STS LABEL APPLICATOR STS808-3 User manual

V.2.00

LABEL APPLICATOR

FOR ONE AND TWO LABELS

STS808-3

User manual

STS 808

LABEL APPLICATOR

MC

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

V.2.00

Technical data

Power supply: 220Vac, 50Hz.

Own consumption: < 100VA.

Electrical connecting: cable with plug type 'SHUKO'.

Dimensions: 365mmW, 245mmH, 330mmD.

Diameter of the container: 25 ... 160mm.

Length of the container: 80 ... 240mm.

/distance between the container guides/

Diameter of label roll: < 200mm.

Spool diameter: 50 ... 70mm.

Roll / Label Width: 25 ... 150mm.

Label length: 25 ... 500mm.*

Distance between the labels: > 2,5mm.

Pulling speed: 0,1m/s.

* the sum of the lengths of the two labels should not be greater than the circumference

of the container.

- 2 - STS808

Description

The machine is designed to place one or two self-adhesive labels (front and rear) on

cylindrical containers of different diameter and length with smooth walls. The labels must be

on one roll, (front and rear - placed consecutively) on the roll guide.

The containers need to be placed and removed manually. The beginning of the work is

performed by pressing the built-in 'Start' button or by an external start / 'Start' pedal

connected to the intended coupling /.

The control panel allows you to count the labels which has been used.

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

Preparation for work and setup.

The orientation of the container (left-right) is selected, depending on the direction of

the printed labels. Adjust the pressure arm and idler roller according to the diameter of the

container. Adjust the guides so that the container is in the middle of the working area.

The label roll is placed on the Label bar so that the labels are against the gluing area.

The position is fixed with the two magnetic roll guides. The roller drag arm is positioned in the

center of the roller.

The pressure roller is "unlocked" by moving forward. Label bar is loaded according to

the attached scheme. The sensor is positioned so that labels pass through its working area. It

is trained according to the attached manual. Next to the peel edge is positioned the beginning

of the label (front - with two labels). The pressure roller is locked. The guides of the label strip

are positioned and fixed to the edges without compressing it.

Set the required parameters in the machine menu. Start without a container for

control. The new label (front label - with two labels) must be up to the peeling edge. If

necessary, adjustments are made.

At any time, pressing the C button for more than 3 seconds causes the counter to be

reset.

The brightness and contrast of the display can be changed as desired.

- 3 -

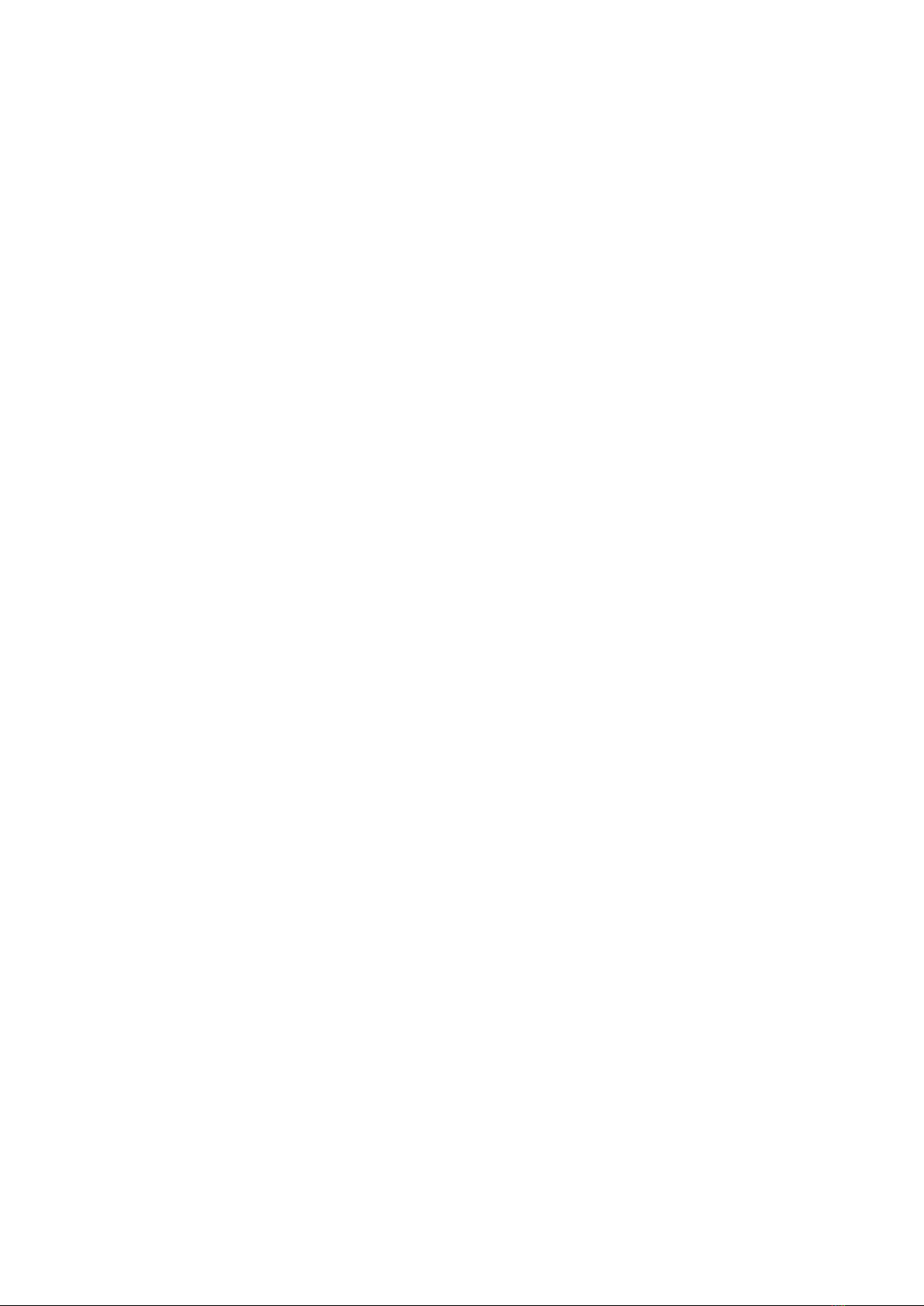

Label Path Diagram

Pulling roller

Pressure roller

Peel edge

Label Path Drive roller Container idler

roller

SensorGuiding rollerGuiders

Container pressure arm

V.2.00STS808

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

- 4 -

STS 808

LABEL APPLICATOR

MC

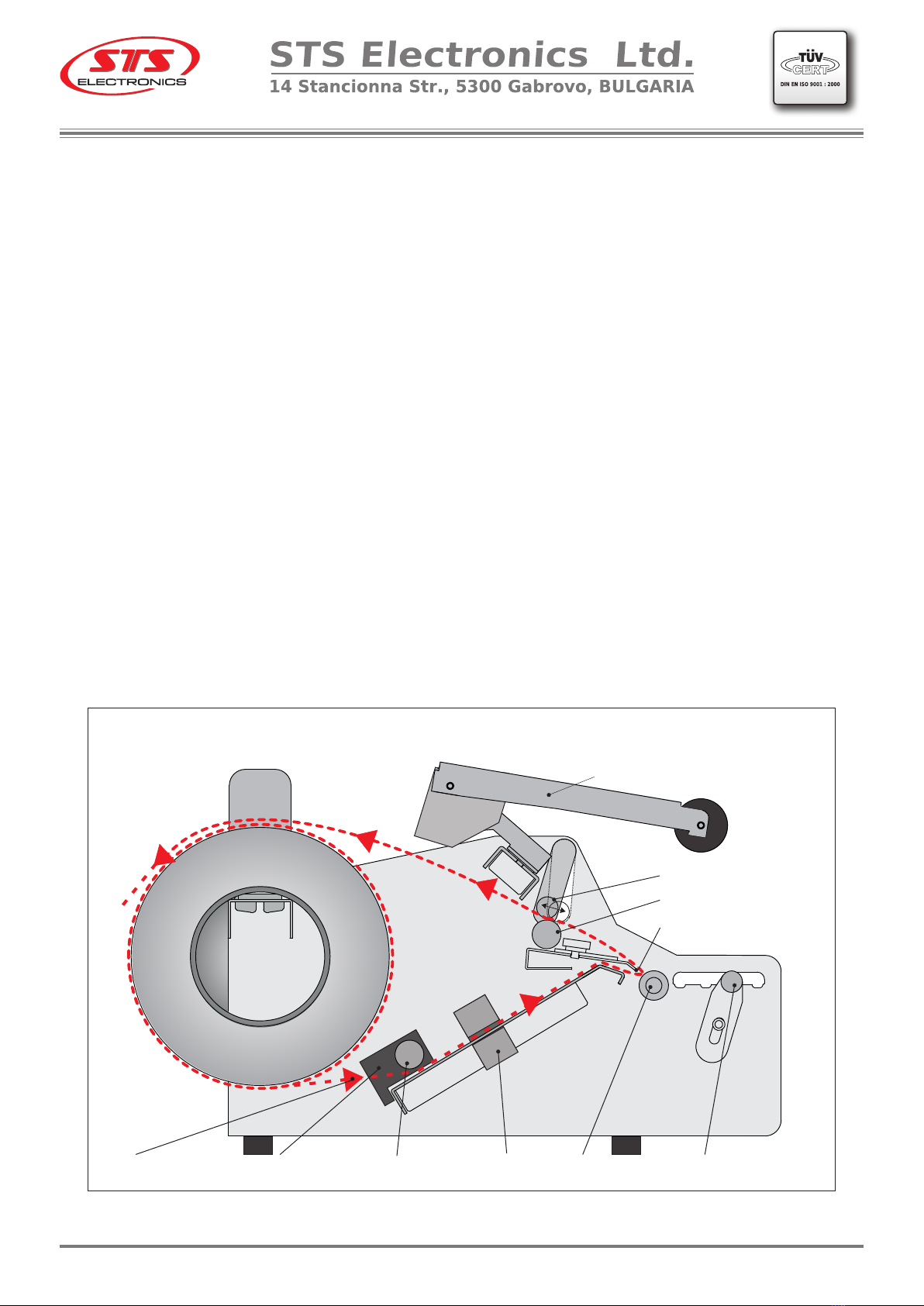

Control Panel

Button ‘Start’

Peel Edge

Drive Roller

Idler Roller

Pulling Roller

Pressure Roller

Magnetic Roll Guides

Label Roll Bar

Label Drag Arm

Container Guides

Container Pressure Arm

V.2.00STS808

Pressure Mechanism

Guiding Roller

Connector for external start

Power Connector

Power Switch

Magnetic Roll Guides

Label Guides

Label Drag Arm

Guides for Labels

Label Sensor

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

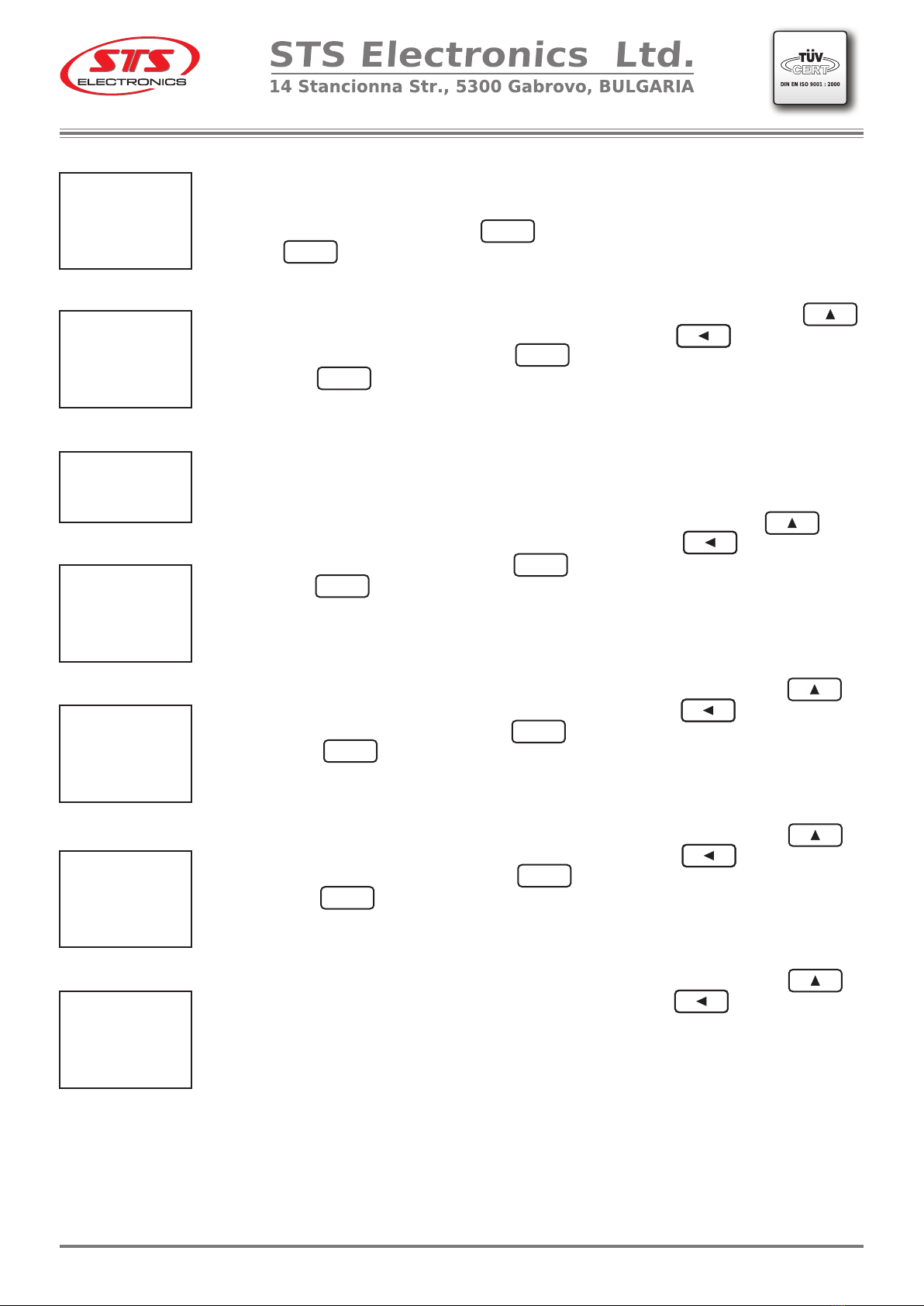

After the machine is switched on, an advertisement logo, the

machine type / one label - 1, two labels - 2 or the combined version - 3 /, the

software version will be displayed. After that will be shown the operating

mode - fig.1.

The labeling process is performed by pressing the built-in 'Start'

button or by an external start / 'Start' pedal connected to the connector /.

The display shows the execution - fig.2. Upon completion of the process,

the label counter grows. If you want to reset the counter you can just press

the button at any time more than 3 seconds.

Access to the menu is password protected. By pressing and holding

the button for more than 3 seconds, a password window is displayed

- fig.3. Cancel by pressing the button and accessing the input menu

by pressing the button - fig.4. Entering the password is done by

changing the digit by pressing the button .

Moving to the next digit is done by pressing the button By pressing

the button returns you at the beginning to enter the password.

The password for this machine is 8083 - it is static and can not be

change by the user. When the password is incorrect on the screen comes

up notice for error - fig.5. By pressing button starts from beginning to

enter the correct password fig.3. By pressing the button cancel the

password menu and the control panel is returning in operating mode - fig.1.

A correctly entered password gives access to parameter changes.

The first window to display is a language selection - fig.6. By pressing the

button language is changing cyclically - fig.7. Confirm the desired

choice by pressing The next parameter is mode selection / 1, 2

labels/ - fig.8.

By pressing the button ONE LABEL / TWO LABELS mode is

cyclically changed. Confirm the desired choice by pressing the button

Select mode ‘ONE LABEL’.

When selecting 'ONE LABEL' mode and confirming it, proceed to the

next parameter - offset stop - fig.9. Its value determines the correct

positioning of the beginning of a next label to the peeling edge. Its

determination depends on the length of the label and is given in

Application 1.

Entering is done by changing the digit by pressing the button

Moving to the next digit is done by pressing the button The process

is cyclical.

- 5 -

Control Panel and Setup

MODE 1 LABEL

------------------------------

WAIT START

000

NUMBER LABELS

fig.1

MODE 1 LABEL

------------------------------

EXECUTION

001

NUMBER LABELS

fig.2

PASSWORD

------------------------------

* * * *

PASSWORD

------------------------------

* * * 0

PASSWORD

------------------------------

ERROR!

ИЗБОР НА ЕЗИК

------------------------------

> БЪЛГАРСКИ

АНГЛИЙСКИ

fig.3

fig.4

fig.5

fig.6

SELECT LANGUAGE

------------------------------

>ENGLISH

BULGARIAN

fig.7

SELECT MODE

------------------------------

> ONE LABEL

TWO LABELS

fig.8

V.2.00STS808

C

M

C

C

M

C

M

M

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

OFFSET STOP

------------------------------

017

^

------------------------------

[001 ... 999 mm]

fig.9

TIME MOVE MOTOR

------------------------------

02.00

^

------------------------------

[00.00 ... 60.00 s]

fig.10

MODE SELECT

------------------------------

ONE LABEL

>TWO LABELS

fig.11

DISTANCE LABELS

------------------------------

01.17

^

------------------------------

[00.90 ... 30.00 cm]

fig13

OFFSET STOP 1

------------------------------

017

^

------------------------------

[001 ... 999 mm]

fig.14

OFFSET STOP 2

------------------------------

017

^

------------------------------

[001 ... 999 mm]

fig.15

LABELS GAP

------------------------------

03

^

------------------------------

[ хх (mm) ]

fig.12

- 6 - STS808

V.2.00

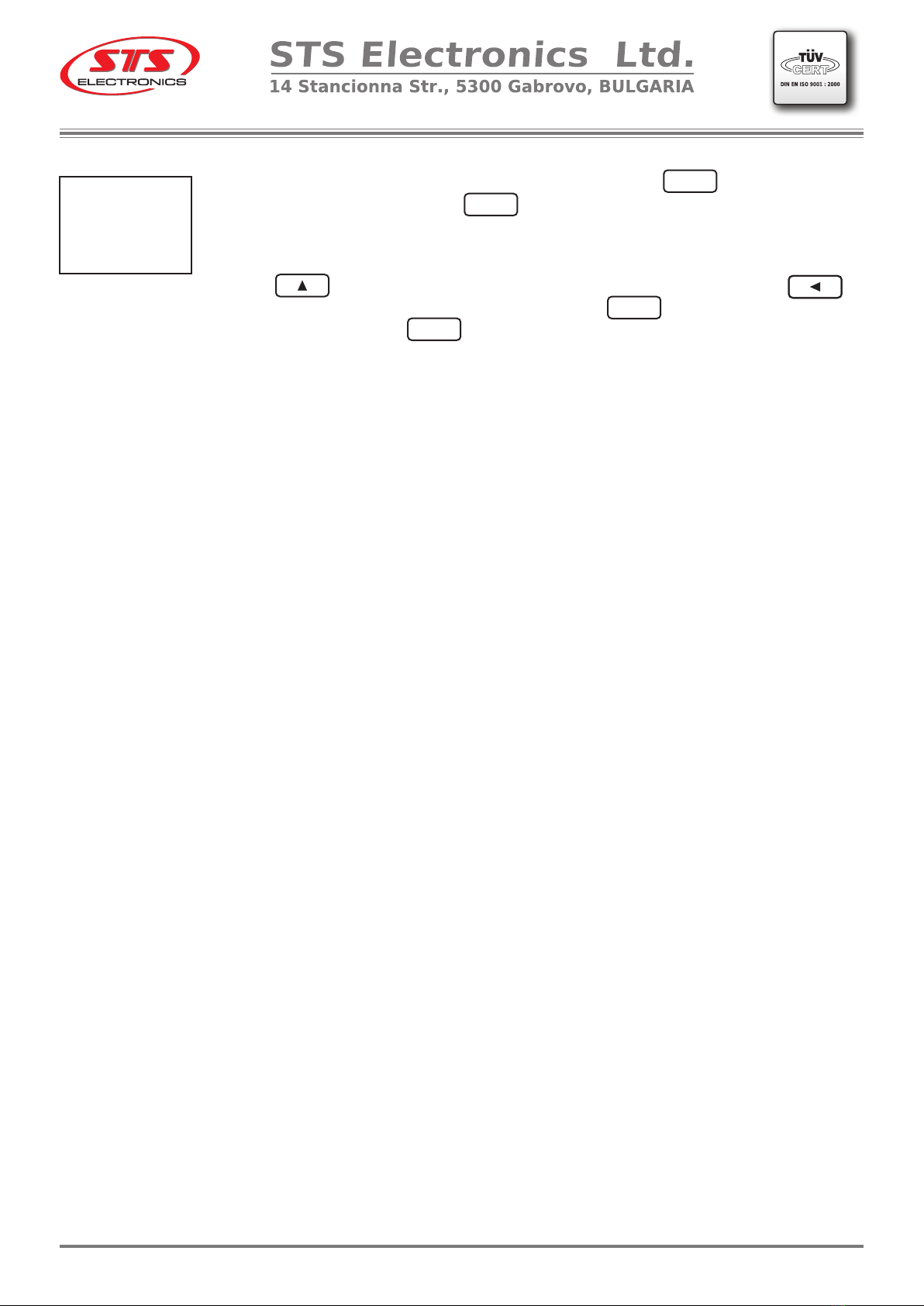

By pressing the button the display is reset. By pressing the

button the set offset is confirmed and the next parameter - time move

motor- Fig. 10 is set. The value determines the time for rotation of the

container in order to stick the label better. It is set by the user at his

decision. Entering is done by changing the digit by pressing the button

Moving to the next digit is done by pressing the button The process

is cyclical. By pressing the button the display is reset. By pressing

the button the set time is confirmed and switched to operating mode

- fig.1.

Select Mode 'TWO LABELS'.

When selecting 'TWO LABELS' in fig. 11, and confirming it, proceed

to the introduction of a next parameter - a gap between the labels - fig.12.

Entering is done by changing the number by pressing the button

Moving to the next digit is done by pressing the button The process

is cyclical. By pressing the button the display is reset. By pressing

the button the entered gap is confirmed and the next parameter -

the distance between the labels is set - fig.13.

From this value depends the correct position of the front / back label.

It is determined by the circumference of the container and the total length of

the two labels, shown in Application 2.

Entering is done by changing the digit by pressing the button

Moving to the next digit is done by pressing the button The process

is cyclical. By pressing the button the display is reset. By pressing

the button the set distance is confirmed and the next parameter is

set - offset stop 1 - fig.14. Its value determines the correct positioning of the

beginning of the front label to the peeling edge. Its definition depends on the

length of the two labels (front, rear) shown in Application 3.

Entering is done by changing the digit by pressing the button

Moving to the next digit is done by pressing the button The process

is cyclical. By pressing the button the display is reset. By pressing

the button the set offset stop 1 is confirmed and the next parameter

is set to offset stop 2 - fig.15. Its value determines the correct positioning of

the beginning of the back label to the peeling edge. Its definition depends

on the length of the two labels (front, rear) shown in Application 4.

Entering is done by changing the digit by pressing the button

Moving to next the digit is done by pressing the button

M

C

C

M

C

M

C

M

C

M

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

The process is cyclical. By pressing the button the display is

reset. By pressing the button offset stop 2 is confirmed and the next

parameter - time move motor - is set. The value determines the time of

rotation of the container in order to stick the label better. It is set by the user.

Entering is done by changing the indicated number by pressing the

button Moving to the next digit is done by pressing the button

The process is cyclical. By pressing the button the display is reset.

By pressing the button the set time is confirmed and switched to

operating mode - fig.1.

If you stay in a parameter menu window for more than 60 seconds

without operation / pressing any key, the machine switches to operating

mode - fig.1. Changes made so far are recorded.

- 7 -

V.2.00STS808

TIME MOVE MOTOR

------------------------------

02.00

^

------------------------------

[00.00 ... 60.00 s]

fig.16

C

M

C

M

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

- 8 -

V.2.00STS808

CONTRAST

------------------------------

>>>>

------------------------------

- CLEAR + UP

Access to the menu to change the display settings is from the

operating mode - fig.1.

By pressing and holding for more than 3 seconds the button

enters the contrast setting - fig.2. The current level is displayed with

bargraph / >>>> ..... /. Adjustment is done step by step with button

for decreasing and button for increasing.

By pressing the button the desired value is memorized and

switches to the brightness setting - fig.3. The current level is displayed with

bargraph / >>>> ..... /. Adjustment is done step by step with button

for decreasing and button for increasing.

The desired value is memorized by pressing the button and

switches to operating mode - fig.1

Setting Contrast and Brightness of the LCD

MODE 1 LABEL

------------------------------

WAIT START

000

NUMBER LABELS

fig.1

fig.2

BRIGHTNESS

------------------------------

>>>>

------------------------------

- CLEAR + UP

fig.3

C

M

C

M

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

- 9 -

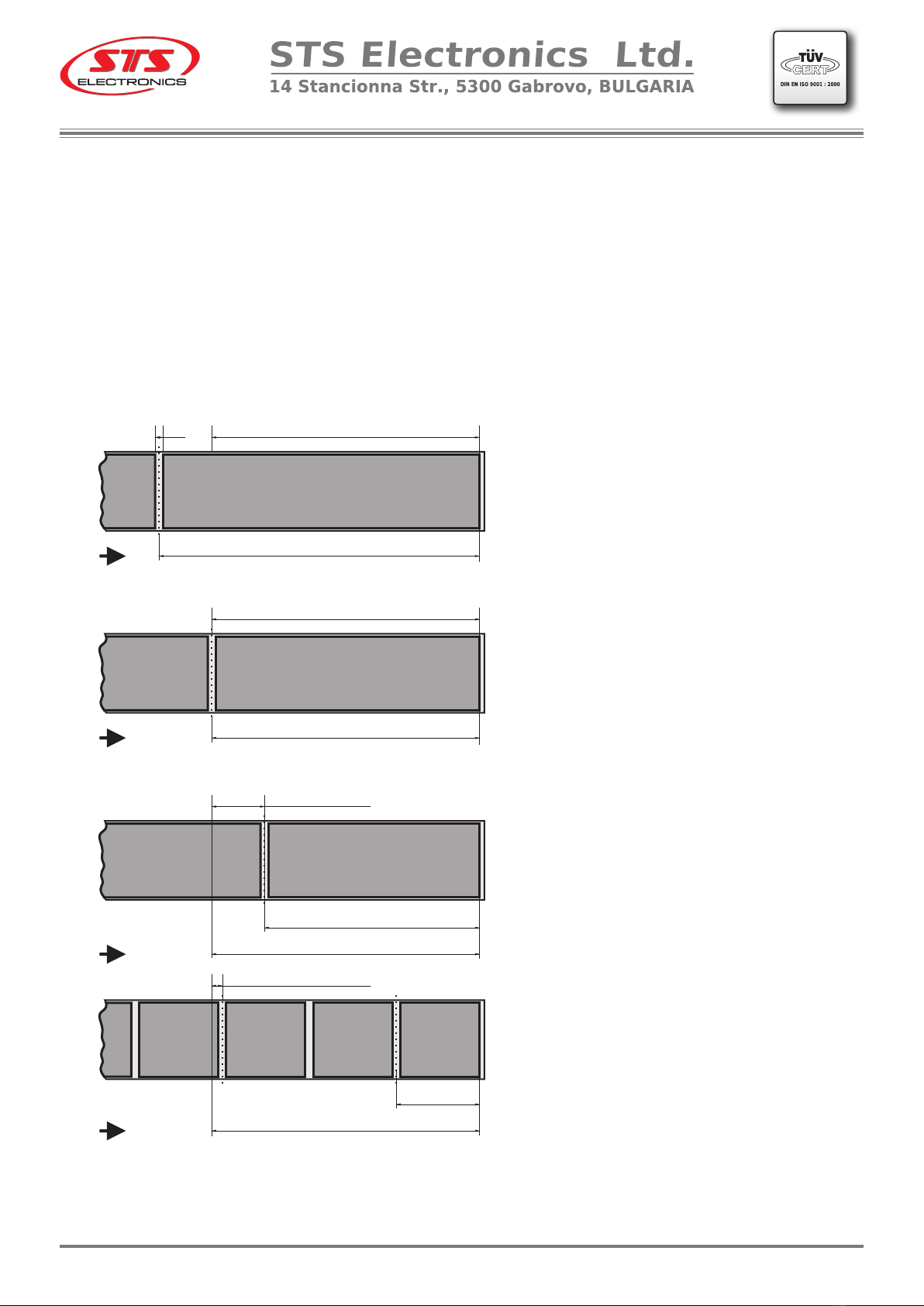

Application 1.

The sensor which detect the end of the label is on 100mm/ L / before peeling edge

and its position can not be changed. This requires the Offset Stop parameter to be entered

the value of which varies depending on the length of the label. It determines the correct

positioning of the beginning of a subsequent label to the peeling edge.

Possible variants are shown in Figure 1.

Determining the value of the parameter - Offset stop.

1. The length of the used label is longer

than L .

The offset value is 100 [mm].

2. The length of the used label and the

half of the gap are equal to L.

The offset value is 100 [mm].

3. The length of the used label is

smaller than L. The offset value is

determined by subtracting the length of

the label and half of the gap from 100

[mm].

4. The length of the used label is several

times smaller than L. The offset value is

determined by subtracting the sum of all

insertable labels and gaps from 100

[mm] and adding half of the gap.

Note: Measured offset results are a

good start. Several adjustments may be

needed to more accurately position the

beginning of the label.

Label

Label

LabelLabel

Label Label Label Label

Label

Label

1.

2

3.

> 100mm

Offset stop = 100mm

Offset stop = 100mm

= 100mm

Offset stop

Offset stop

100mm

<< 100mm

< 100mm

100mm

L0

.

4.

fig.1

V.2.00STS808

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

- 10 -

V.2.00STS808

Application 2.

Determining the value of the parameter - Distance

between labels

L3 = ( ( D*3,14 - L1 - L2 ) / 2 ) /10 [сm]

L3

L1L2

L3

D

length

front label

length

rear label

length between labels

Container/bottle, jar .../

Front Label

Rear Label

Example:

For a container of 73 mm diameter and a label length of 85 mm and 55 mm

respectively, the distance between labels is as follows:

L3 = ((73 * 3,14 - 85 - 55) / 2) / 10 [cm]

L3 = 4.461 [cm].

Enter the value rounded to the second character: 04,46 [cm].

L1 - length front label [mm]

L2 - length rear label [mm]

L3 - length between front and rear label [сm]

D - diameter of the container [mm]

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

L0

2

3

Offset Stop 1 = 100mm

= 100mm

Offset Stop 1

Offset Stop 1

100mm

<< 100mm

< 100mm

100mm

Label

back

Label

back

Label

back

Label

front

Label

front

Label

front

1

> 100mm

Offset Stop 1 = 100mm

Label

back

Label

front

4

- 11 -

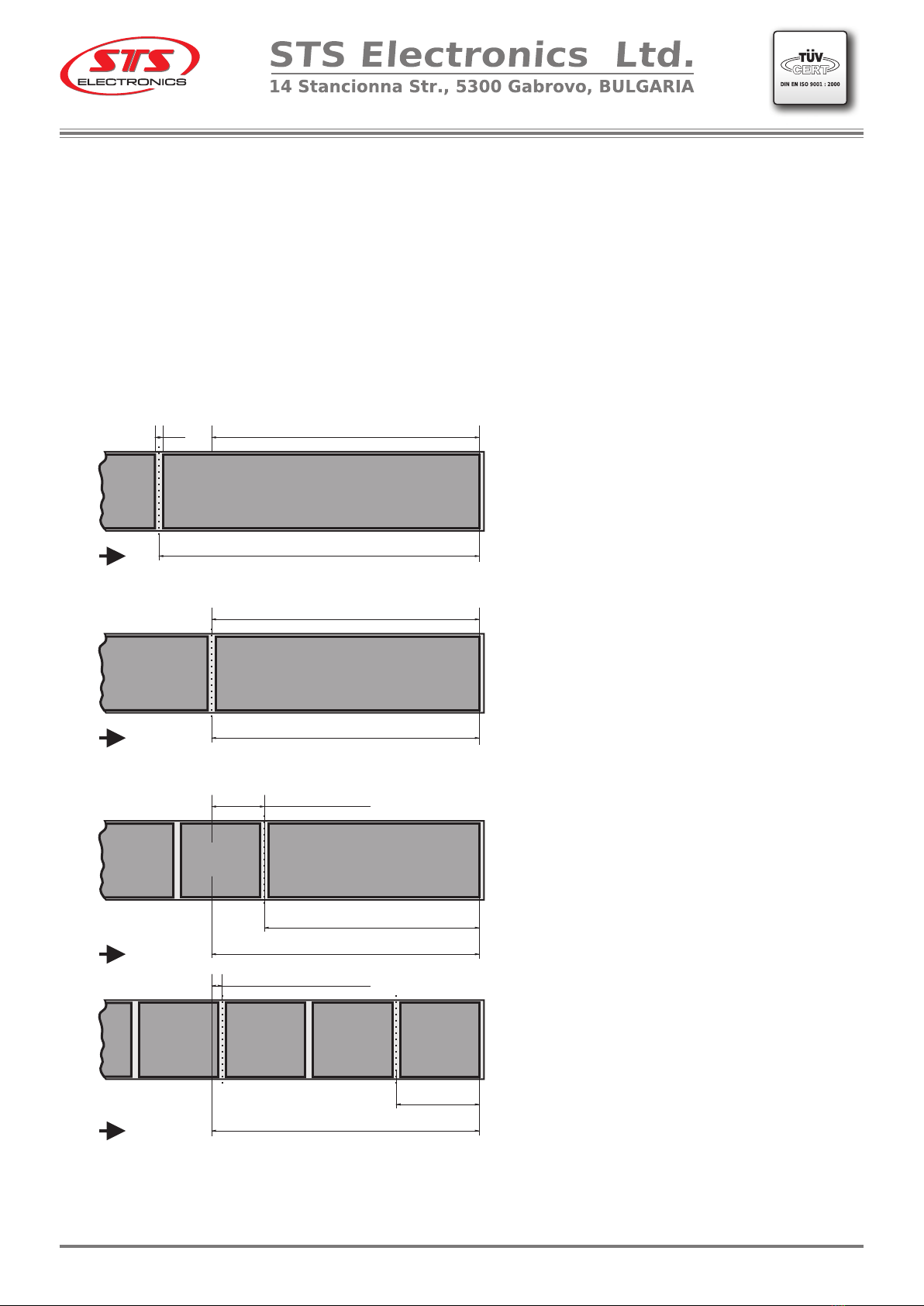

Application 3.

The sensor which detect the end of the label is on 100mm/ L / before peeling edge

and its position can not be changed. This requires the Offset Stop 1 parameter to be entered

the value of which varies depending on the length of the label. Offset Stop 1 determines the

correct positioning of the beginning of a subsequent back label to the peeling edge. The

measurement need to be done from the beginning of the back label.

Possible variants are shown in Figure 2.

Determining the value of the parameter - Offset stop 1.

1. The length of the used label is longer

than L .

The offset value is 100 [mm].

2. The length of the used label and the

half of the gap are equal to L.

The offset value is 100 [mm].

3. The length of the used label is

smaller than L. The offset value is

determined by subtracting the length of

the label and half of the gap from 100

[mm].

4. The length of the used label is several

times smaller than L. The offset value is

determined by subtracting the sum of all

insertable labels and gaps from 100

[mm] and adding half of the gap.

Note: Measured offset results are a

good start. Several adjustments may be

needed to more accurately position the

beginning of the label.

fig. 2

V.2.00STS808

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

- 12 -

V.2.00STS808

Application 4.

Determining the value of the parameter - Offset stop 2.

1

2

3

> 100mm

Offset Stop 2 = 100mm

Offset Stop 2 = 100mm

= 100mm

Offset Stop 2

Offset Stop 2

100mm

<< 100mm

< 100mm

100mm

Label

front

Label

back

Label

back

Label

back

Label

front

Label

front

Label

front

Label

back

Label

front

4

L0

fig.3

The sensor which detect the end of the label is on 100mm/ L / before peeling edge

and its position can not be changed. This requires the Offset Stop 2 parameter to be entered

the value of which varies depending on the length of the label. Offset Stop 2 determines the

correct positioning of the beginning of a subsequent back label to the peeling edge. The

measurement need to be done from the beginning of the back label.

Possible variants are shown in Figure 3.

1. The length of the used label is longer

than L .

The offset value is 100 [mm].

2. The length of the used label and the

half of the gap are equal to L.

The offset value is 100 [mm].

3. The length of the used label is

smaller than L. The offset value is

determined by subtracting the length of

the label and half of the gap from 100

[mm].

4. The length of the used label is several

times smaller than L. The offset value is

determined by subtracting the sum of all

insertable labels and gaps from 100

[mm] and adding half of the gap.

Note: Measured offset results are a

good start. Several adjustments may be

needed to more accurately position the

beginning of the label.

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

NOTES

V.2.00STS808

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

GENERAL CONDITIONS for usage of electronic devices:

The electronic devices are intended to be used in normal climate

conditions in an environment with a normal fire-safety, and without any

aggressive to the body material liquids and gases.

GUARANTEE CONDITIONS:

The guarantee period is 12 months from the date of selling.

The manufacturer does not take responsibility in the following cases:

- non-observance of storage conditions;

- non-observance of transport conditions;

- non-observance of operational conditions;

- natural disasters;

The guarantee is only valid if the device is mechanically intact, and there

is no sign of attempts for eliminating damage by unauthorized personnel.

Transportation expenses are on customer’s account.

Attention: No organic dissolvent agents should be used for cleaning the

front panel!

FACTORY NUMBER:_______________________________________

STS808

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

Table of contents

Other STS Industrial Equipment manuals