, national or international health and safety

legislation, e.g. The Health and Safety at Work Act (HASAWA) in the United Kingdom (UK) and

ensure safety of themselves and others regarding manual handling and working at height

requirements.

During the product installation (and any subsequent work) it will be necessary to employ caution. All

installers and operatives involved from unloading the product until it is deployed in its final installed

location must exercise a full duty of care for themselves and others regarding safety. When lifting

and handling this product, operatives should employ assistance if required. In certain situations, it

may be necessary to use mechanical handling aids. Take care to avoid trip hazards, slippery or wet

surfaces.

Employers and installers should refer to the Health and Safety Executive (HSE) web site in the UK

for full advice and manual handling assessment charts (MAC) tool.

In addition, where no specific instructions are given then reference shall be made, but not restricted

to, where applicable, British Standards and codes of practice such as the following:

- The Health and Safety at Work Act.

- COSHH Control of substances hazardous to health.

- BS 7671 Requirements for electrical installations. IEE Wiring Regulations.

- The Electricity at Work Regulations.

It is the operator’s and installers responsibility to comply with current Company, area, regional,

national or international health and safety legislation.

3.5 Control of substances hazardous to health (COSHH)

Hazardous substances, Control of substances hazardous to health (COSHH) Assessments regards

to materials such as elastomers and oils, etc. used in DigiTRON products are available on request

from the Product Safety Officer at subsea.connectors.productsafety.gb@siemens-energy.com.

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

16 of 35

Unrestricted

4 ABBREVIATIONS

°C Degree Celsius

°F Degree Fahrenheit

A Ampere

ac Alternating Current

API American Petroleum Institute

CE Community European

COSHH Control of substances hazardous to health

CP Cathodic Protection

dc Direct Current

DWG Drawing

EDU Electrical Distribution Unit

EFL Electrical Flying Leads

EMF Electrical Magnetic Field

M Metres

Max. Maximum

Min. Minimum

No. Number

PPE Personal Protective Equipment

REDU Retrievable Electrical Distribution Unit

ROV Remotely Operated Vehicle

SIT Site Installation Test

UNS Unified Numbering System for Metals and Alloys

V Volt

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

17 of 35

Unrestricted

5 SPECIFICATIONS

The following is a basic specification for DigiTRON ROV connectors utilized in the REDUs. Actual

product may vary. Please refer to product specific data sheet(s), website www.siemens.com/subsea

more detailed information.

General specification of the product is listed in section 2.2.

5.1 ROV operated Connector Specification

4 & 7-way

12-way

Misalignment Type

Rotational (0º)

±15º

±15º

Radial

±20mm (0.787”)

±20mm (0.787”)

Angular

±20º

±20º

Mate force

<300N (67 lb)

<500N (67 lb)

De-mate force

240 –360N (54 –81 lb)

480-800N (54 –81 lb)

Maximum mate and de-mate speeds

1 m/s (3.3 ft/s)

1 m/s (3.3 ft/s)

Overload withstand

Axial load

9800N (2,198 lb)

9800N (2,198 lb)

Bending load

500Nm (369 lbf.ft)

500Nm (369 lbf.ft)

Torsion load

500Nm (369 lbf.ft)

500Nm (369 lbf.ft)

Limit of exposure of male pins to seawater 28 days cumulative over lifetime

Table 4 DigiTRON ROV connector specification

Caution. Risk of material damage. Maximum cumulative exposure of the male pins to

seawater is 28 days to prevent corrosion of the pins. If the connectors are to be left

unmated, in seawater, for any length of time Subsea Environment Cap or Dummy Plug

must be fitted to protect the pin contacts in the receptacle connectors. Over exposure will

increase the risk of corrosion damage or marine growth on the contact surfaces of the

receptacle contact pins. This could lead to damage to the seals and insulation within the

plug socket contacts. Plug connectors do not require full dummy connectors for

protection. Siemens Energy Subsea advise the fitting of subsea caps to protect plugs

against marine growth. It is good practice to always fit the protective cap when a

connector is unmated topside prior to deployment to provide mechanical protection.

Caution. Risk of material damage. Unmated receptacles (exposed male pins) should

never be electrically energised subsea (even a small residual voltage). This will very

quickly corrode the pins or cause complete electrical failure of the product.

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

18 of 35

Unrestricted

6 PREPARING PRODUCT FOR USE OR STORAGE

6.1 Product protection and packaging

The REDU is designed to withstand vibration that occurs during transportation. The REDU is

manufactured primarily from 316L stainless steel (UNS S31603), and as such is designed to

withstand harsh environments. However, if not adequately protected, the connector inserts and

exposed parts are susceptible to mechanical damage. Transport caps are fitted to all DigiTRON

connectors before transport, but topside protective caps will be fitted if specified by the customer.

Care should be taken to protect the connectors with bubble wrap or similar wrapping materials to

avoid surface damage during transit.

Caution. Risk of material damage. Transport caps or topside protection caps must always

be fitted to an unmated connector during transport, and should remain in place while

topside before deployment

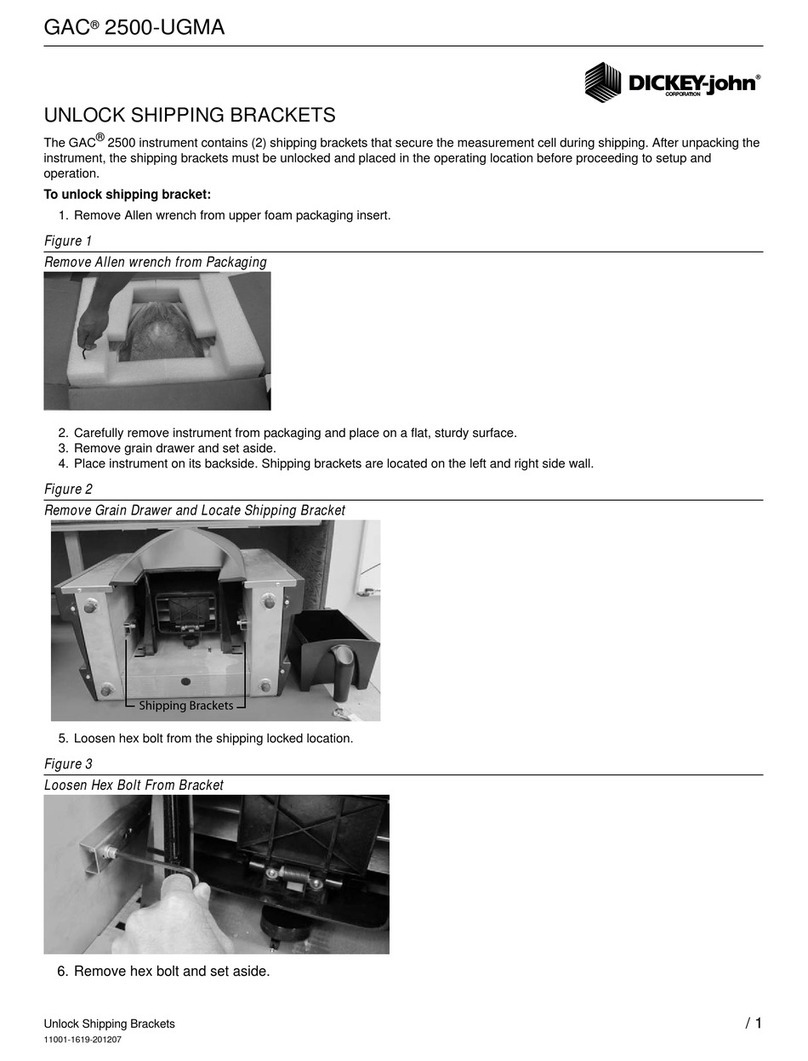

6.2 Lifting

Never attempt to lift the assembly or any part of it manually. Always use a crane or other suitably

rated lifting device.

The REDU box is equipped with two ROV compliant lifting eyes. These two lifting eyes are to be

used to secure buoyancy aids when deployed; they may also be used for handling of the REDU box

prior to deployment.

Ensure the lifting eyes have been assembled and fixed in the correct orientation as shown on the

relevant assembly drawing.

The ‘T’ bar handle should not be used as a sole lifting point until the assembly is subsea and should

only be used to lift the REDU box from the base plate (Figure 4).

Figure 4 REDU lifting points

The REDU box and base plate are NOT to be lifted as a single assembly; there is no locking feature

between the base and the main body. Utilize the two lifting bolts on the REDU box and the 4 lifting

eyes on the Base assembly during any handling manoeuvre (Figure 4).

T-bar for subsea use only

and only for REDU body

Lifting shackles for use

topside or subsea

Lifting eyes for

Base Plate only

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

19 of 35

Unrestricted

6.3 Unpacking

Remove wrapping material taking care to inspect for any surface damage or items that may have

become separated from the product.

For parts supplied individually and wrapped in materials, do not use a knife to cut the wrapping

material, as this may cause damage to any elastomeric parts or painting of the product.

Do not remove transport or topside protection caps until the REDU is ready for installation.

6.4 Storage, protection, and end of life

All connectors come supplied with a transport cap. It is recommended to leave the caps on whenever

possible. The caps must be removed before subsea deployment.

Connector may be fitted with a back plastic Topside Protective Cap (Figure 12), which is available

to purchase separately (customer preference). These caps provide a higher degree of mechanical

protection to the connector than the transport caps.

Refer to section 9.4 for details on the types of caps and dummy connectors available for protection

during storage.

If product has been recovered from subsea use, it should be cleaned before storage. Clean only with

fresh water or 50% citric acid solution. If 50% citric acid wash is not performed, as a minimum, wash

with clean water to remove any saltwater on the products.

Short term storage

Prior to installation the connectors on the REDU are sensitive to environments where grit and dirt

are present. To prevent ingress of the above, they should be stored in a clean dry area and the

connectors should be protected by transport caps or topside protection caps. Transport caps or

protection caps to be removed prior to deployment only.

No carbon steel must be present in the storage of the products to avoid contamination of the stainless

steel.

Transport Cap or Topside Protection Cap for the Stab Plate Connector (Dummy Connector) on the

Base is to be removed prior to deployment only. The protection caps should be removed as late as

possible prior to the Box being installed onto the Base.

Caution. Risk of material damage. Maximum storage temperature accounts for solar gain.

Skin temperature must not exceed 70°C. Suitable protection must be used to ensure

maximum storage temperature is not exceeded.

Caution. Risk of material damage. If storage is carried out in saline conditions, e.g. on a

ship’s deck or hold, then a Subsea Environment Cap or Dummy Plug connector should be

used to protect the receptacle pins from corrosion.

Document No:

IOM-006

Issue Date:

16/11/2020

Revision:

3

Page:

20 of 35

Unrestricted

Long term connector storage

The REDUs must be stored in a clean dry area and be protected by bubble wrap or similar. Suitable

protection caps must be fitted and the storage temperature should be between -40°C and 70°C (-

40°F +158°F). Humidity of the storeroom should be below 75%. Very moist or very dry conditions

should be avoided. The Plug connectors should be protected from strong sunlight and strong

artificial light with a high ultra violet content.

Caution. Risk of material damage. Maximum storage temperature accounts for solar gain.

Skin temperature must not exceed 70°C. Suitable protection must be used to ensure

maximum storage temperature is not exceeded.

Caution. Risk of material damage. Connectors should not be allowed to encounter

solvents, oil, grease or other semi-solid materials.

Repackaging to prevent damage in transport

In the event of a requirement to return the REDU back to Siemens Energy, the REDU should be

transported back in its designated transportation Box. Transport or topside protective cap should be

fitted to the connector(s) and care should be taken to protect the connector(s) with bubble wrap or

similar wrapping materials to avoid any surface damage. Contact Siemens Energy Technical Support

connectortechnicalsupport.gb@siemens-energy.com to discuss details of typical boxes.

Disposal and recycling

Safe disposal or recycling of waste packaging and/or end of life product is recommended by correctly

observing and complying with area, regional, national or international environmental legislation

where applicable.

To return waste packaging and/or end of life product to the manufacturer, contact the Product Safety

Officer at subsea.connectors.productsafety.gb@siemens-energy.com.

This manual suits for next models

1

Table of contents

Other Siemens Energy Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Dickey-John

Dickey-John GAC 2500-UGMA manual

ABB

ABB CPS6000 product manual

Thermo Scientific

Thermo Scientific System IV Installation, Operation, Basic Maintenance

Emerson

Emerson Fisher ATST Desuperheater instruction manual

Eaton

Eaton Airflex WCB2 Series Installation, operation and maintenance manual

Parker

Parker Pneudri Maxi user guide