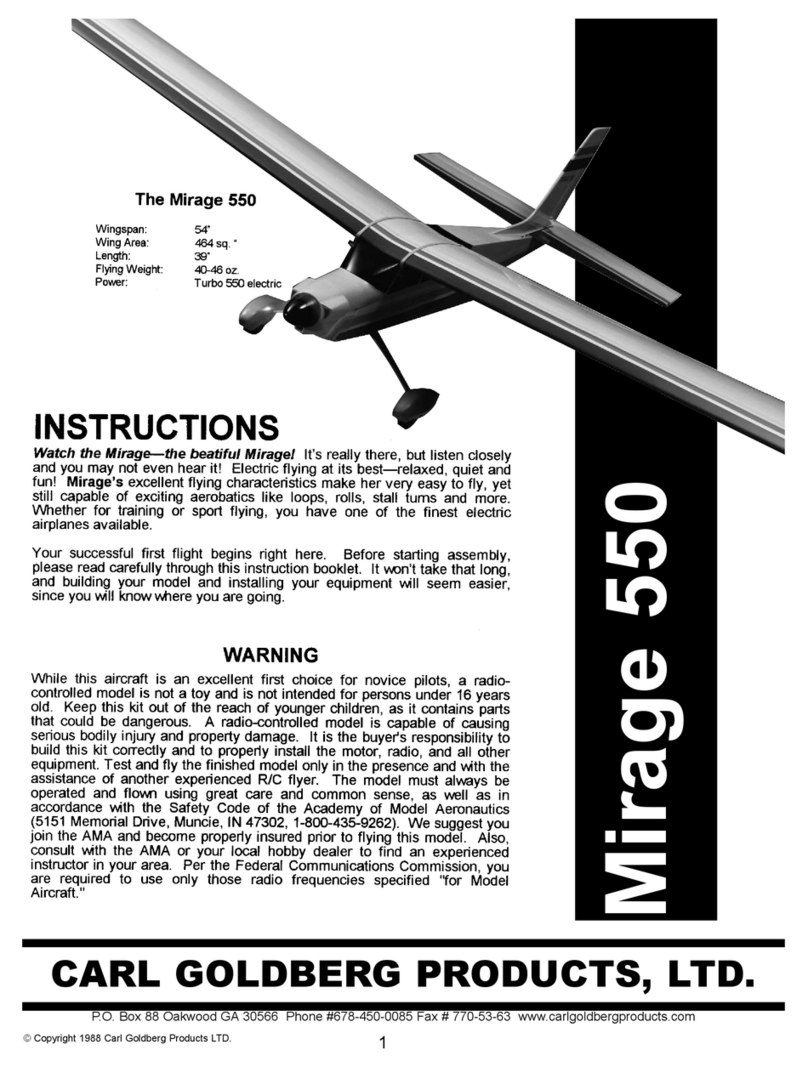

SIGLENT NITRO RASCAL User manual

NITRO RASCAL ARF ASSEMBLY MANUAL

INTRODUCTION:

Congratulations on the purchase of your SIG Nitro Rascal ARF kit!

This model continues the great line of ARF Rascal kits, with their

great looks and superb flight characteristics. The Nitro Rascal

makes an almost perfect aircraft for those modelers looking for a

maximum amount of 1/2A performance out of a great looking

airplane. The Nitro Rascal ARF can be easily flown in smaller

fields but is equally at home on normal club-size flying sites. The

Nitro Rascal ARF was specifically designed to take full advantage

of the great power and reliability of the Norvel .049, .061, or .074

glow engines.

Performance? You bet! The SIG Nitro Rascal ARF is a very

capable airplane. It has a wide speed envelope from very quick at

full throttle to a virtual "crawl" at low throttle. It is fully capable of a

wide range of 3-channel aerobatics including beautiful rudder rolls,

spins, inverted flight, snap rolls, touch and goes, etc. And the

included 2-ounce fuel tank will allow you to enjoy 15 - 20 minute

flights, depending upon fuel management. The kit also includes a

great tail wheel assembly that provides excellent ground handling.

Like it's electric powered cousin, the Nitro Rascal is beautifully built

from balsawood and ply and expertly covered in premium

Oracover®polyester film, using the signature "Rascal" two-color

trim scheme. This also means that the covering on the Nitro

Rascal ARF is easily repairable and easy to work with. Assembly

is straight forward if you follow these instructions carefully.

Deviating from these instructions has the potential to cause

problems later in the assembly process or during flight. The

successful assembly and flying of this model is your responsibility,

so take your time and enjoy the process.

NITRO RASCAL ARF SPECIFICATIONS:

Wing Span: 49"

Wing Area: 324 sq. in.

Length: 32.5"

Flying Weight: 18 - 20 oz.

Wing Loading: 8.0 - 8.8 oz./sq. ft.

Engines: .061 - .074

Radio Requirements: 3 Channels - 1 Micro Receiver

& 3 Micro Servos Required

RADIO EQUIPMENT:

The Nitro Rascal ARF derives its performance from several

factors. Two of these are its light ready to fly weight and generous

wing area. This combination makes for a very favorable wing

loading, allowing the airplane to perform very well with the

recommended Norvel engines. Since the Nitro Rascal ARF is

factory built, you can only control the final ready to fly weight by

choosing the most appropriate airborne radio equipment. In short,

the performance of this model will be great with the right

equipment but will be less so by choosing overweight or

inappropriate radio equipment. This is a simple reality that has to

be addressed. Fortunately, after-market receivers and servos,

appropriate for this model, are not only readily available and are of

good quality, they're now very reasonably priced.

In flight-testing our Nitro Rascal models, we've used a wide variety

of airborne radio equipment. For servos we have used and can

highly recommend Hitec™#HS-55 servos and the MAXX MX-50

servos. Similar servos are also available and can be used in the

Nitro Rascal, provided they are of the same size, weight and power

output. For receivers, we have used and can highly recommend

the Hitec™Electron 6 or the 555 Micro Receivers, as well as the

FMA M5 Micro Receiver. Again, other receivers may be useable

but make sure they are small enough and light enough. For best

performance, always avoid excess weight. DO NOT use single

conversion receivers for this aircraft. Such receivers are more

prone to interference and should NOT be used.

To power the airborne radio system, we used either a 270 or 300

mAh Ni-Cad battery pack. Properly charged, this pack provides an

honest 45 - 60 minutes of safe flying. These results can vary so be

sure to cycle your battery pack to determine the safe amount of

operating time for your particular system.

ENGINE SELECTION:

The Nitro Rascal ARF model was specifically designed around the

Norvel®AME .061 R/C engine. This engine provides a lot of power

1

R

and is perfect for a model of this size. The motor mount can be

easily enlarged a little to accommodate the Norvel®.074 BigMig

R/C engine and this will be covered in this Assembly Manual.

NOTE: Using engines any larger in displacement than the Norvel®

.074 is totally unnecessary and is not recommended.

COVERING MATERIAL:

Your Nitro Rascal ARF has been professionally covered using

Oracover®. This material is world famous for its ease of application,

light weight, and consistency of color. If you live in a dry climate,

you may notice that some wrinkles might develop after removing

the covered parts from their plastic bags. This is perfectly normal

in low humidity climates. The model was covered in a part of the

world with relatively high humidity and therefore the balsawood

was carrying a fair amount of moisture. When exposed to drier air,

the wood typically loses this moisture, dimensionally "shrinking" in

the process. This is what may cause some wrinkles. However,

wrinkles are easy to correct by simply using a heat iron.

We suggest covering the shoe of the iron with thin cotton cloth,

such as an old T-shirt, to prevent scratching. The iron should be

set to about 280O- 300OF. Use the heated iron over the wrinkle to

lightly shrink the material - do not press on it. Then lightly iron the

covering back down to the wood. You can also use a hobby-type

heat gun to re-shrink the covering but you must be very careful

around seams or joints. Re-heating seams may cause them to

"creep", making them unsightly. You must also be careful when

using a heat iron or heat gun when working around the side

windows and windshield - excess heat will distort these plastic

parts.

An easy way to avoid over-heating seams, joints, and the windows

when re-shrinking the covering is to protect them with wet paper

towels. Soak the paper towels in cold tap water and roll them in

strips for joints and seams. For windows and windshields, just

shape the wet towel as needed. The coolness of the wet towels

protects whatever is beneath them from heat.

For reference, your Nitro Rascal ARF was covered in Oracover®

film with the following part numbers:

#10 White and

#21-29 Transparent Red or

#21-59 Transparent Blue

REQUIRED TOOLS:

For proper assembly, we suggest you have the following tools and

materials available:

•A Selection of Glues - SIG Thin and Thick CA

and SIG Kwik-Set 5-Minute Epoxy

•Threadlock Compound, Such as Loctite

®

Non-Permanent Blue

•Screwdriver Assortment

•Pliers - Needle Nose and Flat Nose

•Diagonal Wire Cutters

•Small Power Drill With Selection of Bits

•Pin Vise for Small Dia. Drill Bits

•Hobby Knife With Sharp #11 Blades

•Scissors

•Heat Iron and Trim Seal Tool

•Masking Tape

•Paper Towels

KIT CONTENTS: Perform a complete inventory before starting

assembly.

Pre-Built Parts:

❑1 each Fuselage, Covered

❑1 each Fuselage Battery and Fuel Tank Access Hatch, Covered

❑1 each Fuselage Landing Gear Spreader, Covered

❑1 set Horizontal Stabilizer & Elevator Set, Covered

(With 4 CA Hinges in Place, Unglued)

❑1set Vertical Fin & Rudder Set, Covered

(With 3 CA Hinges in Place, Unglued)

❑1 set Left & Right Wing Panels, Covered

❑1 each Wing Center Section, Covered

❑1 set Plastic Wheel Pants, 1 Left, 1 Right

Formed Wire Parts:

❑1 each Main Landing Gear Wire - .09 dia.

❑1 each Tail Wheel Assembly With Mounting Hardware

❑1 each Elevator Pushrod Wire - .040 x 24"

❑1 each Rudder Pushrod Wire - .040 x 24"

❑1 each Throttle Pushrod Wire - .040 x 14"

Hardware:

❑6 each #2 x 3/8" Battery Hatch (2) and Engine Mounting Sheet

Metal Screws (4)

❑4 each #2 x 1/4" Wheel Pant Mounting Sheet Metal Screws

❑2 each Wheel Pant Mounting Brackets

Molded Parts:

❑1 each #4-40 x 1" Nylon Wing Mounting Bolt

❑1 each SIG 1-1/2" dia. Spinner Assembly With Metal Shaft

Adaptors (2) For Norvel®.061 and .074 Engines

❑1 each 60cc (2.02 oz.) Fuel Tank Assembly With All Required

Hardware

❑1 set Clear Plastic Side Windows - 1 Left, 1 Right

❑1 set Mini Nylon Rudder & Elevator Control Horns

❑3 each Nylon Pushrod Retainers

❑2 each Nylon Wheel Axle Caps

Miscellaneous:

❑1 each 3/16" x 3/8" x 2" Balsawood Fuel Tank Retainer

❑4 each White Self-Adhesive Strips -1/4" x 10" - Wing Joint

Covering

❑2 each Main Wheels - 1-3/4" dia.

❑1 each Instrument Panel, Printed

❑1 each Wheel Fairing Cardstock - 2-1/2" x 4-1/4"

❑1 each Nitro Rascal Decal Set

❑1 each Nitro Rascal Assembly Manual

2

ASSEMBLY:

WINGS:

❑1) Start by using a hobby knife with a #11 blade to clear out the

rear wing bolt holes on the top and bottom of the wing center

section. Test fit the wing center section to the fuselage and secure

with the provided nylon 4-40 wing bolt. The fit will be good, with

the center section well centered on the fuselage.

❑2) Remove the center section from the fuselage and test fit the

wing panels onto the exposed plywood dihedral brace ends. The

fit should be firm. Use 5-minute epoxy to join one of the wing

panels to the wing center section. Apply glue to the correct side of

the exposed rib on the center section and also apply a thin coat

onto the plywood brace. Slide the center section plywood brace

into the slot in the appropriate wing panel. Press the wing panel

firmly in place to the center section. Wipe off all excess glue with

acetone or alcohol and tape the panel securely to the center

section - top and bottom. Allow the epoxy to set and glue the

remaining wing panel in place.

❑3) After the glue has set, use the four provided 1/4" x 10" self-

adhesive strips of white Oracover®film to cover the bottom and top

wing joints, centering the covering over each joint. Save the

excess strip material. Check the fit of the completed wing to the

fuselage. Remove the wing and set it aside for now.

FUSELAGE:

❑1) Using a hobby knife and a sharp #11 blade, clear-out and

open up the various required holes in the fuselage covering; the

rear rudder and elevator control cable exits, the antenna exit hole

on the right fuselage side at the top just behind the window

location and the on/off switch slot on the left fuselage side,

beneath the side window. Also cut the covering away from the

slots on each side of covered plywood landing gear spreader.

❑2) From the kit contents, locate the printed instrument panel.

Use scissors to cut out the instrument panel including a recess at

the top, allowing clearance for the forward cockpit supports. Test

fit the instrument panel in place. Trim as needed for a good fit.

Glue panel to front fuselage cabin former using a little white glue.

❑3) The rudder and elevator servos are now installed into

fuselage. Note that the pre-installed rudder and elevator pushrod

tubes cross each other as the progress to the rear of the fuselage.

Therefore, viewing the fuselage from the rear, the rudder servo is

installed on the right side of the servo tray and the elevator servo

is installed next to it, on the left side. Both servo output arms face

3

toward the fuselage sides at 90Oto the servo body. The throttle

servo is installed with its output arm aligned with the throttle

pushrod tube.

❑4) From the kit contents, locate the two .040 x 24" wire

pushrods for the rudder and elevator and one .040" x 14" pushrod

for the throttle. Using a pair of needle nose pliers, bend a simple

“Z”-bend into one end of each of the three pushrods. Insert the

straight, unbent end of one of the 24”pushrods into one of the

plastic pushrod tubes - just behind the servo tray - and feed it

through to the exit at the rear of the fuselage. This is easiest to do

by running the wire through one of the side window openings.

Install the remaining 24”pushrod in the same manner.

Feed the 14" throttle pushrod wire through the top rear wing

opening and into its plastic tube. Take care not to permanently

bend or kink the pushrod during this process. Remove the servo

output retaining screws in all three servos. Remove the output

arms and attach the "Z" bend end of each pushrod to its

corresponding output arm. Temporarily press each output arm

back in place onto the servos. Plug your servos into the

appropriate receptacles in the receiver and plug the battery pack

into the system. Turn the transmitter on, making sure the trim

levers are in neutral. Now reposition the rudder and elevator

output arms back onto their respective servos, as close to 90Oas

possible to the servo body. The throttle output arm must move

back and forth to operate the engine's throttle lever, so set it at

about 20Oto obtain roughly equal fore and aft movement. With the

output arms correctly in place, re-install the output arm retaining

screws and turn the radio system off.

❑5) The main landing gear is now glued in place in the fuselage

using 5-minute epoxy. First check the fit by sliding the landing gear

in place into the two slots at the bottom, front of the fuselage.

Carefully slide the gear all the way up into place inside the

fuselage to get a feel for the fit. Remove the gear from the

fuselage and use sandpaper to sand the wire, where it contacts the

fuselage sides. Apply 5-minute epoxy into each landing gear slot

on the inside of the fuselage - just enough to fill the slots. Once

again slide the landing gear wire in place into the fuselage.

Carefully wipe off any excess glue with alcohol and allow the glue

to set.

❑6) Fit the covered plywood landing gear spreader in place over

the wire landing gear legs and onto the bottom of the fuselage.

Trim as needed for a good fit. Remove the spreader and apply

5-minute epoxy to its bottom outside edges, where it contacts the

fuselage bottom. Also apply a little glue along the front edge of the

spreader where it butts against the bottom forward fuselage

sheeting. Press the spreader in place, wipe off any excess glue

with alcohol. Tape firmly and allow the glue to set.

❑7) The 2-ounce (60cc) fuel tank supplied with this kit is now

assembled. We suggest using a simple two-line system in this

airplane. One fuel line is connected to the "clunk" or fuel pick-up

line and the engine's carburetor. The second line is the overflow

line for use when filling the tank. This same line is then connected

to the muffler pressure nipple, providing muffler pressure to the

fuel tank. Note that the "sides" of the fuel tank are the flat sides.

The rubber stopper for the tank has two holes all the way through

it. Use these two holes for the two aluminum fuel lines. Slip two

aluminum tubes through the rubber stopper. Slide the smaller

4

diameter rear clamp plate over the two tubes and up against the

rear face of the rubber stopper. Slide the larger diameter front

plate over the two aluminum tubes at the front of the stopper and

up against the stopper itself. Press the clamp bolt through the front

plate and the rubber stopper, back to the rear plate. Use a

screwdriver to start the bolt threads into the rear plate - do not

tighten yet. At the front, leave approximately 1/4" of each tube

exposed in front of the plate. Gently bend the aluminum

overflowtube upwards to about 80Oto reach the top of the tank

body - always leave about 1/32" space between the overflow tube

and the inside of the tank body. Trim the two tubes to appropriate

length and remove any burrs with sandpaper. Install the fuel pick-

up weight onto one end of the silicon tubing. Measure and cut the

tubing length to allow the fuel pick-up weight to just about reach

the rear of the fuel tank, allowing its free movement within the tank-

body when the rubber stopper is fully in place in the front of the

tank. With everything now adjusted and fitting nicely, insert the

tank stopper assembly fully into the front of the tank body and use

a screwdriver to firmly tighten the clamp bolt while holding

the stopper assembly firmly in proper orientation. The bolt

compresses the rubber stopper between the plates, forming a

good tank seal.

❑8) The assembled fuel tank is now installed into the fuselage.

First, trial-fit the tank in place to check for the fit. Insert the tank

into the nose of the fuselage through the bottom Tank Hatch

opening and guide the front of the tank to the pre-cut round

opening in the firewall. The tank stopper should fit through this

hole and the tank body should fit up against the rear face of

the firewall. Remove the fuel tank from the fuselage. Apply a

generous bead of clear silicon adhesive (bathroom type is fine)

around the tank stopper at the front of the tank. Re-install the tank

into the fuselage - make sure it is right side up - and press it

firmly in place against the firewall. From the kit contents, locate the

3/16" x 3/8" x 2" balsawood Fuel Tank Retainer. This retainer is

inserted into the fuselage, between the fuselage sides, at the rear

of the fuel tank to hold it firmly in place to the firewall. If needed,

lightly sand its ends to achieve a firm fit. Hold the retainer in place

and use a drop of two of thin CA glue to hold it in place to each

fuselage side.

❑9) Locate the pre-covered Tank/Battery Hatch from the kit

contents. This hatch has a plywood "lip" at one end and two

pre-drilled holes at the other end. The end with the lip is the front.

The hatch fits into the bottom of the fuselage and is removable for

ready access to the fuel tank and the battery compartment

beneath the tank. Install the front hatch lip into the fuselage,

beneath the landing gear spreader, pressing it firmly in place to the

fuselage.

Hold the hatch in place and use your pin vise and a .046" dia. drill

bit (#56 numbered drill) to drill two holes through the hatch

retention block, directly beneath the two pre-drilled holes. The

hatch can now be secured to the fuselage using the two #2 x 3/8"

sheet metal screws provided - do not over-tighten these screws,

just snug them in place to create the threads. Remove the screws

and the hatch from the fuselage. Apply a drop of thin CA glue into

each screw hole. Allow the glue to set and re-thread the screws

into each hole to establish the threads. Set the hatch and

mounting screws aside for now.

ENGINE INSTALLATION:

5

PROP TALK:

Before installing the engine, it is important to give some thought to

suitable propellers for your airplane/engine combination. We have used

a variety of propellers for our Nitro Rascal ARF models and have

learned that different brands seem to all have different prop shaft

hole diameters. Usable prop sizes for the Norvel®.061 are 6" to 7" in

diameter. APC produces great props in these sizes but they are

produced with large diameter shaft holes. The Norvel .061 engine has

a prop shaft size of .124. APC props in the 6" to 7" diameter have much

larger mounting holes. To mount an APC prop, we found that the

easiest way to center it to the Norvel prop shaft was to "sleeve" its

mounting hole with two short lengths of telescoping K&S aluminum

tubing. The inner piece of tubing has a 1/8" dia. I.D. which fits perfectly.

❑1) Note that the down and right thrust angles have already been

built into the plywood motor mount. Also note that this instruction

assumes you are mounting the Norvel®.061 R/C engine. Begin by

removing the engine muffler from the engine, setting it aside for

now.

From the kit contents, locate the Spinner Assembly bag. You will

also need your prepared and ready to mount propeller. From the

spinner assembly bag, locate the aluminum adapter that has the

smaller hole in its center - this adapter is for the Norvel®.061

engine. Start by sliding the prop shaft washer onto the prop shaft

bolt, followed by the propeller, then the spinner backplate, and

finally, the aluminum spinner adapter ring that fits into the recess

in the back of the spinner backplate.

This assembly is now bolted onto the front of the engine. The

plastic spinner cone is fitted to the spinner backplate, aligning its

tabs into the backplate recesses. Mount the spinner cone to the

backplate using the two provided sheet metal screws.

❑2) Place the engine onto the fuselage engine mount plate. The

correct distance from the back face of the spinner to the very front

of the fuselage is 1/4". Use a scrap piece of 1/4" balsa as a

spacer on the left fuselage side and adjust the position of the

engine as shown. Use a soft lead pencil to carefully mark the four

engine mounting holes onto the plywood engine mounting plate.

Remove the engine.

Use a 1/16" dia. drill bit to drill four "pilot" holes squarely through

the marks in the motor mount.

Mount the engine to the plywood motor mount using the #2 x 3/8"

screws provided. Remove the screws and engine from the motor

mount. To protect these four holes from fuel damage, apply a

couple of drops of thin CA glue into each hole and allow the glue

to set. Now run each screw back into each hole to re-establish the

threads. Before final-mounting the engine, cut two 3" lengths of

small dia. silicon fuel tubing and slide one piece onto each of

the two aluminum fuel tank lines. Re-install the engine to the

motor mount. Trim and connect the two silicon fuel lines to the

carburetor and muffler pressure tap nipple.

6

(Continued...)

In the case of other propeller brands, some, such as Master Airscrew's

6" diameter props, require drilling out their smaller diameter mounting

holes with a 1/8" dia. drill bit. This is always best done with a drill press.

Finally, any propeller used on a model airplane engine should always be

carefully balanced to run true and eliminate undue vibration.

In addition to adapting a propeller to the engine, you must also find a

small metal washer that has a 1/8" I.D. to fit the Norvel .061 prop shaft.

This is because the Norvel®prop shaft bolt is not long enough to engage

the engines threads with the spinner and prop in place, using the

standard Norvel®spinner/washer. We found that a Du-Bro Flat #4

washer worked perfectly.

We suggest that you prepare your propeller for mounting to the engine

before beginning the installation of the engine. For reference, a good

starting prop size for the Norvel®.061 R/C engine would be a 6 x 3.

Later, you can experiment with different pitch numbers and perhaps

even try a larger 7 x 3 prop.

OPTIONAL - MOUNTING THE NORVEL .074 R/C ENGINE:

To mount this engine in your Nitro Rascal ARF, there are two

considerations to address first;

a) Widening the motor mount plate to accept the wider .074

crankcase body.

b) The need to create just a little more clearance for the larger

.074 muffler body.

The following instructions address these two requirements:

a) To accept the .074 crankcase body, each side of the motor

mount opening must be trimmed .040 (just under 3/64") - no more.

To do this, first use a small straight edge and sharp pencil to draw

a parallel line, 1/32" from the inside edge of each side of the motor

mount opening. Use a sanding block or a Dremel®Tool with a

sanding drum bit, to remove the excess material to the line just

drawn. Next use a sanding block to remove the plywood equally

from each side of the mount until the engine slips into place

easily. Use clear or colored dope to protect the exposed wood on

the trimmed motor mount plate.

b) The Norvel .074 muffler body is somewhat larger than the

.061 muffler. Without some trimming, it will come in contact with

the right fuselage side when in place. The balsawood sheeting on

the right fuselage side, at the nose, must be cleared to allow no

contact when the engine/muffler is in place. Simply use a hobby

knife and a sharp #11 blade to carefully cut away enough of the

right side nose sheeting to let the muffler clear without contact.

The exposed wood can then be clear doped or re-covered with a

scrap of covering material to protect it from fuel.

The engine can be mounted using the instructions provided in

Steps #1 and 2 above.

The only remaining engine installation task is to connect the

throttle pushrod to the throttle servo - this will be done in the

RADIO INSTALLATION section.

MOUNTING THE TAIL GROUP:

❑1) From the kit contents, locate the bags containing the

horizontal stabilizer and elevators and the vertical fin and rudder.

7

the Norvel®.061 muffler has an exhaust exit that can be

positioned 360O, we found a lightweight and neat way to make a

simple exhaust extension.

To make this exhaust extension system, you will need a 5"

length of large 1/8" I.D. silicon tubing and a short length (1" or

so) of 3/16" O.D.K&S aluminum tubing. Use a sanding block or

a power-sanding disk to chamfer one end of the aluminum

tubing to a 45Oangle. Clean up any burrs with a hobby knife and

sandpaper. Insert the unchamfered end of the aluminum tubing

into one end of the silicon tubing, about halfway. Insert the other

end of the silicon tubing into the bottom of the fuselage, through

the pre-cut drain hole on the bottom. Guide the tubing up

through the space just behind the engine itself in the motor

mount plate. Continue pulling the tubing until the end with the

aluminum tubing encounters the drain hole. Now gently insert

the aluminum tubing end about halfway into the drain hole, with

the 45Ochamfer facing directly back toward the rear of the

fuselage.

At the top, trim the length of the silicon tubing to allow its end to

be pressed in place over the muffler nipple.

This simple exhaust extension does several things. It provides

a bit more back-pressure to the engine and improves the idle

without sacrificing a noticeable amount of power. Of course,

the number one benefit is that most of the exhaust residue is

directed down and out of the fuselage. Give it a try!

BUILDER’S TIP:

Small engines, running at high rpm's, can create a lot of exhaust

and carb spray that ultimately winds up on your model. Because

Also locate the two plywood control horns. Note that the elevators

and rudder are only temporarily attached to the stabilizer and fin

with unglued CA hinges in their pre-cut slots. Remove the

elevators from the stabilizer and the rudder from the fin. Remove

the CA hinges from the slots.

❑2) The elevators can now be hinged in place to the horizontal

stabilizer. Carefully note that the two pre-drilled holes for the

elevator control horn are on the right elevator half. The supplied

hinges are the CA type. Use only instant or "thin" CA glue to install

these hinges!

Begin by inserting the four CA hinges into the four slots in the

trailing edge of the stabilizer, aligning their center slots along the

trailing edge. Using four thin pieces of wood or cardboard

(business card thickness is about right), insert these into the slots

in the hinge. Now mount the elevators to the exposed hinge

halves, pushing the elevators up to the scrap wood or cardboard

hinge inserts. Remove one of the hinge insert scraps, flex the

elevators downward, exposing the center of the hinge. Apply 3 or

4 drops of thin CA glue to the hinge, at the centerline. Turn the

stabilizer over and repeat this process on the same hinge. Repeat

the same procedure for the remaining three elevator hinges. Any

excess glue can be easily removed with a little SIG CA Debonder

and a paper towel. Because it takes a little time for the CA to fully

"wick" its way all through the hinge and into the surrounding wood,

leave the stabilizer/elevator assembly alone for at least 10 minutes

before moving the elevators. Flex the elevators firmly up and down

to make them supple and easy to move.

❑3) With the elevators in place, the horizontal stabilizer is now

glued in place to the top rear of the fuselage. Use SIG 5-minute

epoxy for this operation.

Begin by mounting the wing to the fuselage. Place the model on a

flat surface, allowing you to view it directly from the front. Prop up

the rear of the fuselage with a scrap piece of wood approximately

3". Apply epoxy glue to the fuselage stabilizer saddle area and

carefully place the stabilizer onto the saddle, centered as closely

as possible. Use pins or small weights to hold the stabilizer firmly

to the fuselage. Carefully view the airplane from the front to see if

the stab is squarely in place in relationship to the wing/fuselage,

without tilting to one side or the other. Make any adjustments

needed to position and hold the stabilizer in this position. Allow the

glue to set completely.

❑4) The vertical fin, without the rudder hinged in place, is now

glued in place to the top of the stabilizer, again using SIG 5-minute

epoxy.

Begin by first test fitting the vertical fin in place into the slot in the

top of the stabilizer, without using any glue. Trim if needed to

achieve full contact with the stabilizer and top rear of the fuselage.

Once again mount the wing to the fuselage and prop up the rear

of the fuselage about 3" with the airplane on a flat surface. Apply

glue to the bottom of the fin and the sides of its locating tab.

Carefully press the fin in place onto the stabilizer and fuselage.

Wipe off any excess glue, using alcohol and a cloth. Again view

the airplane from the front, making sure the fin is in place at 90O to

the stab. Use tape as needed to hold the fin in this position and

allow the glue to set. After the glue sets, remove the tape and the

wing.

❑5) Before hinging the rudder to the vertical fin it must be

prepared by inserting and gluing the tailwheel wire - with its metal

mounting bracket loosely in place - to the bottom leading edge of

the rudder. Measure 1/2" up from the bottom leading edge of the

rudder and place a small mark with a soft lead pencil. Use a 1/16"

drill bit to drill a hole at the previous marked location through the

8

XX

X = X

XX

90 90O

O

center of leading edge of the rudder to a depth of 1/2". Use a

hobby knife and a sharp #11 blade to cut a "V" notch in the

leading edge of the rudder from the hole to the bottom of the

rudder. Trial fit the tailwheel wire into the leading edge of the

rudder to make sure that the wire is flush with the leading edge of

the rudder. When satisfied with the fit of the tailwheel wire remove

it. Mix a small amount of 5-minute epoxy and carefully fill the hole

and the "V" notch with glue. Push the tailwheel wire into position

in the rudder and wipe off any excess glue that squeezes out.

Allow the glue to cure.

The rudder is now ready for hinging to the vertical fin and fuselage

with the three CA hinges.

The hinge slots for upper two CA hinges that fit into the vertical fin

are ready to use. The bottom hinge slot in the rear of the fuselage

has also been pre-cut at the factory, but is covered. It is necessary

to open this slot up to allow placement of the bottom rudder hinge.

To do this, use a sharp #11 blade to find and open the slot.

Reinstall the rudder and hinges and adjust the hinge gap between

the fin and rudder to 1/32". Use a piece of tape to hold the rudder

hard over to one side. On the opposite side, the hinges should be

visible. Apply 4 small drops of thin CA glue to each of the three

hinges at their exposed centers. Untape the rudder and flex it

hard over to the opposite side and again tape it in place. Apply

another 4 drops of glue to the opposite sides of each hinge.

Untape the rudder and position it in neutral. Allow about 10

minutes for the glue to fully "wick" through the hinges. When the

CA glue is fully set, flex the rudder back and forth firmly several

times to loosen and free-up the movement.

❑6) The metal tail wheel bracket/support is now mounted to the

bottom rear of the fuselage, using the supplied #2 x 1/4" screws.

With the fuselage upside down, place the metal support bracket in

front of the tailwheel wire, centered onto the fuselage bottom.

Mark the position of the two mounting holes onto the fuselage with

a soft pencil. Swing the bracket out of the way and use a 1/32" dia.

drill bit to make two pilot holes at the marks just made.

Mount the bracket firmly in place using the two #2 x 1/4" screws.

❑7) From the kit contents, locate the two white plastic control

horns. These are now mounted to the rudder and elevators. Note

that the rudder and elevators have two pre-drilled holes for this pur-

pose. Viewing the airplane from the rear, the rudder horn is mount-

ed on the left side of the rudder. The elevator control horn is

mounted to the bottom right elevator half. To mount the horns,

apply a small amount of thick CA glue to each "spike" and a dab of

thick CA glue to the bottom base of the horn, between the spikes.

Firmly press the control horn in place, making sure the holes are

facing forward toward the front of the fuselage. Allow the glue to

set.

WHEEL PANTS:

❑1) Position the wheel pants in place onto the wire landing gear

axles. Note that the inner facing sides of the wheel pants - the side

facing the fuselage - can be identified by looking inside and

observing the plywood mounting pads. Correctly in place, these

pads should be located against the upright wire landing gear wire.

From your parts bag, locate the two metal landing gear clips and

9

the four #2 x 1/4" mounting screws.

❑2) The wheel pants must first be correctly aligned to the

landing gear wire and the fuselage, before mounting. This is done

by slipping the wheel pants in place over the landing gear wires -

without installing the wheels - and then propping the rear of the

fuselage up 3" off of a flat surface. This provides the correct side

view alignment for mounting the wheel pants.

❑3) Press one of the metal landing gear clips onto the upright

wire leg of the landing gear, immediately next to the wheel pant.

Slide the clip up or down on the wire until the bolt holes are

approximately 3/8" above the axle hole. Use a sharp pencil to

mark the clip's two bolt hole centers onto the wheel pant. After

making these marks, remove the wheel pants from their axles.

Use a pin vise and a .046" dia. drill bit (#56 numbered drill) to drill

guide holes through the wheel pants and the inside plywood

mounting pads, at the marks just made.

❑4) Slip a wheel pant onto its appropriate axle and then insert

one of the wheels into the pant and onto the axle. Continue

pushing the axle through the wheel hub and through the outer

wheel pant hole. Mount the pant and wheel to the landing gear

using the #2 screws through the clip and into the pre-drilled holes

on the side of the pant. Do not over-tighten the screws, just snug

them in place. Repeat this process for the remaining pant and

wheel. Test the wheel pant/wheel relationship, making sure that

the wheels roll freely with little or no friction. Adjust as needed to

achieve free movement.

OPTIONAL LANDING GEAR FAIRINGS:

Included with your kit is a card sheet measuring 2-1/2" x 4-1/4".

This is the material used to make the optional landing gear fairings.

Use the patterns provided in this manual. First remove the wheel

pants. Cut-out two landing gear fairings from the card stock and

bend them sharply in two at their leading edges. Mix a small

amount of 5-minute epoxy and spread it on the inside surface of

the fairing. Place the fairing onto the wire landing gear leg and

clamp or tape the trailing edge together. Align the fairing

accurately with the fuselage and allow the glue to cure.

10

Use light sandpaper (#400 or similar grit) to lightly sand the trailing

edges smooth and sharp. These fairings can now be finished with

Oracover®film or primed and painted. Remount the wheel pants.

RADIO INSTALLATION:

With the servos already mounted, all that remains is to install the

radio system On/Off switch, the battery pack, the receiver and to

connect the rudder, elevator and throttle pushrods. Your airborne

battery pack should be charged and ready to use for these steps

and you should also have some pieces of lightweight foam for

wrapping and packing the battery and receiver within the fuselage.

❑1) The radio system On/Off switch is mounted on the left

fuselage side, beneath the side window. You will see a plywood

rectangle glued to the inside of the left fuselage side - this is the

switch mounting plate. In order to mount your switch you will need

to open the covering over the inner rectangular cutout to accept the

switch lever. Use a hobby knife and a sharp #11 blade to do this

neatly. The On/Off switch can now be mounted to the fuselage

using the mounting hardware that came with your radio system.

In our Nitro Rascal ARF models, we chose to use a Hitec™

aftermarket "Micro" Switch Harness - P/N #54403, in the interest

of its lighter weight and much smaller size.

❑2) Wrap the battery pack in light foam. Plug its connector into

the switch connector and install the pack into the nose of the

fuselage, directly beneath the fuel tank. The pack can be easily

held firmly in place with another piece of foam.

❑3) Plug the servo connectors into the appropriate receiver

receptacles (for most Mode II pilots, the rudder servo is plugged

into the aileron receptacle) and plug the switch connector into the

receiver's battery receptacle. Turn your transmitter on and test the

system to make sure the servos are moving in the correct

directions. Turn the radio system off. At this point, we re-installed

the bottom fuselage hatch. We then installed our foam wrapped

receiver directly onto the floor of the fuselage, in the cockpit area.

We first cut and fit a piece of light foam to fit on the fuselage floor.

We then placed the receiver onto this foam sheet, followed by

another thin foam sheet over the receiver.

The receiver antenna is routed out of the fuselage, through the

pre-drilled hole on the upper right fuselage side, above the side

window. The end of the antenna can then be attached to the top

of the vertical fin with a rubber band and a pin or, as we did, it can

be routed along the fuselage side and held in place beneath the

horizontal stabilizer, again with a rubber band and pin.

❑4) The carburetor arrangement on the Norvel®.061 R/C engine

has the throttle lever moving to the rear for full throttle and forward

for low throttle. Turn your transmitter on and set the throttle stick in

the full "low throttle" position. Set the transmitter throttle trim in the

neutral position to allow equal amounts of trim in either direction.

Now turn on the airborne radio system. The servo output arm on

the throttle servo should be in the low throttle position - arm

forward at about 20O. When the transmitter throttle stick is moved

up toward the full throttle position, the servo output arm should

likewise move toward the rear of the fuselage and in the full

throttle position, it should be about 20Otoward the rear. If

necessary, reposition the servo output arm on the servo until it

moves in this approximate manner. The linkage from the servo to

the engine throttle lever is now made.

Move the throttle servo to the full "low" position using the transmitter.

Use a fine tip felt marker to mark the location of the engine's

throttle lever hole - the lower of the two - onto the throttle pushrod

wire. Slide a plastic pushrod retainer onto the throttle pushrod,

moving it all the way back to the pushrod tube. Use needle nose

pliers to make a 90

O

bend in the pushrod wire at the mark just

made. Trim the end of the bent wire to within about 1/8". Slide the

pushrod retainer forward and flex its arm outward to engage the

end of the wire. Press the wire through the retainers arm.

Test the action of the throttle using the transmitter. It should be

free and without binding. If your transmitter has EPA (End Point

Adjustments), use this feature to optimize the travel of the servo,

matching it to the movement of the throttle lever.

❑5) The rudder and elevator pushrods are now connected to the

control horns at the rear of the fuselage. Again, turn on the

transmitter and place the rudder and elevator trim levers in neutral.

Turn on the airborne radio system. As previously described, the

output arms should be in position to the servo body at 90O. If

necessary, remove the output arms and reposition them back onto

the servo in this position.

Use a small piece of tape to hold the rudder in the neutral position

to the vertical fin. Turn the fuselage upside down. Hold the metal

pushrod wire up against rudder control horn, at the middle hole.

Use a fine tip felt marker to mark the wire exactly where this hole

is. Slide a plastic pushrod retainer onto the pushrod wire, moving

it all the way forward to the fuselage. Use needle nose pliers to

now bend the rudder pushrod wire to a 90Oangle at the mark just

made. Trim the bent wire end to within 1/8" and press the bent end

through the middle hole in the control horn. Slide the retainer

forward and flex its arm to fit over the bent end of the wire.

Remove the piece of tape holding the rudder in neutral.

Test the rudder movement with the transmitter. It should move

smoothly without any binding and right transmitter stick movement

should produce right rudder movement. Check this twice and then

check it again! If needed, use the rudder (aileron) trim lever to set

the rudder in true neutral to the vertical fin.

11

The elevator pushrod is connected to the elevator control horn in

the same manner as the rudder. We suggest using the outermost

hole in the control horn for the attachment point. Again, use small

pieces of tape to hold the elevators in the neutral position to the

horizontal stabilizer.

Test the movement of the elevators using the transmitter to make

sure everything is moving in the correct direction. If needed, use

the elevator trim lever on the transmitter to set the elevators in true

neutral.

RECOMMENDED INITIAL CONTROL MOVEMENTS:

RUDDER: 3/8" RIGHT - 3/8" LEFT

ELEVATORS: 1/4" UP - 1/4" DOWN

(Note that these control movements can be changed later

to suit your particular flying style and preferences)

SIDE WINDOW APPLICATION:

From the contents of your kit, locate the small bag containing the

molded side windows. We suggest using 5-minute epoxy or

RC-56 glue to mount the windows into the inside of the fuselage.

DO NOT use thin CA glue for this step! Use scissors to cut out

each window, leaving about 1/8" of plastic around the edges for a

gluing surface. Apply a thin bead of glue to these edges and press

the window in place from the inside of the fuselage. Use small

pieces of tape to hold the windows in place until the glue sets. A

little alcohol will clean off any excess glue from the windows.

DECAL APPLICATION:

The decals supplied with your Nitro Rascal ARF kit are high

quality Mylar with an extremely aggressive adhesive. These are

not die-cut and must be cut from the sheet with hobby knife and

sharp #11 blade or with sharp scissors.

We suggest the following method to accurately apply these decals.

Carefully cut out the decal with a hobby knife. Lift it carefully off its

sheet with tweezers. Use a product like SIG Pure Magic Model

Airplane Cleaner, Fantastic®, or Windex®to spray the area of the

model that will receive the decal. Then spray the adhesive side of

the decal as well. Lightly position the decal in place on the model.

The liquid cleaner allows the decal to slide easily into the desired

position - do not press down on the decal. Once in position, hold

the decal lightly in place with your finger and use a paper towel to

gently dab the excess liquid away. Use a small squeegee to now

set the decal in place, removing all excess liquid and any air

bubbles. The Sig 4" Epoxy Spreader - #SIGSH678 - is perfect for

this job. Mop up any excess cleaner with a dry cloth and allow the

decals to set overnight. They will be solidly adhered to the model

without any air bubbles.

BALANCE:

IMPORTANT: The model is always balanced fully assembled with

the prop and spinner in place, the complete radio system installed,

and the fuel tank empty.

The correct CG (Center of Gravity) for your Nitro Rascal ARF

model is located precisely at the main wing spar location. This

means that when you place your fingers, one on each side of the

bottom of the wing, at the main spar location, the airplane should

balance in a level position. If the nose hangs low, this means the

model is "nose heavy". If the tail hangs low, this means the model

is "tail heavy". If either of these conditions exist, you must make

adjustments to correct the problem. Never attempt to fly your

model in an out of balance condition. Since the airborne battery

pack is the single heaviest component in the airplane, it can be

used to adjust almost any tail heavy or nose heavy condition. This

is simply done by repositioning the battery pack as needed to

correct the problem. In the unlikely event that moving the battery

pack will not correct the problem, then stick-on type lead weights

may be needed. These are available from your local hobby shop.

PRE-FLIGHT:

Before flying your Nitro Rascal we strongly suggest that you take

the time to break-in your engine and adjust the idle to its lowest

12

possible reliable rpm idle. The high quality of the piston-to-cylinder

fit on Norvel engines makes break-in a must before attempting to

fly the model. Break the engine in per the factory instructions and

DO NOT use the molded plastic spinner provided in this kit during

break in. We recommend that you use an electric starter to start

the engine the first few times and using the propeller spinner/front

thrust washer provided with the engine. This helps to avoid

burning the plastic spinner with the electric starter during the

break-in process.

We use and highly recommend either SIG "Champion" 15% or

25% fuel for the Norvel®.061 and .074 R/C engines. These fuels

have both contain generous oil content, absolutely essential for

high-revving smaller 1/2A engines.

ENGINE TIP: Both the Norvel®.061 and .074 R/C engines have

an offset head idle stop bolt in the left side of the carburetor body,

just behind the needle valve. This bolt is in place to limit the

travel of the throttle arm at low throttle. We have found that if this

bolt is completely removed, the throttle lever can then move further

forward in low throttle movement with the throttle servo. This

means that an even lower idle speed can be obtained. However,

you must experiment a little to obtain the lowest possible reliable

idle speed, without killing the engine. Our experience with this

simple modification has given us very reliable low speed idle

characteristics and - after adjusting the trims on our transmitter -

even the ability to use the "Throttle Cut" feature that is available on

some transmitters.

FLYING:

If you are new to the hobby/sport of flying R/C model airplanes, DO

NOT attempt to fly this model by yourself! There are hundreds of

AMA (Academy of Model Aeronautics) chartered R/C clubs in the

U.S. The easiest way to find clubs in your area is by simply asking

your local hobby retailer. AMA chartered clubs often have qualified

instructors who can teach you how to fly and perhaps even test fly

your model for you. If you are already an R/C pilot, then you will

likely have no problems at all with the Nitro Rascal.

Choose a calm day with little or no wind for the initial flights. This

is important in getting the model properly trimmed. We also

suggest that for the first few familiarization flight you or a flying

buddy hand-launch the model. When hand-launching, the airplane

must be launched straight and level directly into the wind, with the

nose aimed at a point on the ground about 75’in front of you.

NEVER launch the model with the nose pointed up or the wings

tipped to one side or the other. The launch should be firm enough

to achieve flight speed but not overly hard. Later, when you're

more familiar with the airplane and how it flies, you can perform

R.O.G. (Rise Off Ground) takeoffs from smooth surfaces.

Using full throttle at launch is recommended. Fly the model to a

comfortable altitude and throttle back the engine to a comfortable

cruising speed. Use the transmitter trims to adjust the model for

straight and level flight. Once the model is trimmed to your liking

you can begin to explore the Nitro Rascal's flight envelope.

Throttle all the way back and get familiar with the low speed flight

characteristics. This is great information to have when it comes

time to set-up your first landing. While still at low throttle, test the

airplane's stall characteristics. Using the initial control movements

in this manual, we think you will find the stall fairly uneventful and

easy to control.

Throttle up and gain some altitude. The Nitro Rascal is capable

of some really nice 3-channel aerobatics, such as rudder rolls,

inverted flight, snap rolls, spins, high-speed passes, etc. It can do

all of this in a very small amount of flying space. The more you fly

your Nitro Rascal the more you will begin to appreciate the

airplane's agility and throttle reaction.

Landing your Nitro Rascal is typically a pleasure. Throttle back to

achieve a shallow rate of descent, turn into the wind and allow the

airplane to settle in smoothly to a 3-point landing. With a little

either experience, you'll be landing your Nitro Rascal right in front

of you every time!

13

IMPORTANT NOTE: The Nitro Rascal ARF is a small, highly

maneuverable R/C model aircraft that can easily be flown in

smaller flying sites. However, it should always be flown in

areas that are appropriate for such models. NEVER fly this

model in close proximity to people, houses, etc. It is always

best to fly this model at flying sites specifically designated for

R/C models. Do yourself a favor and join your local R/C club -

you'll almost always get assistance and good advice and you

might even make a new friend or two!

FOLD LINE

FOLD LINE

MAIN GEAR FAIRING PATTERN

14

LIMIT OF LIABILITY

The craftsmanship, attention to detail, and actions of the builder/flyer of this model airplane kit will

ultimately determine the airworthiness, flight performance, and safety of the finished model. SIG MFG.CO.’s

obligation shall be to replace those parts of the kit proven to be defective or missing. The user shall

determine the suitability of the product for his or her intended use and shall assume all risk and liability in

connection therewith.

CUSTOMER SERVICE

SIG MANUFACTURING COMPANY, INC.is totally committed to your success in both assembling and flying

the NITRO RASCAL ARF kit. Should you encounter any problem building this kit or discover any missing

or damaged parts, please feel free to contact us by mail or telephone.

SIG MANUFACTURING COMPANY, INC.

P.O. Box 520

Montezuma, IA 50171-0520

SIG MODELER’S ORDERLINE: 1-800-247-5008

(to order parts)

SIG MODELER’S HOTLINE: 1-641-623-0215

(for technical support)

SIG WEB SITE: www.sigmfg.com

WARNING! THIS IS NOT ATOY!

Flying machines of any form, either model-size or full-size, are not toys! Because of the speeds that

airplanes must achieve in order to fly, they are capable of causing serious bodily harm and property

damage if they crash. IT IS YOUR RESPONSIBILITY AND YOURS ALONE to assemble this model

airplane correctly according to the plans and instructions, to ground test the finished model before each

flight to make sure it is completely airworthy, and to always fly your model in a safe location and in a safe

manner. The first test flights should only be made by an experienced R/C flyer, familiar with high

performance R/C aircraft.

The governing body for radio-control model airplanes in the United States is the ACADEMY OF MODEL

AERONAUTICS, commonly called the AMA. The AMA SAFETY CODE provides guidelines for the safe

operation of R/C model airplanes. While AMA membership is not necessarily mandatory, it is required by

most R/C flying clubs in the U.S.and provides you with important liability insurance in case your R/C model

should ever cause serious property damage or personal injury to someone else. For more information,

contact:

ACADEMY OF MODEL AERONAUTICS

5161 East Memorial Drive

Muncie, IN 47302

Telephone: (765) 287-1256

AMA WEB SITE: modelaircraft.org

Table of contents

Popular Toy manuals by other brands

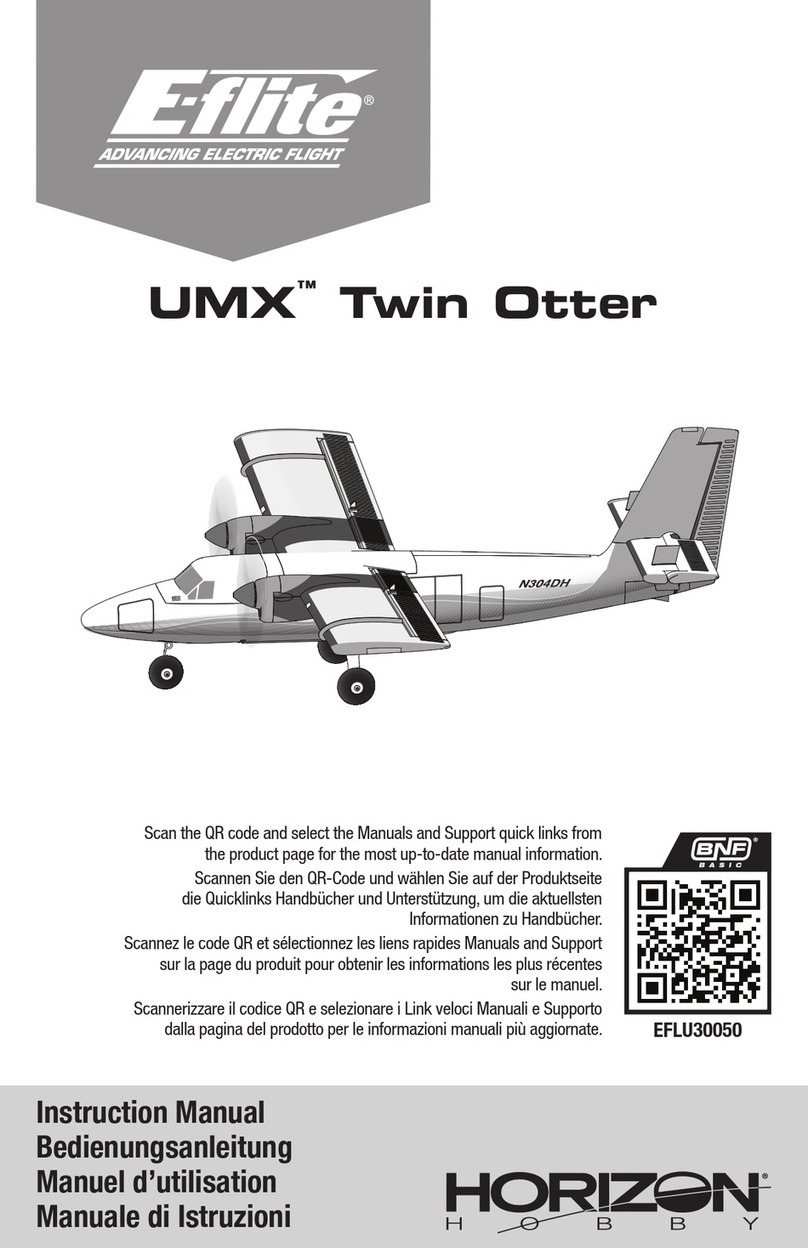

Horizon Hobby

Horizon Hobby E-flite UMX Twin Otter manual

Radio Flyer

Radio Flyer Glide & Go Balance Bike quick guide

Eduard

Eduard Bismarck Assembly instructions

EASYSKY

EASYSKY Micro B-17 Flying Fortress manual

LeapFrog

LeapFrog Little Office Learning Center Parents' guide

LEGO

LEGO City 7684 Building instructions