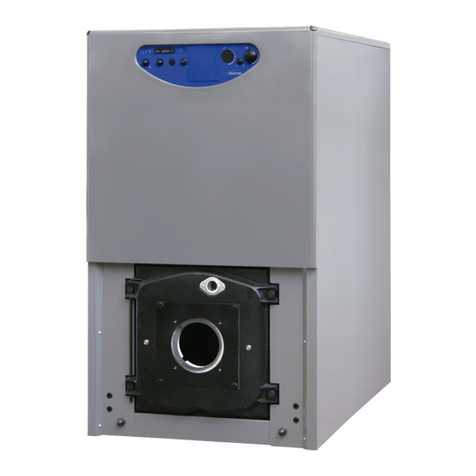

39

wer tie rods, both in the front and rear side

of the boiler, two nuts are tightened, one

of which is used to block the side support

brackets.

The assembly of the casing components

must be carried out in the following way:

– Unscrew with some rotations the second

or third nut of each tie rod.

– Connect the left side (1) on the lower and

upper tie rod of the boiler and adjust the

position of the nut and lock-nut of the

upper tie-rod.

– Block the side by tightening the locknuts.

– In order to assembly the right side (2)

proceed in the same way.

– Connect the rear panel (4) introducing

the two splines in the vents obtained on

each side and lock it with self-threading

screws.

– The protection deflector (5) is fixed to

the control panel (6) with three self-th-

reading screws. Insert the mineral wool

between the two components.

– Fasten the front panel (6) using the pres-

sure pins.

– Unwind the capillary of the thermometer

(7) and and introduce it in the left sheath

of the rear head introducing the contact

spring which must be cut at about 45

mm. The thermometer cable must be

placed above the insulation and must not

contact directly the iron cast body.

– Fasten the cover (8) to the sides of the

boiler using the pressure pins.

- Apply the BOILER TECHNICAL DATA

adhesive plate on the right or left side of

the covering, so as to be legible when the

appliance is installed.

NOTICE: Store the “Test report” and “De-

claration of conformity” placed in the

combustion chamber together with the

documents of the boiler.

4.6 DRAUGHT REGULATOR

WITH THERMOSTATIC

OPERATION

By means of the draught regulator with

thermostatic operation, a continuous va-

riability of the air introduced in the boiler

furnace can be obtained.

By means of a connecting chainlet, this re-

gulator acts on the lower primary air intake

port.

Once the set temperature has been rea-

ched, the regulator decreases the opening

of the air intake port automatically, so to

slow down the combustion and prevent

over-heating.

In order to optimise the combustion on the

upper load port, place a round adjusting

port that distributes the secondary air

countercurrent compared to the path of the

combustion products.

This process further increases the yield

and allows exploiting the combustion more

effectively.

Two types of thermostatic regulators can

be assembled on the boilers.

4.6.1 “THERMOMAT RT-C” Regulator

(fig. 7)

The “Thermomat” regulator is equipped

with a thermosetting resin knob of an

adjustment field from 30 to 100 °C.

Screw the regulator on the 3/4” opening

of the anterior head and orientate the red

index on the upper part.

The lever with the chainlet should be intro-

duced in the regulator holder after having

assembled the instrument holder board

and after having removed the plastic lock.

If the joint is taken out, which fixes the

lever with the chainlet, take care in assem-

bling it again in the same position.

After having placed the knob at 60°C, block

the lever with the chainlet in a slightly

inclined position downwards, so that

the chainlet will be in axis with the air

gate damper. For the adjustment of the

“Thermomat”, which essentially consists

in the determination of the chainlet length,

proceed in the following way:

– Place the knob at 60°C.

– Switch on the boiler with opened air gate

damper.

– When the water temperature of 60° C is

reached in the boiler, fix the chainlet in

such a way on the lever of the air gate

damper, in order to obtain an opening of

about 1 mm.

– Now the regulator is calibrated and it is

possible to choose the desired operating

temperature by rotating the knob.

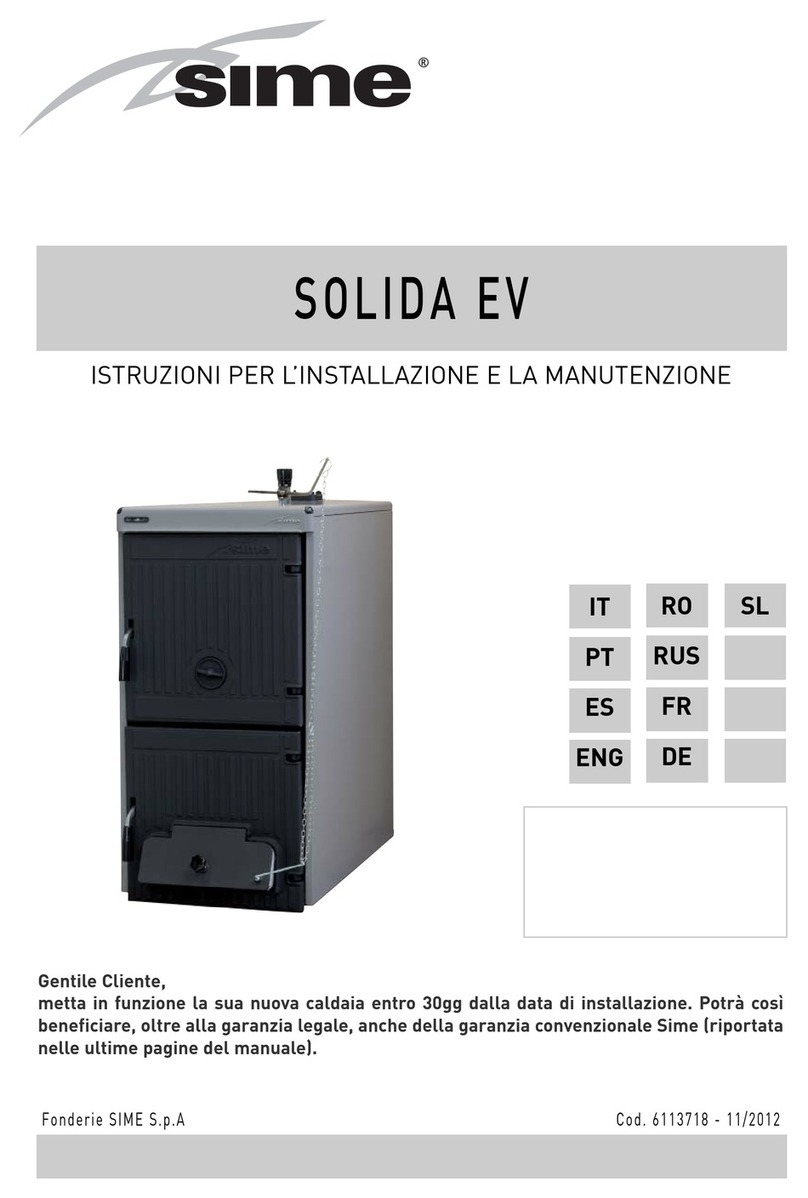

4.6.2 “REGULUS RT2” Regulator

(fig. 8)

The adjustment field is included betwe-

en 30 and 90°C (fig. 8). Follow the same

instructions of the “Thermomat” regulator

for the assembly and the activation.

4.7 SAFETY EXCHANGER

The safety exchanger is supplied upon re-

quest with a kit:

- code 8105200 for SOLIDA EV 3/4/5

- code 8105201 for SOLIDA EV 6/7.

The kit must be used on closed expansion

tank systems with power lower than 35 kW.

Its function is to cool the boiler in case of

over-temperature, by using a thermal di-

scharge valve connected to the exchanger

inlet hydraulically.

In correspondence to the exchanger outlet,

place one drainpipe with funnel and a

siphon that drive to a suitable discharge.

The discharge must be visible for inspec-

tion.

ATTENTION: Failure to comply with this

precaution, a possible activation of the

thermal discharge valve can damage per-

sons, animals and objects, which the ma-

nufacturer is not responsible for.

Before commissioning the boiler, ensure

that the water flow of the thermal dischar-

ge valve is guaranteed.

Fig. 8

“REGULUS RT2” Regulator

Fig. 7

“THERMOMAT RT-C” Regulator