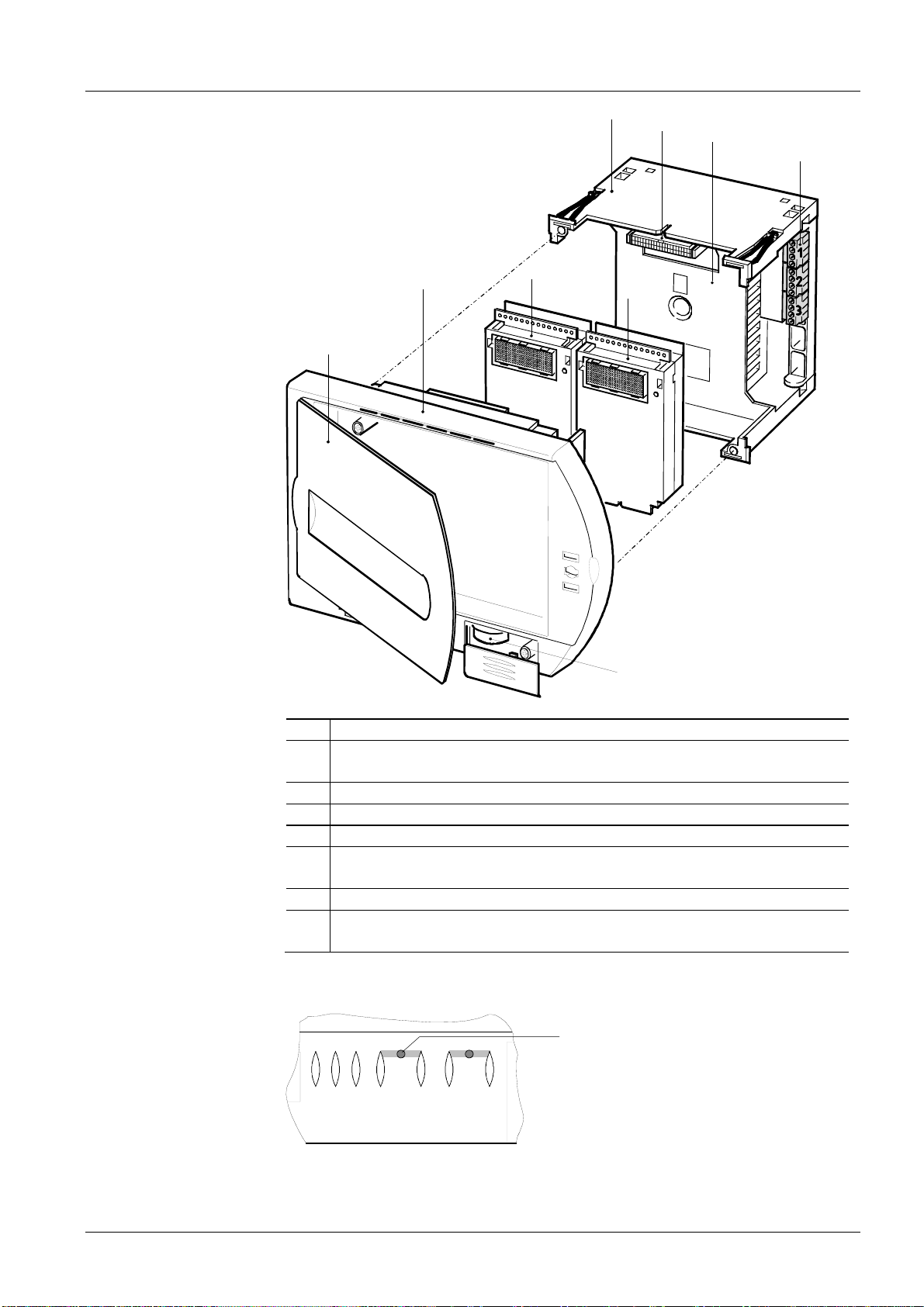

Siemens DESIGO PX -U Series User manual

Other Siemens Measuring Instrument manuals

Siemens

Siemens Sitrans F Series User manual

Siemens

Siemens SENTRON PAC2200 User manual

Siemens

Siemens SITRANS FUH1010 User manual

Siemens

Siemens SITRANS F M MAG 3100 User manual

Siemens

Siemens 3KF9010-1AA00 User manual

Siemens

Siemens SIPROCESS GA700 User manual

Siemens

Siemens SITRANS F M MAGFLO User manual

Siemens

Siemens 13-xx-ST-SBT Series Operation manual

Siemens

Siemens MD-P1 User manual

Siemens

Siemens FIDAMAT 5E User manual

Siemens

Siemens SITRANS F US SONO 3300 User manual

Siemens

Siemens Milltronics BW500 Instruction sheet

Siemens

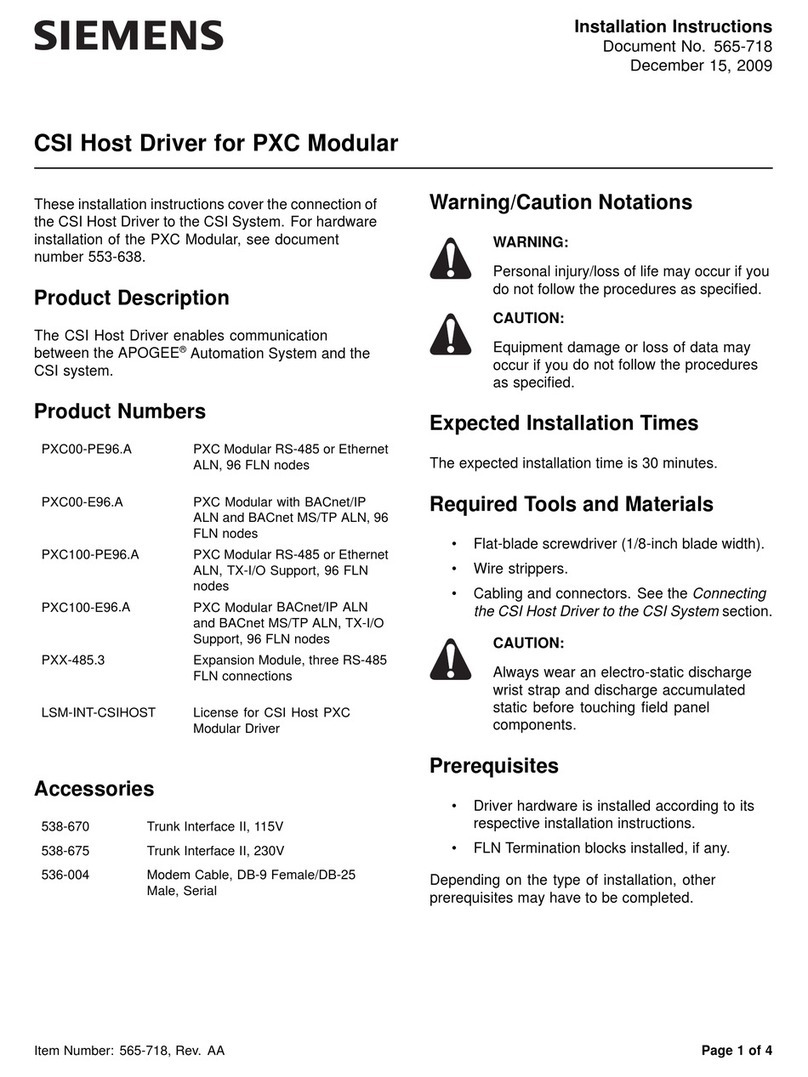

Siemens CSI Host Driver User manual

Siemens

Siemens SITRANS F US User manual

Siemens

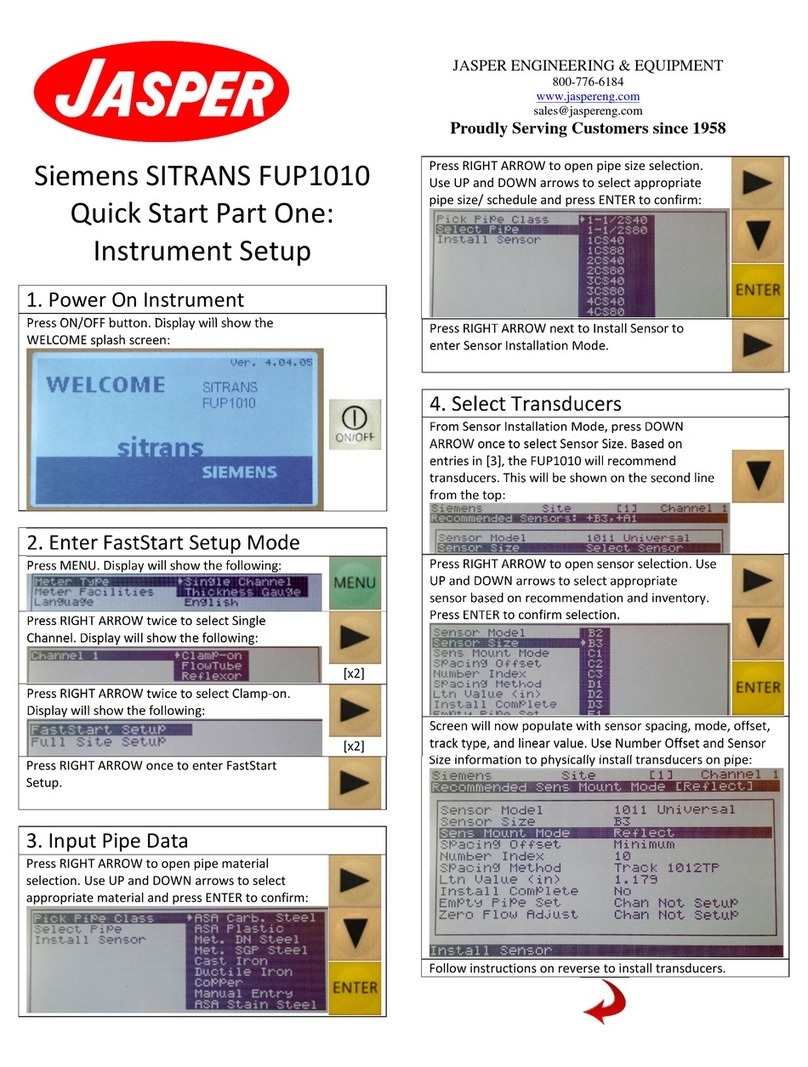

Siemens SITRANS FUP1010 User manual

Siemens

Siemens SENTRON ATC6300 User manual

Siemens

Siemens FS20 User guide

Siemens

Siemens SITRANS F M MAG 3100 User manual

Siemens

Siemens SIPROCESS GA700 User manual

Siemens

Siemens SITRANS F User manual