9

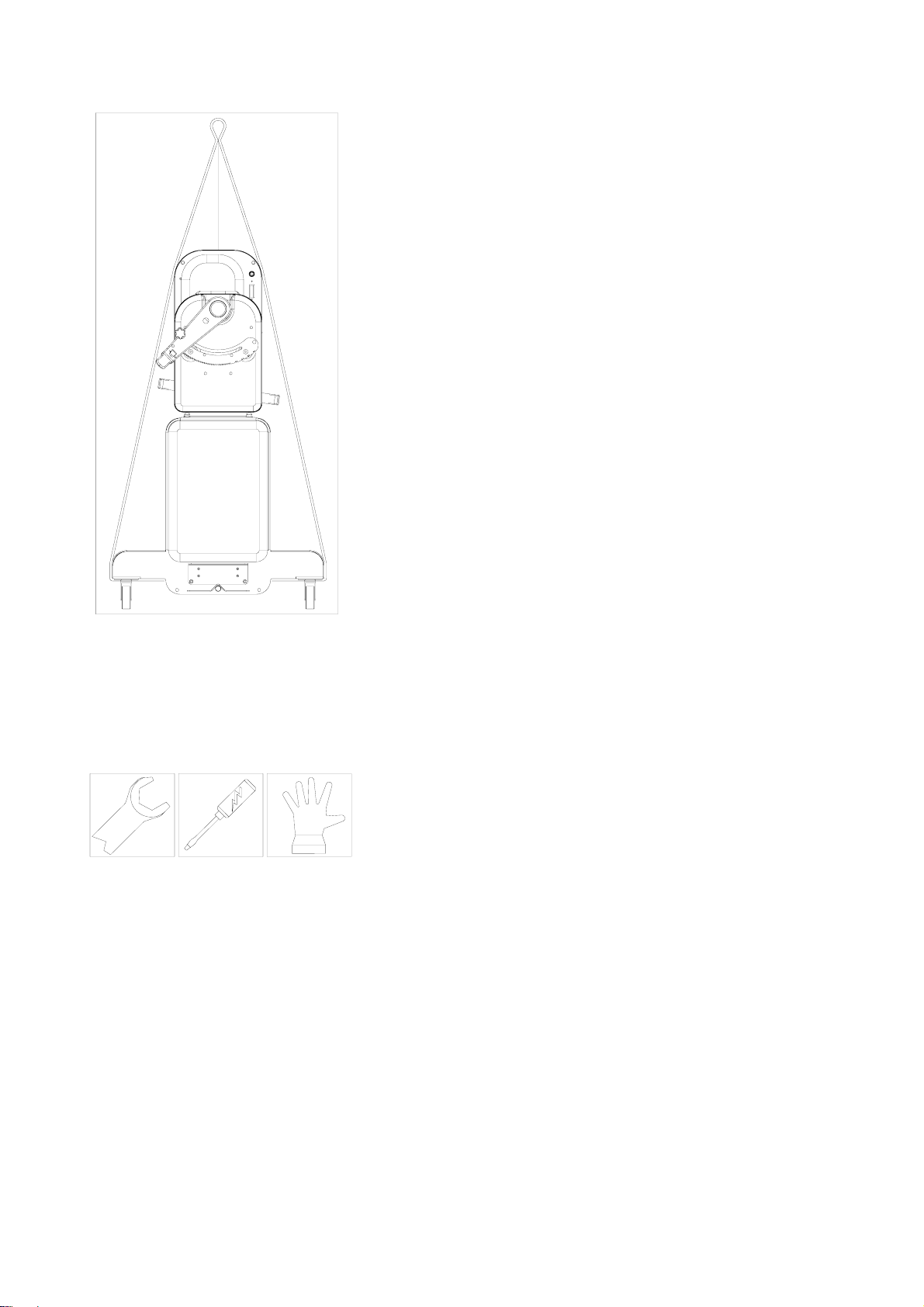

8.8) FIRST STARTUP:Make sure the protection grids are lowered before any operation

when the current is on. Just press button 1 to

start the machine , the closure of the circuit is signalled

by the lighted lamps.

Lower lever 2 as shown

in the figure to test

correct connection, the belt must move to

the direction of the arrow. Conversely, reverse the couple

of wire in the current plug. Carry out the same test if the

machine is fitted with pedals. Eventually test the adjusting

lever of the roller, to approach them, just move lever 4 from

the right to the left, even using your palm smoothly. A

special crack consents movement in a single direction, to

reset it in its open position, press trigger 5 that releases

the crack and consents free movements of the lever.

When the thickness of pasta has been defined, it can be

stored in the memory by means of ratchet 6; this one

prevents the adjusting lever from moving forward the point

established. Make sure the machine is stable and the belts

and scrapers are properly inserted. Make also sure

that the safety microswitches controlling the protection grids work correctly,

when you lift them the machine must stop. The machine is operational.

9.0) OPERATION

9.1) OPERATION. This machine is normally used for the production of puff

pastry. Refer to our trade department for different employments: a set of special

belts is available for grease pastry or others.

To fine down pastry, you must put on the belt a block of pasta composed of

alternate layers of butter or margarine and outside the flour dough. If necessary, it is also

important to dust some flour on the areas in contact with the blocks and the belts and

rollers; in the central area of the crown there’s a special housing for this purpose. Adjust

the rollers so as to reduce thickness by 10-15 % and start the machine. The block will be

dragged towards the rollers and reduced by them; the thickness is reduced and

consequently it will be enlarged and lengthened.

When all the pastry is out of the rollers, the motion must be reversed by means of lever 2

or pedal 3 and, at the same time, the rollers must be tighten to carry out another fining.

The puff pastry becomes wider and wider as the process goes on; for this reason, at the

end of any belt there are two

trays to carry pasta. When they

are full, the rolling pins must be

used to roll up pasta.