Silicon Laboratories Si475X Series Operating instructions

Rev. 0.9 10/16 Copyright © 2016 by Silicon Laboratories AN543

Silicon Laboratories Confidential. Information contained herein is covered under non-disclosure agreement (NDA).

AN543

Si475XPROGRAMMING GUIDE

1. Introduction

This document provides an overview of the programming requirements for the Si475x-A10/A20/A30/A40/A55 and

Si475xC-A55 AM/FM receiver. The hardware control interface and software commands are detailed along with

several examples of the required steps to configure the device for various modes of operation. Table 1 provides a

programming guide cross-reference for each Si475x part released by Silicon Labs to date. This programming guide

focuses on the Si475x/5xC-A55 release; however, features, properties, ranges, and defaults that differ from the

Si475x-A10 to Si475x-A40 are noted as well. Refer to previous versions of this document for earlier firmware

revisions.

2. Overview

This devices in this product family are programmed using commands and responses. To perform an action, the

system controller writes a command byte and associated arguments, which cause the device to execute the given

command. The device will, in turn, provide a response depending on the type of command that was sent.

The device has a slave control interface that allows the system controller to send commands to and receive

responses from the device using 2-wire mode (I2C compatible).

3. Terminology

CTS—Clear to send

STC—Seek/Tune Complete

NVM—Non-volatile internal device memory

Device—Refers to the AM/FM Receiver

System Controller—Refers to the system microcontroller

CMD—Command byte

ARGn—Argument byte (n = 1 to 7)

STATUS—Status byte

RESPn—Response byte (n = 1 to 15)

Table 1. Si475x Firmware Revisions

Part # Part Revision FMRX Component AMRX Component

Si475x-A10 1.0 3.2.3 3.2.3

Si475x-A20 2.0 8.0.8 7.0.5

Si475x-A30 3.0 10.0.8 9.0.6

Si475x-A40 4.0 13.0.11 12.0.10

Si475x-A55 5.5 15.0.2 14.0.1

Si475xC-A55 5.5 15.0.2 14.0.1

AN543

2 Rev. 0.9

4. Control Interface

The Si475x provides an I2C-compatible, 2-wire control interface.

In powerdown mode, all circuitry is disabled except for the device control interface. The device comes out of

powerdown mode when the POWER_UP command is written to the command register. Once in powerup mode,

the device accepts additional commands such as tuning. The device will not accept commands while in

powerdown mode, with the exception of the powerup command. If the system controller writes a command other

than POWER_UP when in powerdown mode, the device does not respond, and the command is ignored.

Setting the RSTB pin low places the device in reset mode. In reset mode, all circuitry is disabled including the

device control interface; registers are set to their default settings, and the control bus is disabled.

4.1. 2-Wire Control Interface

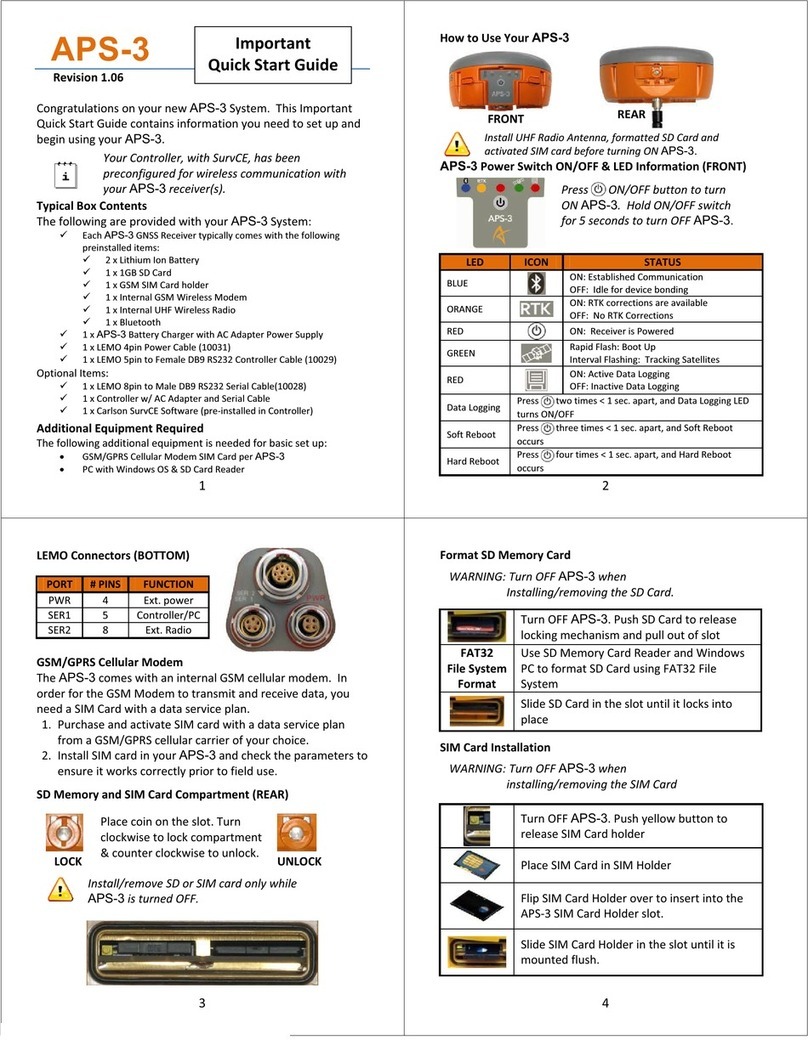

Figure 1 and Figure 2 show the 2-wire control interface read and write timing parameters and diagrams,

respectively. Refer to the Si475x data sheet for timing parameter values.

Figure 1. I2C Control Interface Read and Write Timing Parameters

Figure 2. I2C Control Interface Read and Write Timing Diagram

SCL 70%

30%

SDA 70%

30%

START STARTSTOP

tf:IN

tr:IN

tLOW tHIGH

tHD:STA

tSU:STA tSU:STO

tSP tBUF

tSU:DAT

tr:IN tHD:DAT tf:IN,

tf:OUT

tPD:DAT

SCL

SDA

(Write)

START STOPADDRESS + R/W ACK DATA ACK DATA ACK

A6-A0, 0 Command

7-0 Arg1

7-0

SDA

(Read)

START STOPADDRESS + R/W ACK DATA ACK DATA ACK

A6-A0, 1 Status

7-0 Response

7-0

AN543

Rev. 0.9 3

Two-wire bus mode uses the SCL and SDA pins for signaling. A transaction begins with the START condition,

which occurs when SDA falls while SCL is high. Next, the system controller drives an 8-bit control word serially on

SDA, which is captured by the device on rising edges of SCL. The control word consists of a seven-bit device

address followed by a read/write bit (read = 1, write = 0). The device acknowledges the control word by driving

SDA low on the next falling edge of SCL.

For write operations, the system controller next sends a data byte on SDA, which is captured by the device on

rising edges of SCL. The device acknowledges each data byte by driving SDA low for one cycle on the next falling

edge of SCL. For each write transaction, the first byte is a command and the following bytes are arguments.

For read operations, after the device has acknowledged the control byte, it will drive an eight-bit data byte on SDA,

changing the state of SDA on the falling edges of SCL. The system controller acknowledges each data byte by

driving SDA low for one cycle on the next falling edge of SCL. If a data byte is not acknowledged by the system

controller, the transaction will end. For each read transaction, the first byte is the status byte and the following bytes

are the response data from the receiver.

A 2-wire transaction ends with the STOP condition, which occurs when SDA rises while SCL is high.

5. Powerup and Powerdown

There are two procedures for powering up a receiver to move it from powerdown mode to the powerup mode. The

first is a powerup from internal receiver memory. The second is a powerup from a firmware component patch that is

stored in system controller memory. Patches can be applied to a firmware component by the system controller via

a download mechanism to address field issues, errata, or adjust device behavior. Patches are encrypted and

unique to a particular device firmware version, cannot be generated by customers, and can be used to replace a

portion of the component (to address errata, for example) or to download an entirely new component. The user

must verify that the device contains the correct base firmware to support the patch as described later in this

section.

It has been noted that some crystals require greater startup current and settling times than others. The procedure

below is meant to apply to a wide variety of such crystals, providing maximum current and 40 ms for crystal

oscillation to stabilize. If there are still difficulties with POWER-UP that may be related to your choice of crystal,

please refer to the settings and hardware options in “AN750: Si475x 4 MHz Crystal Compatibility Power-Up

Procedure”.

AN543

4 Rev. 0.9

5.1. Powerup Receiver from Internal Memory

1. Supply VA, VD, and VIO while keeping the RSTB = 0. Power supplies may be sequenced in any order.

2. After a minimum of 100 µs, set RSTB = 1.

3. After a minimum of 100 µs, continue to the next step.

4. Send the POWER_UP command for the desired function (AM, FM).

Supply VA, VD, and VIO while

keeping the RSTB = 0

START

After a minimum of 100 µs,

set RSTB = 1

After a minimum of 100 µs,

continue to the next step

Send second POWER_UP

command for the desired

function (AM, FM)

Commence normal operation

Send POWER_DOWN

command

Send the POWER_UP

command for desired function

(AM, FM)

Wait at least 100 ms

Send command

to force CTS = 1

AN543

Rev. 0.9 5

Example (with crystal 4 MHz, FM function):

1. Provide the initial POWER_UP Command:

2. Apply a wait time of at least 100 ms.

3. Apply the following command:

4. Apply the following command:

Note: For more details on the external circuit for the 4 MHz crystal, see “AN750: Si475x 4 MHz Crystal Circuit and Power-Up

Procedure”.

5. The device is ready to commence normal operation and accept additional commands. Refer to Figure 3.

Action Data Description

CMD 0x01 POWER_UP

ARG1 0X77 NORMAL OPERATION, 4 MHz Crystal

ARG2 0x1F SETS CRYSTAL LOAD CAPACITANCE

Note: Change this value to the capacitance that matches the crystal in use.

ARG3 0x27 SETS CRYSTAL BIAS = 7 w/ FASTBOOT

ARG4 0x00

0x10

0x20

BOOT LOADER

FM Receive, 4 MHz Crystal

AM Receive, 4 MHz Crystal

ARG5 0x00 DIGITAL CORE DISABLED/CRYSTAL OSCILLATOR DISABLED

STATUS NO CTS bit returned

Action Data Description

CMD 0xFB CONTROL REGISTER WRITE COMMAND

ARG1 0X06 CONTROL REGISTER ADDRESS

ARG2 0x80 FORCES CTS = 1

STATUS NO CTS bit returned

Action Data Description

CMD 0x01 POWER_UP

ARG1 0X77 NORMAL OPERATION, 4 MHz Crystal

ARG2 0x1F SETS CRYSTAL LOAD CAPACITANCE

Note: Change this value to the capacitance that matches the crystal in use.

ARG3 0x23 SETS CRYSTAL BIAS = 3 w/ FASTBOOT

ARG4 0x00

0x10

0x20

BOOT LOADER

FM Receive, 4 MHz Crystal

AM Receive, 4 MHz Crystal

ARG5 0x11 DIGITAL CORE ENABLED/CRYSTAL OSCILLATOR ENABLED

STATUS CTS = 1

AN543

6 Rev. 0.9

Figure 3. Powerup Timing

6. If desired, send the POWER_DOWN command.

Example:

7. It is now possible to move to the powerup state by returning to step 4.

POWER_DOWN Command

Action Data Description

CMD 0x11 POWER_DOWN

ARG1 0x00 Disable oscillator (ARG1 may be omitted with the same result)

STATUS →0x80 CTS = 1

VIO

VD

VA

RSTB

SCL

SDA POWER_UP Command

100 µs min

100 µs min

> 10 µs

AN543

Rev. 0.9 7

5.2. Powerup Receiver from a Patch

1. Supply VA, VD, and VI0 while keeping the RSTB = 0. Power supplies may be sequenced in any order.

2. After a minimum of 100 µs, set RSTB = 1.

3. After a minimum of 100 µs, proceed to the next step.

4. (Optional – step 1 of 3 to verify part firmware revision and ROM revision.) Both part firmware revision and ROM

revision must be compatible with a partial patch and ROM revision must be compatible with a full patch. Send

the POWER_UP command for the desired function (AM, FM).

Supply VA, VD, and VIO

while keeping the RSTB = 0

START

After a minimum of 100 µs,

set RSTB = 1

After a minimum of 100 µs,

continue to the next step

Send the POWER_UP

command for the desired

function (AM, FM)

Send POWER_DOWN

command

A

B

Verify Firmware and ROM

revision? A

B

Send PART_INFO command

Wait at least 100 ms

Send second POWER_UP

command for the desired

function (AM, FM)

C

Send the POWER_UP

command with boot loader

function

Send patch data.

Send the POWER_UP

command for the desired

function (AM, FM)

Commence normal operation.

Send POWER_DOWN

command.

Wait at least 100 ms

Send second POWER_UP

command with bootloader

function

B

C

Send command to force

CTS = 1 Send command to force

CTS = 1

AN543

8 Rev. 0.9

Example (with crystal 4 MHz, FM function):

1. Provide the initial POWER_UP Command:

2. Apply a wait time of at least 100 ms.

3. Apply the following command:

4. Apply the following command:

Note: For more details on the external circuit for the 4 MHz crystal, see “AN750: Si475x 4 MHz Crystal Circuit and Power-Up

Procedure”.

5. (Optional – step 2 of 3 to verify part firmware revision and ROM revision). Verify part firmware revision and

ROM revision. Send the PART_INFO command.

Action Data Description

CMD 0x01 POWER_UP

ARG1 0X77 NORMAL OPERATION, 4 MHz Crystal

ARG2 0x1F SETS CRYSTAL LOAD CAPACITANCE

Note: Change this value to the capacitance that matches the crystal in use.

ARG3 0x27 SETS CRYSTAL BIAS = 7 w/ FASTBOOT

ARG4 0x00

0x10

0x20

BOOT LOADER

FM Receive, 4 MHz Crystal

AM Receive, 4 MHz Crystal

ARG5 0x00 DIGITAL CORE DISABLED/CRYSTAL OSCILLATOR DISABLED

STATUS NO CTS bit returned

Action Data Description

CMD 0xFB CONTROL REGISTER WRITE COMMAND

ARG1 0X06 CONTROL REGISTER ADDRESS

ARG2 0x80 FORCES CTS = 1

STATUS NO CTS bit returned

Action Data Description

CMD 0x01 POWER_UP

ARG1 0X77 NORMAL OPERATION, 4 MHz Crystal

ARG2 0x1F SETS CRYSTAL LOAD CAPACITANCE

Note: Change this value to the capacitance that matches the crystal in use.

ARG3 0x23 SETS CRYSTAL BIAS = 3 w/ FASTBOOT

ARG4 0x00

0x10

0x20

BOOT LOADER

FM Receive, 4 MHz Crystal

AM Receive, 4 MHz Crystal

ARG5 0x11 DIGITAL CORE ENABLED/CRYSTAL OSCILLATOR ENABLED

STATUS CTS = 1

AN543

Rev. 0.9 9

Example:

In this example, the part revision is 2.0.0 and the ROM ID is 4. Ensure that partial patches received from Silicon

Labs are intended for use with the part firmware revision and ROM, and that full patches are intended for use with

the ROM ID as shown in Table 2. It is possible to verify the FM and AM component firmware revisions with the

FUNC_INFO command, however, this is not necessary because there is always a unique mapping of component

revision to part revision.

6. (Optional—step 3 of 3 to verify part firmware revision and ROM revision.) Send the POWER_DOWN

command. This step is required before proceeding with the patching procedure if steps 4 and 5 have been

followed.

Example

7. Send the POWER_UP command for boot loader function.

PART_INFO Command

Action Data Description

CMD 0x02 PART_INFO

STATUS →0x80 CTS = 1

RESP1 →0x06 Chip revision, 6

RESP2 →0x35 Part number (last two digits) 0x35 = 53, or Si4753

RESP3 →0x32 Firmware major revision = ASCII character “2”

RESP4 →0x30 Firmware minor revision = ASCII character “0”

RESP5 →0x00 Firmware build version = 0

RESP6 →0x00 Reserved, values will vary

RESP7 →0x00 Reserved, values will vary

RESP8 →0x04 ROM ID

Table 2. Si475x Firmware and ROM Compatibility

Part # Part Revision ROM ID FM Revision AM Revision

Si475x-A10 1.0 2 3.2.3 3.2.3

Si475x-A20 2.0 4 8.0.8 7.0.5

Si475x-A30 3.0 5 10.0.8 9.0.6

POWER_DOWN Command

Action Data Description

CMD 0x11 POWER_DOWN

ARG1 0x00 Disable oscillator (ARG1 may be omitted with the same result)

STATUS →0x80 CTS = 1

AN543

10 Rev. 0.9

Example (with crystal 4 MHz, boot loader function):

1. Provide the initial POWER_UP Command:

2. Apply a wait time of at least 100 ms.

3. Apply the following command:

4. Apply the following command:

5. Send the patch data.

The patch file provided by Silicon Labs typically has a .sg extension. The system controller must send each line of

8 bytes, wait for a CTS, then send the next line of 8 bytes, etc., until the entire patch has been sent. An example

showing the first few lines and final line of a patch file is shown below. Note that the “#” character indicates a

comment and the patch file indicates the required ROM ID for a partial or full download. If the checksum fails, the

part issues an error code, ERR (bit 6 of the STATUS byte received after each 8-byte transfer), and halts. The part

must be reset to recover from this error condition.

Action Data Description

CMD 0x01 POWER_UP

ARG1 0X77 NORMAL OPERATION, 4 MHz Crystal

ARG2 0x1F SETS CRYSTAL LOAD CAPACITANCE

Note: Change this value to the capacitance that matches the crystal in use.

ARG3 0x27 SETS CRYSTAL BIAS = 7 w/ FASTBOOT

ARG4 0x00

0x10

0x20

BOOT LOADER

FM Receive, 4 MHz Crystal

AM Receive, 4 MHz Crystal

ARG5 0x00 DIGITAL CORE DISABLED/CRYSTAL OSCILLATOR DISABLED

STATUS NO CTS bit returned

Action Data Description

CMD 0xFB CONTROL REGISTER WRITE COMMAND

ARG1 0X06 CONTROL REGISTER ADDRESS

ARG2 0x80 FORCES CTS = 1

STATUS NO CTS bit returned

Action Data Description

CMD 0x01 POWER_UP

ARG1 0X77 NORMAL OPERATION, 4 MHz Crystal

ARG2 0x1F SETS CRYSTAL LOAD CAPACITANCE

Note: Change this value to the capacitance that matches the crystal in use.

ARG3 0x23 SETS CRYSTAL BIAS = 3 w/ FASTBOOT

ARG4 0x00

0x10

0x20

BOOT LOADER

FM Receive, 4 MHz Crystal

AM Receive, 4 MHz Crystal

ARG5 0x11 DIGITAL CORE ENABLED/CRYSTAL OSCILLATOR ENABLED

STATUS CTS = 1

AN543

Rev. 0.9 11

The following is an example of a patch file:

# COPYRIGHT=2011 Silicon Laboratories, Inc.

# GENERATED=13:53 May 23 2011

# ROMID=0x04

# PATCHID=0x228C

# REQUIRES=NONE

# SIZE=8272

# FUNCTION=FMRX

# MAJOR=8

# MINOR=0

# BUILD=8

# CRCT=0x81CF

# CRCM=0x0A6C

# CRCP=0xEC8D

# CRCX=0x66EE

# CRCY=0x6381

# CRCZ=0xA805

0x04,0x11,0x81,0xCF,0x00,0x00,0x0D,0xC6

0x05,0xAE,0xE1,0xBD,0xB4,0x90,0x07,0x33

0x06,0xD9,0x3D,0x11,0xF7,0x25,0xCB,0x06

0x17,0x7A,0xF8,0xD0,0x71,0x10,0x3F,0xB7

0x1F,0xBF,0xFF,0x7E,0x42,0xE7,0x53,0x05

…

[Additional Lines]

…

0x08,0x21,0xAB,0xB5,0xF1,0x7A,0xD6,0x5A

0x08,0x10,0x0E,0x9E,0x3B,0xD1,0x01,0xF4

0x08,0xBF,0x8D,0x94,0xB0,0x2D,0xCF,0xFF

0x05,0x8D,0xB1,0x22,0xF2,0x8D,0x22,0x8C

# END

AN543

12 Rev. 0.9

Example:

6. Send the POWER_UP command for the desired function (AM, FM).

Example (with crystal 4 MHz, FM function):

Example (with external clock 4 MHz, FM function):

First line of the patch file example

Action Data Description

CMD 0x04

ARG1 0x11

ARG2 0x81

ARG3 0xCF

ARG4 0x00

ARG5 0x00

ARG6 0x0D

ARG7 0xC6

STATUS →0x80 CTS = 1

Second line of the patch file example

CMD 0x05

ARG1 0xAE

ARG2 0xE1

ARG3 0xBD

ARG4 0xB4

ARG5 0x90

ARG6 0x07

ARG7 0x33

STATUS →0x80 CTS = 1

POWER_UP Command

Action Data Description

CMD 0x01 POWER_UP

ARG1 0x77 Normal operation

ARG2 0x27 Crystal load capacitance = 15.803 pF each pin

ARG3 0x23 Disables CTS interrupt, crystal bias = 3, enable fastboot

ARG4 0x10 FM function, crystal frequency 4 MHz

ARG5 0x11 Crystal

STATUS →0x80 CTS = 1

AN543

Rev. 0.9 13

7. The device is ready to commence normal operation and accept additional commands.

8. If desired, send the POWER_DOWN command.

Example:

9. It is now possible to move to the powerup state by returning to step 7.

POWER_UP Command

Action Data Description

CMD 0x01 POWER_UP

ARG1 0x77 Normal operation

ARG2 0x00 Crystal load capacitance = 5 pF each pin

ARG3 0x23 Disables CTS interrupt, crystal bias = 3, enable fastboot

ARG4 0x10 FM function, clock frequency 4 MHz

ARG5 0x12 External clock

STATUS →0x80 CTS = 1

POWER_DOWN Command

Action Data Description

CMD 0x11 POWER_DOWN

ARG1 0x00 Disable oscillator (ARG1 may be omitted with the same result)

STATUS →0x80 CTS = 1

AN543

14 Rev. 0.9

6. Timing

6.1. Command and Property Timing

When the user reads a response over the I2C bus, the first 8 bits returned are the STATUS register. Bit 7 of the

STATUS register is the CTS bit (Clear to Send). When CTS is 1, it indicates that the chip is ready to receive a new

command. Seek and Tune commands may take longer to complete than most other commands, so they also use

the STC bit (Seek/Tune Complete) to indicate they have completed. STC is bit 0 of the STATUS register.

When the user sends any command, the CTS bit will immediately reset to 0. CTS will remain 0 while the chip

processes the command. When the chip is finished processing the command, the CTS bit will be set back to 1.

Before sending another command, the user may poll CTS by reading the first byte of response until CTS = 1. If the

user has enabled the optional CTS interrupt, then the INTB pin will pulse low immediately after CTS has been set

to 1, to notify the user that the previous command has completed. For information on how to enable the CTS

interrupt, see the INT_CTL_ENABLE property and CTSIEN bit in the arguments for the POWER_UP command.

The commands for seek and tune (FM_TUNE_FREQ, FM_SEEK_START, etc.) will cause CTS to reset to 0 for a

short time, but they will set CTS back to 1 after the seek or tune has started. The seek or tune is progressing even

though CTS has been set back to 1. Although the user is free to send another command at this time, it is highly

recommended to wait until the STC (Seek/Tune Complete) bit has been set to 1 before sending another command.

The only exception is the AM/FM_RSQ_STATUS command, which may be sent at any time because it can be used

to cancel the seek/tune in progress and check the status of which station seek is currently on.

When the seek/tune completes, the STC bit will be set to 1. The user may poll STC by reading the first byte of

response until STC = 1. If the user has enabled the optional STC interrupt, then the INTB pin will pulse low

immediately after STC has been set to 1, to notify the user that the seek or tune has completed. For information on

how to enable the STC interrupt, see the INT_CTL_ENABLE property.

After the seek or tune has completed, the user may acknowledge the completion by sending the AM/

FM_RSQ_STATUS command with the STCACK bit set to 1. This will reset the STC bit back to 0. After this, the

user may send another seek or tune command. Alternatively a new seek or tune command will also clear the STC

bit when it begins.

Figure 4 shows a seek or tune command with the optional CTS and STC interrupts enabled. The timing parameters

are shown in Table 3.

Figure 4. CTS and STC Timing Model

Command

FM_TUNE_FREQ

Control

Bus

tSTC

tINT

CTS

Bit

STC

Bit

Command

FM_RSQ_STATUS

INTB

tCTS

AN543

Rev. 0.9 15

Table 3. Command Timing Parameters for Common Commands

Command tCTS tSTC tINT

POWER_UP 100ms — 3µs

POWER_DOWN <1000 µs — 3 µs

FUNC_INFO <200 µs — 3 µs

SET_PROPERTY <200 µs — 3 µs

GET_PROPERTY <200 µs — 3 µs

GET_INT_STATUS <200 µs — 3 µs

AGC_STATUS <200 µs — 3 µs

ANA_AUDIO_PIN_CFG <200 µs — 3 µs

Table 4. Command Timing Parameters for FM Receiver

Command tCTS tSTC tINT

FM_TUNE_FREQ <200 µs 21 ms 3 µs

FM_TUNE_FREQ (fast tune) <200 µs 5 ms 3 µs

FM_SEEK_START <200 µs See Note below. 3 µs

FM_RSQ_STATUS <200 µs — 3 µs

FM_ACF_STATUS <200 µs — 3 µs

FM_RDS_STATUS <200 µs — 3 µs

FM_RDS_BLOCKCOUNT <200 µs — 3 µs

*Note: tSTC is seek time per channel. Total seek time depends on bandwidth, channel spacing, and

number of channels to next valid channel.

Worst case seek time complete for FM_SEEK_START is:

For Si475x-A30, the seek time will require an additional tSTC + tSTC(FAST) for channel

spacings other than 200 kHz.

Table 5. Command Timing Parameters for AM Receiver

Command tCTS tSTC tINT

AM_TUNE_FREQ 100 µs 40 ms 3 µs

AM_SEEK_START 100 µs See Note below. 3 µs

AM_RSQ_STATUS 100 µs — 3 µs

AM_ACF_STATUS 100 µs — 3 µs

*Note: tSTC is seek time per channel. Total seek time depends on bandwidth, channel spacing, and

number of channels to next valid channel.

FM_SEEK_BAND_TOP FM_SEEK_BAND_BOTTOM–

FM_SEEK_FREQ_SPACING

--------------------------------------------------------------------------------------------------------------------------------------------------

1+

tSTC

AN543

16 Rev. 0.9

6.2. Alternate Frequency (AF) Timing

The Si4754/55/56/57 features a flexible FM tune command that allows for a number of operational choices. While

tuned to the current station, the receiver can quickly tune to candidate FM stations and perform one of three

operations.

1. Tune to the FM station and stay tuned.

2. Tune to the FM station; check the selected signal metrics, and jump back to the original station (AF check).

3. Tune to the FM station; check the selected signal metrics, and decide if the receiver is kept tuned to the FM

station (AF Jump) or re-tuned to the original station.

The timing diagrams for AF tune and AF check are shown in Figure 5 and Figure 6, respectively.

Figure 5. AF Tune Diagram

AF Tune

command

issued

AF Tune

Initiated

F1F1F2

AF station metrics qualified:

Above thresholds

Tuner stays on AF station

Audio Audio

F2

}

F2

T2T3

T1T1

T1 ~ 0.5 ms

T2 ~ 1 ms

T3 ~ 4.8 ms

AN543

Rev. 0.9 17

Figure 6. AF Check Timing Diagram

AF Check

command

issued

AF Check

Initiated

F1F1F2F2 F1F1

AF Station metrics

measured and qualified.

Tuner jumps back to F1

Audio Audio

F2

}

}

T2T4T2

T1T1

T1~ 0.5 ms

T2~ 1 ms

T4 ~ 7 ms

AN543

Rev. 0.9 19

7. Commands and Properties

7.1. Common Commands and Properties

The following properties and commands are common to all receiver modes.

Table 6. Common Receiver Command Summary

Number Name Summary

0x01 POWER_UP Power-up device and mode selection. Modes include operational

function (AM, FM) and audio interface configuration.

0x02 PART_INFO Returns the part information of the device.

0x11 POWER_DOWN Power-down the device.

0x12 FUNC_INFO Returns the firmware revision and patch revision.

0x13 SET_PROPERTY Sets the value of a property.

0x14 GET_PROPERTY Retrieve a property's value.

0x15 GET_INT_STATUS Read interrupt status bits.

0x17 AGC_STATUS Reports the status of the AGC.

0x1B ANA_AUDIO_PIN_CFG Configures the analog audio pins.

0x1C INTB_PIN_CFG Configures behavior of INTB and A1 pins.

Table 7. Common Receiver Property Summary

Number Name Default Summary

A10 A20 A30 A40 A55

0x0000 INT_CTL_ENABLE 0x0000 0x0000 0x0000 0x0000 0x0000 Interrupt enable prop-

erty.

0 0 000

0x0300 AUDIO_ANALOG_VOLUME 0x003F 0x003F 0x003F 0x003F 0x003F Sets the analog audio

volume.

63 63 63 63 63

0x0301 AUDIO_MUTE 0x0000 0x0000 0x0000 0x0000 0x0000 Audio mute property.

0 0 000

AN543

20 Rev. 0.9

Table 8. Status Response for the FM Receiver

Bit 76543210

STATUS CTS ERR XX RSQINT RDSINT ACFINT STCINT

Bit Name Function

7CTS

Clear to Send.

0 = Wait before sending next command.

1 = Clear to send next command.

6ERR

Error.

0=Noerror.

1=Error.

5:4 Reserved Values may vary.

3RSQINT

Received Signal Quality Interrupt.

0 = Received Signal Quality measurement has not been triggered.

1 = Received Signal Quality measurement has been triggered.

2RDSINT

Radio Data System Interrupt.

0 = Radio data system interrupt has not been triggered.

1 = Radio data system interrupt has been triggered.

1ACFINT

Automatically Controlled Features Interrupt.

0 = ACF measurement has not been triggered.

1 = ACF measurement has been triggered.

0STCINT

Seek/Tune Complete Interrupt.

0 = Tune complete has not been triggered.

1 = Tune complete has been triggered.

This manual suits for next models

6

Table of contents

Other Silicon Laboratories Receiver manuals

Silicon Laboratories

Silicon Laboratories SI4830 User manual

Silicon Laboratories

Silicon Laboratories Si4330 User manual

Silicon Laboratories

Silicon Laboratories SI4730 User manual

Silicon Laboratories

Silicon Laboratories SI4734/35-B20 User manual

Silicon Laboratories

Silicon Laboratories EZRADIOPRO Si4060 Operating instructions