Table of contents

1 Preface ...................................................................................................................................................... 5

1.1 Note on the SIMATIC NET glossary ..............................................................................................6

2 Instructions for fitting connectors, attachments and devices...................................................................... 7

2.1 Note on the installation instructions ...............................................................................................7

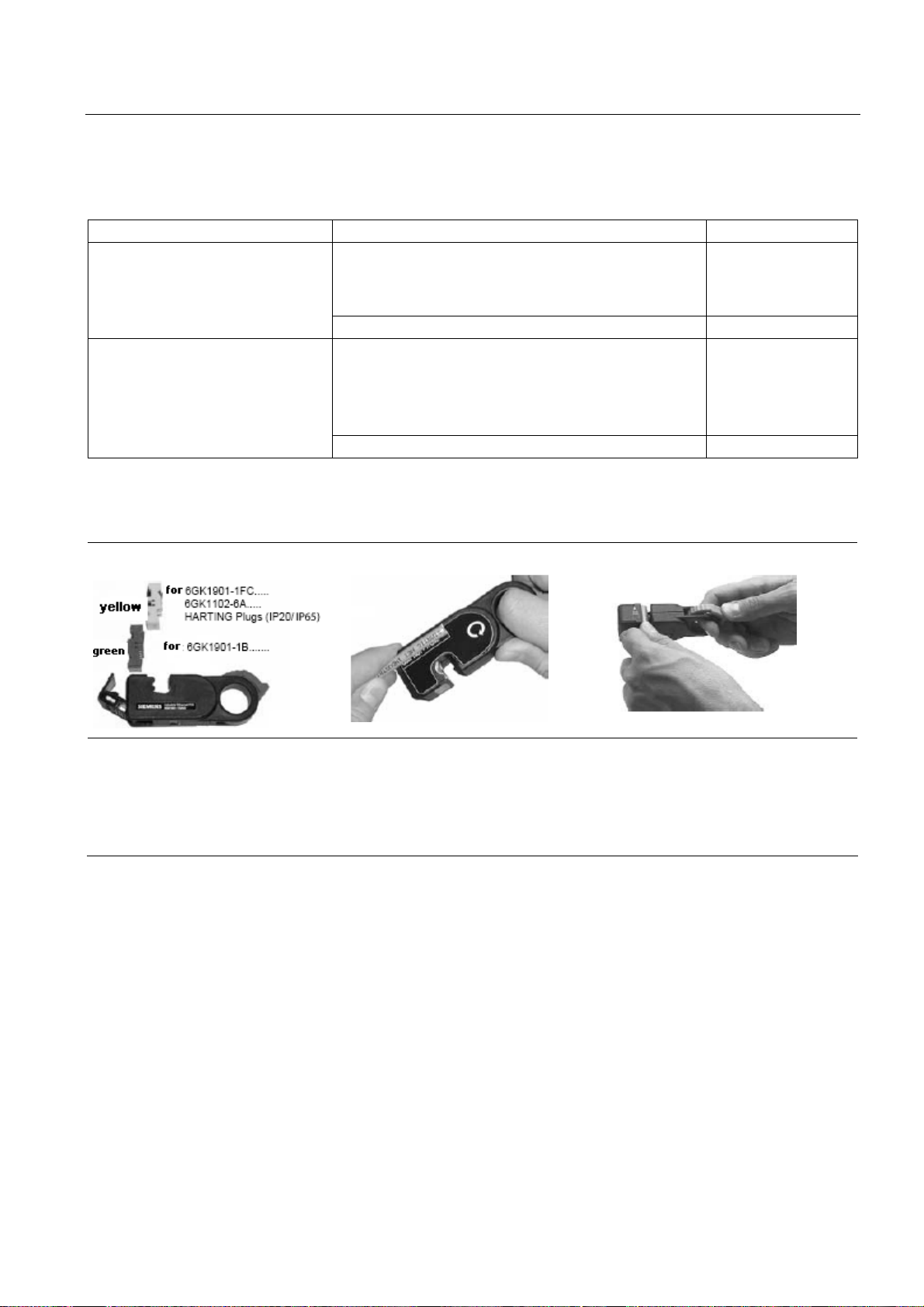

2.2 Industrial Ethernet FastConnect Stripping Tool.............................................................................8

2.3 Electrical networks .......................................................................................................................11

2.3.1 Fitting IE FC cable 2 x 2 with an IE FC RJ-45 plug 180 2x2 .......................................................11

2.3.2 Fitting IE FC cable 2 x 2 with an IE FC RJ-45 plug PRO ............................................................13

2.3.3 Fitting an IE FC cable 2 x 2 with an IE RJ-45 plug PRO .............................................................16

2.3.4 Fitting IE FC cable 2 x 2 with an IE FC RJ-45 plug 180 4x2 .......................................................19

2.3.5 Fitting an IE FC cable 4 x 2 with an IE FC RJ-45 plug 180 4x2 ..................................................21

2.3.6 Fitting the IE FC TP cable with an IE FC M12 plug PRO ............................................................24

2.3.7 Assembling an IE hybrid cable 2 x 2 + 4 x 0.34 with an IE IP 67 hybrid connector ....................27

2.3.8 Fitting the IE FC TP standard cable 4 x 2 GP to an IE IP 67 hybrid connector...........................33

2.3.9 Fitting IE FC outlet RJ-45.............................................................................................................38

2.3.10 Fitting the IE FC RJ-45 modular outlet ........................................................................................39

2.3.10.1 Connecting the RJ-45 Modular Outlet .........................................................................................39

2.3.10.2 Assembling IE FC TP standard cable 4x2 GP and IE FC RJ-45 modular outlet.........................40

2.3.10.3 Fitting IE hybrid cable 2x2 + 4x0.34 and IE FC RJ-45 modular outlet.........................................43

2.3.11 Assembly of Industrial Twisted Pair connectors ..........................................................................46

2.3.11.1 Assembling Industrial Twisted Pair Connectors ..........................................................................46

2.3.11.2 Fitting a 9-pin D-sub plug.............................................................................................................48

2.3.11.3 Fitting a 15-pin D-sub plug...........................................................................................................51

2.4 Optical networks ..........................................................................................................................54

2.4.1 Fitting an IE FC FO cable with a BFOC connector......................................................................54

2.4.2 Fitting an IE FC FO cable with an SC plug..................................................................................58

2.4.3 Fitting an SC RJ plug to a plastic FO cable (POF) ......................................................................63

2.4.4 Fitting an SC RJ plug to PCF FO cable.......................................................................................65

2.5 Power supply................................................................................................................................69

2.5.1 Fitting the energy cable 5 x 1.5 with a power plug PRO..............................................................69

2.5.2 Fitting a 7/8" energy connector to an energy cable .....................................................................72

2.5.3 Connecting the 7/8" energy connector to a module.....................................................................74

3 Installing network components in cabinets............................................................................................... 75

3.1 SIMATIC NET components..........................................................................................................75

3.2 IP degrees of protection...............................................................................................................77

3.3 Guidelines for setting up networked automation systems in buildings ........................................79

3.3.1 General notes on networking bus cables.....................................................................................79

3.3.2 Protection from electric shock......................................................................................................79

3.3.3 Mechanical protection of bus cables............................................................................................80

3.3.4 Electromagnetic compatibility of fiberoptic cables .......................................................................82

3.3.5 Connecting fiber-optic cables.......................................................................................................83

Passive network components

System Manual, 02/2013, C79000-G8976-C282-01 3