SITRANS WS300

Operating Instructions, 04/2021, A5E45050935-AC 3

Table of contents

1 Introduction ........................................................................................................................................... 5

1.1 Operating instructions scope................................................................................................ 5

1.2 Purpose of this documentation ............................................................................................ 5

1.3 Industrial Use Note .............................................................................................................. 5

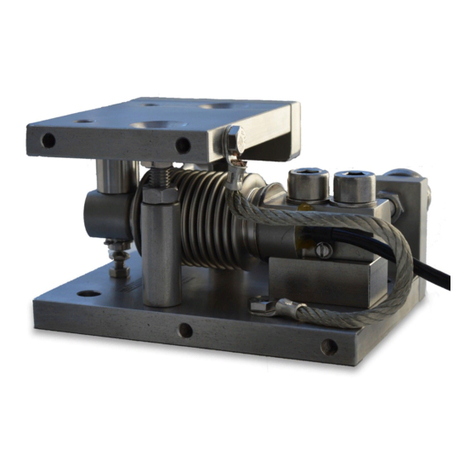

2 Description............................................................................................................................................. 6

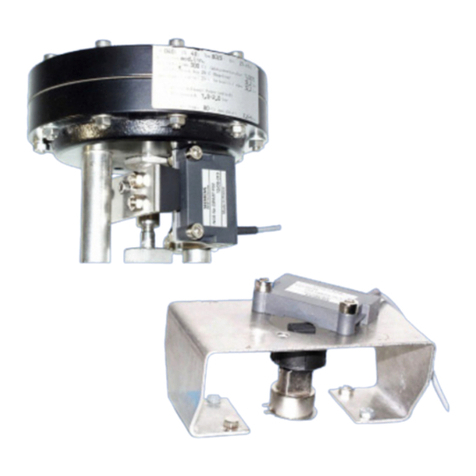

2.1 SITRANS WS300 speed sensor overview ............................................................................... 6

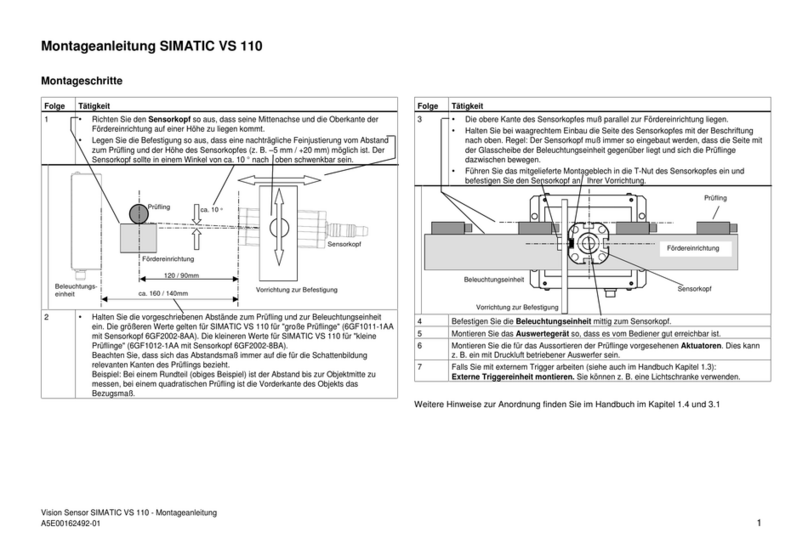

3 Installing/mounting ............................................................................................................................... 7

3.1 Installation note................................................................................................................... 7

3.2 Dimension drawings ............................................................................................................ 7

3.3 Mounting ............................................................................................................................ 8

3.4 Mounting to a tail pulley...................................................................................................... 9

3.5 Mounting to a bend or snub pulley..................................................................................... 11

3.6 Mounting using optional threaded shaft coupling............................................................... 13

3.7 General installation steps................................................................................................... 14

3.8 Hazardous area installations............................................................................................... 16

3.8.1 Product nameplates ........................................................................................................... 16

3.8.2 Instructions specific to hazardous area installation ............................................................. 18

4 Connecting .......................................................................................................................................... 20

4.1 Interconnection ................................................................................................................. 20

4.2 Terminals (standard version).............................................................................................. 21

4.2.1 Terminal connections to Siemens Milltronics integrators..................................................... 22

4.2.2 Terminal connections to SIWAREX FTC integrator ............................................................... 22

4.2.3 Terminal connections to WL241 ......................................................................................... 22

4.3 Terminals (IS version) ........................................................................................................ 23

4.3.1 Terminal connections to Siemens Milltronics integrators..................................................... 23

4.3.2 Terminal connections to SIWAREX FTC integrator ............................................................... 23

4.3.3 Terminal connections to WP241......................................................................................... 24

5 Service and maintenance .................................................................................................................... 25

5.1 Inspection.......................................................................................................................... 25

5.2 Recommended spare parts................................................................................................. 25