We reserve the right to alter specifications. www.swegon.com 3

GB.TBLZ172.190411

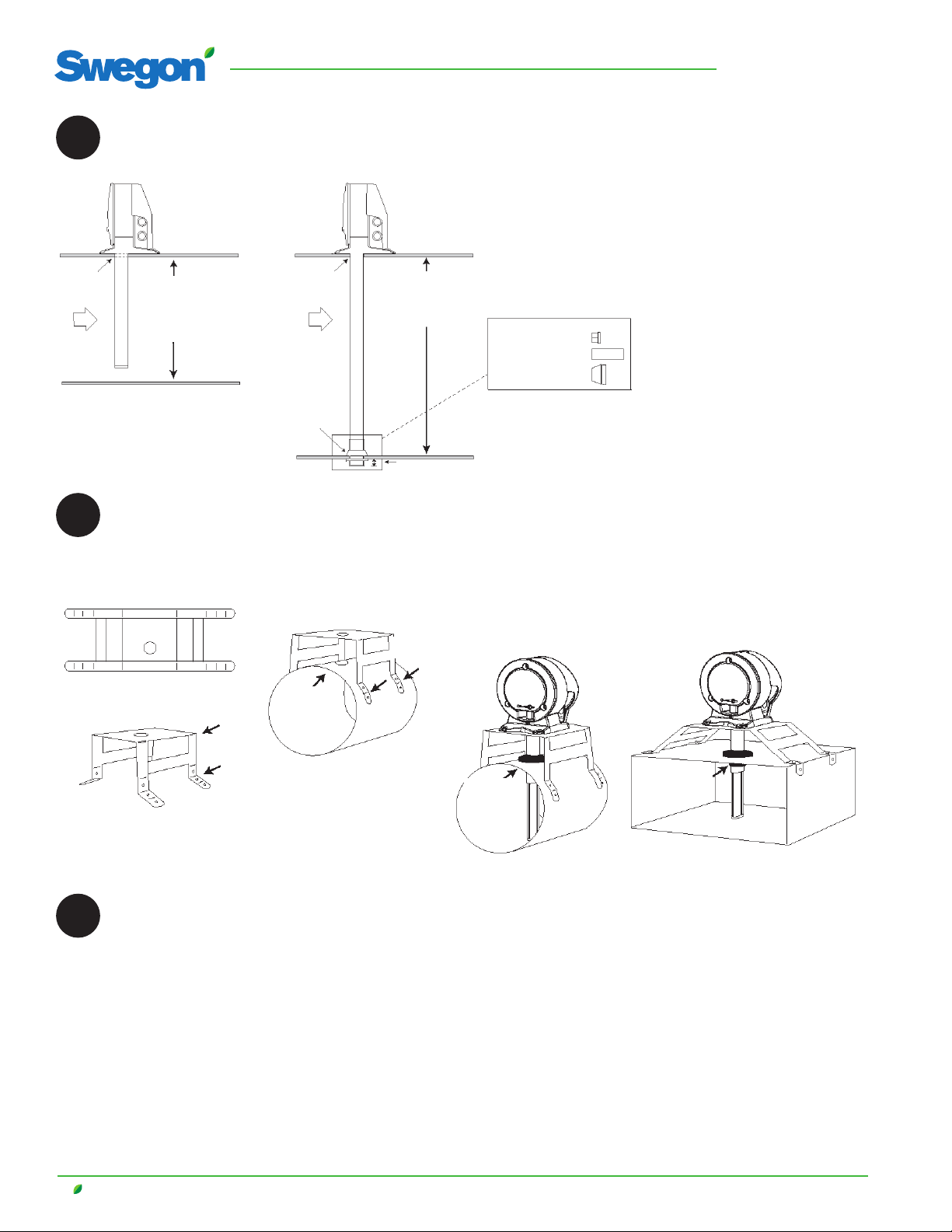

• Open the cover above the junction hood by lifting the catch.

• Insert the cable through any cable grommet.

When using another type of grommet, remove them premounted

by first pressing through one side and then through the other

(1-2).

• Connect the cables according to the wiring diagram in Section 6.

1

2

Drill holes in the duct.

• Make holes without 38 mm installation bracket.

• Make holes with 51 mm installation bracket (see

point 9).

3

Do not cut this end!

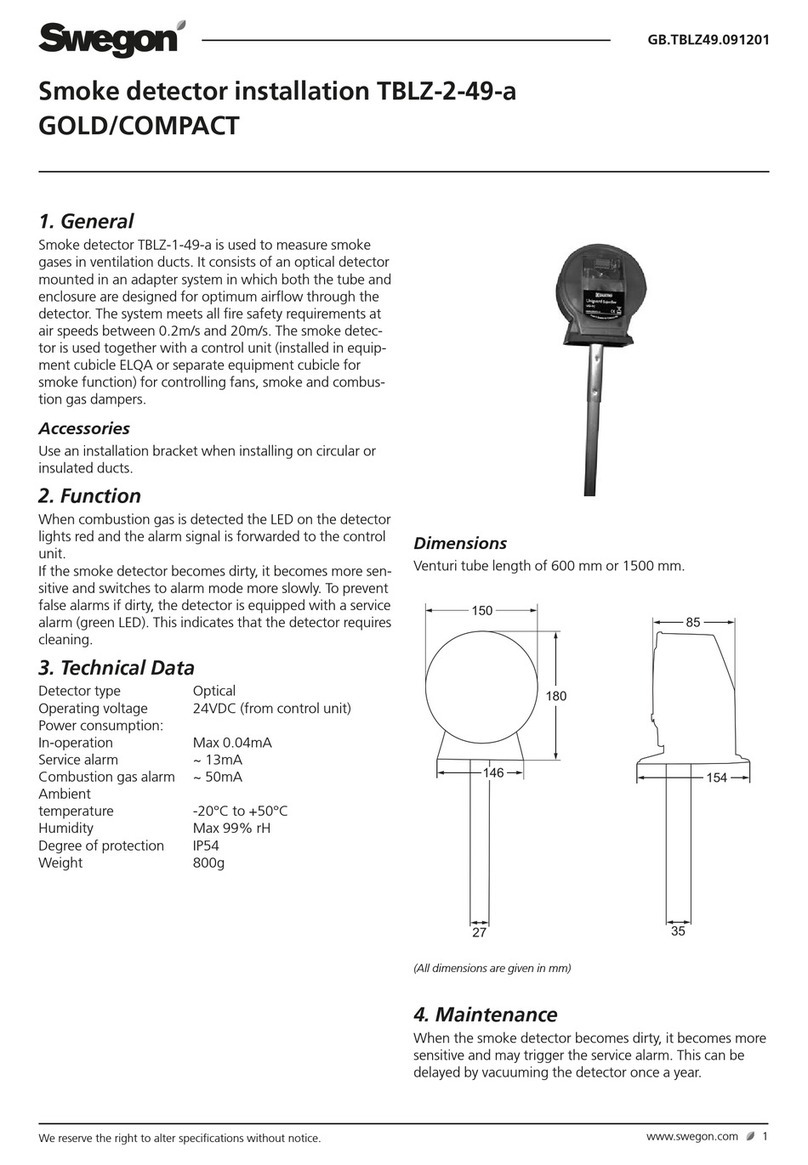

• Measure the ventilation duct.

• Cut the tube.

• The tubes must cover at least 90% of the duct’s width.

Detectors with venturi tubes of 600 mm are intended for ducts

with a max. duct width of 600 mm.

• Insert the end plug.

• Insert the seal onto the tube.

• Insert the tube into the bottom of the detector box.

• Lock the tube using the stop screw

4

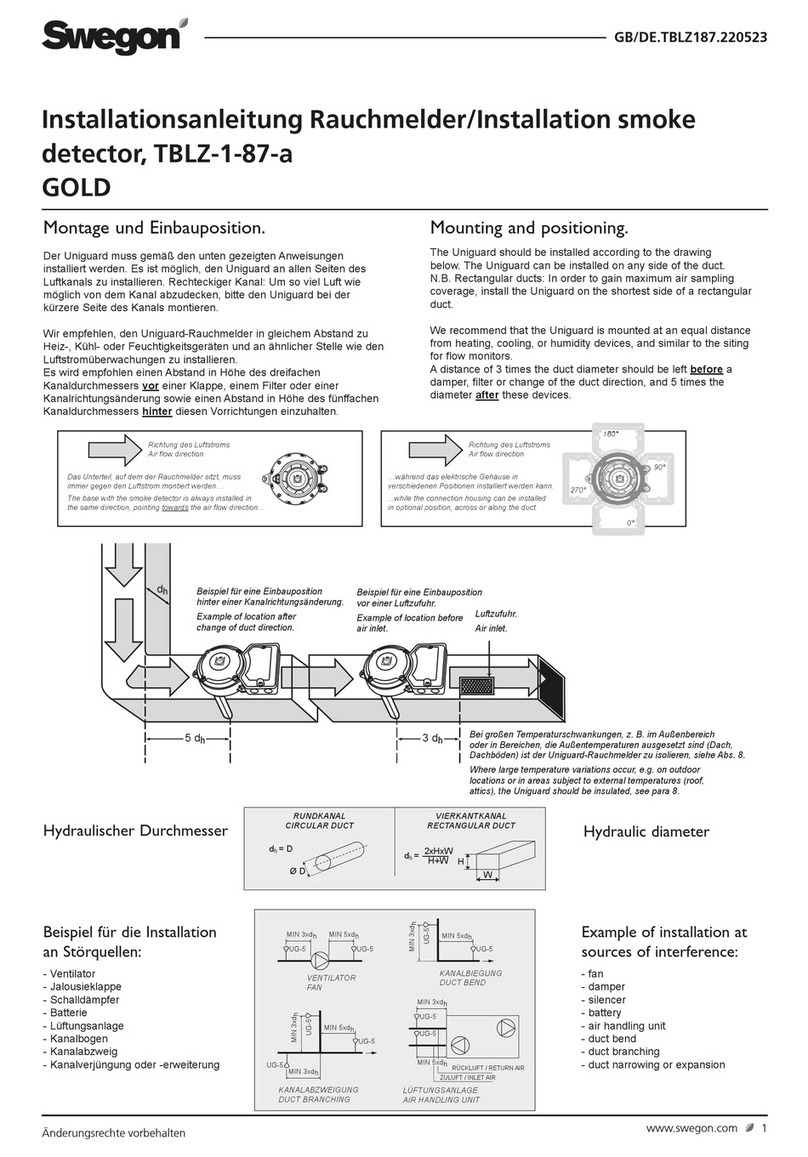

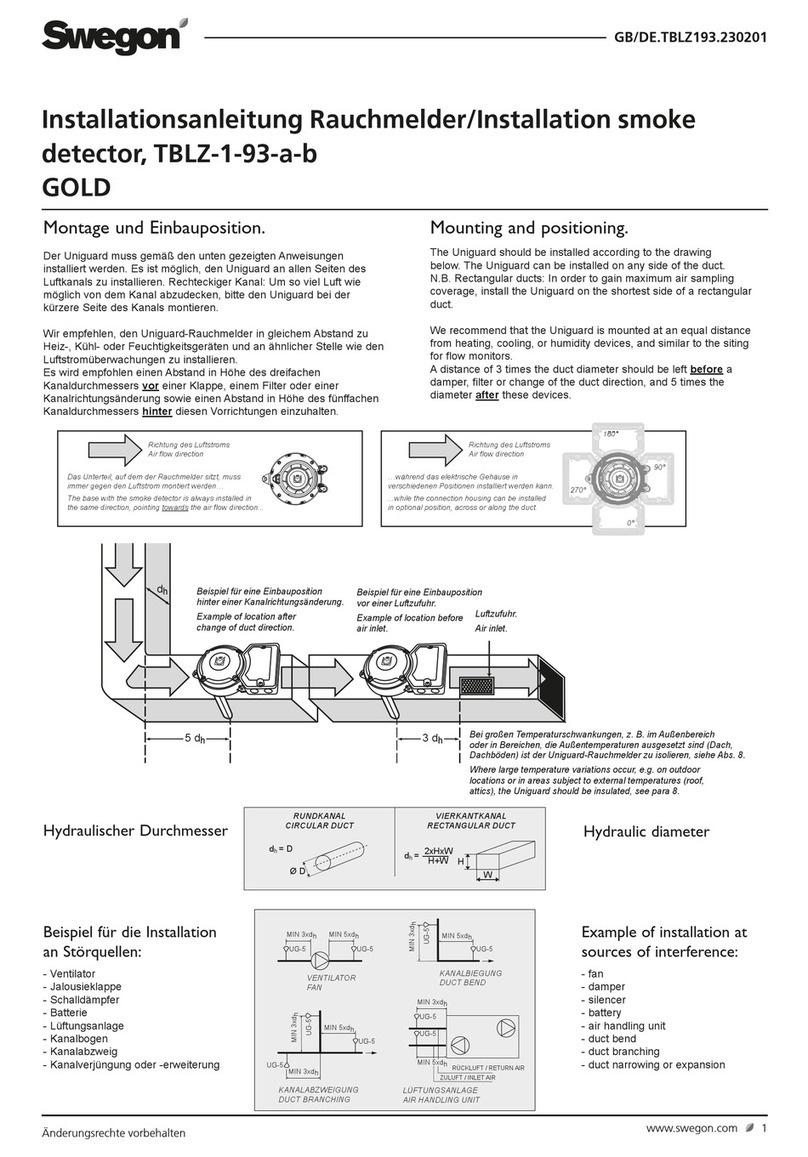

• Install the tube and detector on the duct.

• Secure the detector box at 3 points at the markings of the

arrows.

Important! IMPORTANT!

The direction arrows (see the shape of the detector’s base or the top

of the housing) must point in the same direction as the air flow in

the duct.

End plug

Stop screw

Seal

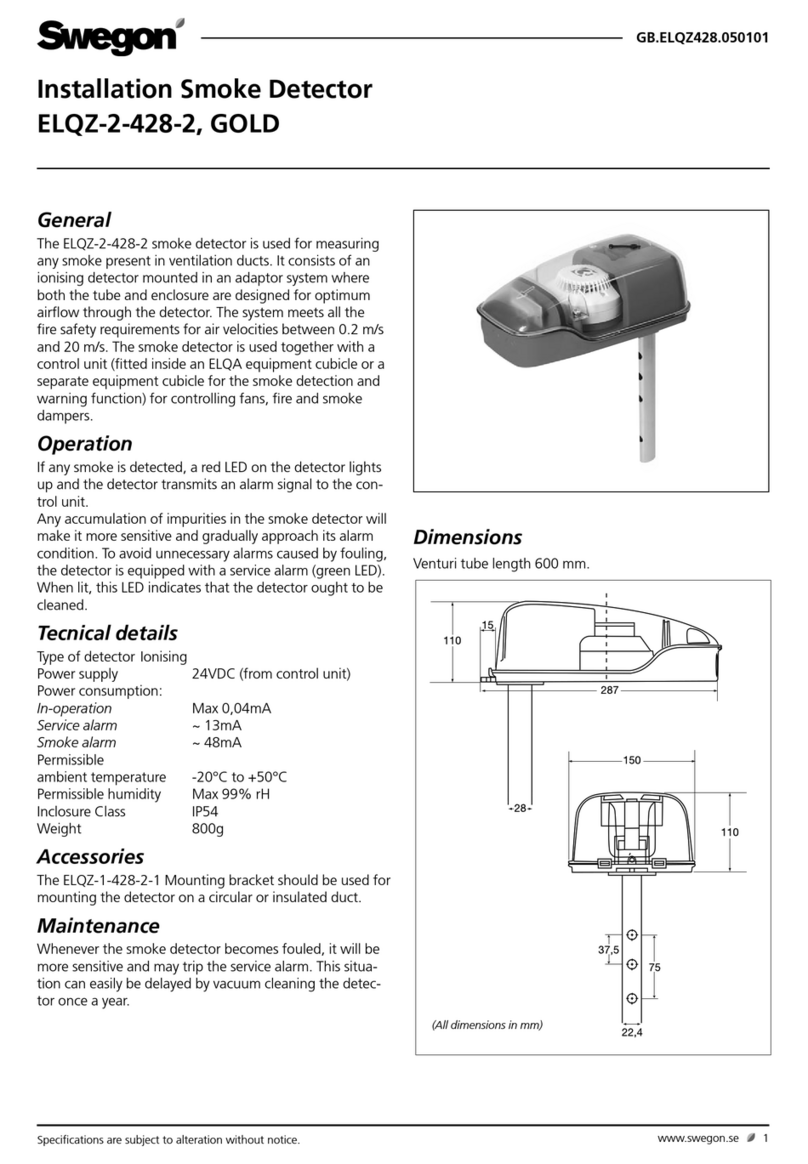

5Flow indicator.

The detector is equipped with an indicator, a red plastic

tab, which, when the detector is correctly installed,

swings out due to the air flow.

6Electrical installation.

Important!

If the indicator does not

move, consider moving

the detector or install a

fan tube.

Flow indicator

Venturi tube with auxiliary fan

7Performance checks.

Check the detector using the smoke detector tester in

spray form.

• Move the "test hole plug" to the side

and then quickly spray.

In the event of a tripped alarm, the

LED shines red on the circuit board and

the detector. In the event of a tripped

service alarm, the LED shines green on

the detector and yellow on the circuit

board.

• Reinstall the test hole plug.

Important!

Do NOT drill holes for signs or similar in the plastic cover. This can

cause leakage that seriously affects the function of the detector.