Silfradent MEDIFUGE CGF User manual

FT 01-MUE-MEDIFUGE_Rev10.docx Silfradent S.r.l. March 2021 age 2 of 28

TABLE OF CONTENTS

INFORMATION TO THE USER ........................................................................................................ 4

Notice ........................................................................................................................................ 4

Meaning of Pictogra s ............................................................................................................. 4

Warnings ................................................................................................................................... 5

Classification of the device ...................................................................................................... 5

Safety and safe switching off ................................................................................................... 5

Safety Warning ......................................................................................................................... 6

Electric Hazards ...................................................................................................................... 6

Mechanical Hazards ................................................................................................................. 6

Other Hazards. ........................................................................................................................ 6

Precautions ............................................................................................................................... 7

MEDIFUGE CGF Features .......................................................................................................... 7

Waste Disposal ......................................................................................................................... 8

Guarantee ................................................................................................................................. 8

Transport and Storage.............................................................................................................. 8

DESCRIPTION ................................................................................................................................ 9

Field of Application and Use ..................................................................................................... 9

Description of CGF .................................................................................................................. 9

Intended Use .......................................................................................................................... 9

General Description ................................................................................................................. 9

Equip ent of Centrifuge ........................................................................................................10

Accessories Provided with the MEDIFUGE CGF .....................................................................10

Disposable arts.................................................................................................................... 10

Sterilisable Containers ........................................................................................................... 12

Commercial Tools .................................................................................................................. 13

Instruments Specially Designed for the CGF ............................................................................. 14

Targhetta dati MEDIFUGE CGF ...............................................................................................15

Barcode of the device ............................................................................................................ 15

Codice a barre scatola ..................................................... Errore. Il segnalibro non è definito.

Rotor Label ........................................................................................................................... 16

Fuses .......................................................................................................................................16

INSTALLATION AND MAINTENANCE OF THE CENTRIFUGE ........................................................16

Installation and Use ...............................................................................................................16

Removing the Equipment from ackaging ................................................................................ 16

reparing the Centrifuge ........................................................................................................ 17

Maintenance and Cleaning .....................................................................................................17

Cleaning of the Centrifuge ..................................................................................................... 18

Disinfecting the Centrifuge ..................................................................................................... 18

Sterilization of the Centrifuge ................................................................................................. 18

Cleaning of Accessories .......................................................................................................... 18

Sterilization of Accessories ..................................................................................................... 19

Maintenance of the Centrifuge ................................................................................................ 19

Technical Support ................................................................................................................. 19

Removing the Rotor .............................................................................................................. 20

Replacement of the UV Lamp ................................................................................................. 20

Manual opening of the lid ....................................................................................................... 20

OPERATION ..................................................................................................................................21

Description of Control Panel ..................................................................................................21

Setting and Viewing Operating Data .....................................................................................21

Description of Operation ........................................................................................................ 21

General Description of CGF Preparing Process ......................................................................23

repare a Membrane with CGF K1 FM ................................................................................... 23

Use of Fibrin Injector CGF K1 INF ........................................................................................... 23

Using CGF with THE HOMOGENIZER ROUND UP ...................................................................24

SERVICE .......................................................................................................................................25

Troubleshooting .....................................................................................................................25

Safety Warning .......................................................................................................................27

ELECTROMAGNETIC ENVIRONMENT ...........................................................................................28

FT 01-MUE-MEDIFUGE_Rev10.docx Silfradent S.r.l. March 2021 age 3 of 28

Fig. 1-1 Centrifuge

Fig. 1-2 Accesories

FT 01-MUE-MEDIFUGE_Rev10.docx Silfradent S.r.l. March 2021 age 4 of 28

INFORMATION TO THE USER

NOTICE

Please note

The Italian version of this anual is the aster fro which translations derive.

In case of any discrepancy, the binding version is the Italian text.

Read these instructions for installation, use and aintenance of the device, before beginning operation,

in order to avoid i proper use and any type of da age or injury.

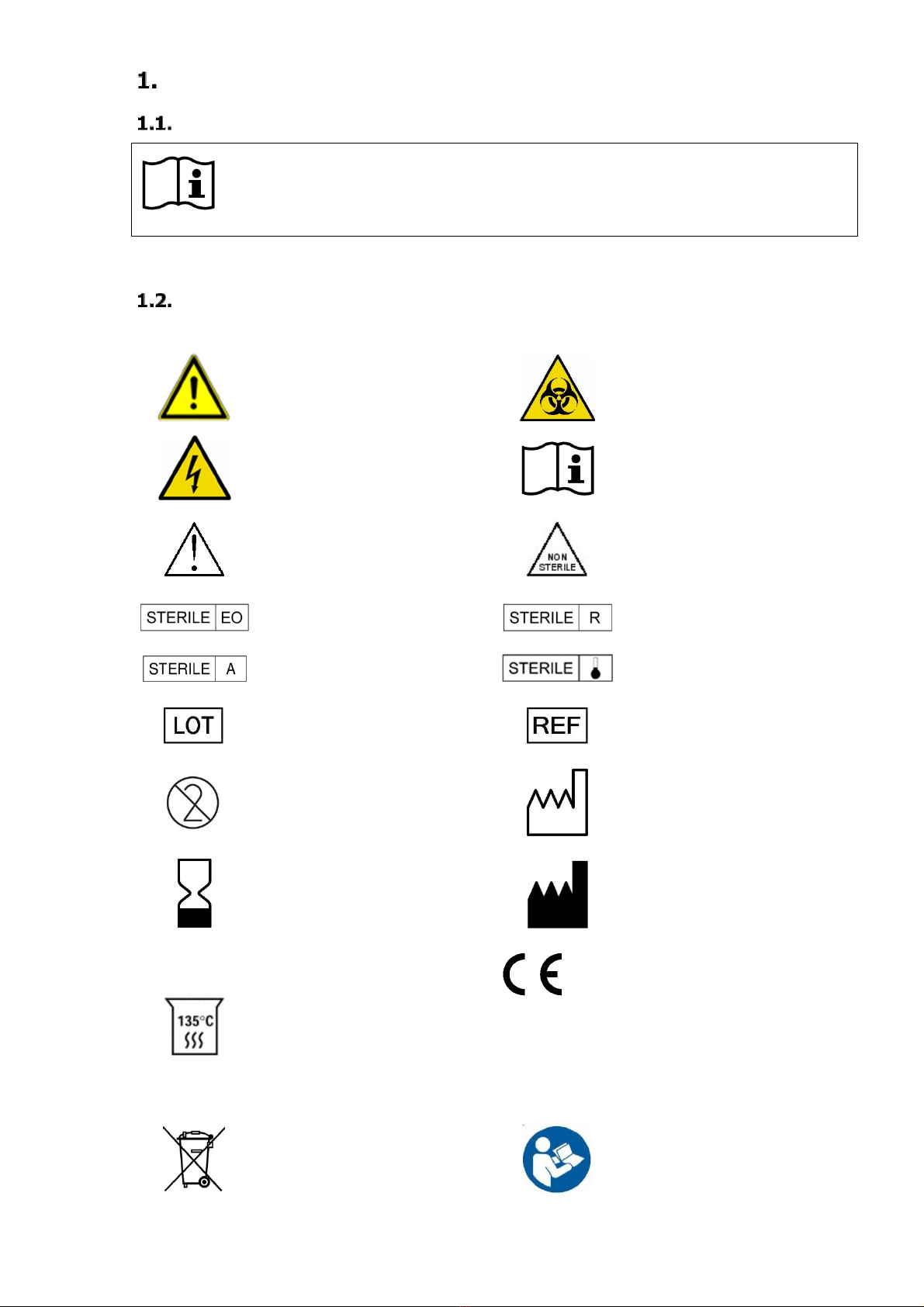

MEANING OF PICTOGRAMS

Both packaging of components and this booklet contain the symbols explained below.

Hazardous situations for the opera-

tor and/or the patient.

Biological hazard.

Electrical hazardous situation

Consult instructions for use or

Consult operating instructions.

Caution, consult accompanying doc-

uments.

The device has not been sterilized; it

must be sterilized before use.

Sterilized using Ethylene Oxide.

Sterilized using irradiation.

Sterile medical devices processed

using aseptic techniques.

Sterilzed using steam or dry heat

Batch Code Catalogue number

Do not re-use

Date of manufacture: this symbol is

adjacent to the date that the product

was manufactured

Use by date: close to this symbol

there is the expiry date

Manufacturer’s data: this symbol is

adjacent to the name and address of

the manufacturer.

Steam sterilisable at max 135°C

This symbol is a mandatory marking

for devices entering the European

market to indicate conformity with

the essential health and safety re-

quirements set out in European Di-

rectives.

The symbol may be accompanied by

a four-digit identification number of

the notified body.

Not for general waste: this symbol is

used to mark devices that are reusa-

ble and not contaminated at the end

of the device life.

Read instruction for use

FT 01-MUE-MEDIFUGE_Rev10.docx Silfradent S.r.l. March 2021 age 5 of 28

WARNINGS

This manual is designed to the centrifuge for dental

practice and specialized outpatient clinic MEDIFUGE

CGF with its accessories, for its intended purposes

The Manufacturer of this medical device is:

Silfradent S.r.l.

VIA G. Di Vittorio N°35/37

47018 S. Sofia (FC), ITALY

Tel. +39 0543 970684 Fax +39 0543 970770

Silfradent S.r.l. congratulates and thanks you for

choosing this device.

Below, we provide some preliminary information to help

you in the initial use of the equipment.

It is important that you make sure that the package

contains the guarantee certificate and that this is filled

in and stamped by the retailer.

The accessories provided with MEDIFUGE CGF were se-

lected to perform each operation necessary for prepar-

ing and using CGF in a sterile ambient to avoid contam-

ination of autologous implant material.

Please note.

Before removing the equipment from packaging, check that all the components described in para-

graphs 2.2 (Centrifuge) and 2.3 (accessories suitcase) are in.

After carefully extracting the components of MEDIFUGE

CGF from the packaging, place them on a table and

check that there are no damages deriving from

transport, in this case immediately contact the retailer.

Silfradent S.r.l. has drafted this Manual with the aim to

help the user and facilitate the start-up and operation

of the equipment.

Silfradent S.r.l. accepts no responsibility for

changes to the equip ent or da ages to third

parties arising fro isuse.

Each piece of equip ent is supplied with a copy

of this booklet

Compliance with the instructions contained in this tech-

nical document is necessary for correct operation.

The use of the equipment for uses different from those

indicated in these instructions and in the brochures is

absolutely forbidden.

Non-compliance with the instructions herein contained

results in the immediate termination of the guarantee.

Please note.

For any request, always quote:

The date of purchase, device model and serial number which can be found on the data label on the

back side of the MEDIFUGE CGF.

The removal of the data plate causes the warranty to be forfeited

CLASSIFICATION OF THE DEVICE

The equip ent is classified:

According to the type of protection against electric haz-

ards. Equipment supplied by an external source of elec-

tric energy.

Class I equip ent

According to the degree of protection against direct and

indirect contacts. No applied part

According to the degree of protection against liquid pen-

etration. Console is classified as IpX0.

According to the degree of safety of use in the presence

of an anesthetic mix inflammable with air, oxygen or ni-

trous oxide.

NO PROTECTION.

According to the conditions of use. Equip ent for continuous operation, the operating

cycles are preset.

SAFETY AND SAFE SWITCHING OFF

Before using the equipment, the user must check equip-

ment status. Stop operation if there are components

that are not in perfect conditions.

Turn off the mains switch and disconnect the power

cord from mains socket before leaving the device unat-

tended.

Never use the machine in the case of damages.

Always check the expiry date of the disposable accesso-

ries and the integrity of their packaging before using.

Table of contents

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual