-1-

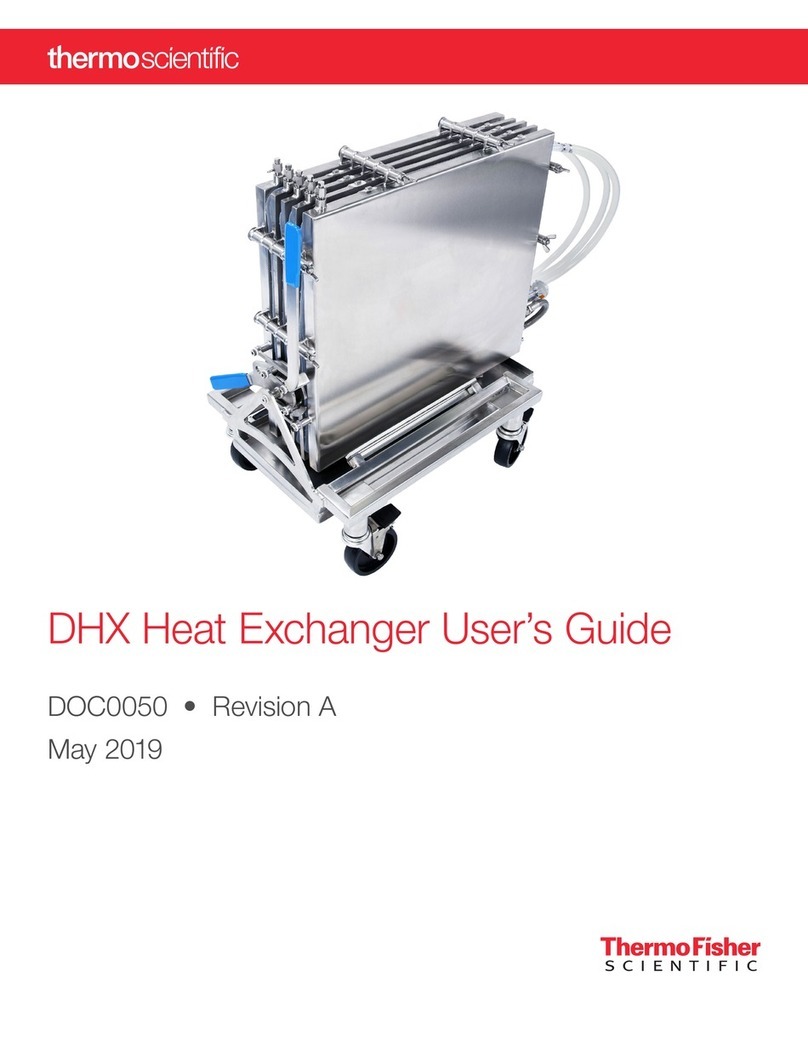

System IV Liquid to Liquid Heat Exchanger

Instruction and Operation Manual

Table of Contents

PREFACE

Compliance ............................................................................................ 3

WEEE/RoHS .......................................................................................... 3

After-sale Support ................................................................................... 4

Warranty ................................................................................................. 4

Unpacking .............................................................................................. 4

Out of Box Failure................................................................................... 4

SECTION I

Safety

Warnings ................................................................................................ 5

SECTION II

GeneralInformation

Description ............................................................................................. 6

Specifications ......................................................................................... 6

SECTION III

Installation

Site......................................................................................................... 7

Facility Water Requirements................................................................... 7

Electrical Requirements .......................................................................... 8

Voltage Selection ................................................................................... 8

Plumbing Requirements .......................................................................... 8

Fluids ..................................................................................................... 9

Filling Requirements ............................................................................... 10

Auto Refill Device (Optional) .................................................................... 10

Flow Control ........................................................................................... 10

Auto Restart ........................................................................................... 10

SECTION IV

Operation

Start Up .................................................................................................. 11

Temperature Controller ............................................................................ 12

Tune Loop ............................................................................................... 13