SilverStar SR-6000 User manual

Steam Generator

User's Manual

Model: SR-6000

* To use the product correctly, plese read this operation instruction carefully.

http://www.silverstar.co.kr

NO

♠ Before use

What is vapor generator - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - -

3

Names of parts of product - - - - - - - - - - - - - - - -

- - - - - - - - - - - -

3

Product specification

- - - - - - - - - - - - - - - - - - - -

- - - - - - - - - -

4

Circuit diagram - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - -

4

Product characteristics - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - -

5

Precautions of safety use - - - - - - - - - - - - - - - -

- -

6∼9

♠ Use

Confirmation before use - - - - - - - - - - - - - - - -

- - - - - - - - - - - -

9

Assembly and use - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - -

10

♠ After use

Cleaning method - - - - - - - - - - - - - - - - - - - - -

- - - -

11

♠ Others

Breakdown

drawing

- - - - - - - - - - - - - - - - - - - - -

- - - - - - - - -

12

Troubleshooting - - - - - - - - - - - - - - - - - - - - -

- - - - - - -

13

2

What is SR-6000

SR-6000 is composed of the vapour generated between pressure containers

that store water and generate vapours, and the iron that can perform ironing

work.This product functions with antomatism of water. Vapour generator owns

basic functions of industrial boiler. Miniaturized design is easy in installation

and convenient for use. It is the product that can improve work efficiency and

save energy, can be used safely and conveniently in common clothes factory,

mall, supermarket, tailor's shop, laundry etc..

Name of various parts of product

3

pressure meter

indicating light

switch

safety valve

fittings

enclosure

Water tank

iron

power cord

power cord

steam pipe

cable holder

Product specification

Product name Vapour generator

Type SR-6000

Voltage 120/220V~,50/60㎐

Vapour generator power 1,500W

Electric iron power 120V/800W,220V/1,000W

Vapour pressure 3.5bars

Product weight 25kg

Product dimension 420×250×830h

Circuit diagram

QS : power switch PCB : Pcb board P S/W : Switch of iron

T.F : Fuser M : Electromagnetic pump S S/W : Vapour switch of iron

H1 : Heater P : Pressure switch T. S : Thermostat of iron

LED : Indicator SOL. V : Electromagnetic valve H2 : Iron Heater

4

PCB

Product characteristics

♣ This product satisfies relevant technical requirements for customer's safety.

♣ This product is energy saving product improving basic energy consumption

of boiler.

♣ This vapour generator has four major safety devices.

- automatic pressure cutting switch attached

- safety valve that can discharge pressure in the vapour container in case of

excessive pressure generated because of product abnormality

- two automatic temperature controllers preventing (over temperature attached) do

you mean of over heat?

- the fuser installed internally preventing (over temperature) (over heat) beause of

failure of thermolator

♣ There are two specifications of this vapour generator, 120V and 220V.

- Before it is connected to the socket for use, whether rated voltage is consistent

with voltage required by the product must be confirmed.

♣ When electromagnetic valve is started, 2.5 ~ 4.0 BAR vapour bursts out

through the iron. If the water in pressure container is used up, no vapour

is generated.

♣ This product includes accessories of hook, measuring cup, funnel,

measuring rod etc.

♣ Refer to Page 4 for other product specifications.

Refer to Operation Instructions of the product for precautions and use

method.

♣ When you are using , if water bottle without water, motor temperture

become hot, product stop work.Give the water after one hour become

work.Use this product( keep water in bottle).

Repair or disassembly of the product at will is not permitted!

The agent nearby must be contacted to repair!

5

Precautions of safe use

♣ The following is indication of precautions marked to prevent occurance of

accidents for correct, safe use of product.which is expected to be abided by.

♣ Precautions of safe use, such as unexpected hazard caused by inadequate

use,are classified by "Warning" and "Caution" according to hazard degree and

emergency situation of hazard.

Inadequate use may

Inadequate use may cause

Warning! cause severe injury, Caution light injuryor accident

even fatal accident. of product damage.

6

Warning!

Power

★ Wet hand is prohibited

from pulling or inserting

power plug

----------------------

To avoid electric shock.

★ In case of power

connection, the socket with

earthing wire must be used.

★ In case of pulling power

plug, the hand must grasp

the plug. Pulling plug in same

method as pulling power wire

with hand is prohibited.

----------------------

To avoid electric shock caused

by wire break.

★ Use of power wire knotted

is prohibited.

----------------------

To avoid electric shock caused

by wire break.

Precautions of Safe Use

7

★ Power wire can not be

extruded by heavy object or

product.

----------------------

-

Short circuit of power wire may

become the reason of electric

shock and fire.

★ It must be used on the

plug more than 120V/25A,

220V/15A individually.

----------------------

Many products used in the same

time, may become the reason of

overtemperature (over heat) and

fire.

★During use of product,

safety valve should not be

contacted or opened.

----------------------

To avoid scald.

Warning!

Power

Warning!

Use

120/220V

★ It should be used after

confirmation of rated voltage

conforming to required

voltage of product,

----------------------

Operation of abnormal current

may cause a fire.

Precautions of Safe Use

8

★ It should be paid special

attention to that use, or

contact by children should be

prevented.

----------------------

To avoid scald.

★ During product use, spraying

at human body or contacting

vapour is prohibited.

★ Except for iron clothes, it can

not be used for other purpose.

----------------------

-

The vapour of high pressure and

high temperature may cause

★ In case of idleness for

long term, vapour generator

should be kept after all water

in it is cleaned and dried.

----------------------

Sediments may be caused in

vapour generator kept with

water.

Warning!

Use

★ During product use, as

baseplate temperature is very

high, contact with any object

should be avoided, Attention

should be paid during use.

----------------------

To avoid scald.

Cautio

n

Sweepi

ng and

keepin

g

Precautions of Safe Use

※ The water can not be used: special water for iron, chemical water preventing calcium,

perfume or mixture of perfume.

Confirmation before Use

1. Confirm the 2. Use in this kind

used voltage of place

● Check if the service ● Plain plateform,

voltage is same as surface, level plane

the product voltage without inclination

9

★ After use, the cleaning must

be made after power plug is

pulled out.

★ Washing powder or detergent

can not be used for cleaning.

----------------------

To avoid electric shock and

shortened service life of product.

★ Product disassembly or

prodcut transformation is

prohibited.

----------------------

It may cause product damage

and failure, electric shock.

★ Clean water without

foreign matters or mineral

substance shall be used.

----------------------

It can prolong service life of

product.

Cautio

n

Sweepi

ng and

keepin

g

Warning!

Others

Cautio

n

Others

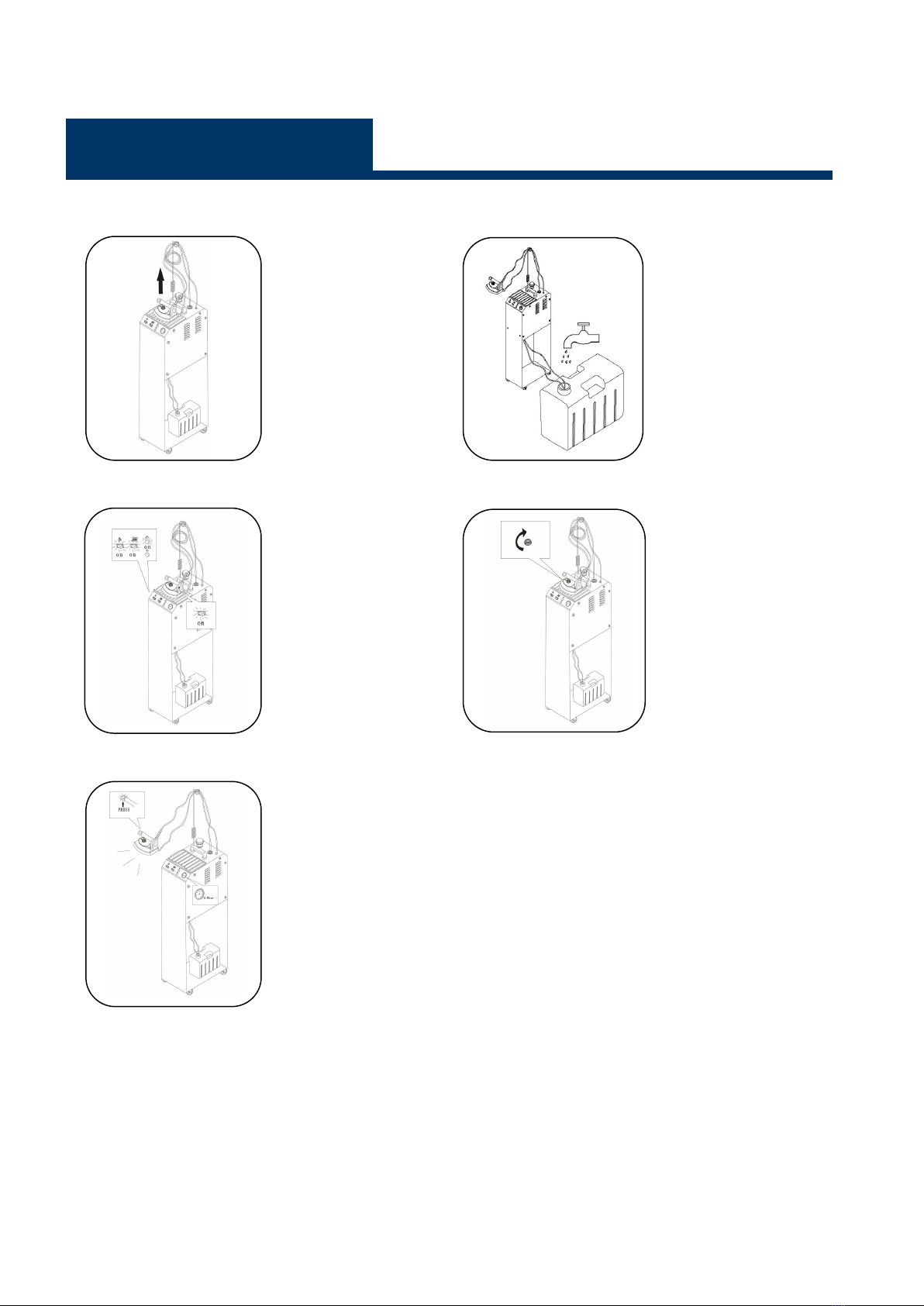

Assembly and Use

1. Setting of hook 2. Put Water

● Install the hook Put water into water

according to the bottle, also suction

drawing,hang power pipe and hanst pipe

wire and vapour put into bottle too.

tube on the hook.

3. Power connection 4. Thermolator

● After confirmation adjusted to high

of the voltage insert temperature

the plug, switch on ● Adjust the thermolator

power switch and iron to the position of high

switch. temperature.

5. Normal use

● When the pointer

of pressure meter

indicate 3.5 bar, LED

indicator will light up.

Then vapour switch

can be pressed for

use.

♣ When you are using , if water bottle without water, motor temperture

become hot, product stop work.Give the water after one hour become

work.Use this product( keep water in bottle).

10

Cleaning method

11

★ Clean once a month.

★ Open the salfly valve,give 1/2 water

in this bottle.Throug the valve drain the

water(try 2-3 times)

★ After repeated operation, power on

and heat for about 15 minutes, to

eliminate moisture in pressure

container completely.(Safety valve

should be in open state right now)

★ Service life can be prolonged.

★When disassembling, the agent

should be contacted first to take any

measures.

★ Vapour hole on press iron

baseplate may be blocked by

foreign matters, which requires

cleaning by prod often.

------------------------

Thus service life of press iron can

be prolonged.

Troubleshooting

Common problems Cause Solution

●The indicating light in ●The power is cut off. ●Check if the socket is well

front of product is

OFF.

●The socket is not well connected.

connected. ●Check if there is any failure of

●Failure of socket. socket.

●The iron can't be ●The automatic thermoregulator ●Adjust the automatic thermoregulator

heated up. is set at lowest position. to necessary position.

●The temperature of base plate ●The base plate of iron is heating up,

of iron is too low. pls wait for completion.

●The switch in front of product ●When heating up is impossible with

is turned to

OFF.

above measures, pls contact your

agent for repair.

●The iron runs normally, ●There is no water in bucket. ●Add water to

bucket.

but steam amount is ●The steam boiler in front of ●Turn the switch to ON, waiting for

little or no steam is product is closed. lighting up of indicating light.

produced. ●The steam indicating light is ●Wait for steam indicating light to be

not ON. ON.

●The steam hole at base plate ●Contact your agent for repair when

of iron is blocked. no steam is produced after taking

above measures.

●Water jets out from ●Too much water in bucket. ●Observe the water volume in

base plate of iron. ●Auto thermoregulator is at low bucket,and pour it out when there

temperature position. is too much water

●The base plate of iron is at ●Adjust the automatic thermoregulator

middle positoin. to necessary position.

●Wait for heating completion of base

plate of iron.

●The steam ejects out ●Cut off power and connect the

continuously,the agent for repair.

solenoid valve can

not be closed.

●There is sufficient ●Cut off power and connect the

water in bucket, but agent for repair.

the steam indicating

light is not ON.

●The safety valve is ●Cut off power and connect the

closed, but there is agent for repair.

still air leakage.

●The pressure gauge ●Cut off power and connect the

points to over 4.5bar. agent for repair.

●During use, the steam ●No abnormality present, pls

indicating light is don't worry.

twinkling.

●During use, spot may ●The inappropriate liquid or ●Refer to page 10 for inappropriate

be left on clothes. unclean water is used. water. Tap water should be used.

13

HEAD OFFICE & FACTORY

104-5,Shinpyong-Ri,Shinbuk-Myoun,Pochun-Kun,Kyoungki-

Do,Korea

TEL:82-31-531-8131~6 FAX:82-31-531-8130

E-mail :

Table of contents

Other SilverStar Iron manuals