Silverwing AEROPRAKT A22 FOXBAT User manual

Pa

g

e 2 - © SilverWin

g

Aviation

,

2005

Pa

g

e 3 - © SilverWin

g

Aviation

,

2005

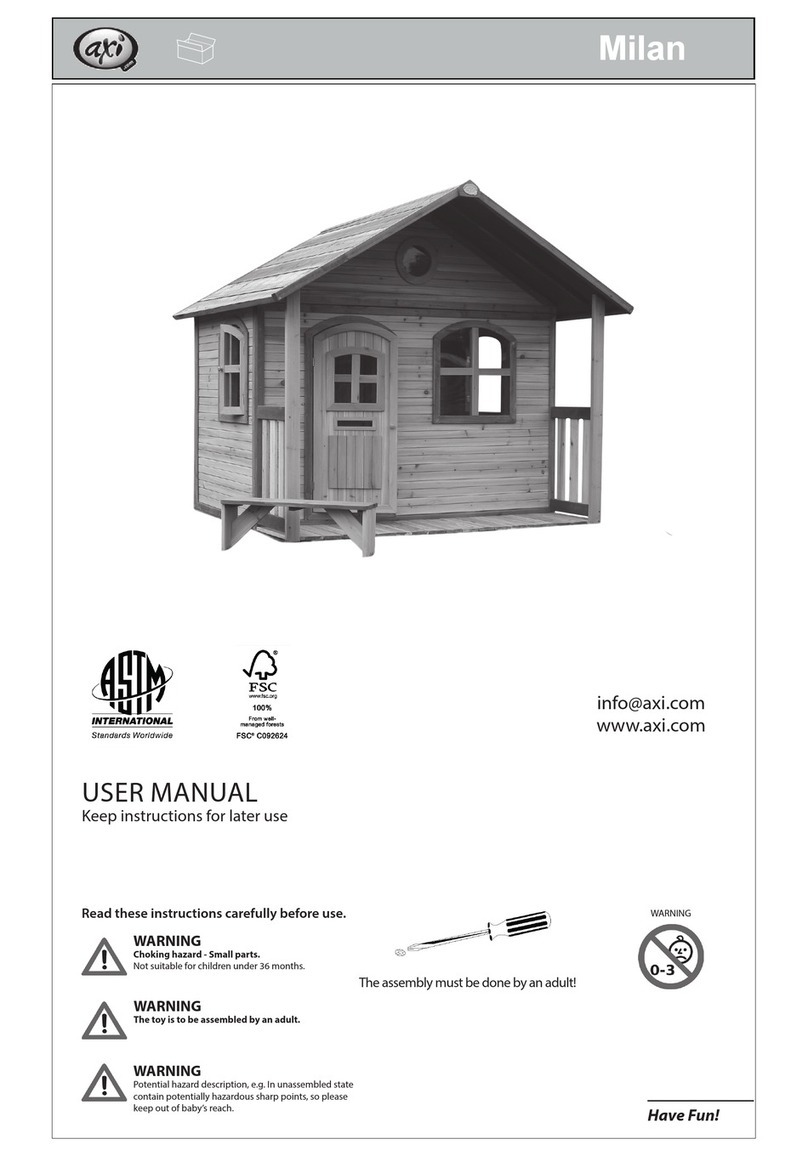

Introduction to the Aeroprakt A22 Foxbat

The prototype A22 was conceived during 1996 on the drawing board of

Antonov Design Bureau engineer Yuri Yakovlev - purely as an easy-to-fly

450-525 kg aircraft with excellent pilot and passenger comfort and

competitive all-round performance. It was intended that pilots of average

ability would be able to operate the A22 in safety from the typically short

ultralight airstrips found around the world.

The design is aimed squarely at the growing ultralight market in Western

Europe and the USA although examples are also operating in UAE, Malaysia

and Eastern Europe. In Germany the A22 has achieved certification to the

stringent BFU-95 requirements. Approval in UK to BCAR'S' via PFA

engineering was achieved in late 2001. Standard engine is the 100 bhp

Rotax 912ULS, with the 80 bhp 912UL available as an option.

Known in Australia South Africa and the UK as the ‘Foxbat’, the A22 is a

quality-engineered aircraft with no aerodynamic vices. The airframe is in

riveted aluminium with part Ceconite type fabric-covered wings and control

surfaces. It retains adequate control response in all axes at speeds down to

30 kts and provides the unthreatening STOL capability of a genuine

ultralight. Yet it can cruise at 85-90kts on 14ltrs/hr and has a range of more

than 500 miles. The cockpit is very roomy with excellent visibility and

plenty of luggage space in a container behind the seats.

This aircraft is an excellent choice for pilots of either ultralights or GA light

aircraft. Equally at home on short ultralight airstrips or GA bitumen the

Foxbat is a plane that can introduce light aircraft pilots to a much wider

choice of destinations, and give ultralight pilots a level of speed and, in

particular comfort, previously unavailable within the weight limit.

Building the Foxbat

Although the Foxbat is a modern aircraft in concept it uses a very

conventional method of construction in riveted Alclad aluminium. The kit is

supplied with some of the fuselage, much of the wings, tailplane, fin and

control surfaces pre-riveted. The builder’s riveting (using ‘pop’ rivets)

consists of fitting the cabin floor-pan (which is partly pre-drilled), finishing

and riveting the wing and fin tips, securing the fin itself and various

mounting brackets and webs to the bare fuselage monocoque. Final riveting

includes all the glazing, including the windscreen.

The A22 Build Manual is illustrated with around 100 exploded-view drawings

that cover each step of the assembly process together with easy-to follow

Pa

g

e 4 - © SilverWin

g

Aviation

,

2005

text. As an option, a full set of engineering reference drawings is available

on CD at extra cost.

The bulk of the airframe construction work is centred on the fuselage and

consists of fitting the control mechanisms (torque tubes, push rods,

bell-cranks, cables, etc) the main components of which are factory

finished, anodised and/or plated. The factory requires the wings, tailplane

and control surfaces to be pre-riveted in jigs leaving the builder to add the

fuel tanks, as well as covering and painting. At every point where a rotating

action takes place, an aerospace-quality rose-joint or bearing is pre-pressed

into the bracket.

The airframe can be assembled and finished to a rolling but bare stage

before buying the engine, instruments and covering system. This means

purchases of major items can be staggered to suit the budget or build

schedule – for example, if six months or more is planned to build the plane,

there is little point in having an expensive engine bolted to the airframe (or

in a box) using up its warranty time. After installing the engine the final

finishing involves installing and connecting the fuel tanks, covering and

painting, and fitting instruments, windscreen, and other glazing.

One person, working at a steady and meticulous pace can build a finished

aircraft from a Foxbat kit in around 500 hours (or fewer with an assistant) -

some jobs need extra hands for completion. With good planning, a largish

double garage will be a big enough workshop space to complete all the

sub-assemblies (including covering and painting them) providing the wings

and tailplane are stored elsewhere while work progresses on the fuselage.

Obviously a larger space is required for the final assembly of the aircraft

although this can be done outdoors prior to Final Inspection and trailer

transportation to the airfield for Test Flying. With a little practice, two

people can detach the standard wings quite easily in about 30 minutes. Re-

assembly takes about the same.

Pa

g

e 5 - © SilverWin

g

Aviation

,

2005

INTRODUCTION TO BUILDING

Before you begin….

1. Thoroughly read through the complete construction manual several

times so you are completely familiar with each stage of the process.

2. Make sure you understand all the diagrams/drawings.

3. Check your parts against the parts list to ensure you have all the items

you need.

4. Prepare your workshop and collect together all the tools you need.

Construction of the Foxbat requires no really specialised tools – a set of

metric spanners, a hand pop-rivet gun, flat and cross-head

screwdrivers, long-nose and standard pliers some files and cutters are

the main requirements. Later, you will need lifting tackle for the

engine – but this can be hired for the day or so you will need it.

5. If you are buying the kit in stages, plan when you will need the engine,

covering/paint and instruments, so that they can be ordered in plenty

of time.

6. If you are in doubt about anything – call SilverWing Aviation for

clarification. Once a hole is drilled, it can’t be un-drilled! So take your

time.

7.

8. Constructing your Foxbat should be an enjoyable experience – much of

it is an assembly process, with actual making of parts kept to the

minimum - many of the rivet holes are measured and, in some cases,

drilled. Final covering and painting the aircraft is a straightforward if

time consuming job which done well will give you an aircraft which will

not only fly well but will last you many years.

9. Should you require assistance at any time, just contact SilverWing

Aviation for help and guidance.

10. Happy constructing!

SilverWing Aviation, PO Box 9050, Gold Coast MC, Qld 9726

(07) 5597 0391 & 0413 900 892

Pa

g

e 6 - © SilverWin

g

Aviation

,

2005

AEROPRAKT A22 FOXBAT

PARTS LIST

REGIME - ITEM NUMBER - PART DESCRIPTION - (DRAWING NUMBER) - AEROPRAKT

NUMBER

FUSELAGE/WINGS/ETC

1. MONOCOQUE (1.050+) 2.0100

2. WING R/L (6.500) 3.2000

3. STRUT R/L (4.510) 3,2900

4. FLAPERON R/L (6.500) 0.3700

5. FIN (2.030+) 1.3400

6. RUDDER ((3.500) 0.3300

7. TAILPLANE (8.500) 1.3100.00

8. ELEVATOR (8.500) 3.3200

9. TRIM TAB (9.500) 1.4000

10. BEAM R/L (1.010) 0.0116

11. LG BEAM R/L (1.020) 0.4350

12. GUSSET R/L (1.030) 0.0148

13. ANGLE R/L (1.030) 0.0149

14. ANGLE R/L (1.030) 0.0150

15. HINGE X 4 (1.040) 0.1391

16. SUPPORT (1.130) 0.0156

17. BASEPLATE (1.140) 0.0164

18. BRACKET R/L (1.140) 0.0108

19. LG BRACKET R/L (1.150) 1.4130

20. LG BRACE R/L (1.150) 0.4150

21. LG BRACKET R/L (1.160) 0.4140

22. FITTING (1.160) 0.4150

23. BRACE R/L (1.050) 1.1371

24. BRACE R/L (1.050) 1.1372

25. BRACE R/L (1.060+) 1.1373

26. FITTING X 9 (1.070 +) 1.1377

27. BRACKET (18.010) 0.7625

28. BRACE X 3 (1.090/110) 1.1374

29. BRACE X 3 (1.090 +) 1.1375

30. BRACE X 3 (1.100 +) 1.1376

31. FLOORING (1.170) 0.0119

32. ANGLES R/L (1.180) 0.0171

33. DOUBLER (1.190) 0.0172

34.

DOUBLER X 2 (1.190) 0.0173

35. SUPPORT (1.200) 3.4307

36. GUSSET X 2 (1.200) 3.4307

37. FLOORING (1.210) 0.0120

38. GUSSET R/L (1.220) 2.0147

39. BEAM (1.310) 1.0121

40. ANGLE (1.310) 0.0194

41. BELT (18.020) 0.7626

UNDERCARRIAGE

1.MAIN LEG R/L (1.270) 5.4110

2.AXLE X 2 (1.300) 3.4133.BLOCK X

2 (1.300) 8.4121

4.PLATE X 2 (1.300) 3.4123

5.MATCO 5.00-5 (+ BRAKE) X 2

6.SUPPORT (1.280) 3.4308

7.FLANGE (1.280) 3.4324

8.STRUT (1.280) 3.4300

9.NOSELEG (1.290) 3.4300

10.MATCO 6.00-6

11.AXLE (1.290) 1.4301

12.SPACER X 2 (1.290) 1.4316

MOULDINGS, ETC

1.PROP: SPINNER

2.SPINNER BACKPLATE

3.ENGINE COWLING UPPER

4.ENGINE COWLING LOWER

5.WING FILLETS R/L 0.1500

6.WHEELSPAT FRONT

7.WHEELSPAT RIGHT

8.WHEELSPAT LEFT

9.FIN CAP 0.3409

10.FLAPERON COWL 1.5400.04

11.CENTRAL CONSOLE 0.7152

12.INST: HOUSING 1.7151

13.INST: PANEL DURAL: 0.7001

14.INST: PANEL CARBON

15.WINDSCREEN 0.1301.00

16.SIDEWINDOW R/L 0.1301.01

17.TOPWINDOW 0.1303

18.PITOT HEAD/TUBES

FUEL SYSTEM

1. TANK R/L (17.100) 3.6120.00

2. FAIRING (18.100) 0.7627.01

3. GASCULATOR (SKYCRAFT,ETC)

4. J/TUBE (17.010) 3.6100.01

5. F/COCK X 2 (17.100)

6. T/PIECE X 2 (17.020)

7. DRAIN VALVE (17.020)

Pa

g

e 7 - © SilverWin

g

Aviation

,

2005

ENGINE AND ANCILLARIES

1. E/MOUNT (10.010+) 0.6401.01

2. E/MOUNT (10.010+) 0.6402.00

3. BRACKET (10.020+) 0.6402

4. ROD (10.020) 0.6403

5. LUG (10.020) 0.6401

6. BEARINGS (10.020) 0.6404

CONTROLS (THROTTLE/CHOKE)

1. BRACKET L (16.010) 3.6018

2. BRACKET R (16.010) 3.6019

3. T/LEVER L (16.010+) 3.6025

4. T/LEVER R (16.010+) 3.6026

5. C/TUBE (16.010) 3.6021

6. F/CLAMP (16.010) 3.6029

7. SPACER (16.010) 3.6016

8. C/STOP (16.020) 3.6017

9. SHACKLE (16.020) 3.6023

10. HANDLE (16.020) 1.6028

11. I/CABLE (16.020+) 2.6040

12. O/CABLE (16.020+) 2.6041

13. C/LEVER (16.030) 1.6051

14. C/CABLE (16.030+) 1.6055

15. BRACKET (16.040) K20.2.42.02

16. J/BLOCK (16.040) K20.0.42.03

17. COVER (16.040) K20.2.42.05

18. CABLE X 2 (16.040) 1.6056

19. B/CABLE X 2 (16.050) 3.6040.00

CONTROLS (PEDALS)

1. PEDALS (11.050) 4.5210.01C6

2. PEDALS (11.050) 4.5210.02C6

3. BRACKET R (11.050) 3.5270.01

4. BRACKET L (11.050) 3.5270.02

5. CABLE R (11.050+) 5.5230.01C6

6. CABLE L (11.050+) 5.5230.02C6

7. ROD (11.050) 0.5240.01

8. ROD (11.050) 0.5240.02

CONTROLS (STICK)

1. S/HINGE (13.040+) I.5124.02

2. S/HINGE (13.040+) 1.5167.00

3. C/SHAFT (13.040+) 0.5123

4. BRACKET (13.030) 1.5502

5. ANGLE (13.030) 1.5124.04

6. SHAPE (13.030) 1.5124.05

7. HINGE (13.030) 1.5124.01

8. PLATE (13.030) 1.5124.03

9. BRACKET (13.010) 1.5168

10. BRACKET (12.020+) 2.5181

11. STOP (13.020) 1.5168

12. PAD (13.020) 1.5169

13. C/STICK (1.260+) 0.5122.00

14. BELLCRANK (12.030+) 1.5182

15. SLEEVE (12.030) 0.5186

16. ROD (12.040) 2.5132.00

17. ROD (12.040) 1.5183.00

18. COVER (1.330) 1.0196

19. FRAME 4 (15.010) 0.0940

20. C/GUIDE X 2 (15.010) 1.5500.04

21. PAD X 2 (11.020) 5.5293.00

22. CABLE R/L (11.020) 5.5230.01CB

23. BRACKET L (11.030) 5.5251.00

24. BRACKET R (11.030) 5.5252.00

25. CABLE R/L (11.030+) 5.5230.02

26. GUARD (11.030) 5.5253.00

27. SHACKLE (11.010) 0.5269.00

28. BELLCRANK (12.010) 1.5185

29. ROD (12.050) 1.5183.00

30. ROD (12.050) 1.5186.00

DOORS/FITTINGS

1. DOOR R/L (1.530) 0.1350.00

2. HINGE X 4 (1.500) 0.1380.00

3. HANDLE R/L (1.510) 0.1375.00

4. SPRING R/L (1.510) 0.1379.00

5. HANDLE R/L (1.510) 0.1376.00

6. PIN X 4 (1.600) 0.1350

7. G/STRUT (1.610) 0.1350.00

8. VENT (1.520) 1.1385.00

9. “K” D/EXCLUDER STRIP

CONTROLS (FLAP MECHANISM)

1. BRACKET R/L (14.010) 1.5405

2. BRACKETS (14.010+) 1.5400.01

3. C/STOP (14.010+) 1.5400.03

4. PAD R/L (14.010) 1.5400

5. ROCKER (14.020) 1.5403

6. LEVER (14.020+) 1.5402

7. BRACKETS (14.020) 1.5400.02

8. C/PLATE (14.020) 1.5404

9. BEARING (14.020) 1.5400.06

10. BEARING (14.020) 1.5400.07

11. HANDLE (14.030) 1.5401

12. SPRING (14.030) 1.5400.05

13. CABLE (14.030) 1.5407

14. C/STOP (14.030) 1.5404.03

15. C/SHAFT (13.050+) 1.5410

16. C/RING (13.050+) 1.5410.01

17. C/SHAFT (13.060+) 0.5123.00

Pa

g

e 8 - © SilverWin

g

Aviation

,

2005

18. ROD (13.060) 1.5408.00

19. TRIMCABLE (7.500) 1.5503.00

LUGGAGE AND SEATS

1. L/BAG (1.320) 1.8101

2. F/E TUBE (1.320) 0.8102

3. U/TUBE (1.320) 0.8103

4. L/TUBE (1.320) 0.8104

5. GUSSET (1.320) 0.8105

6. GUSSET (1.320) 0.8106

7. BELT (1.340) 0.7550.02

8. BELT (1.340) 0.7550.03

9. BELT (1.340) 0.7550.01

10. LUG (1.340+) 0.7550.10

11. SPACER (1.340) 0.7550.12

12. SEAT X 2 (1.350) 1.7560

13. SQUAB X 2 (1.350) 1.7561

CONTROLS (BRAKES, MATCO)

1. M/CYLINDER (19.010+)

2. C/TUBE (19.010+)

3. B/LEVER 19.010+)

4. T/PIECE X 2 (19.010)

5. S/CYLINDER (19.010)

ELECTRICAL

1. FUEL PROBE X 2 (18.100)

2. P/WIRE (18.100+) 0.7609.01.00

3. WIRE (18.040+) 0.7605

4. WIRE (18.050) 0.7612

5. F/GAUGES X 2

FOR REMAINING ELECTRICAL PARTS

SEE ROTAX AND OTHER COMPONENT SUPPLIER’S OWN PARTS LISTS, WHICH ARE

PROVIDED WITH YOUR KIT.

NUTS/BOLTS/FASTENERS/ETC

SUFFICIENT QUANTITY OF THE VARIOUS SIZES AND TYPES ARE PROVIDED TO

COMPLETE YOUR KIT. ALL THREADS ARE METRIC. SEE THE ASSEMBLY

DRAWINGS FOR EXACT DETAILS.

ORDER REPLACEMENTS FROM SILVERWING AVIATION OR SPECIALIST FIRMS

SUCH AS AIRCRAFT SPRUCE.

COVERING AND PAINT

A FOXBAT-SPECIFIC KIT OF “POLYFIBER” MATERIALS CAN BE SUPPLIED BY

SILVERWING AVIATION. CONTACT US DIRECTLY FOR INFORMATION. THE 2-

PACK STRUCTURAL ADHESIVE FOR FABRIC-TO-DURAL ATTACHMENT IS

AVAILABLE IN ONE-JOB QUANTITIES FROM SILVERWING AVIATION.

TYRES AND TUBES

AIRCRAFT QUALITY 6” WITH CHOICE OF PROFILES. ORDER

REPLACEMENTS FROM SILVERWING AVIATION OR SPECIALIST FIRMS

ADVERTISING IN THE AVIATION PRESS.

Pa

g

e 9 - © SilverWin

g

Aviation

,

2005

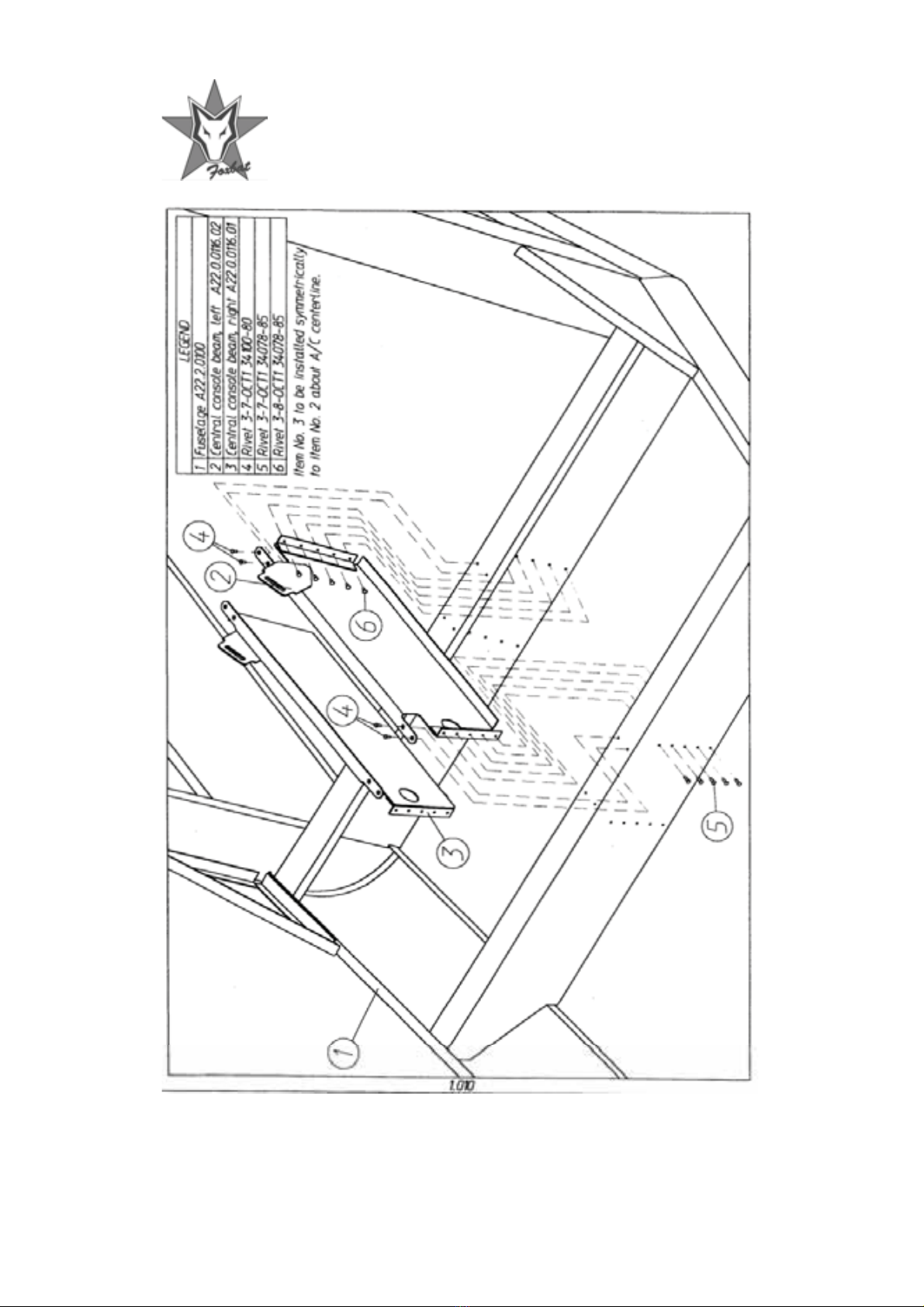

PAGE ONE

DRAWING NUMBER 1.010

Installing the Central Console Beams

SEE DRAWING FOR PARTS REQUIRED

Recommended job for two persons with fuselage monocoque supported as

required

1. Locate and inspect the left and right central console beams as

illustrated in the drawing.

2. Offer up both parts ensuring that their orientation is exactly as shown in

the drawing. Clico in place then check the fit and alignment.

3. Re-check steps 1 and 2.

4. Working from side to side alternately replace the clicos with rivets.

5. Thoroughly examine the finished work and compare it with the drawing.

Notes:

Pa

g

e 10 - © SilverWin

g

Aviation

,

2005

Pa

g

e 11 - © SilverWin

g

Aviation

,

2005

PAGE TWO

DRAWING NUMBER 1.020

Installing the Landing Gear Support Beams

SEE DRAWING FOR PARTS REQUIRED

Recommended job for two persons with the fuselage monocoque supported

as required.

1. Locate and inspect the left and right landing gear (LG) beams illustrated

in the drawing.

2. Offer up both parts to the fuselage ensuring that their orientation is

exactly as shown in the drawing. Clico in place.

3. Re-check steps 1 and 2.

4. Working from side to side alternately replace the clicos with rivets.

5. Thoroughly examine the finished work and compare it with the drawing.

Notes:

Pa

g

e 12 - © SilverWin

g

Aviation

,

2005

Pa

g

e 13 - © SilverWin

g

Aviation

,

2005

PAGE THREE

DRAWING NUMBER 1.030

Installing the Door Gussets

SEE DRAWING FOR PARTS REQUIRED

Recommended job for two persons with fuselage monocoque supported as

required

1. Locate and inspect the angle pieces and gussets as illustrated in the

drawing (left and right sets).

2. Offer up the three parts to the fuselage left side ensuring that their

orientation is exactly as shown in the drawing. Clico in place then check

the fit and alignment.

3. Re-check steps 1 and 2.

4. Working from end to end alternately replace the clicos with rivets.

5. Thoroughly examine the finished work.

6. Repeat on right-hand side.

Notes:

Pa

g

e 14 - © SilverWin

g

Aviation

,

2005

Pa

g

e 15 - © SilverWin

g

Aviation

,

2005

PAGE FOUR

DRAWING NUMBER 1.040

Installing the Door Hinges

SEE DRAWING FOR PARTS REQUIRED

Recommended job for one person with the fuselage monocoque supported

as required

1. Locate and inspect door hinges as illustrated in the drawing. Select the

correct size bolts with stiff nuts and washers.

2. Loosely assemble both hinges in turn on the left side exactly as shown on

the drawing.

3. Re-check steps 1 and 2.

4. Tighten stiff-nuts until the hinges are snug and firm. Don’t over-tighten.

5. Thoroughly examine the finished work.

6. Repeat on right-hand side.

Notes:

Pa

g

e 16 - © SilverWin

g

Aviation

,

2005

Pa

g

e 17 - © SilverWin

g

Aviation

,

2005

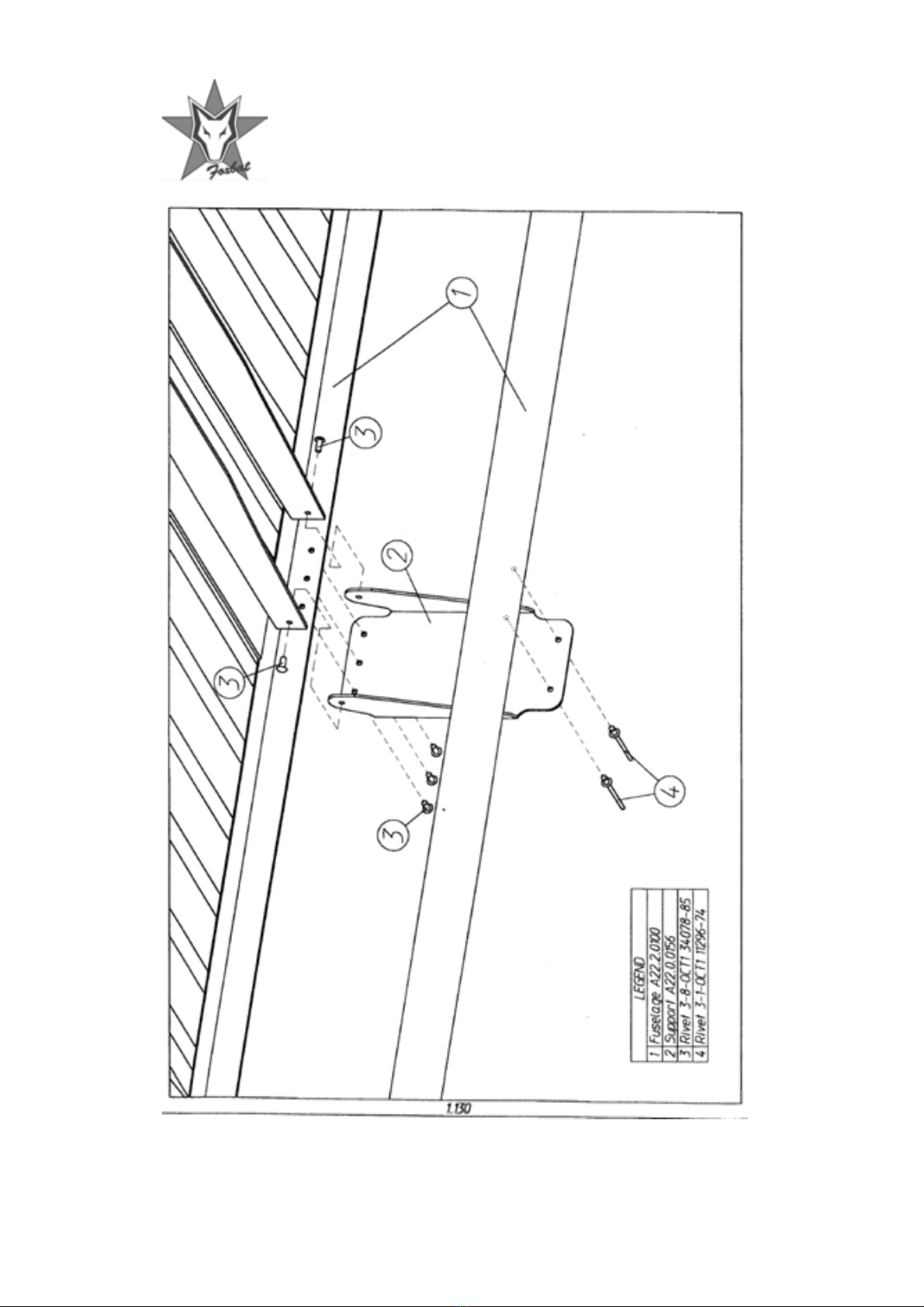

PAGE FIVE

DRAWING NUMBER 1.130

Installing the Upper Central Support

SEE DRAWING FOR PARTS REQUIRED

Recommended two persons job with the fuselage monocoque supported as

required

1. Locate and inspect the support bracket as illustrated in the drawing.

2. Offer up parts and pre-assemble with clicos exactly as shown in the

drawing.

3. Re-check steps 1 and 2. When you are completely satisfied that the

assembly is correct replace clicos with rivets working outwards from the

top centre.

4. Very carefully centre-punch, drill and pop-rivet the bottom of the

bracket to the cross-spar as shown in the drawing. Make certain to use

the correct drill and rivet size. Double-check before drilling.

5. Thoroughly examine the finished work.

Notes:

Pa

g

e 18 - © SilverWin

g

Aviation

,

2005

Pa

g

e 19 - © SilverWin

g

Aviation

,

2005

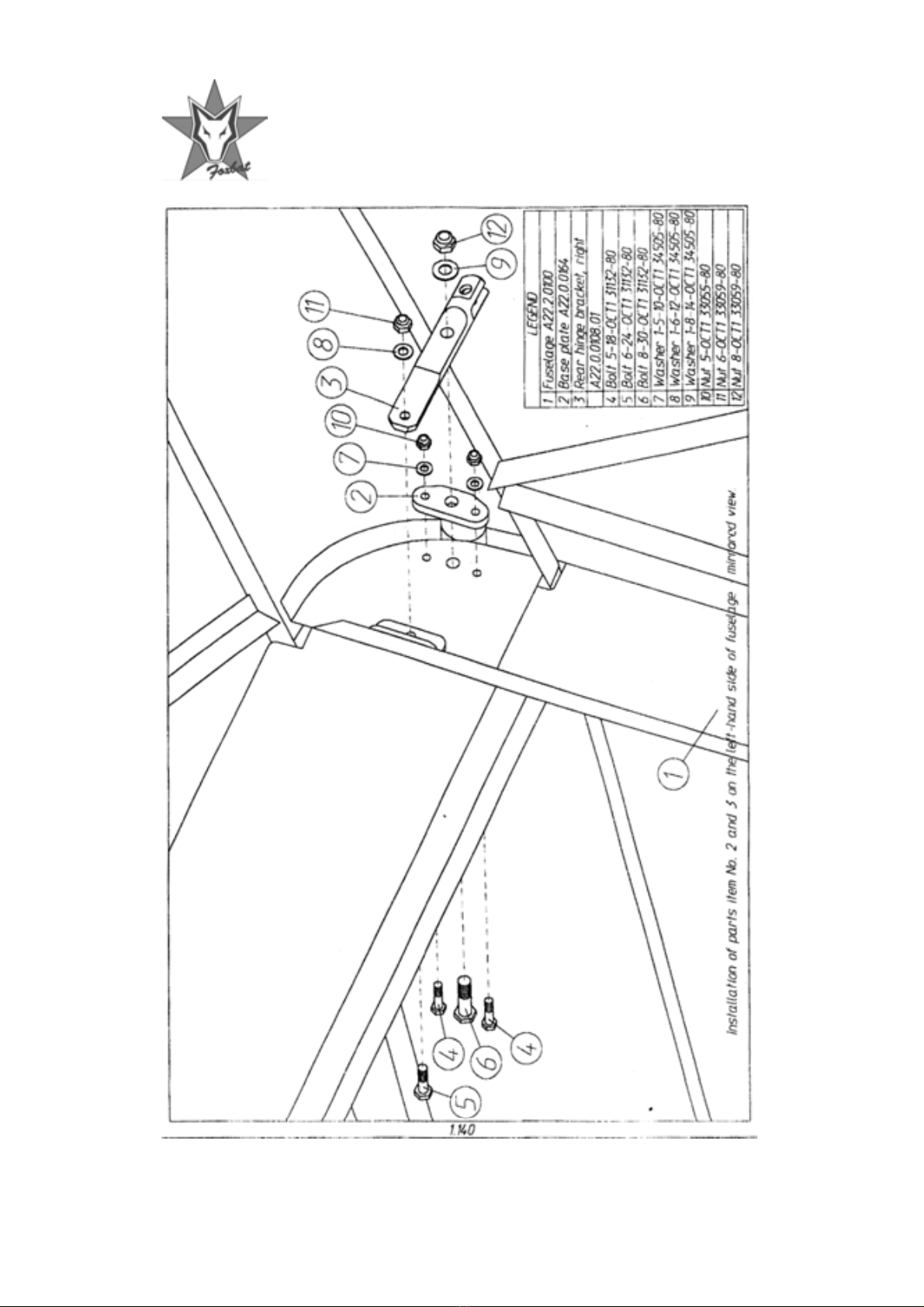

PAGE SIX

DRAWING NUMBER 1.140

Installing the Wing Rear Hinge Bracket

SEE DRAWING FOR PARTS REQUIRED

Recommended one person job with the fuselage monocoque supported as

required

1. Locate and inspect base plate and rear hinge bracket as illustrated in

the drawing. Select correct sized bolts with stiff-nuts and washers.

2. Offer up and loosely assemble parts exactly as shown in the drawing.

3. Re-check steps 1 and 2.

4. Tighten stiff-nuts until the assembly is snug and firm. Don’t over-

tighten.

5. Thoroughly examine finished work.

6. Repeat on left-hand side.

Notes:

Pa

g

e 20 - © SilverWin

g

Aviation

,

2005

Pa

g

e 21 - © SilverWin

g

Aviation

,

2005

PAGE SEVEN

DRAWING NUMBER 1.150

Installing the LG Spring Upper Brackets and Braces

SEE DRAWING FOR PARTS REQUIRED

Recommended one person job with fuselage supported as required

1. Locate and inspect LG spring bracket and brace as illustrated on the

drawing. Select the correct size bolts with stiff-nuts and washers.

2. Offer up and loosely assemble parts exactly as shown on the drawing.

3. Re-check steps 1 and 2.

4. Tighten stiff-nuts until the assembly is snug and firm. Don’t over-

tighten.

5. Thoroughly inspect finished work.

6. Repeat on right-hand side.

Notes:

Popular Toy manuals by other brands

REVELL

REVELL SUMMER ACTION FLYING LIGHTS Assembly manual

Vmar

Vmar CESSNA L-19 BIRD DOG Assembly & operation manual

Hasbro

Hasbro Decepticon Midnighter XR-4 81056 instructions

Flyzone

Flyzone B-25 mitchell user manual

LeapFrog

LeapFrog Sing & Snuggle Violet Parents' guide

VQ Models

VQ Models CESSNA 188 AGWAGON instruction manual