SIGMA TEK RFID 131 User manual

RFID 131

RFID Reader

with USB and CAN Connection

Date of creation: 22.12.2016

Version date: 01.07.2020

Article number: 01-691-131-E

Publisher: SIGMATEK GmbH & Co KG

A-5112 Lamprechtshausen

Tel.: 06274/4321

Fax: 06274/4321-18

WWW.SIGMATEK-AUTOMATION.COM

Copyright © 2016

SIGMATEK GmbH & Co KG

Translation from German

All rights reserved. No part of this work may be reproduced, edited using an electronic system, duplicated or dis-

tributed in any form (print, photocopy, microfilm or in any other process) without the express permission.

We reserve the right to make changes in the content without notice. The SIGMATEK GmbH & Co KG is not responsi-

ble for technical or printing errors in the handbook and assumes no responsibility for damages that occur through

use of this handbook.

RFID READER RFID 131

01.07.2020 Page 1

RFID Reader RFID 131

The RFID reader is an installable device for reading and writing to RFID card. Communica-

tion with other bus participants is established over the CAN bus or USB interface. The

reader is supplied with +24 V.

The RFID reader is installed in a cutaway of the control cabinet. The status LED in the

upper left corner blinks in a 1 s cycle and indicates the readiness of the device. With a CAN

message, it can also be controlled via the application.

RFID 131 RFID READER

Page 2 01.07.2020

Contents

1Technical Data ........................................................................ 4

1.1 Performance Data.........................................................................4

1.2 Electrical Requirements...............................................................4

1.3 RFID Reader ..................................................................................4

1.4 Environmental Conditions...........................................................5

1.5 Miscellaneous ...............................................................................5

2Mechanical Dimensions......................................................... 6

3Connector Layout................................................................... 7

3.1 Applicable Connectors.................................................................8

4Mounting Instructions............................................................ 9

4.1 Mounting Position ........................................................................9

5General Instructions..............................................................10

5.1 Ground.........................................................................................10

5.1 Shielding......................................................................................10

5.2 ESD Protection............................................................................10

5.3 User Guidelines ..........................................................................11

6CAN Bus.................................................................................12

6.1 Node ID Assignment...................................................................12

6.1.1 Node-IDs (CAN Open SDO)..............................................................12

6.2 Number of CAN Bus Participants .............................................13

RFID READER RFID 131

01.07.2020 Page 3

6.3 CAN Bus Data Transfer Rate .....................................................14

6.4 CAN Bus Termination.................................................................15

6.5 CAN Protocol...............................................................................15

6.5.1 CAN Object Definition....................................................................... 15

6.5.2 CAN –Object Dictionary................................................................... 16

6.5.3 Serial Interface.................................................................................. 17

6.5.4 Example Communication - Scanning Tags....................................... 17

7USB Interface Connections..................................................23

7.1 Use with Windows-based Systems...........................................23

8FCC Statement.......................................................................24

9Cleaning the Front.................................................................25

10 Disposal .................................................................................26

RFID 131 RFID READER

Page 4 01.07.2020

1 Technical Data

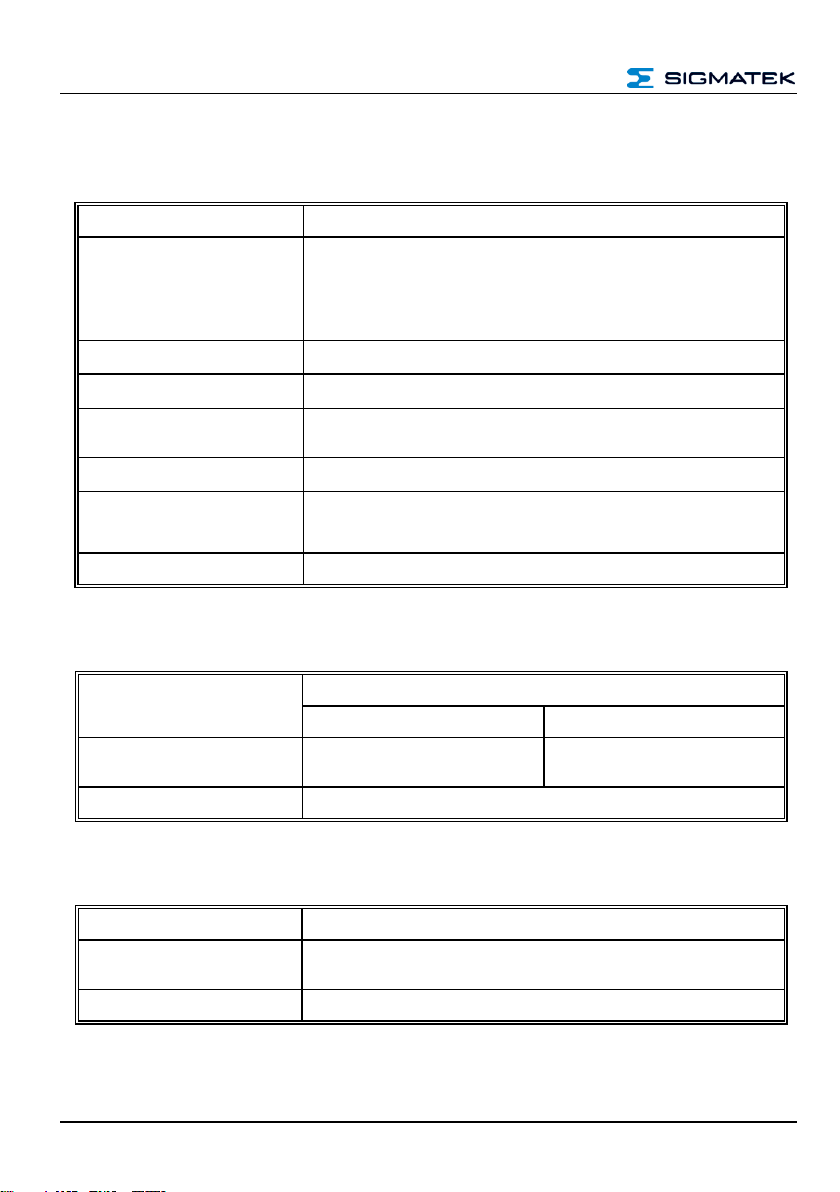

1.1 Performance Data

Protocol

ISO 15693, ISO 14443A, ISO 14443B

Supported cards

Mifare Ultralight/Ultralight C

Mifare Classic Mini/1K/4K

Mifare Desfire EV1 2K, 4K 8K

Mifare Pro, Plus

ISO15693 NXP ICOD SLI, TI TagIT, standard cards

RF power

100 mW EIRP

Operating frequency

13.56 MHz

Reading distance

up to 5 cm

(depending on the tag, antenna and ambient conditions)

Write distance

approximately 70 % of the read distance

Interfaces

1x USB device 2.0, (Type Mini-B)

1x CAN bus

Status LEDs

yes, blinks in 1 s frequency and indicates the readiness of the device

1.2 Electrical Requirements

Supply voltage

typically +24 V DC

minimum +18 V DC

maximum +30 V DC

Current consumption

Power supply +24 V

minimum 45 mA

maximum 60 mA

Inrush current

2 A for 2 ms

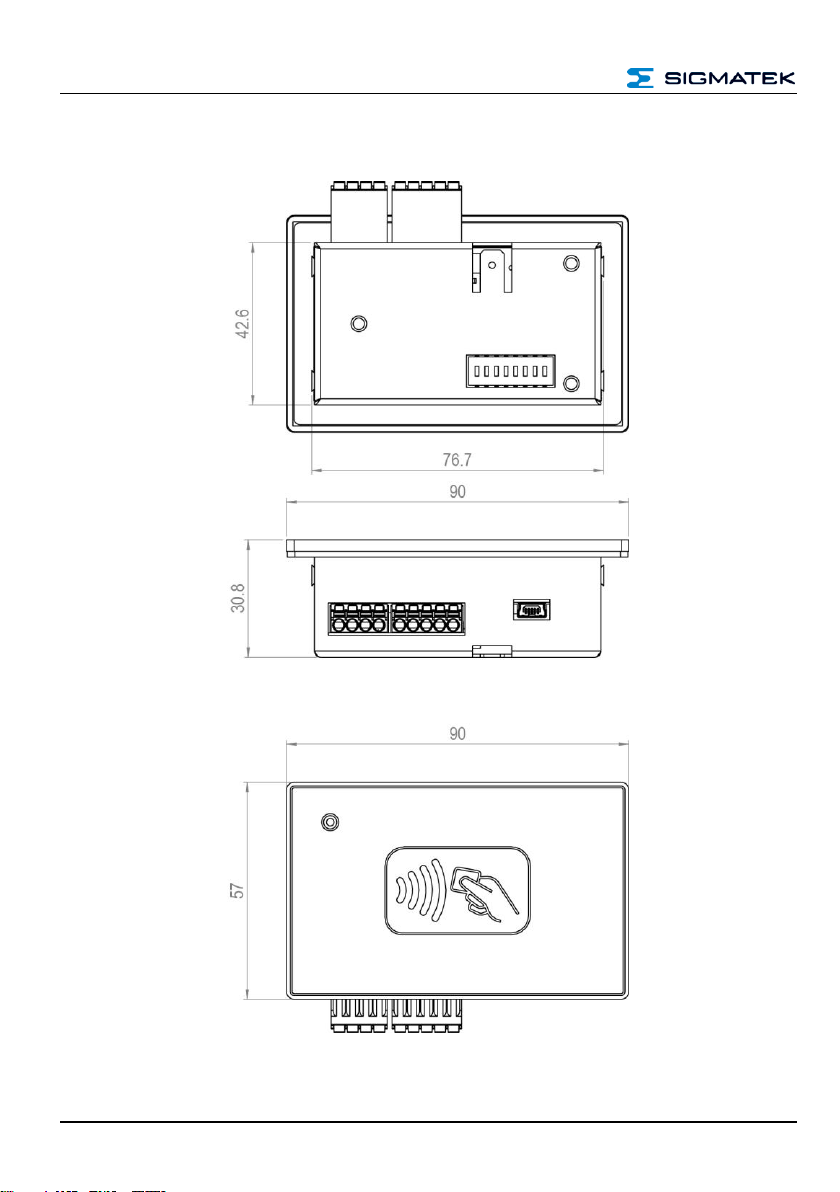

1.3 RFID Reader

Dimensions

90 x 57 x 30.8 mm (W x H x D)

Material

front: acrylic glass

back: chromated sheet steel

Weight

110 g

RFID READER RFID 131

01.07.2020 Page 5

1.4 Environmental Conditions

Storage temperature

-20 ... +85 °C

Environmental temperature

0 ... +55 °C

Humidity

0-95 %, non-condensing

EMC resistance

according to EN 61000-6-2 (industrial area)

EMC noise generation

according to EN 61000-6-4 (industrial area)

Radio Communication Conformity

Europe

according to ETSI EN 300 330 (2014/53/EU, RED Directive)

Radio Communication Conformity

USA

FCC CFR 47 Part 15

Product safety

EN 60950-1:2006

Vibration resistance

EN 60068-2-6

2-9 Hz: amplitude 3.5 mm

9-200 Hz: 1 h (10 m/s2)

Shock resistance

EN 60068-2-27

duration 11 ms, 18 Shocks

15 g (150 m/s2)

Protection type

EN 60529

protected through the housing

front: IP65

cover: IP20

1.5 Miscellaneous

Article number

01-691-131

Hardware version

2.x

RFID 131 RFID READER

Page 6 01.07.2020

2 Mechanical Dimensions

RFID READER RFID 131

01.07.2020 Page 7

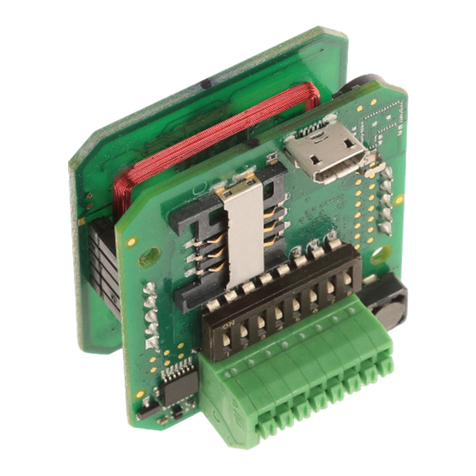

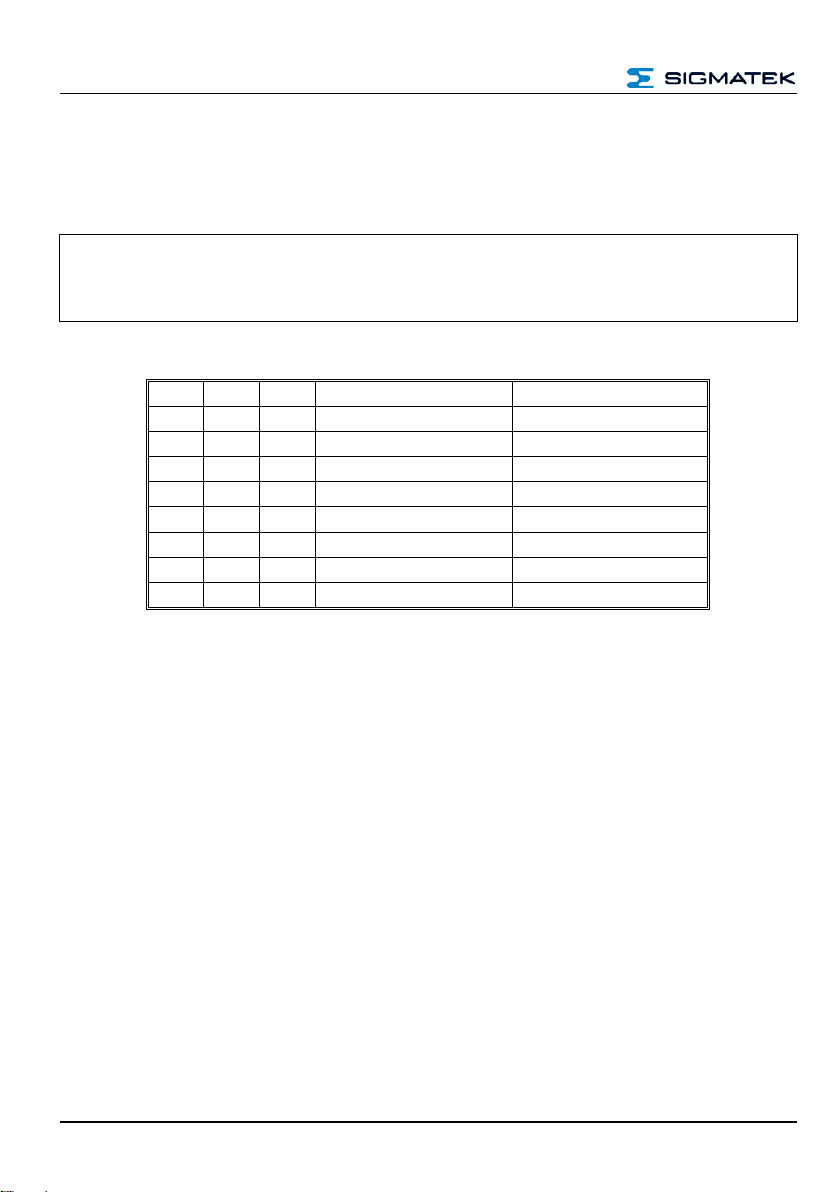

3 Connector Layout

X1: USB-Device 2.0 (Type Mini-B)

n.c. = do not use

X2: CAN Bus (5-pin Phoenix Contact)

X3: Visualization (4-pin Phoenix Contact)

Pin

Function

1

+5 V

2

D-

3

D+

4

n.c.

5

GND

Pin

Function

1

CAN A (LOW)

2

CAN B (High)

3

CAN A (CAN LOW)

4

CAN B (High)

5

CAN GND

Pin

Function

1

+24 V supply

2

+24 V supply

3

GND

4

GND

RFID 131 RFID READER

Page 8 01.07.2020

S1: DIP-Switch

3.1 Applicable Connectors

Connectors:

X1: USB Type Mini-B on a USB Type A cable, max. length 3 m

(not included in delivery)

X2: 5-pin Phoenix plug with spring terminals FK-MCP 1.5/ 5-ST-3.5

(Included with delivery)

X3: 4-pin Phoenix plug with spring terminals FK-MCP 1.5/ 5-ST-3.5

(Included with delivery)

Connections:

Stripping length:

10 mm

Mating direction:

parallel to the conductor axis or circuit board

Conductor cross section rigid:

0.2-1.5 mm2

Conductor cross section flexible:

0.2-1.5 mm2

Conductor cross section AWG/kcmil:

24-16

Conductor cross section flexible with

ferrule without plastic sleeve:

0.25-1.5 mm2

Conductor cross section flexible with

ferrule with plastic sleeve:

0.25-0.75 mm2 (reason for reduction d2 of the

ferrule)

RFID READER RFID 131

01.07.2020 Page 9

4 Mounting Instructions

The following guidelines must be observed when installing the RFID reader:

- For installation with the screw-in brackets provided, it is recommended that the in-

stallation panel have a material strength of 3 mm. Material strengths from 1 to 4

mm are also allowable. The screw-in brackets can be tightened with a maximum

torque of 0.15 Nm. For this purpose, a 3x0.5 flat-tip screw driver is required.

- To avoid damage to the front, it is important to ensure that during installation, the

mounting surface clean (free of debris, uneven areas). Unevenness can lead to

voltages on the front or contamination from dust and water.

4.1 Mounting Position

Since very little heat is generated, no specific clearance is required.

Sufficient air circulation however, must be ensured so that no trapped heat can developed.

Section side view: section top view

RFID 131 RFID READER

Page 10 01.07.2020

5 General Instructions

5.1 Ground

The RFID reader must be connected to ground through the assembly on the control cabinet

or over the connection provided. It is important to create a low-ohm ground connection, only

then can error-free operation be guaranteed. The ground connection should have a maxi-

mum cross section and the largest (electrically conductive) surface possible.

5.1 Shielding

To wire the USB interface, a USB 2.0 cable must be used. When using the CAN bus inter-

face, a shielded cable must be used. Noise signals can therewith be prevented from reach-

ing the electronics and affecting the function.

5.2 ESD Protection

Before any device is connected to, or disconnected from the reader, the potential should be

equalized (by touching the control cabinet or ground terminal). This will allow the dissipation

of electrostatic loads (caused by clothing/shoes).

RFID READER RFID 131

01.07.2020 Page 11

5.3 User Guidelines

CAUTION!

The RFID reader cannot always be operated with an interface (USB or CAN). Simulta-

neous operation is not supported and causes the reader to malfunction.

CAUTION!

The USB interface is not used to operate the device.

Here, as can be seen under "Electrical Requirements", an additional external voltage

supply is required.

Technical changes to the device, as well as improper use can lead to the loss of the

FCC license and generate interference, which can affect the function of nearby de-

vices.

Please note the national standardization when operating the wireless device.

Further information on the use, as well technical data can be found in the separate manual

for the RFID reader series. This can be acquired through the support.

RFID 131 RFID READER

Page 12 01.07.2020

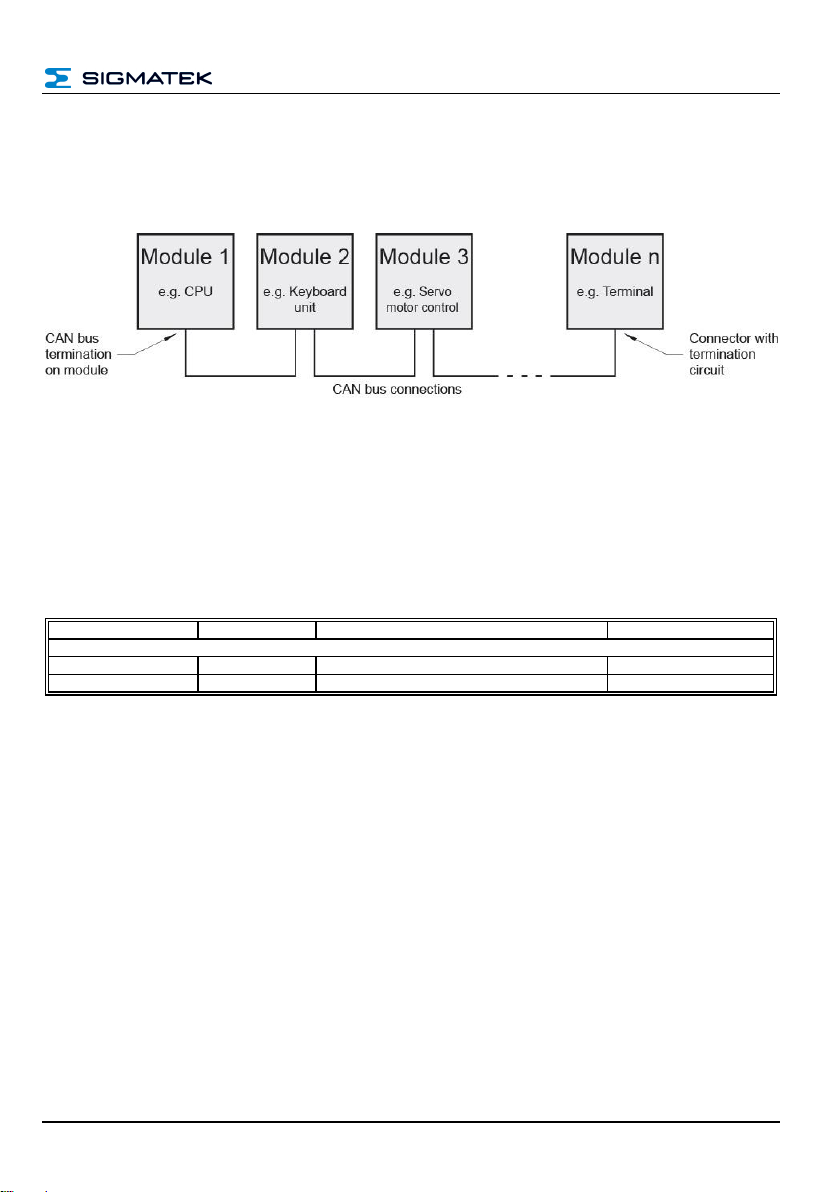

6 CAN Bus

This section explains how to correctly configure and use the CAN bus. The CAN bus inter-

face is based on the CAN-Open standard according to EN50325-4. For the configuration,

the device ID and the data transfer rate must be set.

6.1 Node ID Assignment

Each CAN bus participant in the system is assigned its own node identification number

(Node ID). With this Node ID, data can be exchanged with other stations connected to the

bus. In a CAN bus system however, each Node ID can only be assigned once!

6.1.1 Node-IDs (CAN Open SDO)

SW 4

SW 5

SW 6

SW 7

SW 8

Node ID

Off

Off

Off

Off

Off

1

On

Off

Off

Off

Off

2

Off

On

Off

Off

Off

3

On

On

Off

Off

Off

4

Off

Off

On

Off

Off

5

On

Off

On

Off

Off

6

Off

On

On

Off

Off

7

On

On

On

Off

Off

8

Off

Off

Off

On

Off

9

On

Off

Off

On

Off

10

Off

On

Off

On

Off

11

On

On

Off

On

Off

12

Off

Off

On

On

Off

13

On

Off

On

On

Off

14

Off

On

On

On

Off

15

On

On

On

On

Off

16

RFID READER RFID 131

01.07.2020 Page 13

Off

Off

Off

Off

On

17

On

Off

Off

Off

On

18

Off

On

Off

Off

On

19

On

On

Off

Off

On

20

Off

Off

On

Off

On

21

On

Off

On

Off

On

22

Off

On

On

Off

On

23

On

On

On

Off

On

24

Off

Off

Off

On

On

25

On

Off

Off

On

On

26

Off

On

Off

On

On

27

On

On

Off

On

On

28

Off

Off

On

On

On

29

On

Off

On

On

On

30

Off

On

On

On

On

31

On

On

On

On

On

32

6.2 Number of CAN Bus Participants

The maximum number of participants on the CAN bus depends on the cable length, termi-

nation resistance, data transfer rate and the drivers used in the participants.

With a termination resistance of 2x 20 , a minimum of 100 participants are possible.

RFID 131 RFID READER

Page 14 01.07.2020

6.3 CAN Bus Data Transfer Rate

Various data transfer rates (baud rates) can be set on the CAN bus. The longer the bus line

is, the lower the data transfer rate that must be selected.

In delivery condition, the CAN Baud rate is set to 500 kbits/s.

The CAN bus transfer rate can be freely configured via DIP switch, if a device is ex-

changed or incorrectly configured, the DIP switch must be checked or set correctly.

SW 1

SW 2

SW 3

Mmximum length

Baud rate (in kBaud)

Off

Off

Off

60 m

615

On

Off

Off

80 m

500

Off

On

Off

160 m

250

On

On

Off

320 m

125

Off

Off

On

400 m

100

On

Off

On

800 m

50

Off

On

On

1200 m

20

On

On

On

30 m

1000

These values are valid for the following cable: 120 , Twisted Pair.

Note: For the CAN bus protocol: 1 kbits/s = 1 kBaud

RFID READER RFID 131

01.07.2020 Page 15

6.4 CAN Bus Termination

In a CAN bus system, both end modules must be terminated. This is necessary to avoid

transmission errors caused by reflections in the line.

6.5 CAN Protocol

Each message contains up to 8 bytes. The data transfer takes place according to CiA

DS301. Several CAN messages may be necessary for one frame on the RFID reader.

6.5.1 CAN Object Definition

Direction from the point of view of the control controlling the module.

Object Number

Direction

Name

Cycle Time

SDO

0x580 + Node ID

Receive

SDO request

not cyclic

0x600 + Node ID

Transmit

SDO response

not cyclic

RFID 131 RFID READER

Page 16 01.07.2020

6.5.2 CAN –Object Dictionary

Index

(hex)

Subindex

Size

(bytes)

Access

Description

2000

0

256

SEG_WO

RFID –Request

2002

0

1

EXP_RO

Number of FW information entries (here: 4)

2002

1

2

EXP_RO

FW version

2002

2

4

EXP_RO

Serial number of the product

2002

3

16

SEG_RO

Product name in ASCII

2002

4

2

EXP_RO

Bootloader version

2003

0

1

EXP_WO

Special commands

0xE0 … Switch to bootloader

(e.g. for FW update)

0xF0 … Hard reset of the RFID reader

(This command entry in the Object Dictionary is

reset in the firmware immediately after recogni-

tion)

2005

0

4

EXP_RW

LED Access:

Bit 0 –Bit 13: switch on time in ms (0 bis 16383)

Bit 14 –Bit 27: switch off time in ms (0 bis 16383)

Bit 28: Direct control

0 … LED off

1 … LED on

Bit 29: Blink-enable

0 … Direct control is used

1 … The LED flashes at the indicated times

(Direct control is ignored)

Bit 30 –Bit 31: Reserved

2200

0

256

SEG_RO

RFID –Response (the actual length returned in

the initiate segmented read packet varies with the

length of the RFID reader response (max. 256

bytes))

Accesses from the point of view of the control that controls the module:

SEG_WO .. segmented write only access

SEG_RO .. segmented read only access

EXP_WO .. expedited write only access

EXP_RO .. expedited read only access

EXP_RW .. expedited read/write access

RFID READER RFID 131

01.07.2020 Page 17

6.5.3 Serial Interface

The data from and to the RFID hardware (2000 RFID - Request, 2200 RFID - Response)

are forwarded by the microcontroller from/via the serial interface. The protocol documenta-

tion of the HF-RFID Reader can be obtained separately from the support department. It

describes the complete communication processes.

6.5.4 Example Communication - Scanning Tags

Here a short communication example is shown which CAN messages are necessary to

perform a SCAN.

To read or write data from or to the RFID reader, the protocol must be transferred from the

HF-RFID reader via the CanOpen protocol.

Message to the RFID Reader:

Byte

Data

Description

0

0x21

CANOpen Header (structure see CANOpen Specification) →Command “initiate down-

load request”

1

0x00

2 Byte Index (see Object Dictionary) →0x2000 = RFID request according to Object

Dictionary

2

0x20

3

0x00

1 Byte Subindex (see Object Dictionary)

4

0x06

Data (structure see CANOpen Specification (different depending on command).

In our case the length of the “Scaan Tags" command is given here

5

0x00

6

0x00

7

0x00

Response from the RFID Reader:

Byte

Data

Description

0

0x60

CANOpen Header … command “initiate download response”

1

0x00

2 Byte Index

2

0x20

3

0x00

1 Byte Subindex

4

0x00

Reserved (always 0)

5

0x00

6

0x00

7

0x00

RFID 131 RFID READER

Page 18 01.07.2020

After the reader has confirmed the message, the next message is sent.

Message to the RFID Reader:

Byte

Data

Description

0

0x03

CANOpen Header (structure see CANOpen Specification) →Command “download

segment request”

1

0x00

Here follows the data (in this case the Scan Tags command of the reader)

Byte 1… command “Scan Tags”

Byte 2… Status code to reader (always 0x00)

Byte 3-4 … length of the data

Byte 5 … card type

Byte 6 …CRC

Byte 7 … not used →0x00

2

0x00

3

0x01

4

0x00

5

0x02

6

0x03

7

0x00

Response from the RFID Reader:

Byte

Data

Description

0

0x20

CANOpen Header … command “download segment response”

1

0x00

Reserved (always 0)

2

0x20

3

0x00

4

0x00

5

0x00

6

0x00

7

0x00

Now the Scan Tags command should have been successfully sent to the firmware of the

RFID reader via the CanOpen protocol. To be able to read the response to the Scan Tags

command we have to read the response from the module. The response of the command is

provided by the firmware in the designated area (0x2200 RFID Response) in the object

dictionary.

An SDO upload must be initiated to read this data.

Table of contents