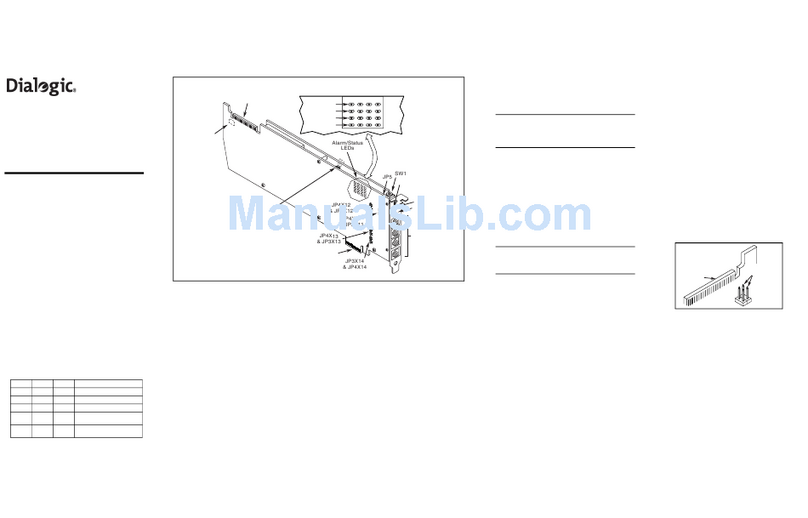

Input Point Module (AFI5100)

1.7 Links and Jumpers

The following table outlines the link settings for the AFI5100 :

Link Description Value

LK1, LK2 Links 1 and 2 are used to configure

whether Fire Over-ride (FOR) will oper-

ate in Enhanced FOR mode or Normal.

Enhanced mode also requires the

connection of a supervision circuit to

the Fire Over-ride Input.

To enable Normal

Mode:

LK1 LK2

NORMAL

FOR

To enable En-

hanced Mode:

LK1 LK2

NORMAL

FOR

LK4, LK6 Links 4 and 6 control whether Fire

Over-ride (FOR) is enabled.

If the links are set to FOR operation,

activation of the FOR input will cause

the outputs to return to the NO position.

If the links are set to the off position,

FOR input will have no effect on the

state of the output relays.

FOR operation

active:

LK4 LK6

FORENABLE

FOR operation

ignored:

ENABLE

LK4 LK6

FOR

LK3, LK5 These auxiliary links have been included for further enhancement of the system.

LK7 LK7 affects the reset action when the

RESET link (LK9) is set and the power

turned on.

See LK9 below for a description of how

to reset the unit.

LK7

If the jumper on Link 7 is set as shown,

it is set to “Full Reset” mode.

LK7

If the jumper on Link 7 is taken off, it is

set to “Partial Reset” mode.

LK8 This is a General Purpose links that has been included for further enhancement

of the system.

LK9 Memory Clear and Reset

Setting LK9 and turning the power off and on will reset the IPM. A full or partial

reset can be achieved by setting LK7 on or off.

If LK7 is set, the IPM will fully reset and any firmware loaded into the memory will

be erased. You will need to re-program the IPM with firmware again before it can

operate.

If LK7 has the jumper removed, the microcontroller will be rebooted but the firm-

ware will remain in memory.

LK10 EOL Termination (Bus)

This link allows the RS485 BUS com-

munications channel to be terminated

in noisy or lengthy comms.

Note: Units located at the end of bus

lines only should have this link set.

RS485 BUS port

not terminated.

LK10

EOL

RS485 BUS port

terminated.

LK10

EOL

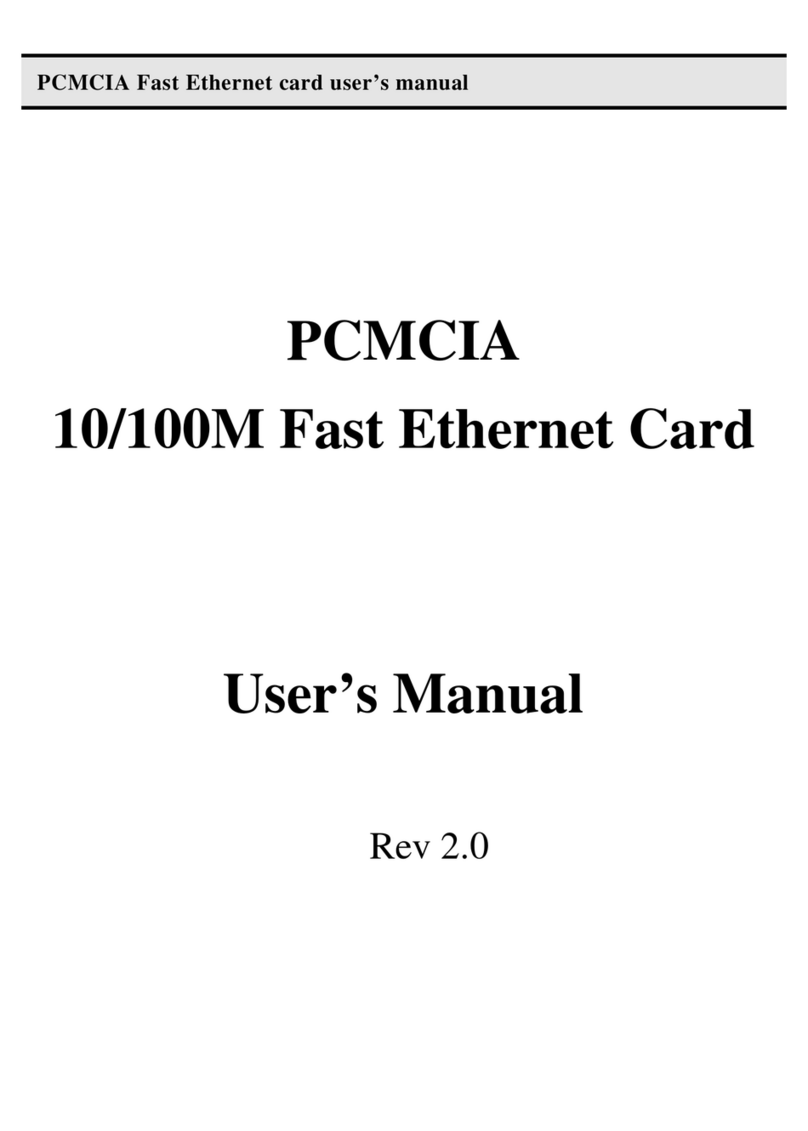

LK11 – LK14 FOR Activation

These links allow FOR activation to be

enabled or disabled for each individual

relay output.

Enabling Fire Override for a relay

means that when the FOR input is

activated, the relay output switch to the

NO position.

LK11

FOR EN

FOR DIS

LK12

In the above diagram LK11 (Relay 1) is

set to FOR Enabled and LK12

(Relay 2) is set to FOR Disabled.

9

Siemens Building Technologies

Fire Safety & Security Products 02.2005