Sime Dewy Equipe P100 Box User guide

Dewy Equipe Box

P100-P600

All descriptions and illustrations provided in this manual have been carefully prepared but we reserve the right to make

changes and improvements in our products that may affect the accuracy of the information contained in this manual.

................................................................................................................................... pag. 4

............................................................................................................................................... pag. 12

...................................................................................................................................................... pag. 20

.............................................................................................................................. pag. 23

IT IS A STATUTORY REQUIREMENT THAT ALL GAS APPLIANCES ARE INSTALLED BY COMPETENT PERSONS,

IN ACCORDANCE WITH THE GAS SAFETY (INSTALLATION AND USE) REGULATIONS (CURRENT EDITION).

The manufacturer’s instructions must not be taken as overriding any statutory requirements, and failure to

comply with these regulations may lead to prosecution.

No modifications to the appliance should be made unless they are fully approved by the manufacturer.

DO NOT OPERATE ANY ELECTRICAL SWITCH, OR USE A NAKED FLAME. TURN OFF THE GAS

SUPPLY AND VENTILATE THE AREA BY OPENING DOORS AND WINDOWS CONTACT THE GAS EMERGENCY

SERVICE ON 0800111999.

DEWY EQUIPE P100 BOX

DEWY EQUIPE P200 BOX

180

790

396

156

567

90

272

307

777

S3

M

R

G

1600

648

307

390

470

1100

640

180

790

396

156

567

90

272

307

777

S3

M

R

G

1600

390

640 630

648

307

2010

2010

4

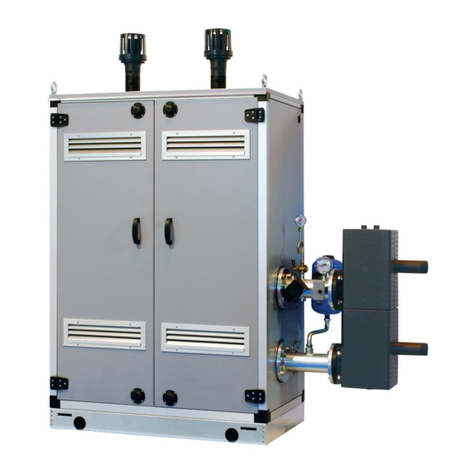

are

pre-mixed condensation heating modu-

les intended only for heating, inter-con-

nectible and easy to assemble, designed

to work singularly or in sequence/casca-

de automatically.

They are designed and constructed to

meet European directives 92/42/CEE,

2009/142/CEE, 2014/30/UE, 2014/35/UE.

Fig. 1

FIXTURES

M System supply (Flange PN6-DN100)

R System return (Flange PN6-DN100)

G Gas (Flange PN6-DN50)

S3 Condensate drain ø 40

5

DEWY EQUIPE P300 BOX

DEWY EQUIPE P400 BOX

470630 390 18 0

6401730

790

396

15 6

567

90

272

307

777

S3

M

R

G

648

307

1600

180

790

396

15 6

567

90

272

307

777

S3

M

R

G

1600

648

307

6402200

470630 470390

2010

2010

Fig. 1/a

FIXTURES

M System supply (Flange PN6-DN100)

R System return (Flange PN6-DN100)

G Gas (Flange PN6-DN50)

S3 Condensate drain ø 40

6

DEWY EQUIPE P500 BOX

DEWY EQUIPE P600 BOX

180

790

396

15 6

567

90

272

562

1197

S3

M

R

G

1600

180

790

396

15 6

567

90

272

562

1197

S3

M

R

G

1600

1090

1090 2830

3300

307

648

307

648

470630 470630 470 390

390

630

470

630

470

2010

2010

Fig. 1/b

FIXTURES

M System supply (Flange PN6-DN100)

R System return (Flange PN6-DN100)

G Gas (Flange PN6-DN50)

S3 Condensate drain ø 40

7

Nominal heat output (80-60°C) kW 94.9 189.8 284.7 379.6 474.5 569.5

Nominal heat output (50-30°C) kW 103.4 206.8 310.2 413.6 517.1 620.5

Minimum heat output G20 (80-60°C) kW 29.3 29.3 29.3 29.3 29.3 29.3

Minimum heat output G20 (50-30°C) kW 32.1 32.1 32.1 32.1 32.1 32.1

Minimum heat output G31 (80-60°C) kW 29.3 29.3 29.3 29.3 29.3 29.3

Minimum heat output G31 (50-30°C) kW 32.1 32.1 32.1 32.1 32.1 32.1

Nominal heat input kW 96.6 193.2 289.8 386.4 483.0 579.6

Minimum heat input G20 kW 30.0 30.0 30.0 30.0 30.0 30.0

Minimum Minimum heat input G31 kW 30.0 30.0 30.0 30.0 30.0 30.0

Min-max operating yield (80-60°C) % 97.7-98.2 97.7-98.2 97.7-98.2 97.7-98.2 97.7-98.2 97.7-98.2

Min-max operating yield (50-30°C) % 107.0-107.0 107.0-107.0 107.0-107.0 107.0-107.0 107.0-107.0 107.0-107.0

Operating yield at 30% (40-30°C) % 108.0 108.0 108.0 108.0 108.0 108.0

Energy yield markings (CEE 92/42) «««« «««« «««« «««« - -

Heat modules n° 1 1 1 of + 2 of 1 of + 3 of

1 of 2 of

Exhaust temperat. at Q. Nominal (80-60°C) °C 64 64 64 64 64 64

Exhaust temperat. at Q. Minimum (80-60°C) °C 51 51 51 51 51 51

Exhaust temperat. at Q. Nominal (50-30°C) °C 45 45 45 45 45 45

Exhaust temperat. at Q. Minimum 50-30°C) °C 40 40 40 40 40 40

Minimum/Maximum exhaust capacity g/s 15/46 15/92 15/138 15/184 15/230 15/276

CO2 at Q. Nominal/Minimum G20 % 9.0/9.0 9.0/9.0 9.0/9.0 9.0/9.0 9.0/9.0 9.0/9.0

CO2 at Q. Nominal/Minimum G31 % 10.0/10.0 10.0/10.0 10.0/10.0 10.0/10.0 10.0/10.0 10.0/10.0

Feeding tensionV-Hz 230-50 230-50 230-50 230-50 230-50 230-50

Electrical power absorbed W 330 660 990 1320 1650 1980

Absorbed power IPX4D IPX4D IPX4D IPX4D IPX4D IPX4D

CE certification n° 1312BP4142 1312BP4142 1312BP4142 1312BP4142 1312BP4142 1312BP4142

Category II2H3P II2H3P II2H3P II2H3P II2H3P II2H3P

Type B23-53/B23P-53P B23-53/B23P-53P B23-53/B23P-53P B23-53/B23P-53P B23-53/B23P-53P B23-53/B23P-53P

NOx class 5 5 5 5 5 5

Max operating pressure bar 5 5 5 5 5 5

Max operating temperature °C 85 85 85 85 85 85

Water content modules l 19.6 36.3 55.9 72.6 92.2 108.9

Single module temperature regulation °C 20/80 20/80 20/80 20/80 20/80 20/80

Supply pressure G20/G25 mbar 20/25 20/25 20/25 20/25 20/25 20/25

Supply pressure G31 mbar 37 37 37 37 37 37

Number of nozzles n° 1 2 3 4 5 6

Nozzle diameter G20/G25 ø 11.0 11.0 11.0 11.0 11.0 11.0

Nozzle diameter G31 ø 8.4 8.4 8.4 8.4 8.4 8.4

Consumption at nom./min. power G20 m3/h 10.22 20.44 30.67 40.89 51.11 61.33

Consumption at nom./min. power G31 kg/h 7.50 15.01 22.51 30.02 37.52 45.03

kg 240 390 620 770 1000 1150

8

9

1

26

25

22

5

6

27 18

17

24

15

16

10

11

9

814

13

M

R

G

S3

23

12

28

Fig. 2

KEY

1 Hydraulic separator (optional)

5 Condensate trap

6 Gas valve

8 Fan

9 Heating probe (SM)

10 Safety thermostat 95°C

11 Exhaust thermostat

12 Primary exchanger

13 Diaphragm

14 Differential pressure switch

15 Water pressure transducer

16 Air escape valve

17 Non return valve

18 Distributor

22 3-way drain valve

23 System supply valve

24 Manual drain vent

25 Gas tap

26 8 litre expansion tank (optional)

27 5 BAR safety valve

28 Condensate trap frost sensor

FIXTURES

M System flow

R System return

G Gas

S3 Condensate drain

10

11

1

2

3

4

5

6

7

8

9

10

11

13

24

14

15

16

19

20

21

22

23

Fig. 3

KEY

1 System return manifold

2 Gas manifold

3 Gas isolation valve

4 System supply manifold

5 Gas isolation valve

6 Fan

7 Ignition electrode

8 Ionisation electrode

9 Ignition transformer

10 Exhaust thermostat

11 Control panel

13 Air pressure switch

14 Heating probe (SM)

15 Safety thermostat 95°C

16 Differential pressure switch

19 Pump

20 5 BAR safety valve

21 Manual drain

22 Flow isolation valve

23 3-way isolation valve

24 Shunt box

12

The boiler must be installed in a fixed

location and only by specialized and quali-

fied person in compliance with all instruc-

tions contained in this manual. The instal-

lation of this boiler must be in accordance

with the relevant requirements of the

current Gas Safety (installation and use),

the local building regulations, and and

I.E.E. wiring regulations.

Detailled recommendations for air sup-

ply are given in BS5440:2. The following

notes are for general guidance:

– It is not necessary to have a pur-

pose provided air vent in the room or

compartment in which the appliance

is installed. However, suitable clear-

ances for maintenance and servicing

should be provided, see fig. 1.

.

BS6644:2005 has a requirement that the

temperatures in a room or compartment

do not exceed certain levels:

– 25°C at floor level (0-100 mm)

– 32°C at mid level (1.5 M above the floor

level)

– 40°C at ceiling level (0-100 mm from

ceiling)

The following is provide for your guidan-

ce only, and assumes the ventilation air

is taken directly from outside. The sizes

of the vents may need to be increased in

respect of other appliances installed in

the same area, and seasonal use. Take

care that the position of low level vents

would not subject to adverse weather

conditions, ie flooding.

Installed in a room

High level (within 15% of the room height

from ceiling) - 2 cm2/KW of net heat

input

Low level (low as possible within 1 metre

from floor natural gas, 250 mm LPG)– 4

cm2/KW of net heat input. Therefore a

single 60 BFR (58 KW net input) boiler

would require 116 cm2 at high level and

232 cm2 at low level. A single 100 BFR

(98 KW net input) boiler would require

196 cm2 at high level and 392 cm2 at low

level.

Installed in a compartment or enclosure

High level (within 15% of the room height

from ceiling) - 5 cm2/KW of net heat

input.

Low level (low as possible within 1 metre

from floor natural gas, 250 mm LPG) – 10

cm2/KW of net heat input.

Therefore a single 60 BFR (58 KW net

input) boiler would require 290 cm2 at

high level and 580 cm2 at low level.

A single 100 BFR (98 KW net input) boiler

would require 490 cm2 at high level and

980 cm2 at low level.

Installed in a room

High level (within 15% of the room height

from ceiling) - 2 cm2/KW of net heat

input

Low level (low as possible within 1 metre

from floor natural gas, 250 mm LPG)– 2

cm2/KW of net heat input

Therefore a single 60 BFR (58 KW net

input) boiler would require 116 cm2 at

high level and 116 cm2 at low level.

A single 100 BFR (98 KW net input) boiler

would require 196 cm2 at high level and

196 cm2 at low level.

Installed in a compartment or enclosure

High level (within 15% of the room height

from ceiling) - 5 cm2/KW of net heat

input

Low level (low as possible within 1 metre

from floor natural gas, 250 mm LPG)– 5

cm2/KW of net heat input.

Therefore a single 60 BFR (58 KW net

input) boiler would require 290 cm2 at

high level and 290 cm2 at low level.

A single 100 BFR (98 KW net input) boiler

would require 490 cm2 at high level and

490 cm2 at low level.

and

heat modules, inter-connectible by flan-

ge, are supplied with an external pre-

painted zinc-coated laminate case.

Available separately:

– Double box (size: 1100 x 790 x 1600) for

hydraulic separator code 8101527 (fig.

4)

– Hydraulic separator kit code 8101552

for modules

and code 8101553 for modules

– Sequence/cascade control unit code

8096301 supplied for

and code 8096308

supplied for

–

Polypropylene exhaust manifold kit for

indoor installation (purposely treated to

resist weathering when installed outdo-

ors):

code 8102510 for module

code 8102530 for module

code 8102531 for module

code 8102532 for module

code 8102533 for module

code 8102534 for module

– Exhaust terminal code 8089530 for

outdoor installations.

1600

470

308

11 00 790

396 396

635

562

Fig. 4

Before connecting the boiler it is recom-

mended that the system be flushed in

accordance to BS 7593, to eliminate any

foreign bodies that may be detrimental to

the operating efficiency of the appliance.

When connecting up the boiler the clear-

ances in fig 1 should be respected.

The boiler is supplied with a valve pack

part number 5184817.

The gas connection must be made using

seamless steel or copper.

Where the piping has to pass through

walls, a suitable insulating sleeve must

be provided. When sizing gas piping,

from the meter to the boiler, take into

account both the volume flow rates (con-

sumption) in m3/h and the relative den-

sity of the gas in question.

The sections of the piping making up

the system must be such as to guaran-

tee a supply of gas sufficient to cover

the maximum output available, limiting

pressure loss between the gas meter

and any apparatus being used to not

greater than 1.0 mbar for family II gases

(natural gas). An adhesive data badge is

sited inside the front panel; it contains all

the technical data identifying the boiler

and the type of gas for which the boiler

is arranged.

To ensure safe disposal of the conden-

sate produced by the flue gases, refer-

ence should be made to BS6798:2000.

The boiler incorporates a condensate

trap which has a seal of 75 mm, there-

fore no additional trap is required. The

condensate should ideally be discharged

internally into an internal waste pipe

(washing machine/sink waste) or a soil

pipe to avoid the risk of freezing. External

pipe runs should be avoided, but if it is

necessary, the pipework should be at

least 32 mm and protected from the risk

of freezing with a waterproof insulation

and the length kept to a minimum and

not exceeding 3 m. termination should be

into an external gully or purpose made

soakaway.

The exhaust terminal for single module

cod. 8089530 is required for this type

of installation. For separately supplied

accessory assembly see fig. 5.

Refer to fig. 5/a-5/b-5/c for this type of

installation.

The indicated solutions have the exhaust

13

Fig. 5

STAFFA TELAIO

CALDAIA

GMR

Pmin

Pmax

400

DEWY EQUIPE P200 BOX - Right side exhaust manifold kit

ø 160

521

DEWY EQUIPE P200 BOX - Left side exhaust manifold kit

Fig. 5/a

14

400

H

ø 200

DEWY EQUIPE P300-P400 BOX - Right side exhaust manifold kit

DEWY EQUIPE P300-P400 BOX - Left side exhaust manifold kit

Fig. 5/b

15

DEWY EQUIPE P500-P600 BOX - Right side exhaust manifold kit

DEWY EQUIPE P500-P600 BOX - Left side exhaust manifold kit

ø 250

H

Fig. 5/c

manifold positioned both on the module’s

right and left and the use of extensions,

supplied separately.

The kit code 8101532 supplied as option

for

,

can be installed both with con-

nections on left or right side

and is made

up of the following components (fig. 6):

– System supply/return flanged section

code 6291968

–

Expansion vessel 8 liters code 6245108,

connection pipe code 6227661, gaskets

and nipple.

The kit code 8101533 supplied as option for

,can be

installed both with connections on left or

right side and is made up of the following

components models it is formed (fig. 6/a):

– System supply/return flanged section

code 6291971

–

Expansion vessel 8 liters code 6245108,

connection pipe code 6227661, gaskets

and nipple.

16

Fig. 6/a

Fig. 6

BOILER 1 BOILER 2 BOILER 3 BOILER 4

DEWY EQUIPE P200 DEWY EQUIPE P300 DEWY EQUIPE P400

DEWY EQUIPE P500

DEWY EQUIPE P600

BOILER 1 BOILER 2 BOILER 3 BOILER 1 BOILER 2 BOILER 3

KEY

L Live

N Neutral

C RVA 47 regulator

R1 536 Ohm resistance (1)

R2 562 Ohm resistance (1)

R3 604 Ohm resistance (1)

R4 649 Ohm resistance (1)

(1) Resistances are supplied in RVA

47 sequence/cascade kit code

8096301/08.

Fig. 6/b

17

The head available of the generator sup-

ply/return manifolds vs. the flow rate is

shown on the chart of fig. 7.

Hydraulic separator load losses are indi-

cated in the diagram in fig. 7.

400

500

600

700

PORTATA (m3/h)

51015

0

100

200

300

∆p (mbar)

Dewy Equipe /Murelle Equipe

800

20

CAPACITY (m3/h)

100

150

5

PORTATA (m3/h)

10 15 20 25 30

0

50

∆p (mbar)

35 40 45

200

CAPACITY (m3/h)

Fig. 7

BOILER 1 BOILER 2 BOILER 3 BOILER 4

DEWY EQUIPE P200 DEWY EQUIPE P300 DEWY EQUIPE P400

DEWY EQUIPE P500

DEWY EQUIPE P600

BOILER 1 BOILER 2 BOILER 3 BOILER 1 BOILER 2 BOILER 3

KEY

L Live

N Neutral

C RVA 47 regulator

R1 536 Ohm resistance (1)

R2 562 Ohm resistance (1)

R3 604 Ohm resistance (1)

R4 649 Ohm resistance (1)

(1) Resistances are supplied in RVA

47 sequence/cascade kit code

8096301/08.

Fig. 6/c

18

The hydraulic separator is supplied

separately in a kit code 8101552 com-

plete with gaskets, nuts and fastening

screws (fig. 8).

The hydraulic separator is supplied sepa-

rately in a kit code 8101553 complete

with gaskets, nuts and fastening screws

(fig. 9). The plant is supplied with three

supporting “C” brackets that should be

used only to rest the compensator onto

the ground.

Each module is supplied with a power

cord which, if replacement is required,

must be ordered from SIME. 230V – 50 Hz

single phase voltage is required using a

fuse protected main switch with at least

3 mm. between contacts. Observe the L –

N polarity and earthing connection.

Fig. 10

KEY

EV1 Gas valve coil

EV2 Gas valve coil

EA Ignition electrode

ER Ionisation electrode

TS Safety thermostat 100°C

V Fan

TPA Water pressure transducer

PI Pump

SA Condensate trap frost sensor

SM Heating probe

TR 230 – 24V transformer

PD Differential pressure switch

SV Fan board

TF Exhaust thermostat

PA Air pressure switch

TRA Ignition transformer

RSA Resistance 100 (Ω)

R Resistance*

* The resistance in sequence/cascade instal-

lations is supplied in RVA 47 unit kit code

8096301/08. Use the resistance according to

module use (Boiler 1,2,3 or 4).

CONNECTOR SPARE PART CODES:

code 6278613

code 6299971

code 6293595

code 6293594

code 6293593

C

Fig. 8

C

Fig. 9

19

Modules are electrically connected to the terminal

board in the shunt box.

Insert the rubber pipe of the module that has to be con-

nected into the corresponding hole on the box wall.

Fix the rubber pipe to the internal wall of the box using

the straps provided.

Fig. 11

Fig. 11/a

Remove the two upper screws from the shunt

box supplied with the box and adjust the box

cover downwards. Remove the black orifice cap

and insert regulator RVA 47. Connect regulator

RVA 47 to the power supply, as shown in the

layout of Figure 6/b-6/c. After completing the

connection, close the box cover.

20

Built according to Low Voltage direc-

tive CEE 2006/95 and powered at 230

Volt, via a transformer it sends 24 Volt

power to the following components: gas

valve, safety thermostat, heating probe,

water pressure transducer and air pres-

sure switch. An automatic and continual

modulation system permits the boiler to

adjust power to the various system or

user needs. Electronic components are

guaranteed to operate in a temperature

range from 0 to +60°C.

Errors or malfunctions are indicated by

flashing LEDs as shown in fig. 12.

The electronic board is equipped with the

following devices:

– (10 fig. 13)

Adjusts maximum heating power.

To increase the value, rotate the trim-

mer clockwise, to reduce it, rotate the

trimmer counter-clockwise.

– (6 fig. 13)

Trimmer to vary the gas valve ignition

pressure level (STEP). According to

the type of gas the boiler is designed

for, the trimmer must be adjusted to

achieve a burner pressure of appro-

ximately 6.5 mm H2O for methane

gas and 9.5 mm H2O for propane gas

(G31).

To increase pressure, rotate the trim-

mer clockwise, to reduce it, rotate

the trimmer counter-clockwise. The

slow ignition pressure level can be set

during the first five seconds after the

burner is lit.

– (5 fig. 13)

The electronic board is programmed,

during heating, with a technical bur-

ner delay of about 90 seconds that

is performed both at cold start and

subsequent ignitions.

This is to prevent rapid ignitions and

shutdowns that could, in particular,

occur in systems with high load los-

ses. Each time the boiler restarts,

after the slow ignition, for about 1

minute it will run at minimum modu-

lation pressure before moving to the

set heating pressure. The addition of

a bridge will cancel both the program-

med technical delay and the minimum

pressure operating period at ignition.

In this case, the time between shut-

down and the next ignition will depend

on a 5°C differential detected by the

heating probe (SM).

– (13 fig. 13)

For correct module operations, the dip

switches must be positioned as indica-

ted below:

– (14 fig. 13)

The bridge must always be .

– (15 fig. 13)

This will normally be off.

It is only engaged in sequence/casca-

de installations with several boilers.

No communication with

“Logical Remote Control”

blinking red led

Green led off without

power supply

Blinking red air pressure switch fault led

Insufficient water pressure

blinking red led (*)

Heating probe fault blinking red led (SM)

System safety valve triggered

blinking red led (*)

Red ignition lock led:

turn the CR/OFF/INV/RELEASE

selector to the release

( ) position

to restore operations

Safety/exhaust thermostat triggered blinking

red led. Turn the CR/OFF/INV/RELEASE

selector to the release ( ) position

to restore operations

(*) If all leds are off, check water pressure transducer connec-

tions.

Fig. 12

Flame detection circuit fault blinking red led

Blinking red fan fault led. 30 minutes after the fan turns off, the board attempts

to restart it. To identify where the fault occurred in sequence/cascade installations,

turn the CR/OFF/INV/RELEASE selector on each module to the ( ) position

and check where the red fault led blinks.

Other manuals for Dewy Equipe P100 Box

2

This manual suits for next models

5

Table of contents

Other Sime Heater manuals

Popular Heater manuals by other brands

Brant Radiant Heaters

Brant Radiant Heaters DX2-20-60 user manual

Myson

Myson Rio Operating installation and instructions

Oceanic

Oceanic OCEACV100IFW2 instructions

PVG

PVG SRE 10x C operating manual

Schwank

Schwank ecoSchwank-X 6 - IL-X 25 Installation & owner's manual

VTS Medical Systems

VTS Medical Systems WING W Series Technical documentation