GEAFOL- / CARECO-Cast-resin Transformer/ Operating Instructions

© 2021 Siemens Energy Page 4

General information and

safety notes

1.1 General information

Note

Siemens Energy AG does not accept any liability for

damage and failures that result from the non-ob-

servance of these operating instructions.

These operating instructions are part of the transformer

delivery. Store the operating instructions near the

transformer. Please read the operating instructions prior to

handling the transformer and observe the information they

contain. This is how you ensure safe and disturbance-free

function.

Note

In addition to these operating instructions, special

contractual agreements and technical documentation

apply to a special transformer design and the associ-

ated supplementary equipment.

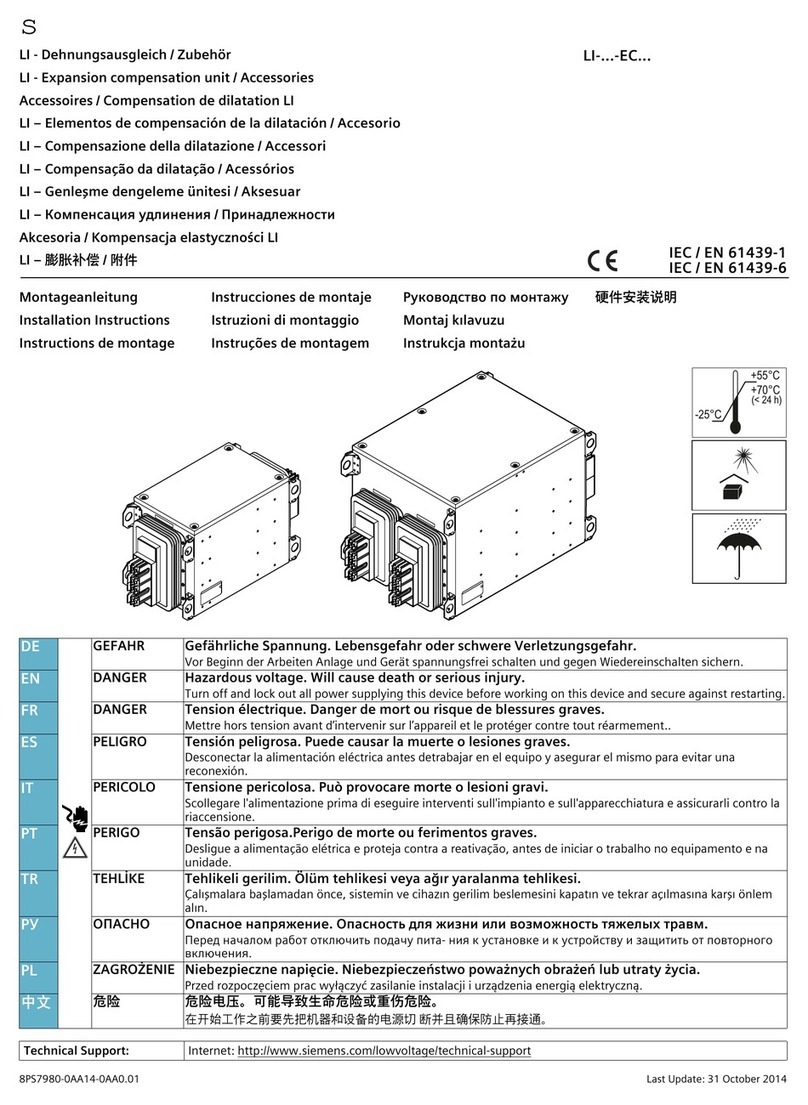

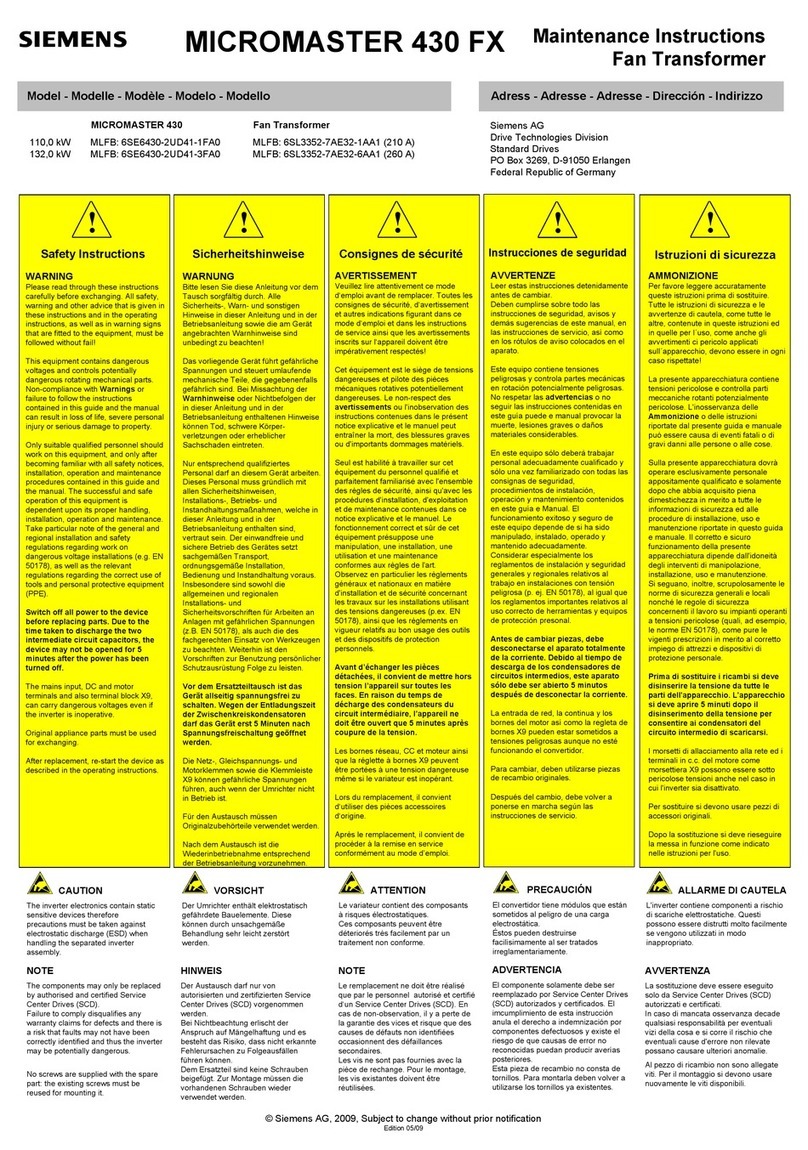

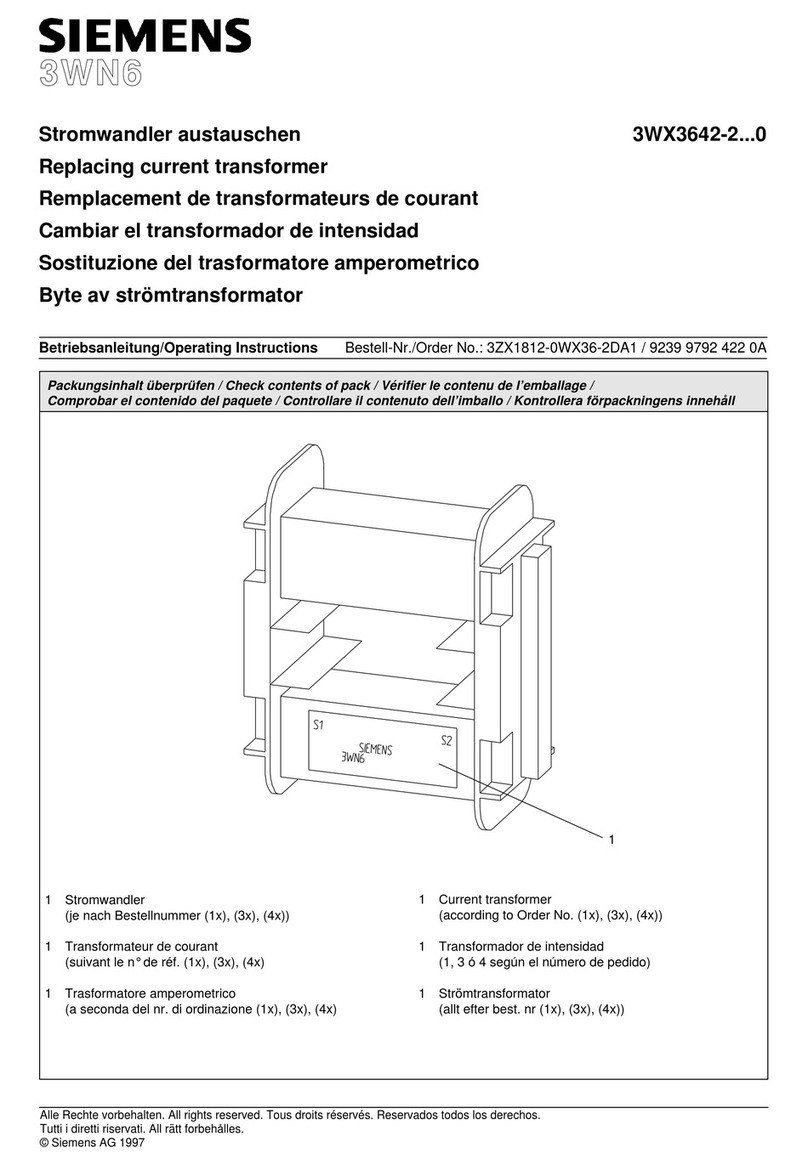

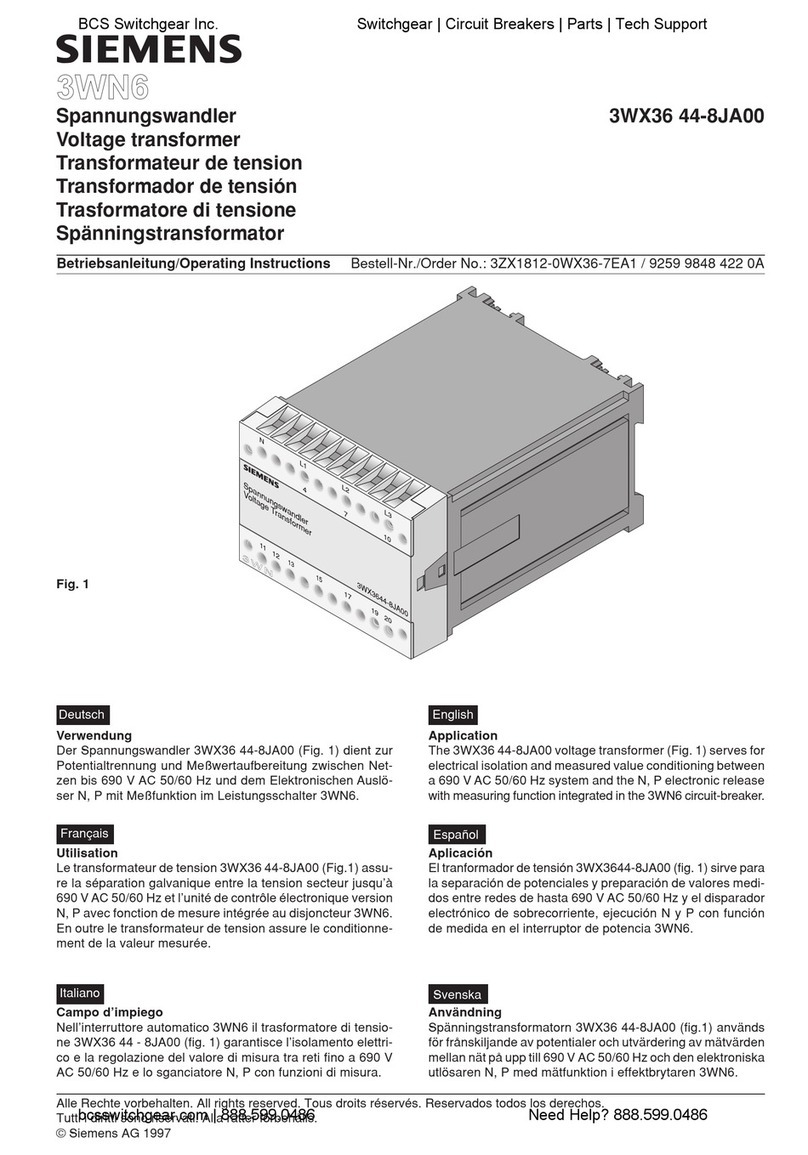

Please refer to the other operating instructions supplied

with the product.

The described transformers correspond to the state-of-the-art

at the time these operating instructions were printed.

Siemens Energy AG reserves the right to change individual

components and accessory parts in the interest of further

development. The changes serve to improve the

performance and safety. The significant features are

retained. The operating instructions are always being

updated with new contents.

The latest versions of the operating instructions, the

declaration of incorporation and the declarations of

conformity are available in electronic form in the

Online Support

(https://www.siemens-

energy.com/global/en/offerings/power-

transmission/transformers/geafol-

transformers.html#Downloads)

If you have any technical questions, please contact

Technical Support

(kirchheim-sck.energy@siemens-energy.com)

or the local contact addresses on the back of this manual.

1.2 Intended use

The transformers described in these operating instructions

have been designed for stationary use in general engineering

applications.

Unless otherwise agreed, the transformers have been

designed for use in plants and equipment in industrial

environments.

The transformers have been built based on state-of-the-art

technology and are shipped in an operationally reliable

condition. Changes made by users could affect this

operational reliability and are forbidden.

The transformer have been designed solely for the

application described in the IEC 60076-11. Do not operate

the transformer outside the specified power limit. Other

operating conditions must be contractually agreed.

1.3 Obligations of the user

The company operating the unit must ensure that all persons

assigned to work on the transformer have read and

understood these operating instructions and that they

comply with them in all points in order to:

Eliminate the risk to life and limb of users and others

Ensure the operational safety of the transformer.

Avoid disruptions and environmental damage

through incorrect use.

Comply with the following safety instructions:

Shut down the transformer and disconnect the power before

you carry out any work on them.

Make sure that the transformer cannot be turned on

accidentally, e.g. lock the key-operated switch. Place a

warning notice at the drive connection point which clearly

indicates that work is in progress on the transformer.

Carry out all work with great care and with due regard to

"safety".

For all work, carefully comply with the relevant regulations

for work safety and environmental protection.

Comply with the instructions on the rating plates and

warning plates attached to the transformer. The rating plates

and warning plates must be kept free from paint and dirt at

all times. Replace any missing rating or warning plates.

In the event of changes during operation, switch off the

drive unit immediately.