SIGRIST VisGuard 2 Extractive User manual

Document number: 14265E

Version: 1

Valid from: S/N 704010 /

SW V529

INSTRUCTION MANUAL

VisGuard 2 Extractive

Sampling System

Visibility Monitor / Dust Monitor

Copyright© SIGRIST-PHOTOMETER AG, subject to technical changes without notice 4/2018

SIGRIST-PHOTOMETER AG

Hofurlistrasse 1

CH-6373 Ennetbürgen

Switzerland

Tel. +41 41 624 54 54

Fax +41 41 624 54 55

inf o@photometer.com

w w w .photometer.com

Contents Instruction Manual VisGuard 2 Extractive

14265E/1 3

Contents

1General user information........................................................................................5

1.1 Terms used in this document (glossary) ........................................................5

1.2 Purpose of the Instruction Manual ...............................................................5

1.3 Target group of the documentation .............................................................5

1.4 Additional documentation ..........................................................................5

1.5 Copyright provisions ..................................................................................5

1.6 Document storage location .........................................................................6

1.7 Order document ........................................................................................6

1.8 Proper use ................................................................................................6

1.9 User requirements .....................................................................................6

1.10 Declaration of conformity ...........................................................................6

1.11 Use restrictions ..........................................................................................6

1.12 Dangers when not used properly .................................................................7

1.13 Meaning of the safety symbols....................................................................7

1.14 Meaning of the pictograms.........................................................................8

2Sampling systems ..................................................................................................9

2.1 Different versions.......................................................................................9

2.2 Designation of the components...................................................................9

2.3 Technical data .........................................................................................10

2.3.1 Technical data for the fan KTNPI/G1......................................................10

2.3.2 Technical data for the fan KZTN2..........................................................10

2.3.3 Technical data for the valve unit ST2MP3...............................................11

2.3.4 Technical data for the sample heater KW5.............................................11

3General safety points ...........................................................................................12

3.1 Dangers when properly used.....................................................................12

3.2 Residual risk............................................................................................13

3.3 Warning and danger symbols on the instrument .........................................13

3.4 Preventing undesirable online access attempts ............................................14

4Design and function ............................................................................................15

4.1 Design of the sampling system..................................................................15

4.2 Functional description of the most important elements ................................16

4.2.1 Valve unit for multiple sampling ...........................................................16

4.2.2 Sample divider for single sampling ........................................................17

4.2.3 Flow rate monitoring ...........................................................................17

4.2.4 Suction fan.........................................................................................18

5Mounting ...........................................................................................................19

5.1 Sampling point ........................................................................................19

5.2 Sample transport .....................................................................................19

5.2.1 General information ............................................................................19

5.2.2 Dimensioning of the lines ....................................................................19

5.2.3 Selecting and laying the lines ...............................................................20

5.3 Additional components ............................................................................20

5.3.1 Connection for external instruments (KZTN9) .........................................20

5.3.2 Valve unit (ST2MP3) ............................................................................20

5.3.3 Back pressure nozzle KZTN6 and pressure monitor KZTN7 .......................21

5.3.4 Sample divider KTNPI2.........................................................................22

5.3.5 Sample heater KW5 ............................................................................23

5.3.6 Filter KZTN3 .......................................................................................23

5.3.7 Suction fan KTNPI/G1 or KZTN2 with motor circuit breaker MSS1 .............23

5.3.8 Purging air connection and flow divider KZTN2.1....................................24

5.4 Sample return .........................................................................................24

Instruction Manual VisGuard 2 Extractive Contents

4 14265E/1

6Electrical installation ............................................................................................25

6.1 Safety pointers for the electrical connection................................................25

7Commissioning ...................................................................................................26

8Servicing.............................................................................................................27

8.1 Servicing schedule ...................................................................................27

8.2 Checking for leaks ...................................................................................28

8.3 Checking the sampling points ...................................................................28

8.4 Replacing the suction fan filter cartridge KZTN3 ..........................................29

8.5 Cleaning the sample lines .........................................................................29

8.6 Replacing the purge air filter on the VisGuard 2 Extractive ............................30

9Troubleshooting on additional components ............................................................31

9.1 General troubleshooting...........................................................................31

9.2 Malfunctions on the sample heater KW5....................................................32

9.3 Malfunctions on the valve unit ST2MP3......................................................32

9.4 Malfunctions on the suction fan ................................................................33

10 Repair work ........................................................................................................34

10.1 Replacing the sample heater KW5 .............................................................34

10.2 Replacing the valve unit ST2MP3 ...............................................................35

10.3 Replacing the suction fan .........................................................................36

11 Customer service information ...............................................................................37

12 Decommissioning/Storage ....................................................................................38

12.1 Decommissioning the system ....................................................................38

12.2 Storing the components ...........................................................................38

13 Packaging/Transport/Returning .............................................................................39

14 Disposal .............................................................................................................40

15 Spare parts list ....................................................................................................41

16 Appendix............................................................................................................42

17 Index..................................................................................................................44

Makr o

Makr o

General user information Instruction Manual VisGuard 2 Extractive

14265E/1 5

1General user information

1.1 Terms used in this document (glossary)

Please refer to our website for specialist terms: www.photometer.com/en/glossary/

1.2 Purpose of the Instruction Manual

This Instruction Manual provides the user with helpful information about the entire life cycle

of the VisGuard 2 Extractive and its peripheral devices. Before commissioning the instrument,

you should be completely familiar with the Instruction Manual.

1.3 Target group of the documentation

This Instruction Manual describes the dimensioning, installation and operation of the Vis-

Guard 2 Extractive sampling system, which is used for the continuous measurement of dust

in gases at temperatures of up to 40 °C (maximum temperature for the fan). It is intended

for planners and installers who are responsible for the installation and operation of the me a-

suring instrument. This document supplements the existing Instruction Manual for the Vis-

Guard 2 and may only be used in combination with this manual.

1.4 Additional documentation

DOC. NO.

TITLE

CONTENT

14162E

Instruction Manual

Contains the most important information about the

overall life cycle of the instrument.

14165E

Reference Manual

More sophisticated menu functions and worksteps

for advanced users.

14166E

Brief Instructions

The most important functions and the servicing

schedule.

14289E

Data Sheet

Descriptions and technical data about the instru-

ment.

14168E

Service Manual

Repair and conversion instructions for service engi-

neers.

14288DEF

Declaration of Con-

formity

Compliance with the underlying directives and

standards.

1.5 Copyright provisions

This document has been written by SIGRIST-PHOTOMETER AG. Copying or modifying the

content or giving this document to third parties is permitted only with the express consent of

SIGRIST-PHOTOMETER AG.

Instruction Manual VisGuard 2 Extractive General user information

6 14265E/1

1.6 Document storage location

This document is part of the product. It should be stored in a safe place and always be close

at hand for the user.

1.7 Order document

The most recent version of this document can be downloaded at www.photometer.com

(first time registration required).

It can also be ordered from a SIGRIST representative in your country (Instruction Manual

“Customer service information”).

1.8 Proper use

The sampling system is designed for measuring gaseous media in non-explosive atmospheres

of up to 40 °C together with the VisGuard 2 Extractive.

1.9 User requirements

The instrument may be operated only by trained technical personnel who have read and un-

derstood the content of the Instruction Manual.

1.10 Declaration of conformity

Current technological principles were followed in designing and manufacturing the instru-

ment. They comply with the applicable guidelines concerning safety and duty to take due

care.

EU: The measuring instrument meets all applicable requirements within the European Union

(EU) for carrying the CE mark.

Please refer to the separate declaration of conformity for details. Section 1.4

1.11 Use restrictions

EXPLOSION

HAZARD!

Operation in an inappropriate environment.

Use in explosive areas can cause explosions, which can lead to the death of persons in the

vicinity.

It is not permitted to operate the instrument in explosion hazardous areas or rooms.

It is not permitted to use the instrument with explosive sample substances.

General user information Instruction Manual VisGuard 2 Extractive

14265E/1 7

1.12 Dangers when not used properly

DANGER!

Operation when not used properly.

Improper use of the components can cause injuries to persons, process -related consequential

damage and damage to the components.

In the following cases, the manufacturer cannot guarantee the protection of persons and

the components and therefore assumes no legal responsibility:

The components have been used in a way not included in the described area of applic a-

tion.

The components have not been properly mounted or set up.

The components have not been installed or operated in accordance with the Instruction

Manual.

The components have been operated with accessories which SIGRIST-PHOTOMETER AG

has not expressly recommended.

Improper changes have been performed to the components.

The components have been operated outside the defined specifications.

1.13 Meaning of the safety symbols

All danger symbols used in this document are explained below:

DANGER!

Danger due to electrical shock that may result in serious bodily injury or death.

Non-observance of this notice may lead to electrical shocks and death.

EXPLOSION

HAZARD!

Danger due to explosion that may result in serious bodily injury or death.

Non-observance of this notice may cause explosions resulting in serious property damage

and death.

WARNING!

Warning about bodily injury or hazards to health with long-term effects.

Non-observance of this warning may lead to injuries with possible long-term effects.

CAUTION!

Notice about possible material damage.

Non-observance of this notice may cause material damage to the instrument and its

peripherals.

Instruction Manual VisGuard 2 Extractive General user information

8 14265E/1

1.14 Meaning of the pictograms

All pictograms used in this document are explained below:

Additional information about the current topic.

Practical procedures when working with the VisGuard 2 Extractive.

Manipulations on the touchscreen.

The screenshot is an example and may differ from current device.

Sampling systems Instruction Manual VisGuard 2 Extractive

14265E/1 9

2Sampling systems

2.1 Different versions

As the sampling system is adapted to individual measurement needs, a large number of dif-

ferent versions are required. Which version is used depends primarily on the following:

The sampling type, i.e. single or multiple sampling.

The maximum line length from the sampling point to the measuring instrument.

The following table provides an overview of the different versions available.

An overview of the measuring points can be found in the corresponding drawings.

Sampling type

Line length

Drawing

Single

0 .. 5 m

VISGUARD2/GSS5-TU

Single

5 .. 30 m

VISGUARD2/GSS30-TU

Single

30 .. 500 m

VISGUARD2/GSS500-TU

Multiple

30 .. 200 m (> lengths on request)

VISGUARD2/GSSM-TU

Each version is made up of a different number of components, such as lines, adapters, con-

trol elements, electrical equipment etc. The components required in each case can be found

in the respective drawing.

2.2 Designation of the components

The sampling system is made up of various mechanical and electrical components . Some of

these are fitted with rating plates containing details of the electrical connection values. The

designation of the VisGuard 2, SICON and SIPORT 2 can be found in the VisGuard 2 Instruc-

tion Manual.

Instruction Manual VisGuard 2 Extractive Sampling systems

10 14265E/1

2.3 Technical data

2.3.1 Technical data for the fan KTNPI/G1

Data

Values

Service voltage

3 x 400 VAC/50 Hz, optional 230 VAC/50 Hz

Power consumption

1.1 kW, Cos = 0.82

Weight

Approx. 22 kg

Noise level

Better than 64 dB(A)

Mounting type

Horizontal or vertical

Motor protection

External, e.g. MSS1

Model

SD4n / SE4n

Ambient temperature

Max. 40 °C

Medium temperature

Max. 80 °C

Dimensions

W x H x D: 358 mm x 357 mm x 375 mm

For more details, see drawing KTNPI/G1-MB Section 16

2.3.2 Technical data for the fan KZTN2

Data

Values

Service voltage

230 VAC/50 Hz (standard type)

Power consumption

0.19 kW, Cos = 0.70

Weight

Approx. 8.5 kg

Noise level

Better than 62 dB(A)

Mounting type

Horizontal or vertical

Motor protection

Integrated

Model

SE20

Ambient temperature

Max. 40 °C

Medium temperature

Max. 80 °C

Dimensions

W x H x D: 224 mm x 264 mm x 244 mm

For more details, see drawing KZTN2-MB Section 16

Sampling systems Instruction Manual VisGuard 2 Extractive

14265E/1 11

2.3.3 Technical data for the valve unit ST2MP3

Data

Values

Service voltage

24 VDC

Power consumption

Valves open or closed de-energized, 11.2 W per channel

Material

Coated steel

Dimensions

W x H x D: 744 mm x 730 mm x 153 mm (for six channels)

For more details, see drawing ST2MP3-MB Section 16

2.3.4 Technical data for the sample heater KW5

Data

Values

Service voltage

115 or 230 VAC, 50/60 Hz (depending on model) connected to

on-site socket

Power consumption

42 W

Weight

Approx. 2 kg

Temperature increase

Max. 90 °C (no flow rate)

Max. 40 °C at flow rate 25 l/min

Dimensions

W x H x D: 350 mm x 310 mm x 40 mm

For more details, see drawing KW5-MB Section 16

Instruction Manual VisGuard 2 Extractive General safety points

12 14265E/1

3General safety points

3.1 Dangers when properly used

DANGER!

Damaged instrument or cabling.

Touching damaged cables may lead to electrical shocks or death.

The instrument may be operated only when the cables are undamaged.

The instrument may be operated only if it has been properly installed or repaired.

DANGER!

Dangerous voltage inside the instrument.

Touching live components inside the instrument may lead to electric shocks resulting in

death.

The instrument must not be operated when the housing is removed.

DANGER!

Damage to the instrument due to incorrect service voltage.

If the instrument is connected to an incorrect service voltage, the instrument can be da m-

aged.

The instrument may be connected only to voltage sources as specified on the rating

plate.

DANGER!

Missing Instruction Manual after the instrument changes hands.

Operating the instrument without knowledge of the Instruction Manual may lead to injuries

to persons and damage to the instrument.

If the instrument changes hands, always include the Instruction Manual.

If the Instruction Manual is lost, you can request a replacement.

Registered users can download the current version at www.photometer.com.

CAUTION!

Penetration of moisture as well as condensation on the electrical components dur-

ing servicing duty.

If moisture enters the instrument, the VisGuard 2 Extractive can be damaged.

Work inside the instrument may be performed only in a dry room and at room tempera-

ture. The instrument should be at operating or room temperature (avoid condensation

on optical and electrical surfaces).

CAUTION!

The use of aggressive chemicals when cleaning.

Use of aggressive chemicals can cause damage to instrument components.

Do not use aggressive chemicals or cleaning agents when cleaning.

Should the instrument come in contact with aggressive chemicals , clean it thoroughly

with a neutral cleaning agent.

General safety points Instruction Manual VisGuard 2 Extractive

14265E/1 13

3.2 Residual risk

WARNING!

According to the risk assessment of the applied safety directive DIN EN 61010-1,

there remains the risk of the displayed measuring values being incorrect. This risk

can be reduced with the following measures:

Use an access code to prevent unauthorized persons from changing parameters.

Perform the specified servicing duties.

3.3 Warning and danger symbols on the instrument

WARNING!

There are no warning or danger symbols on the instrument.

Users must ensure that they observe the safety measures as specified in the Instruction Man-

ual at all times when working with the instrument and its peripheral equipment, even if no

warning or danger symbols are attached to the instrument.

The following sections must be internalized:

Section 1.8

Section 1.11

Section 1.12

Section 1.13

Section 3.2

Observe safety pointers when performing the described procedures.

Observe local safety pointers.

Instruction Manual VisGuard 2 Extractive General safety points

14 14265E/1

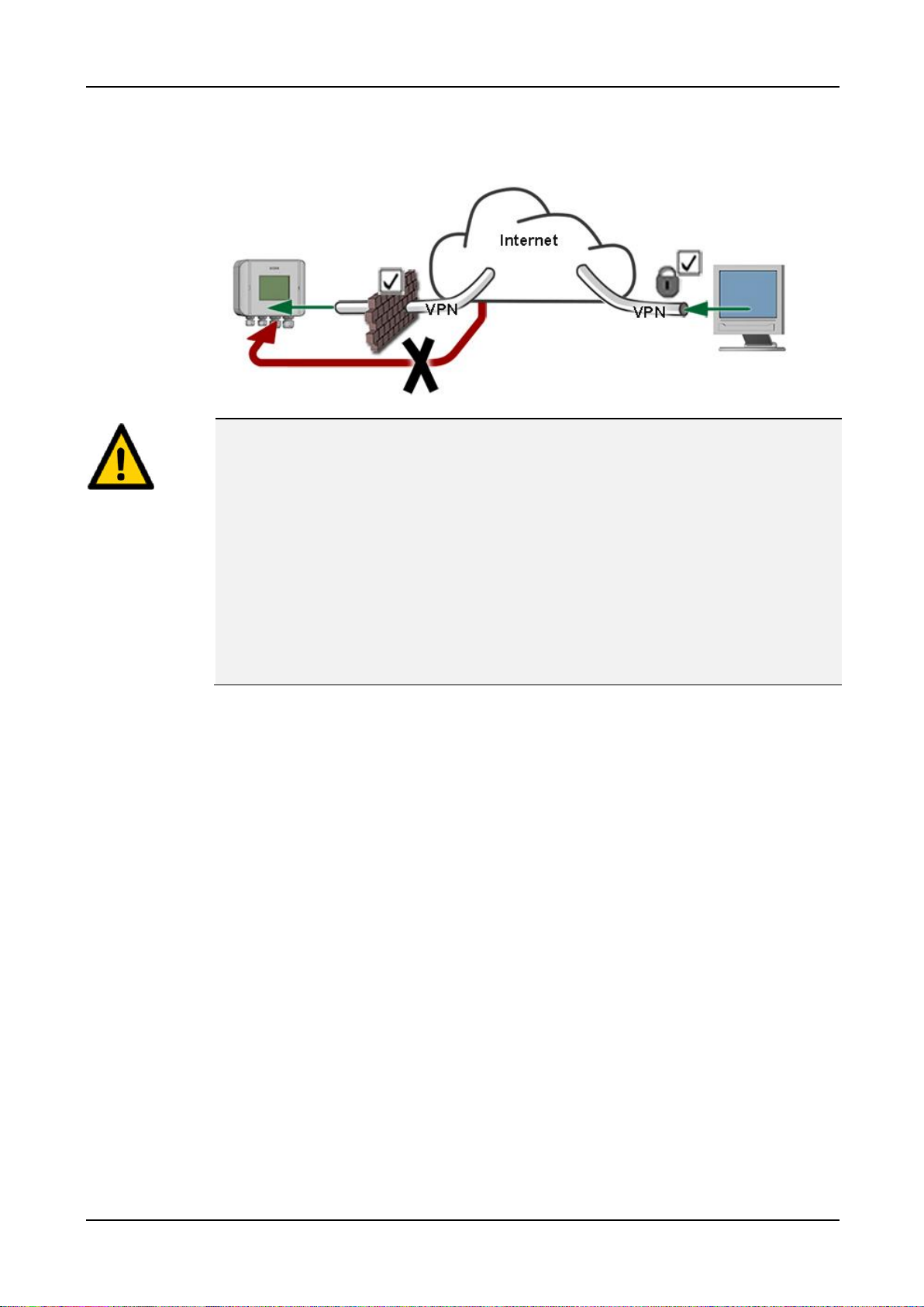

3.4 Preventing undesirable online access attempts

WARNING!

SIGRIST instruments are equipped with an integrated web user interface and

Modbus TCP interface, thus offering state-of-the-art administration and control

possibilities. However, if these are connected directly to the Internet, then any In-

ternet user can in principle access your instrument and change the configuration.

Please note the following points to prevent this:

Never connect the instrument directly to the Internet.

Operate it behind a firewall and block access to the instrument.

Only connect to branch offices via VPN.

Change the standard password on commissioning.

Always keep up to date with the latest changes regarding Internet security so that you

can react promptly in the event of alterations.

Install the latest updates immediately (also for the router and firewall).

Design and function Instruction Manual VisGuard 2 Extractive

14265E/1 15

4Design and function

4.1 Design of the sampling system

The sampling system can be divided up into the following areas:

Sample taking ensures that a re-

presentative sample of the medium

to be measured is taken at the cor-

rect point. The sampling point comes

directly into contact with the monito-

red, “contaminated” area. All other

components can be protected by po-

sitioning them in “clean” areas.

Sample transport is essentially ma-

de up of lines that are used to trans-

port the sample from the sampling

point to the measuring instrument.

The correct dimensioning and routing

of the lines are decisive for this part

of the measuring system. When mul-

tiple sampling is carried out, a valve

unit is installed downstream of samp-

le transport to ensure the correct

measuring point is selected.

Figure 1: Overview of the sampling system

Sample conditioning and monitoring is made up of optional components that are used

to condition the sample and monitor the sample flow.

Finally, the sample return ensures that the sample is returned to a suitable point in an en-

vironmentally friendly manner. The fan is an important part of the sample return and genera-

tes the necessary vacuum for the sample flow. The purging air required by the photometer is

also part of the sample return (photometer documentation).

Instruction Manual VisGuard 2 Extractive Design and function

16 14265E/1

4.2 Functional description of the most important elements

4.2.1 Valve unit for multiple sampling

Figure 2: Principle of continuous sample taking

a

Measurement of sample “P1”

b

Measurement of sample “P2”

Continuous sample transport is the most reliable concept for multiple sampling. Here, the

samples from all measuring points are continuously suctioned in by a valve unit with two or

more channels. Only the sample that is to be measured at the specific time is released by the

corresponding valve and allowed to enter the measuring instrument. Section 5.3.2

The advantage of this system is that all measuring points are constantly in operation and no

static sample flows can arise. This means that almost no deposits build up in the lines, with

peaks in measuring values or blockages virtually ruled out.

The samples are switched via a control unit, which is also used to allocate the measuring va-

lue to the correct sampling point.

P1 P2

a b

P

P1 P2

P

Design and function Instruction Manual VisGuard 2 Extractive

14265E/1 17

4.2.2 Sample divider for single sampling

The sample divider is used on sampling systems with long lines (> 30 meters). It is shown in

detail in drawing KTNPI2-MB.

The principle of the sample divider is based on the main f low being suctioned in by a suction

fan. A smaller bypass flow –the sample itself –is branched off from this main line and fed

through the measuring cell on the photometer. The pressure conditions inside the sample di-

vider maintain the flow rate through the measuring cell independently. An optional pressure

monitor can be attached to a back pressure nozzle for monitoring the sample flow. Section

5.3.4

The main flow is much greater than the sample flow through the measuring instrument.

Thanks to the high flow velocity, losses and deposits in the suction line can be reduced.

4.2.3 Flow rate monitoring

Figure 3: Principle of flow rate monitoring

a

Pressure monitor

b

Back pressure nozzle

Pressure monitors (a) are installed in the sampling system for the optional monitoring of the

sample flow. These measure the pressure drop on the back pressure nozzles (b), which are

inserted directly into the sample flow. The integrated signal contact in the pressure monitor

sends a status signal to the control device. Section 5.3.3

The limits on the pressure monitor usually have to be set on site while the system is running.

a b

+

-

Instruction Manual VisGuard 2 Extractive Design and function

18 14265E/1

4.2.4 Suction fan

The vacuum required for sample taking is generated by a suction fan. A suction fan with

higher or lower suction power is used depending on the sampling system.

A filter can be optionally installed upstream of the suction fan as shown in drawing KZTN3-

MB. On suction fans with a higher power, electrical actuation is made with a contactor. This

contactor is optional on suction fans with a lower power.

Mounting Instruction Manual VisGuard 2 Extractive

14265E/1 19

5Mounting

5.1 Sampling point

The selection of the sampling point is decisive for the sample quality of the medium to be

measured. Observe the following information when selecting the sampling point:

Pay attention to local regulations (suction height above the road).

The sample taking should enable representative recording of the particle concentration

(do not install in recesses).

Ensure that only the measuring medium is suctioned in. Foreign substances that can

block the sample lines or even destroy parts of the system must be kept at bay. The op-

tional SIGRIST splash guard is suitable for this, for example:

- Splash guard for concealed installation, drawing KZTN8/1-MB

- Splash guard for surface installation, drawing KZTN8-MB

5.2 Sample transport

5.2.1 General information

The goal of sample transport is to feed the gas sample through the measuring cell on the

measuring instrument without distortion. For this reason, high velocities are required in the

transport lines. The dimensioning of the sample lines, how the lines are routed and the selec-

tion of the line material are decisive for the quality of sample transport and accuracy of the

measurement.

5.2.2 Dimensioning ofthe lines

The dimensioning of the sample lines is made at the factory of SIGRIST -PHOTOMETER AG.

The dimensioning is based on the construction plans, which have to be provided to us in the

tendering phase.

The dimensioning of the inner line diameters is made according to the line length and gua-

rantees that the required sample quantity in the measuring cell is maintained.

Instruction Manual VisGuard 2 Extractive Mounting

20 14265E/1

5.2.3 Selecting and laying the lines

CAUTION!

Deposits in supply lines over longer distances.

Depending on the line material, deposits can build up in the supply lines over longer dis-

tances.

Only use lines with smooth inner surfaces for sample transport.

Coarse inner surfaces cause major friction losses and provide ideal conditions for partic-

les to accumulate in the line.

Please note the following when laying the sample line:

We recommend using the gray, flame-retardant electrical hoses. As a rule of thumb, the

less joints and radii and the shorter the lines, the better the sample transfer.

Outdoor sample lines must be well insulated, protected against the weather and heated

when required so that the dew point cannot be undershot.

5.3 Additional components

5.3.1 Connectionfor external instruments (KZTN9)

An optional connection for external instruments KZTN9 can be integrated in the sampling

system. Using this connection, some of the sample is made available to other measuring in-

struments in order to determine CO, NOXetc. The sampling system is thus used to a fuller

potential and the installation costs for additional instruments are justified.

The connection for external instruments KZTN9 is integrated in the sampling system using

hose connections. The detailed dimensions of this connection piece can be found in drawing

KZTN9-MB.

5.3.2 Valve unit (ST2MP3)

The valve unit ST2MP3 is used on multiple sampling systems and ensures the correct alloca-

tion of the sample to the measuring points. The samples from all measuring points flow con-

tinuously through the sampling system. Using two-way valves, a sample is branched off and

fed to the photometer for measurement.

The valve unit is fitted with corresponding mounting flanges and is installed directly to a wall

or stand as close to the measuring instrument as possible. The connection is made via hoses.

The corresponding dimension can be found in drawing ST2MP3-MB.

Table of contents

Popular Laboratory Equipment manuals by other brands

Ocean Optics

Ocean Optics MonoScan-2000 user manual

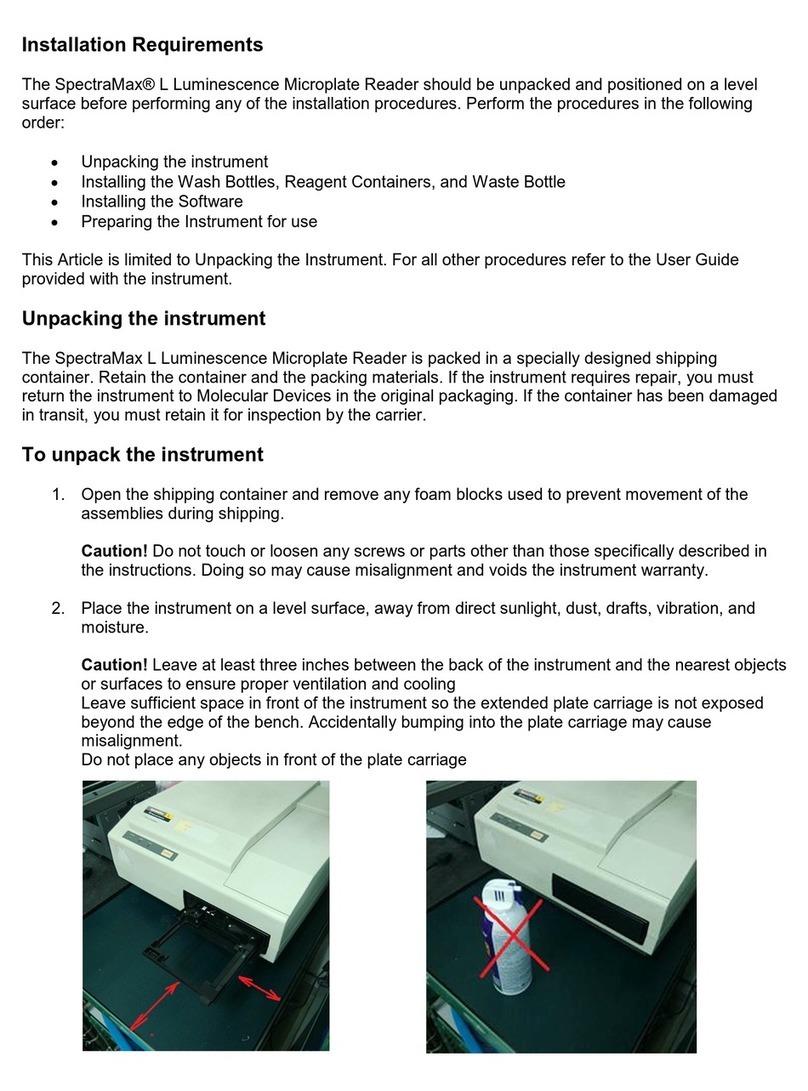

Molecular Devices

Molecular Devices SpectraMax L INSTALLATION PROCEDURE

Singer Instruments

Singer Instruments PIXL LIGHT CURTAIN quick start guide

TCS

TCS 3506-01 operating instructions

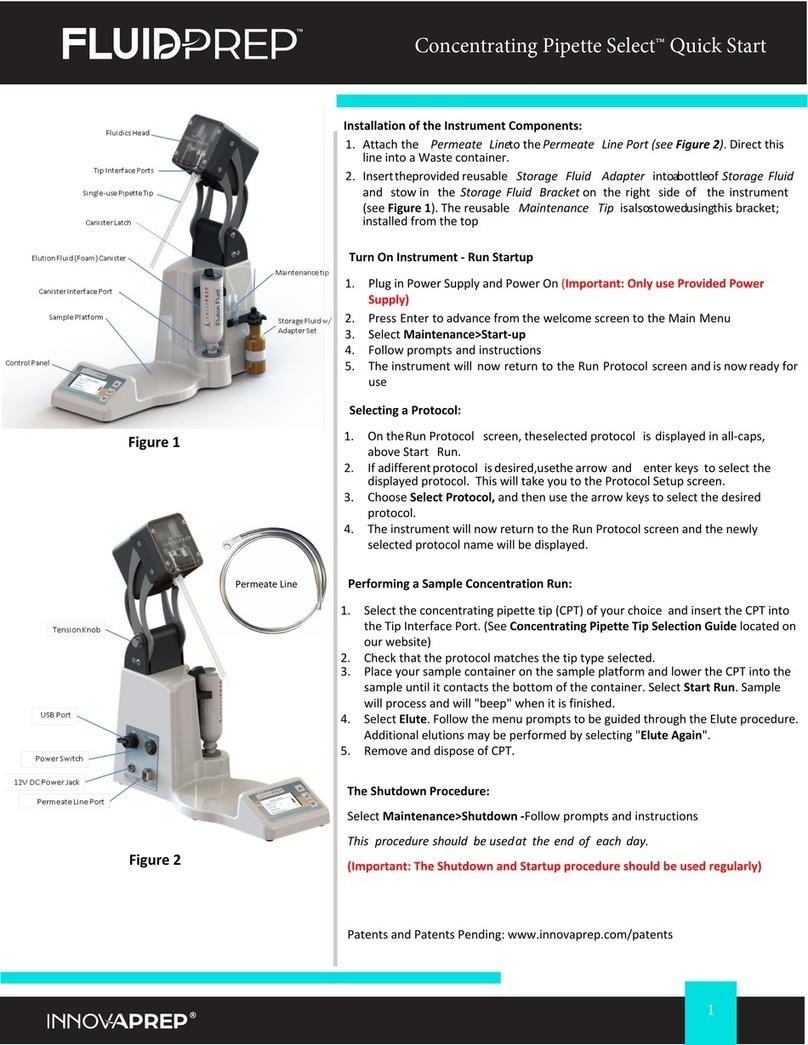

InnovaPrep

InnovaPrep FLUIDPREP Concentrating Pipette Select quick start

Stryker

Stryker RemB 6400-276-000 Instructions for use