2.1 BOILER ROOM

The boiler room should feature all the

characteristics required by standards

governing liquid fuel heating systems.

2.2 BOILER ROOM DIMENSIONS

Position the boiler body on the founda-

tion bed, which should be at least 0

cm high. The body should rest on a sur-

face allowing shifting, possibly by

means of sheet metal.

Leave a clearance between the boiler

and the wall of at least 0.60 m, and

between the top of the casing and the

ceiling of m (0.50 m in the case of

boilers with incorporated D.H.W. tank).

The ceiling height of the boiler room

should not be less than 2.5 m.

2.3 CONNECTIN UP SYSTEM

When connecting up the water supply

to the boiler, make sure that the speci-

fications given in fig. are observed.

All connecting unions should be easy to

disconnect by means of tightening

rings. A closed expansion tank system

must be used.

2.3.1 Filling the water system

Before connecting the boiler, thor-

oughly flush the system to eliminate

scale which could damage the appli-

ance.

Filling must be done slowly to allow any

air bubbles to be bled off through the

air valves.

In closed-circuit heating systems, the

cold water filling pressure and the pre-

charging pressure of the expansion

vessel should be no less than or equal

to the height of the water head of the

installation (e.g. for water head of 5

meters, the vessel pre-charging pres-

sure and installation filling pressure

should be at least 0.5 bar).

2.3.2 Characteristics of feedwater

The water used for the central heating

system should be treated in the follow-

ing cases:

– For extensive systems (with high

contents of water).

– Frequent addition of water into the

system.

– Should it be necessary to empty the

system either partially or totally.

2.3.3 D.H.W. storage tank

The “RONDÒ -ESTELLE ” boilers may

be matched with the separate boiler

units “BA100 -BA150 -BA200 ”.

The glass enamelled D.H.W. storage

tank comes with a magnesium anode

to protect the boiler and an inspection

flange for checking and cleaning.

The magnesium anode must be

checked annually and replaced if it

is worn.

Fit a safety valve calibrated to 6 bar

on the tubing of the cold water supply

to the boiler unit ( 2 fig. 2).

In case the system pressure is exces-

sive fit an appropriate pressure

reducer. If the safety valve calibrated

to 6 bar frequently intercepts, fit an

expansion vessel with a capacity of 8

litres and a maximum pressure of 8

bar ( fig. 2). The tank should be of

the membrane type, made of natural

rubber “caoutchouc”, which is suitable

for foods.

2.4 CONNECTIN UP FLUE

The flue is of fundamental importance

for the proper operation of the boiler; if

not installed in compliance with the

standards, starting the boiler will be

difficult and there will be a consequent

formation of soot, condensate and

encrustation.

The flue used to expel combustion

products into the atmosphere must

meet the following requirements:

– be constructed with waterproof

materials, and resistant to smoke

temperature and condensate;

–

be of adequate mechanical resilience

and of low heat conductivity;

– be perfectly sealed to prevent cool-

ing of the flue itself;

– be as vertical as possible; the termi-

nal section of the flue must be fitted

with a static exhaust device that

ensures constant and efficient

extraction of products generated by

combustion;

–

to prevent the wind from creating

pressure zones around the chimney

top greater than the uplift force of

combustion gases, the exhaust outlet

should be at least 0.4 m higher than

structures adjacent to the stack

(including the roof top) within 8 m;

– have a diameter that is not inferior

to that of the boiler union: square or

rectangular-section flues should

have an internal section 0%

greater than that of the boiler union;

– the useful section of the flue must

conform to the following formula:

S resulting section in cm2

K reduction coefficient for liquid

fuels:

– 0.045 for firewood

– 0.030 for coal

– 0.024 for light oil

– 0.0 6 for gas

P boiler input in kcal/h

H height of flue in meters, mea-

sured from the flame axis to the

top of the flue reduced by:

– 0.50 m for each change of

direction of the connection

union between boiler and flue;

– .00 m for each metre of

union itself.

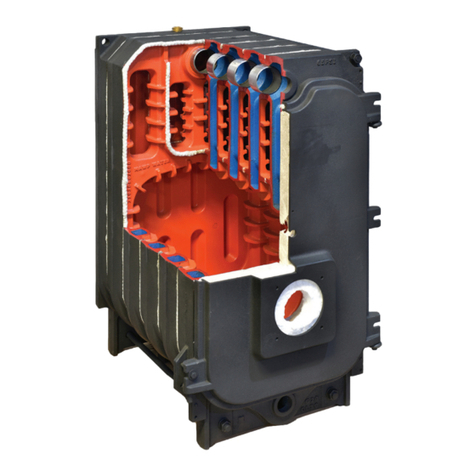

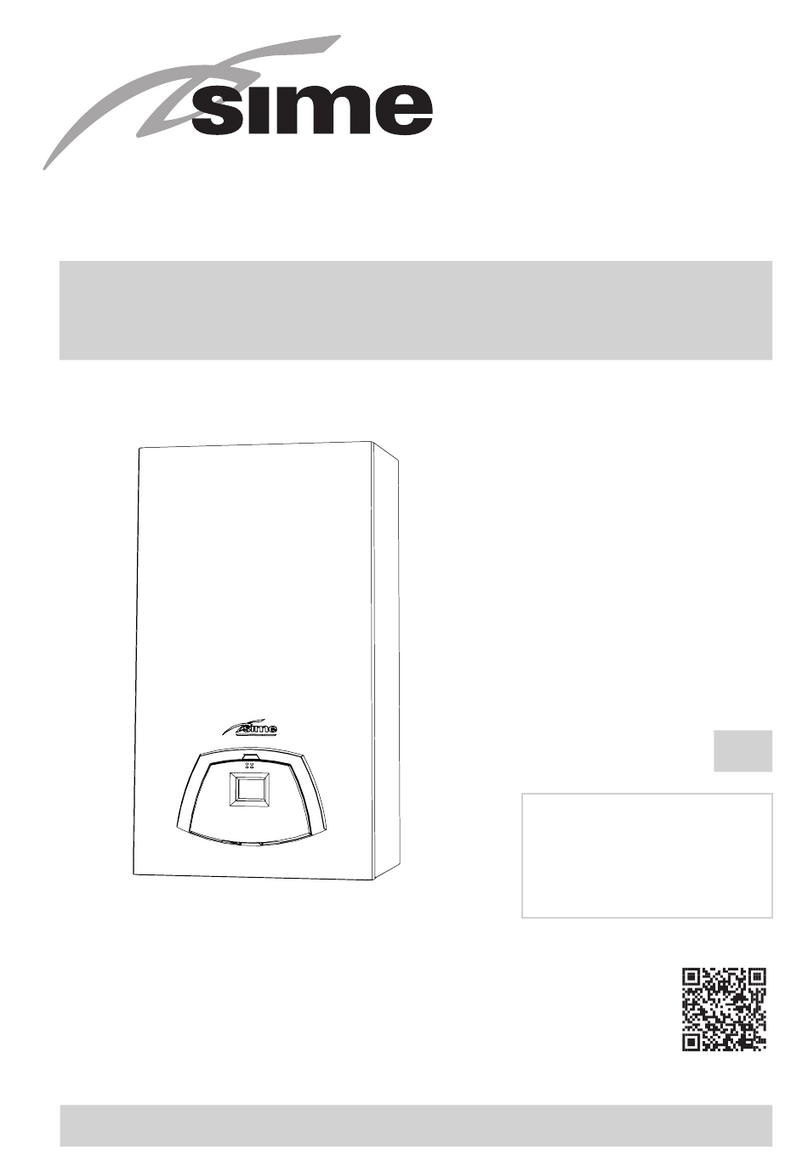

2.5 FITTIN THE

CASIN “RONDÒ”

The casing and the control panel are

supplied in separate cardboard pack-

ages. The housing package also con-

tains the boiler documents and the

glass wool for insulating the cast iron

body. To fit the casing, proceed as fol-

lows (fig. 5):

– fit the lower front ( ) and back (2)

brackets to the heads with the four

TE screws supplied;

– insert the upper brackets (5) on the

tie-rods, fixing them with nuts;

– insulate the cast iron body with

glass wool, fixing it with the two

springs supplied;

– fit the left side (3) and the right side

(4) by inserting them in the tangs on

the brackets ( -2);

– fix the sides to the upper brackets

(5) with the four self-tapping screws

supplied;

– fit the two back panels (6) and (7) of

the sides with the ten self-tapping

screws supplied;

– fit the front panel (8) fixing it to the

sides with pin clutches

– fit the control panel (9) inserting the

two lower tangs of the panel on the

drains on the sides, and fix it with

the two self-tapping screws sup-

plied. Before carrying out this opera-

tion unwind the capillaries of the two

thermostats and the thermometer

and place the respective feelers in

the sheath ( 0), fixing all with a capil-

lary pin. Insert the burner cable into

the hole on the right or left side;

– screw the hydrometer feeler on the

connection ( );

27

P

S=K√H

2 INSTALLATION