SILENT KNIGHT SD505-DUCT User manual

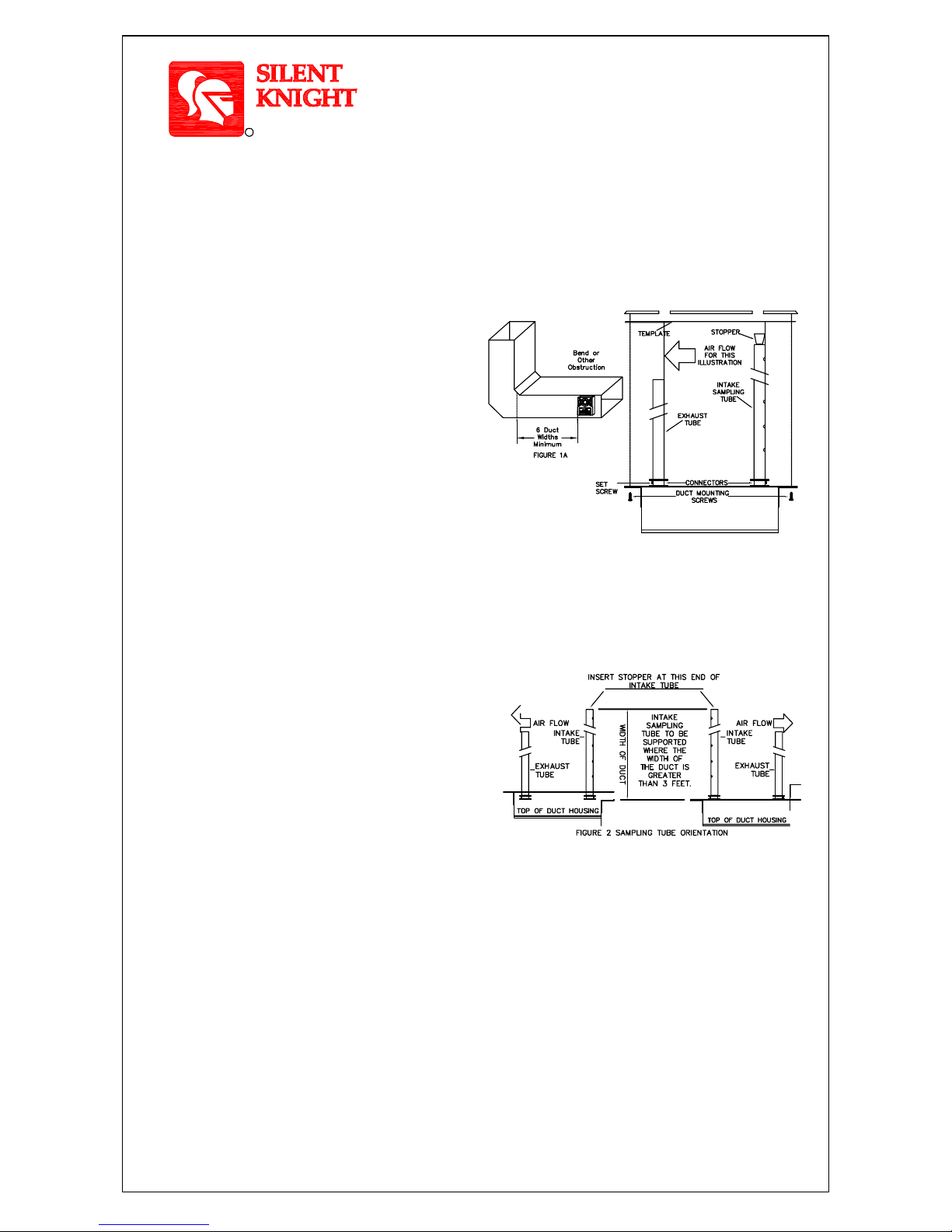

II. MOUNTING THE DETECTOR

The sampling tubes may be ordered to a desired length or

ordered in one of 3 standard lengths and cut per requirements.

The intake sampling tube consists of a piece of steel piping with

a series of holes drilled the entire length of the tube and should

extend the entire width of the duct. The holes must be facing

into the air flow (see Figure 2). The exhaust tube consists of a

piece of steel piping approximately 7-1/2" long.

1. Remove paper backing from mounting template AP 121 (packaged in installation kit) and

affix to duct at desired location.

2. Using template as a guide, drill 4 mounting holes (3/32" diameter) for duct mounting

screws (4 #12 x 1/2" sheet metal screws packaged in installation kit). Drill or punch holes

for sampling tubes in air ducts (1-3/8" diameter), using template as a guide. Clean all holes.

Duct Smoke Detector Location

Requirements: To prevent false alarms the detectors should

not be mounted in areas of extreme high or low temperatures,

in areas where high humidity exist, or in areas where duct air

may contain gases or excess dust. The duct detector should,

when possible, be located a minimum of six duct widths

downstream from a source of turbulence (bends, inlets, or

deflection plates). At these locations, air flow is less turbulent

and the air/smoke mixture should be more homogenous.

Refer to NFPA 90A, 72, and 101 for more information. See

Figure 1A and 1B.

Exception: Where it is physically impossible to locate

the duct detector accordingly, the duct detector can be

positioned closer than six duct widths, but as far as

possible from inlets, bends, or deflection plates.

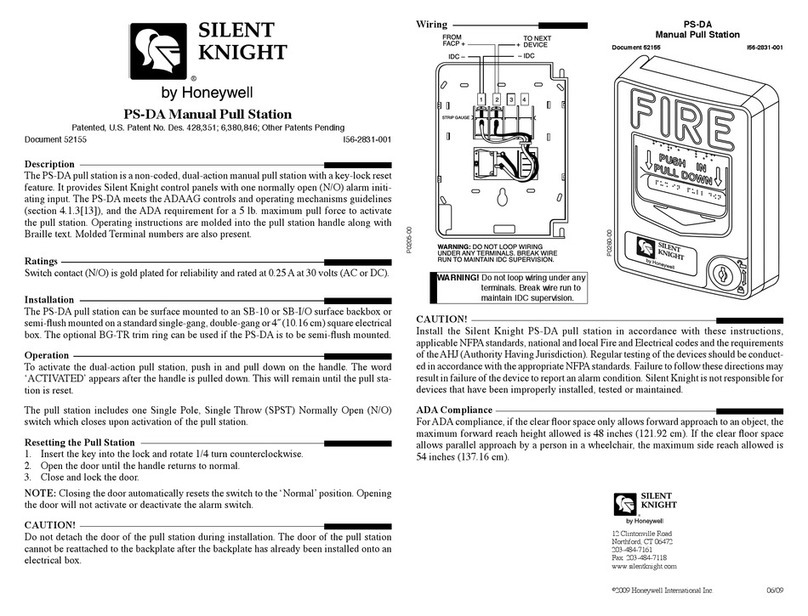

These are Installation Instructions (DWG.# HA-06-094) for the Duct Housing customized as follows:

SD505-DUCT Duct Housing with the SD505-APS Analog Photoelectric Smoke Sensor*

SD505-DUCTR Duct Housing with the SD505-APS Analog Photoelectric Smoke Sensor & Relays*

SD505-DTS-K Remote Test Switch

INSTALLATION INSTRUCTIONS FOR THE

DUCT SMOKE DETECTOR

A. DUCT PREPARATION

C. SAMPLING TUBE ASSEMBLY (See Figure 2)

The Duct Detectors are designed for use in ducts where the air velocities are

from 300 to 4000 feet per minute. Verify this by checking specifications of

installation and if necessary, use an Alnor Model 6000P velocity meter (or

equivalent) to check the air velocity. See Figure 2 for sampling tube

orientation to air flow direction.

B. VERIFY AIR FLOW AND DIRECTION

FIGURE 1B: DUCT HOUSING MOUNTING

TOP OF DUCT HOUSING

To verify proper sampling of air, use a Dwyer Model 4000 differential pressure gauge (or equivalent). See Figure 3 for

gauge connections. The pressure differential between input sampling tube and exhaust tube should be greater than

0.01" of water and less than 1.2" of water.

E. MOUNT THE DUCT HOUSING(See Figure 1B & 2)

Move duct housing/sampling tube assembly to desired location. Use 4 mounting screws (4 #12 x 1/2" sheet metal screws,

packaged in installation kit) to secure the housing to the air duct.

1. Sampling tube connectors are equipped with set screws, which allow the tubes to be mounted only in directions shown in

Figure 2. Establish proper orientation considering airflow direction.

2. Insert intake and exhaust tubes into connectors, align set screw to set screw hole in tubes andtighten firmly.

1. Cut the intake sampling tube to the desired length.

2. Firmly insert the stopper (packaged in installation kit) in the end of the INTAKE sampling tube.

INTAKE SAMPLING TUBES STANDARD LENGTHS:

Installation Instructions (P/N 1700-09882 HA-06-094) Page 1 of 3

F. VERIFY AIR SAMPLING (See Figure 3)

D. MOUNT SAMPLING TUBES (See Figure 2)

Specifications subject to change without notice. *September 2014

For duct widths of 1.0' to 2.5'

For duct widths of 2.5' to 5.0'

For duct widths of 5.0' to 10.0'

SD505-T2

SD505-T5

SD505-T10

I. LOCATION REQUIREMENTS

R

by Honeywell

1. With power source de-energized and the smoke detector not installed, wire

all connections per engineering drawings. Refer to the applicable figures below

depending on your duct housing model number.

2. With all wiring in place, install the detector head.

3. Energize the duct detector.

Wiring must conform to applicable local codes, ordinances and regulations

covering these types of devices. Wire the detectors according to the

engineering drawings for the particular job requirements. These detectors

are not intended for open area protection, nor should they be used for

open air protection. Refer to NFPA 90A and NFPA 72 for general and

additional information on Duct Smoke Detectors concerning operation

and installation. Terminals are suitable for up to #14 gauge wire.

B. DETECTOR WIRING

A. GENERAL INFORMATION

III. ELECTRICAL INSTALLATION

FIG. 3 AIR SAMPLING

VERIFICATION

EXHAUST TUBE

HOLE &

CONNECTOR

LOW PRESSURE

SIDE

DWYER #4000 DIFFERENTIAL

PRESSURE GAUGE(OR

EQUIVALENT) WITHTUBING

AND SIZE 0 RUBBERSTOPPERS

(HA PART# 0700-01118).

HIGH PRESSURE

SIDE

INTAKE TUBE

HOLE &

CONNECTOR

Specifications subject to change without notice. *September 2014

Installation Instructions (P/N 1700-09882 HA-06-094) Page 2 of 3

NOT USED

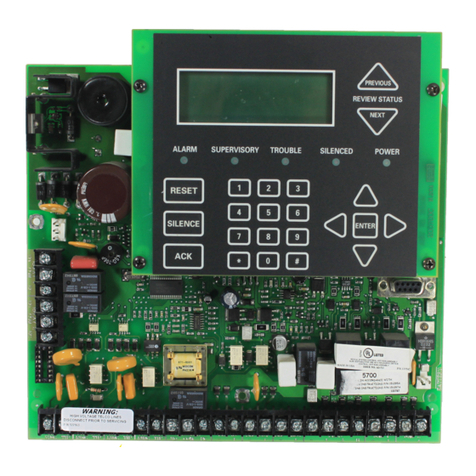

The SD505-DUCT is not a self-contained sensor.

This product is compatible only with fire alarm

control panels that utilize Silent Knight's Digital

Communications Protocol.

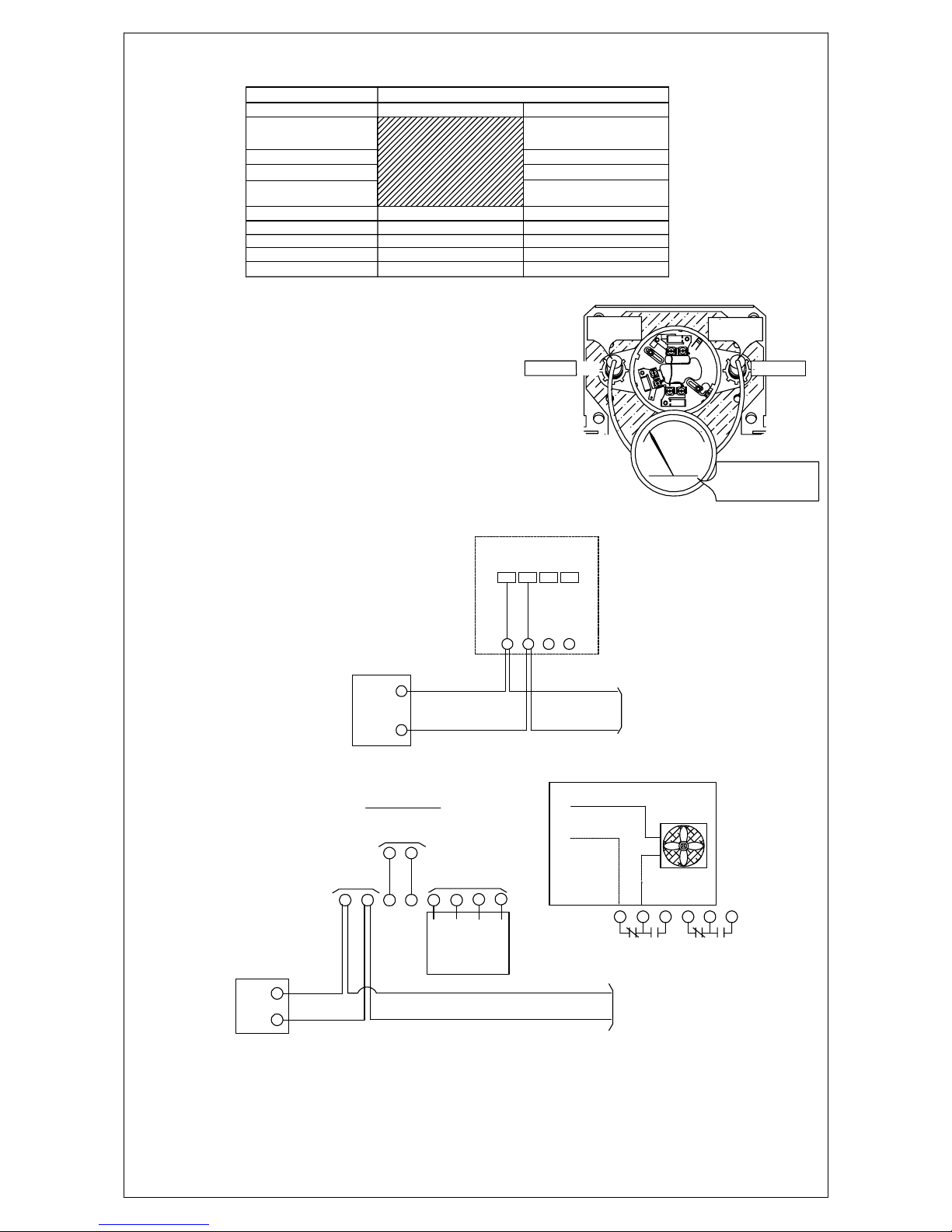

C. WIRING DIAGRAMS

UL LISTED

CONTROL PANEL

LOOP INTERFACE

S (+)

SC (-)

STANDBY and ALARM current should

be 0.55mA

TO NEXT

SENSOR

-R +RL2L1

1 2 3 4

ANALOG SENSOR

Terminate Remote Accessories as indicatedabove (if required).

This is not a self-contained stand alone detector.

A U.L. Listed Analog Addressable Fire System is required.

ANALOG ADDRESSABLE

FIELD LOOP WIRING

OBSERVE POLARITY

INPUT VOLTAGE

24 V.D.C.

S (+)

SC (-)

UL LISTED

CONTROL PANEL

A.A.

CONTROL

PANEL

ADDRESSABLE

LOOP

13 14

20 mA Standby

62mA Alarm

1 2

+-

SD505-DUCTR WIRING DIAGRAM

SUPPLY VOLTAGE

TO NEXT SENSOR

OR RETURN

TO CONTROL PANEL

TROUBLE

10.0A @ 250VAC

6

10

ALARM CONTACTS

10.0A @ 250VAC

NONCC

3 4 5

NO

C

NC

8

7

FAN

REMOTE TEST

SWITCH

(Test function only. Does not reset.)

FAN SHUTDOWN EXAMPLE

Test

SW GND PILOT

LED ALARM

LED

911 12

SD505-DTS

SD505-DUCT WIRING DIAGRAM

Maximum SLC Resistance

SLC Input Current

Aux. Power Input Current

Trouble Relay Contact Rating

Operating Voltage

Alarm Relay Contact Rating

Air Velocity Rating

Humidity

Operating Temperature

0.5mA

10% ~ 85% RH Non-Condensing

50 Ohms

32F ~ 100F

2.5A @ 30VDC

24VDC

10A @ 24VDC

SPECIFICATIONS

20mA Standby

62mA Alarm

RATING

SD505-DUCT

300 ~ 4000 ft./min.

0.5mA

10% ~ 85% RH Non-Condensing

50 Ohms

32F ~ 100F

300 ~ 4000 ft./min.

SD505-DUCTR

SPECIFICATIONS

10A @ 115VAC

10A @ 240VAC

12 Clintonville Road

Northford, CT 06472

Phone: 203-484-7161 * Fax: 203-484-7118 Specifications subject to change without notice.*September 2014

Installation Instructions (P/N 1700-09882 HA-06-094) Page 3 of 3

R

by Honeywell

SD505-DUCTR AND SD505-DTS-K

WIRING CONNECTIONS

REFER TO INSTALLATION INSTRUCTIONS(HA-06-094)

* SILENT KNIGHT DETECTORS ARE INTENDED FOR USE WITH AIR DUCTVELOCITIESFROM300TO4000FEETPERMINUTE.

VERIFY THIS BY CHECKING THE SPECIFI CATIONS OF HVAC INSTALLATIONANDIFNECESSARY,USEANALNOR

MODEL 6000P VELOCI TY METER OR EQUIVALENTTOCHECKAIRVELOCITY.

* PRESSURE DIFFERENTIAL MEASUREMENTS SHOULD BE MADE USINGADWYERPRESSUREGAGE(CATALOG

#2003 - 3" WATER FULL SCALE) TO INSURE AIR FLOW IN THISCHAMBER. THEPRESSUREDIFFERENTIAL

BETWEEN INPUT AND EX HAUST TU BE SHOULD B E BETWEEN0.01AND1.2INCHESOF WATER.

* DO NOT INSTALL WHERE AMBIENT TEMPERATUREEXCEEDS100°F(38°C).

FOR TERMINALS 3,4,5,6,7,8DO NOT USE LOOPED WIRE UNDER TERMINALS. BREAK WIRE RUN TO PROVIDE SUPERVISION OF CONNECTION.

CAUTION:

24 VDC

(+) (-) NC COM NO NC COM NO

ALARM

TROUBLE

TEST GND PILOT ALARM SLC- SLC+

SW LED LED

+ BASE -

BJ

5

910

105

50K

730

473 702

N4

MM

76A

N4

2447W9

A

VDE

EBYEBYEBYEBYEBY

EBY

2127H1

A

Bot t om View

MADE I N INDONESIA

105

335

2004

105

2004

1P

9

1V H

BJ

5

673 1016E

C2K

G43

673

10

16E

104

105 50K 730

105

50K

730

471

473

910

1V H

105

105

V104

103

D217

725S

D217

725S D217

725S

102

153

104

153

473

A7

5

473

A7

5

2T

105

50K

730

473

473

105

474

473

LM393

75M

CR7RG4

V104

153

472

153

105

50K

730

473

474

2004

2004

152

152

A7

5

1V H 1P

9

472

2T

1P

9

702

152

473

152

473

473

2T

A7

5

A7

5

TEST GND PILOT ALARM

LED LED

Class A (Style 6) Wiring

SC-

SLC OUT IN

TEST GND PILOT ALARM SLC- SLC+

SW LED LED

EBYEBY

EBY

TEST GND PILOT ALARM SLC- SLC+

SW LED LED

EBYEBY

EBY

TEST GND PILOT ALARM SLC- SLC+

SW LED LED

Silent Knight Control Panel

S+ SC-

SLC S+

SC-

SLC OUT IN

S+ SC-

SLC S+

EBYEBY

EBY

Class B (Style 4) Wiring

Silent Knight Control Panel

This manual suits for next models

2

Table of contents

Other SILENT KNIGHT Smoke Alarm manuals

Popular Smoke Alarm manuals by other brands

BRK electronic

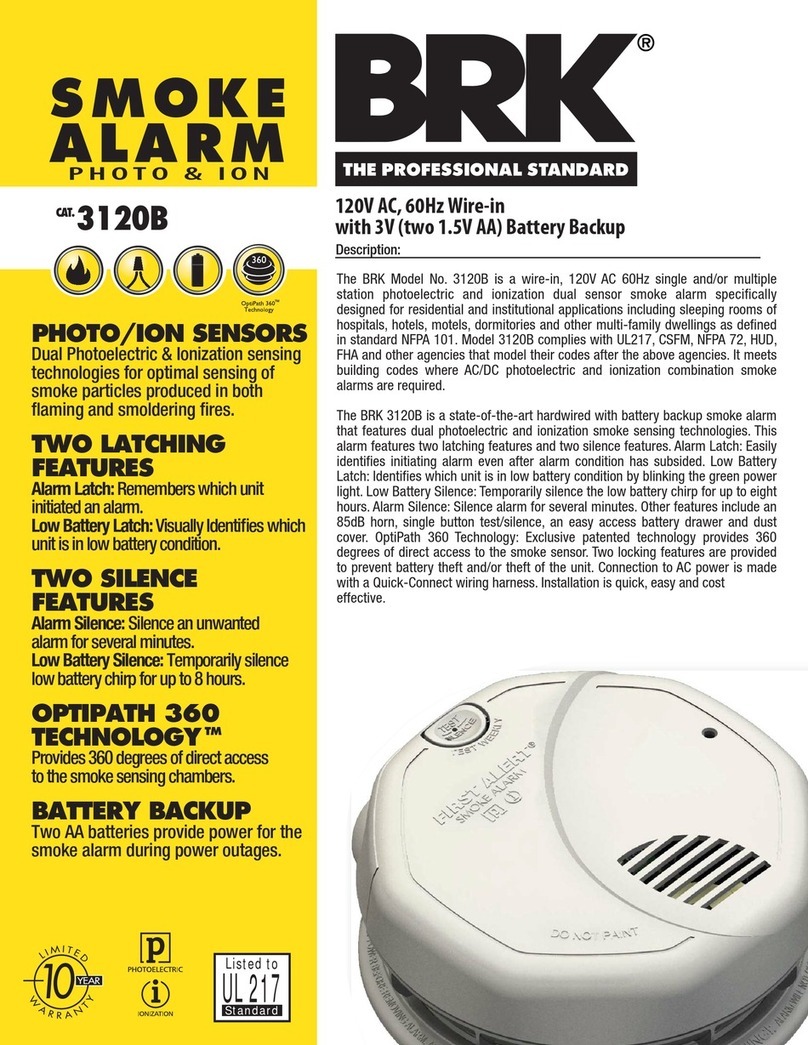

BRK electronic P H O T O & I O N 3120B Technical specifications

ELRO

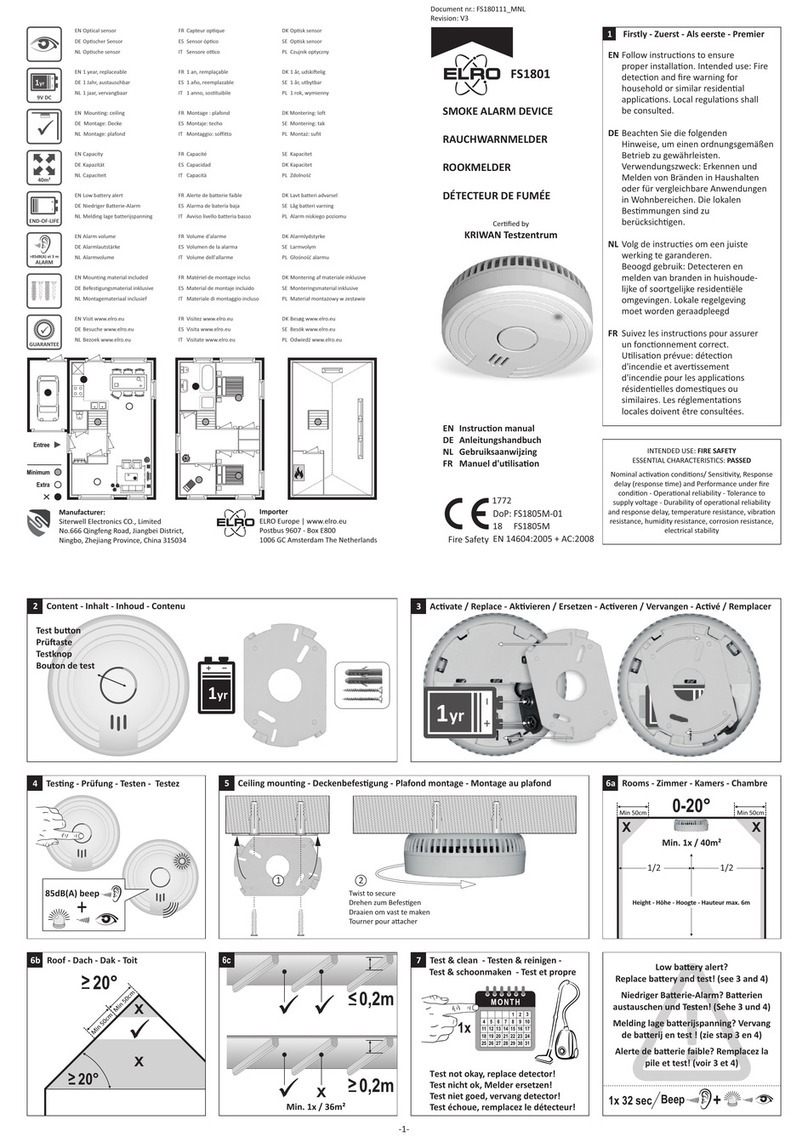

ELRO FS1801 instruction manual

Silent Call Communications

Silent Call Communications SD4-SS Installation and operation manual

Quell

Quell Q9080 manual

SB

SB SB-SK540 quick start guide

Brooks

Brooks Firetracker FT1-SB System manual

Uplink

Uplink 4555 Installation & user guide

Bosch

Bosch D1255RB/D1256RB/D1257RB installation instructions

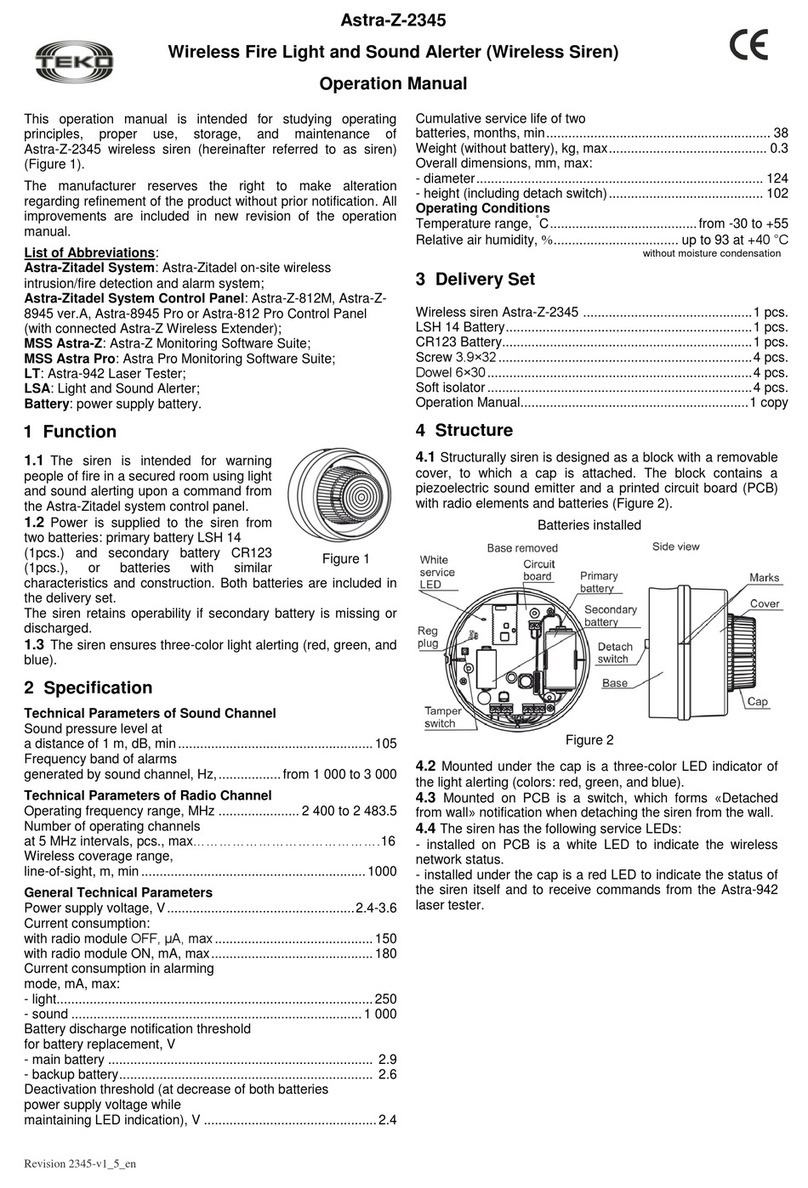

teko

teko Astra-Z-2345 Operation manual

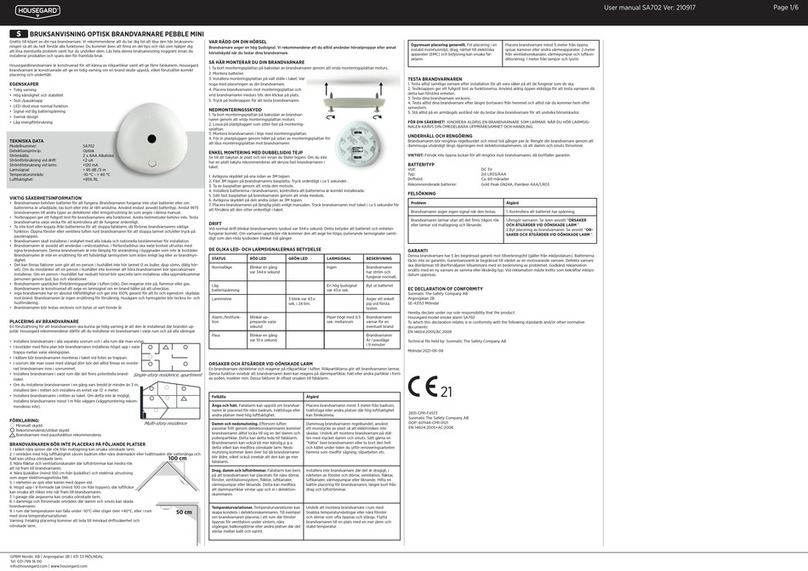

Sunmatic

Sunmatic Housegard PEBBLE MINI user manual

System Sensor

System Sensor Innovair flex 2D51 Installation and maintenance instructions

Swegon

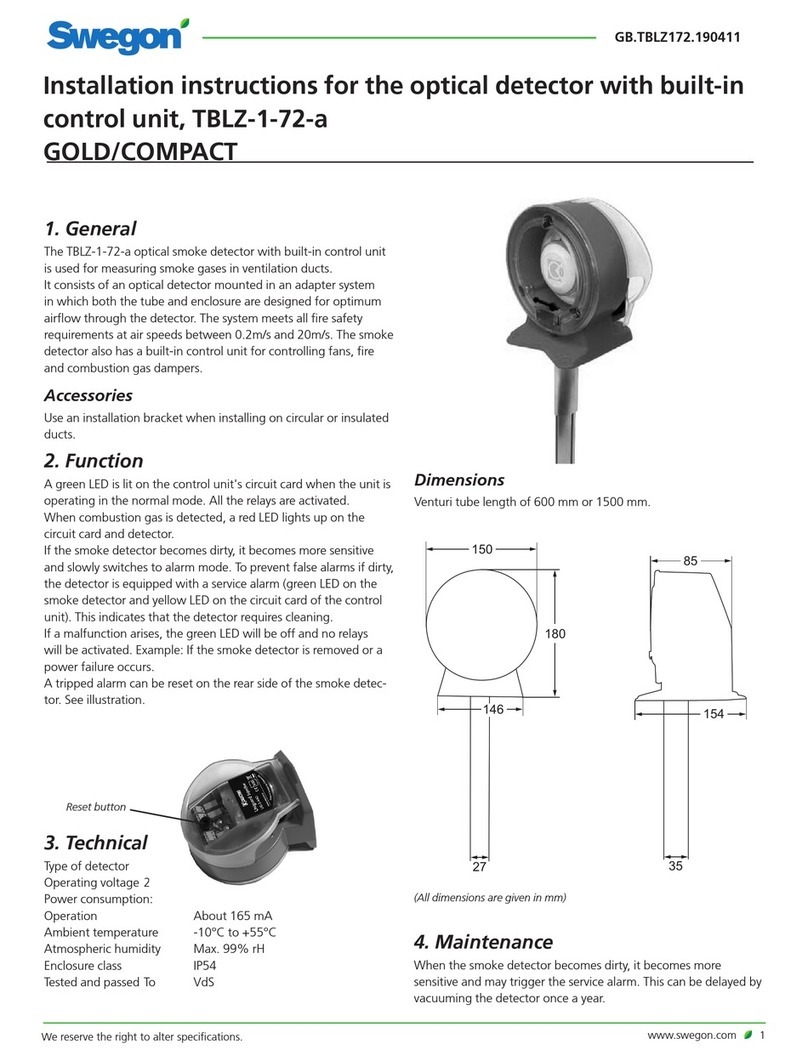

Swegon TBLZ-1-72-a GOLD installation instructions