Sigma Metalytics PMV Pro PRO User manual

ERIFIER

Precious Metal

PRO

MANUAL

MODEL #2601

2

Contents

Caution ..................................................................................................................................3

PMV PRO Diagram ............................................................................................................4

PMV PRO Functions .........................................................................................................5

Power On and Calibrate .................................................................................................6

Setup ......................................................................................................................................7

Metal Selection ...................................................................................................................8

Weight Entry .......................................................................................................................9

Measurement Screen ....................................................................................................10

Measurement Interpretation ....................................................................................11

Wand Use ...........................................................................................................................14

PC Interface ......................................................................................................................15

External Bridge Use ......................................................................................................16

Thickness Calibration ..................................................................................................18

3

CAUTION

Read Before Use

• The onboard sensors and bridges are very sensitive to stress. DO

NOT press on them, place objects on them, or lift the device by the

bridges. Stress can cause miscalibration and damage.

• The plastic cover on the display protects the screen from damage.

DO NOT remove the plastic cover from the display.

consistent with the selected metal or alloy, are INFORMATIONAL ONLY and any judgment about or action taken with regard to any

sample is entirely the responsibility of the user. To ensure accuracy, thoroughly read the included instructions and be aware of the

special conditions which may affect the readings.

Power

CalMetal MeasureWeight

[█]

10 mm05 51 02 52 03 53 04 54 05 55 06 56 07 57 08 105 11058 09 59 001 511 021 521 031 531 140

Place sample against dotted lines where indicated.

Precious Metal

Firmware Version: 1.01

FPGA Version: 1.03

Database: 1.03

Small Sensor

and Bridge

Large Sensor

and Bridge

Sample Placement

Circle

Active Sensor

Lamps

Dimensions

Lamps

Measurement

Scale

Sample Placement

Circle

Sample must cover inside

of placement circle

External

Bridge

Connector

Wand

Connector

Power

Connection

PMV Pro

Sample must cover inside

of placement circle

4

Enter

Button

5

PMV PRO Functions

The PMV PRO uses up to four different measurements to determine if a coin or bar is

consistent with genuine precious metals.

The four measurements are:

1. The PMV PRO measures the sample’s resistivity just under

the surface of the metal. This ensures there are no contaminants or foreign metals in

or near the surface.

2. Using the sensors above and below the sample, the PMV PRO measures

the sample’s bulk resistivity. This measurement checks the entirety of the sample

and ensures there are no contaminants or foreign metals anywhere between the two

sensors.

3. The PMV PRO electronically measures the thickness of the

sample using the average thickness of the face of the sample.

4.

the sample is the correct density. The user must enter the measured weight of the

sample to perform this test.

6

Firmware Version: 1.01

FPGA Version: 1.03

Database: 1.03

Power On and Calibrate

Power on your PMV PRO by pressing the POWER button. The device will display the serial number,

turned on. This calibration checks the internal components and prepares the device for use. Press the

CAL button to calibrate. The device will check each sensor then show the READY screen.

7

Setup

You may change some settings in the SETUP screen. To access the SETUP screen, press the RIGHT

button on the READY screen. Use the UP and DOWN buttons to select the category, and use the RIGHT

and LEFT buttons to change the selection within a category. Press the ENTER button when done to exit

the SETUP screen.

Note: You do not need to setup the device each time you use it, the settings are saved between uses.

8

Metal Selection

Prior to taking a measurement, you must select the appropriate metal or alloy from the metal selection

database. Press the button open the selection menu. Use the LEFT and RIGHT buttons to

navigate between metal categories, and use the UP and DOWN

a category. When ready, press the ENTER, , or WEIGHT

9

Weight Entry

To enter the weight of a sample, press the WEIGHT button. You can either select from the options listed

in the English Units (Ozt) and Metric Units (grams) categories, or you can manually enter a weight on

your own. Use the LEFT and RIGHT buttons to navigate between categories, and use the UP and DOWN

buttons to select options within a category. When ready, press ENTER, , or

the selection.

Manual Weight Entry

To manually enter weight, use the UP and DOWN

buttons to select the type of weight you want to enter.

Press the ENTER button to change the indicated

weight. Use the LEFT and RIGHT buttons to select the

digit and use the UP and DOWN buttons to change

the digit value. Press the or button

10

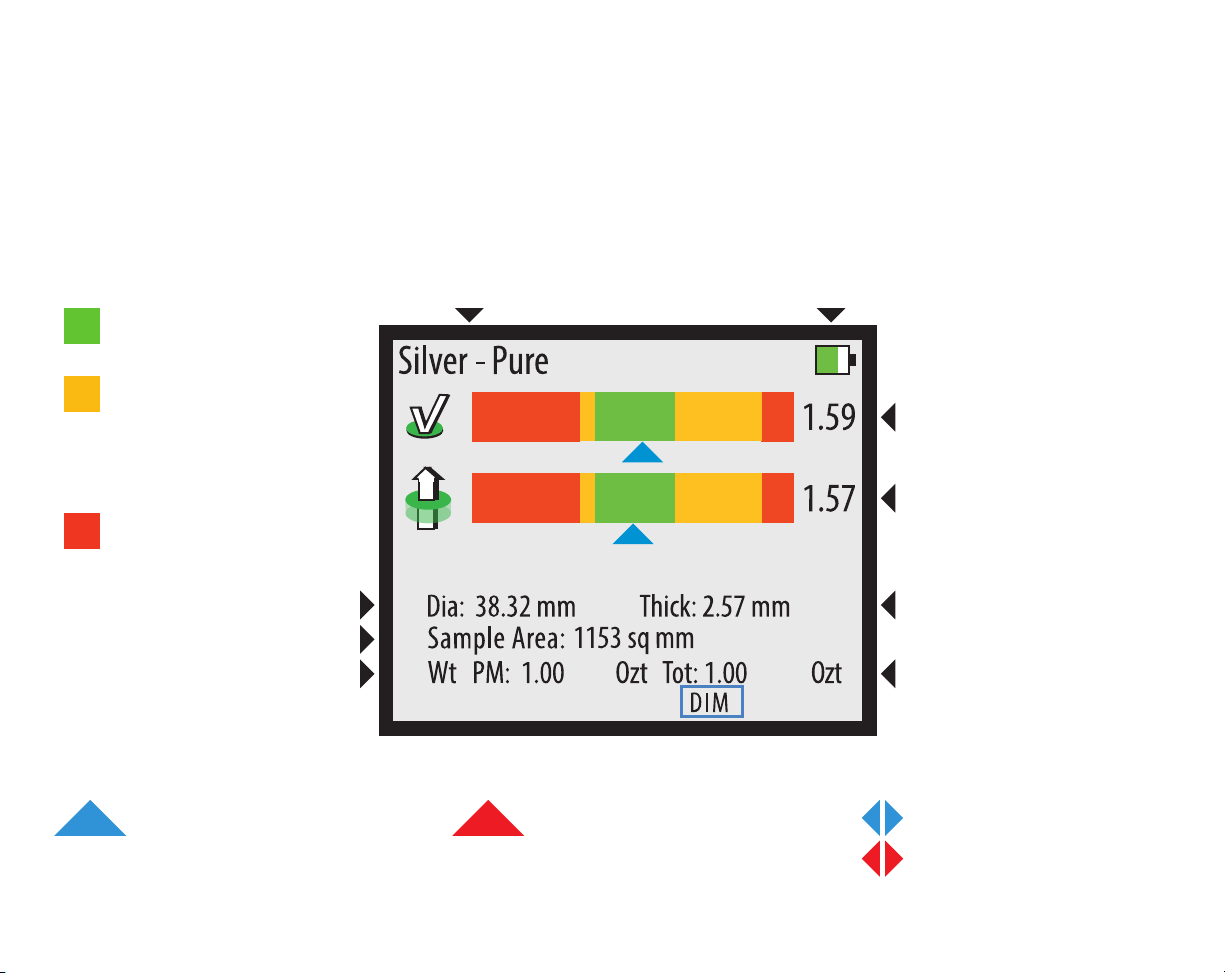

Sample consistent with

selected metal

aspects of sample, like

size, weight, and

markings.

Sample inconsistent

with selected metal

Measurement Screen

The MEASUREMENT screen will display when taking a reading. Below is a basic explanation of each

part of the screen. The screen will not display the diameter, thickness, or weight if weight mode is

Indicates the device is getting a

reliable reading.

Indicates the device is getting an

unreliable reading, treat result

with caution.

Indicates the result is off the

11

Measurement Interpretation

2.32

1.71

The device is getting a reliable reading

and the reading is consistent with the

selected metal.

The device is getting a reliable reading

that the surface of the sample is

inconsistent with the selected metal.

The device is getting a reliable reading

indicates that the bulk of the sample is

inconsistent with the selected metal.

The red arrows indicate that the

indicating a problem with the sample.

A red arrow on the top bar means the

sample is too small. Try measuring

with a smaller sensor.

A red arrow on the bottom bar means

the sample is too thin. Try measuring

with a smaller sensor.

12

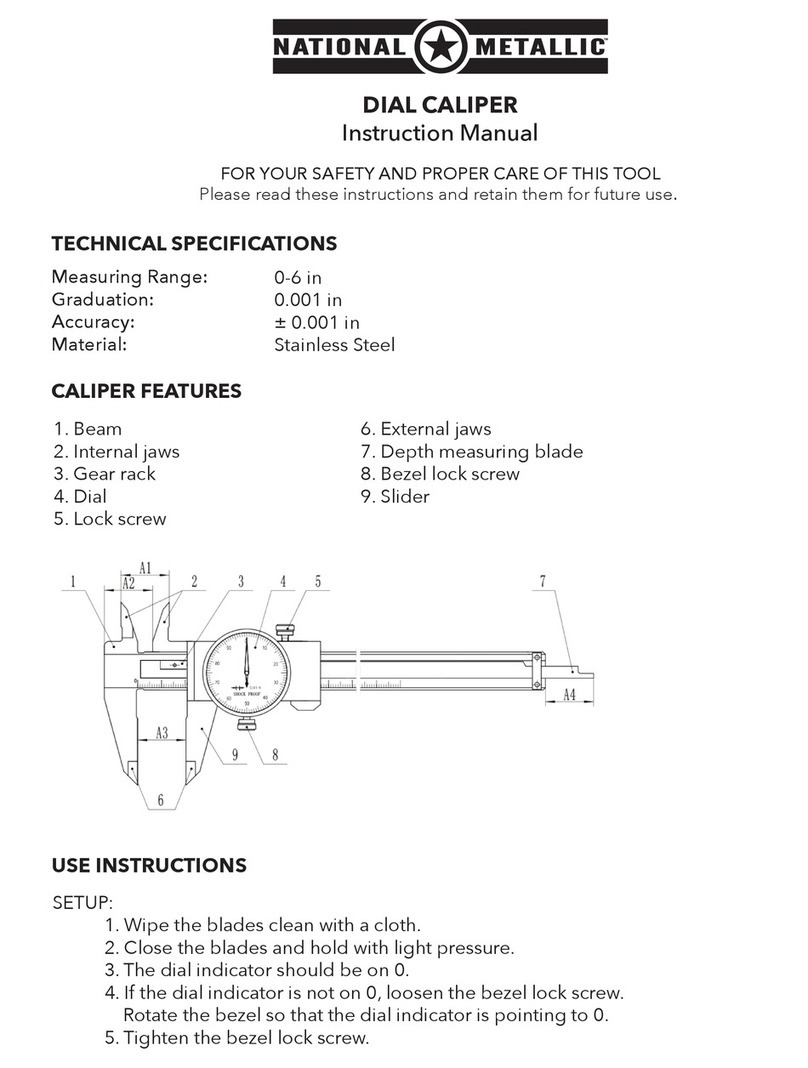

Dimension Verification

To verify the dimensions of a sample, the correct metal must be selected and the correct weight must be

entered. To verify the dimensions of a sample, press the button while the device is reading

the sample. Select the shape of the sample using the UP and DOWN buttons. Once the DIMENSION

screen appears, you may move the sample away from the sensor.

• align the right edge of the sample to the vertical dotted line indicated by the

illuminated LED. The left edge of the sample is expected to fall within the green range indicated on

the screen. If the edge falls within the range, then the sample’s density is consistent with the selected

metal. If the left edge falls outside of the green range, then the sample’s density is inconsistent with

the selected metal.

• align the right edge of the sample to the vertical dotted line indicated

by the illuminated LED. Use the UP and DOWN buttons to adjust the indicated width on the screen

to match the width of the sample. While adjusting the width, the illuminated LED may change

to indicate a different vertical dotted line. Re-align the right edge of the sample to the new line.

With both the right edge and width aligned properly, the sample’s left edge should fall somewhere

within the green range. If the edge falls within the range, then the sample’s density is consistent

with the selected metal. If the left edge falls outside of the green range, then the sample’s density is

inconsistent with the selected metal.

The PRO must be actively reading a sample when is pressed to perform dimension

13

Dimension Verification Diagram

14

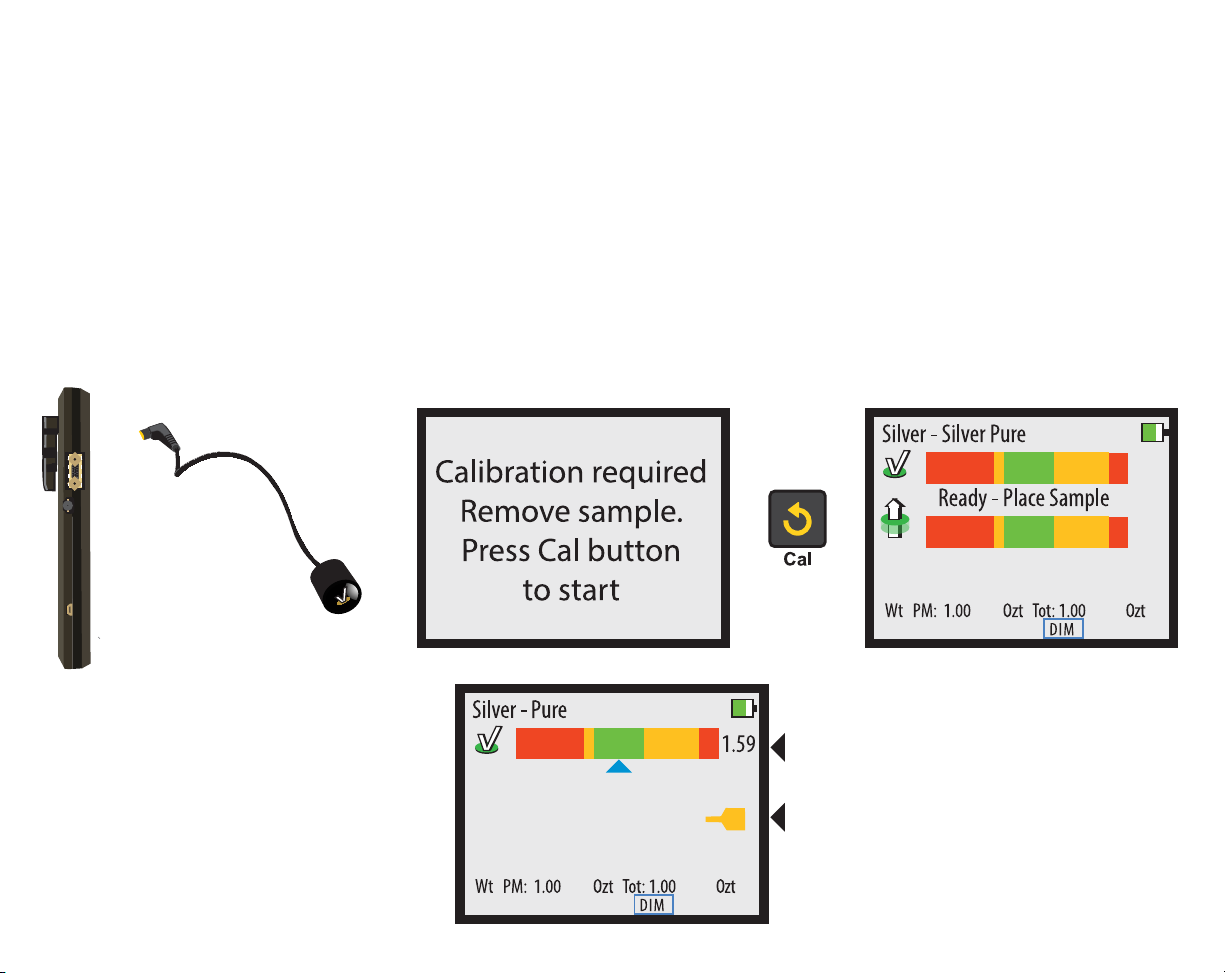

Wand Use

Wands are optional attachments for the PMV PRO. To use a Wand attachment, plug the Wand into the

Wand Connector on the right-hand side of the device. When you plug in the Wand, the device will ask

for calibration. Remove all samples from the device and ensure the Wand is at least one inch away from

any metal, then press the CAL button. When the READY screen is displayed, you may touch the face of

the Wand to a sample.

When measuring with the Wand, only the reading will display. There will also

be a yellow Wand indicator on the screen indicating the device is using the Wand’s sensor.

Refiners

When the Wand is touched to metal,

the screen will change to show the

results of the reading. There is only

one bar and a yellow icon appears to

indicate that the wand is in use.

15

PC Interface

The PMV PRO is capable of using a Windows PC (Windows 7, 8, 10, and 11) as an interface for the

sigmametalytics.com/pro-pc) and following the included download and installation instructions.

Once the program is successfully downloaded and installed, plug the PRO device into your PC using the

included USB cable.

To install the PRO PC interface:

1.

3. Your computer might show a warning that the .MSI was stopped from running because it might be

dangerous. Click “Learn More” and then “Run Anyway” to install the program.

4. The program will install to the C: drive by default, but you may select a custom folder.

5.

“PMV PRO.”

6. Connect your PRO to your computer using the included USB cable. Power on your device and run the

PMV PRO program to get started.

7. While using the PRO with the PC interface, the readings will display on both the device’s display and

the PC application.

16

External Bridge

The External Bridge is an optional attachment for the PMV PRO. To use the External Bridge, plug the

External Bridge into the External Bridge connector on the right-hand side of the device. When you

plug in the External Bridge, the device will ask for calibration. Remove all samples from the device and

External Bridge, and ensure the External Bridge’s plunger is in the up position. Then press the CAL

button. When the READY screen is displayed, you may place your sample under the External Bridge

may move the sample around under the plunger to test various areas.

When measuring with the External Bridge, the Basic and will display, just

like using the onboard sensors.

The sample must be no more than 45mm thick. The sample must cover the entire black circle on the

External Bridge platform throughout testing.

17

External Bridge Dimension Verification

overview. When verifying dimensions with the External Bridge, enter the measured weight, then, press the button

while the device is reading the sample. The device will display an initial DIMENSIONS screen. You must enter the measured

scale or calipers to measure the width. Once you have entered the width, press the button again and the device

For bars with angled

sides, measure width

from the middle of

each side.

Refer to Page 9 for data entry.

18

Thickness Calibration

In the event that your PRO device’s onboard sensors become miscalibrated, it may be important to re-

samples. Once the device displays the READY screen, press and hold the CAL button for 3 seconds. The

THICKNESS CALIBRATION screen will appear. Place the included calibration disk under the affected

sensor, then press the ENTER button. Leave the calibration disk under the sensor until the screen

returns to the MEASUREMENT screen.

With correct calibration, the calibration disk should be measured at about 1.60 - 1.61 mm thick. If your

device reads the calibration disk as more than 0.1 mm thinner or thicker than expected, please contact

us.

This re-calibration is only rarely needed and should only be performed if the device is showing

clear signs of a thickness mis-calibration. Because of the way the PRO electronically measures the

thickness of coins based on the face of the coin, the PRO’s indicated thicknesses for coins tends to be

Thickness Calibration

Cal

Press Cal and hold 3 seconds

Place Calibrator

under sensor.

Press Enter button

to cal

Press

Enter

When Done

Calibration

Power

CalMetal MeasureWeight

[█]

10 504540353025mm 05 2015 6055 80757065 105 110100959085 135130125120115 140

Place sample against dotted lines where indicated.

Silver-Silver Pure

Wt PM: 1.00 Ozt Tot: 1.00 Ozt

DIM

Ready - Place Sample

Place calibration

coin under each sensor that

that needs to be

calibrated

19

20

Common Questions

1.

Our “Pure Silver” range is calibrated to put .9999 silver in the green and .999 silver in the yellow on the right. We do this

because we so frequently see .999 silver counterfeited that we want all users to be cautious of .999 silver samples and

to check the other aspects (markings, weight, and size) of the sample prior to making any judgment. If you are using an

2.

The left side of the reading range indicates less resistivity and the right side indicates more resistivity. If a sample reads to

the left, it means it is less resistive than expected; if a sample reads to the right, it means it is more resistive than expected.

3.

Modern coinage is designed to have the same resistivity as older 90% silver coinage to ensure they all work in vending

machines. The best way to ensure your quarters are 90% silver is to check their weight: modern quarters are about 0.5

grams lighter than older quarters.

4.

The device needs to be actively measuring the sample when you press the MEASURE button to bring up the dimensions

5.

The device will ask for calibration when powering on and when plugging in an attachment. In regular use, we recommend re-

of all samples and press the CAL button to re-calibrate.

6.

The PMV PRO electronically measures thickness and takes the average thickness from the face of the coin while trying to

account for relief, design, and lettering. Mints and retailers measure coin thickness using calipers at the rim, not the face.

Because of this different method of measuring, the PRO’s thickness measurement is usually slightly thinner than what’s

published by the mint or retailers.

7.

The PMV PRO can go for 6 - 8 hours of constant use before needing a charge. The device has a high-capacity battery, so you

can leave it charging overnight or for long periods without damaging the system.

This manual suits for next models

1

Table of contents

Other Sigma Metalytics Measuring Instrument manuals