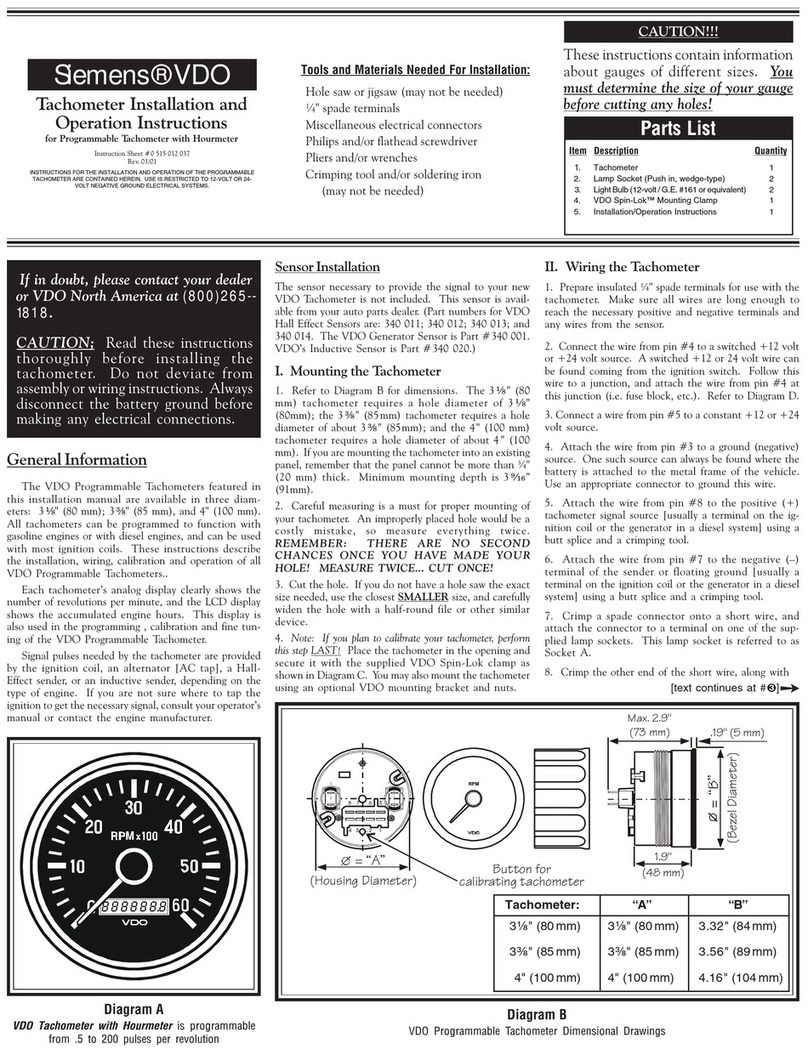

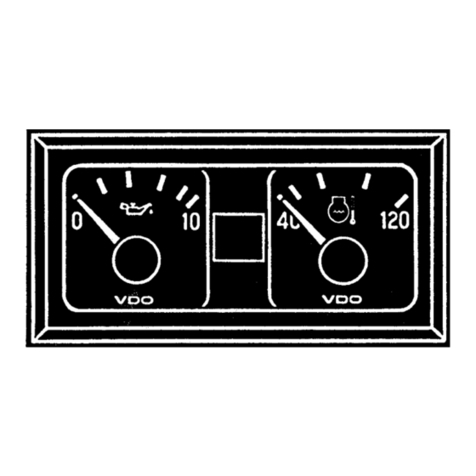

9'2 6SLQ/RN

0RXQWLQJ &ODPS

9'2

0RXQWLQJ

%UDFNHWV

RSWLRQDO

'DVK 3DQHO

è > PP@

0D[LPXP 7KLFNQHVV

'DVK 3DQHO

ê > PP@

0D[LPXP 7KLFNQHVV

0LQLPXP 0RXQWLQJ 'HSWK

PP

0LQLPXP 0RXQWLQJ 'HSWK

Diagram G

LCD Sequences as they appear during Automatic

Calibration

2. Manual Calibration with a known value

()

If you know the exact calibration value for the vehicle and

type of sensor you are using (pulse-per-mile or pulse-per-

kilometer), you may use that value to manually calibrate the

speedometer.

To calibrate your VDO Speedometer manually:

1. Press and hold in the button on the front of the speed-

ometer as you turn on the ignition. Hold in the button until

the word is displayed on the LCD readout.

Diagram H

LCD Sequences as they appear during Manual Calibration

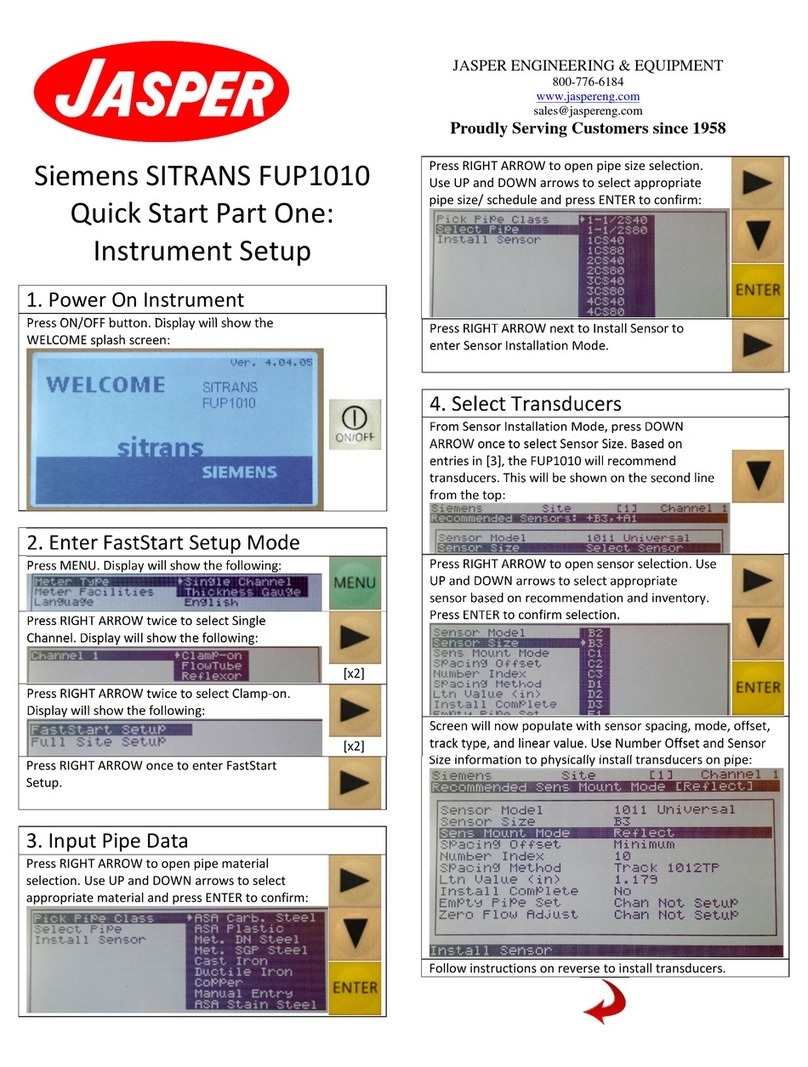

Diagram C

Proper mounting of the VDO Speedometer

Calibration of the VDO Speedometer with LCD Display is

a relatively simple procedure, and can be accomplished in

any of three ways:

·Automatic calibration when driving on a

road with the exact distance of 1 mile

clearly defined; or on a dynomometer...

·By the input of the known pulse-per-mile

(kilometer) for the vehicle and sensor

being used with the speedometer...

·Using a reference point for adjustment

or fine tuning.

You gain access to the calibration functions by pressing the

button on the front of the speedometer and holding it in

while you turn on the ignition. As you continue to hold in

the button, the display will change...scrolling through the

three calibration methods and stopping on each one for about

two seconds.

III. Calibrating the Speedometer

Ì

Diagram E

The LCD on the speedometer will show this display

during, then after the self-test.

Diagram F

Calibration modes as displayed on the Speedometers LCD

However, if the speedometer detects any kind of error dur-

ing your run, the LCD will display the following message:

F 0.0 . This means no useable impulse was detected.

In this case, simply turn off the ignition, and start the pro-

cess again.

REMEMBER: During the auto-calibration run, the

pointer on the speedometer will not operate.

1. Autocalibration ( )

The display lists the auto-calibrate mode as ;

the pulse-per-mile mode as ; and the reference/

fine-tune mode as . When you see the method

you wish to use, let go of the button and that function will

be enabled. See Diagram F.

The auto-calibration function can be used successfully only

on: Ê A road with the distance of one mile accurately des-

ignated or Ë A dynomometer.

To use the autocalibrate mode:

1. Press the button on the front of the speedometer, hold it

in, and start the engine. Release the button when the dis-

play reads, .

2. After three seconds, the word will show on

the display. When you are ready to begin your calibration

run, press the button again. The display will now begin flash-

ing the word .

3. Drive the reference distance of one mile (or 1 kilome-

ter). NOTE: As you drive this distance, the speedometer

needle will not register or move. This is a normal occur-

rence during the autocalibration process.

4. When you have gone exactly one mile, press the button

again. If the electronic impulse rate detected by the

speedometers microprocessor is within the calibration range

limits of 500 to 399,999, the rate will be shown on the LCD

display. For example, your reading might be P16000 =Cali-

bration Range 16000). Such a display indicates that the

impulse rate detected during the reference mile you drove

exactly matches the microprocessors programmed rate for

1 mile. That means the speedometer is now perfectly cali-

brated to provide the most accurate display possible of both

speed and distance. The speedometer finishes its

autocalibration by moving the pointer through a full sweep,

then back down to zero.

MPH

km/h

_b

_b

MPH

km/h

_b

4ebY^WdUcd

1VdUbdUcd

DbY`4YcdQ^SU

D_dQ\4YcdQ^SU

MPH

km/h

dXU^

dXU^

3_]Uce`QVdUb#cUS_^Tc

3_]Uce`gXU^i_e`ecXRedd_^

GXU^²cdQbd³Q``UQbcRUWY^

TbYfY^W

dUcd

]Y\U

MPH

km/h

1^e]RUbS_]Uce`gXU^

i_ebU\UQcUdXURedd_^

4YWYdcRUWY^V\QcXY^WcdQbdY^WgYdX

dXUcUS_^TTYWYdVb_]dXUbYWXd

dXU^

dXU^

5. For wiring of the lights, see Diagram D.

6. Reconnect the battery and turn on the ignition to make

sure the speedometer is working. When you turn on the

ignition, the speedometer will do an automatic self-test. Dur-

ing this self-test, the pointer moves over the whole scale

range, and the LCD display shows the word . After

the test is completed, the display will reveal either the trip

distance or the total distance, depending on which one was

selected when the ignition was turned off. Since this is the

first time power has been applied to the instrument, the read-

ing will be 0.0 , or 0.0 . If everything is working

properly, the installation is complete. If it isnt, re-check

your wiring.

2. As soon as you see the word , release the

button. After a few seconds, the display will start flashing a

series of numbers (factory default setting) that you can

change to represent the correct calibration impulse value.

For example, a number like 50000 will show on the display,

with each digit flashing in turn, except for the last digit on

the right, which is fixed: first, the second 0from the right;

then the third 0 from the right; then, thenext 0; and finally,

the 5.

3. As each number flashes, press the button to change it

until the correct digit appears (that is, the number you wish

to input).

For example, lets say the number that represents the cor-

rect calibration value for your vehicle and sensor is 43850.

When you begin the manual calibration process, the LCD

displays a default value. Each digit, except the one farthest

to the right, will flash, in turn, from right to left. Wait until

the second digit from the right starts to flash again. When it

does, press the button to start cycling through the numbers

available for this digit. When the number 5 appears, re-

lease the button.