Page 6 SITRANS LR 400 – INSTRUCTION MANUAL 7ML19985FH03

mmmmm

Specifications

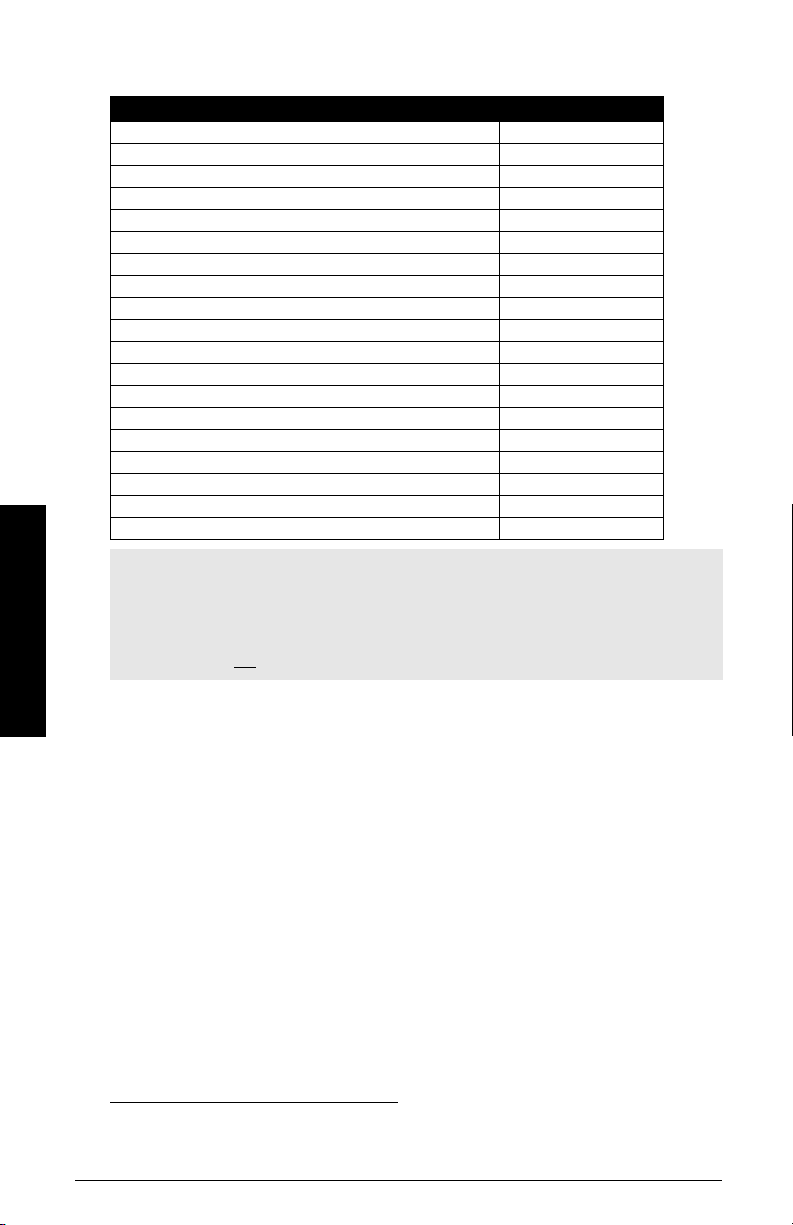

Weight

• Weight of instrument and flange

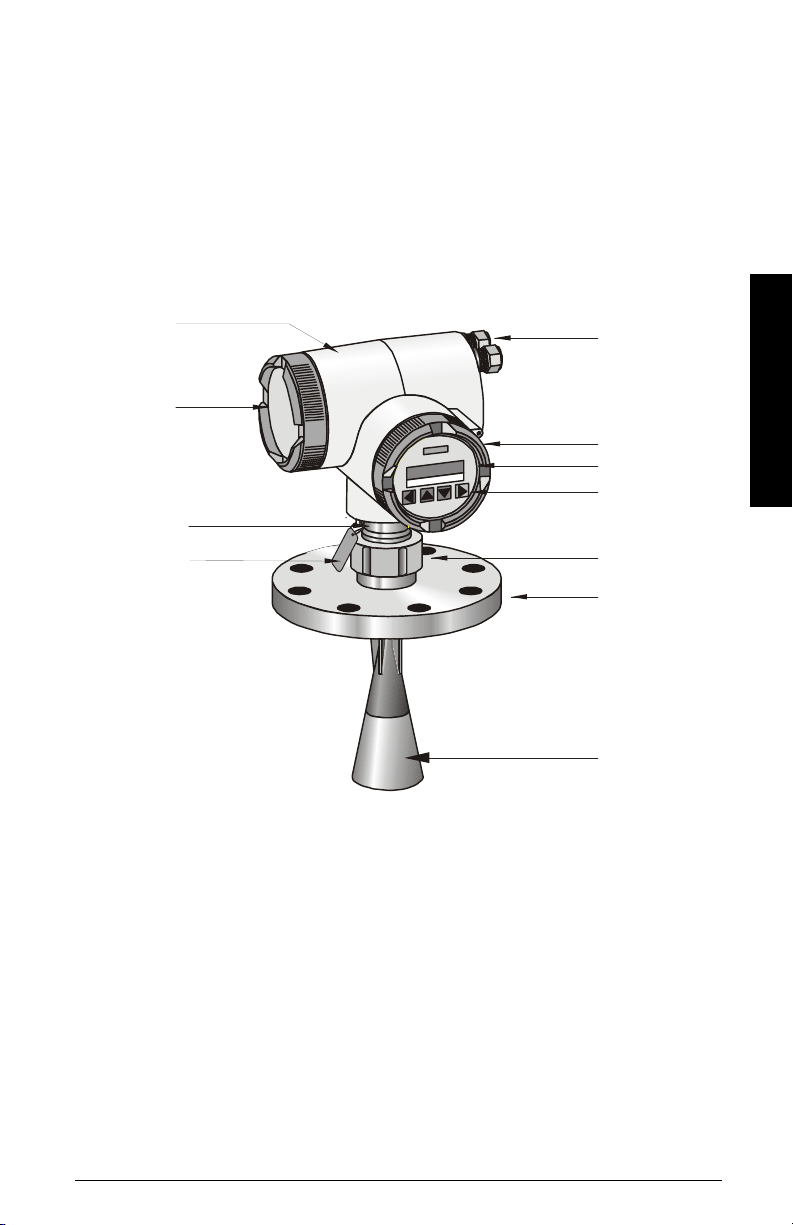

Enclosure

• construction Die-cast aluminum, painted

• conduit 2 x M20

or 2 x ½” NPT

• ingress protection Type 4X/NEMA 4X, Type 6/NEMA 6, IP 671

Environmental2

location: indoor/outdoor

altitude: 2000 m max

ambient temperature: -40 to 65°C (-40 to 149°F)

relative humidity: suitable for outdoor (Type / NEMA 4X, 6/ IP67)

installation category II

pollution degree 4

• Process Temperature -40 to 200°C (-40 to 392°F),optional -40 to 250°C

(-40 to 482°F)

Process Connection Weight

Universal, 3" / 80 mm, flat faced, 0.5 bar maximum 10.9 kg (24 lbs)

Universal, 4" / 100 mm, flat faced, 0.5 bar maximum 12.7 kg (28 lbs)

Universal, 6" / 150 mm, flat faced, 0.5 bar maximum 15.0 kg (33 lbs)

DN80 PN16, flat faced 11.9 kg (26.1 lbs)

DN80 PN40, flat faced 12.9 kg (28.4 lbs)

DN100 PN16, flat faced 13.2 kg (28.9 lbs)

DN100 PN40, flat faced 15.5 kg (34.1 lbs)

DN150 PN16, flat faced 19.2 kg (42.1 lbs)

DN150 PN40, flat faced 24.1 kg (43.1 lbs)

3", 150 lb class, raised faced 12.2 kg (26.8 lbs)

3", 300 lb class, raised faced 14.3 kg (31.5 lbs)

4", 150 lb class, raised faced 14.8 kg (32.5 lbs)

4", 300 lb class, raised faced 20.2 kg (44.4 lbs)

6", 150 lb class, raised faced 20.1 kg (44.2 lbs)

6", 300 lb class, raised faced 31.8 kg (69.9 lbs)

JIS DN80 10K, flat faced 11.9 kg (26.1 lbs)

JIS DN100 10K, flat faced 13.2 kg (28.9 lbs)

JIS DN150 10K, flat faced 19.2 kg (42.1 lbs)

Easy Aimer 11.8 kg (26 lbs)

Note:Please ensure these are the most recent specifications. Contact your Siemens

Milltronics representative, or check our web site at www.siemens-milltronics.com for

the most up-to-date information.

WARNING: This product is designated as a Pressure Accessory per Directive

97/23/EC and is not intended for use as a safety device.

1. Use only approved, suitable sized hubs for watertight applications.

2. See Process/Ambient de-rating curves in Appendix III.