10

EN

WING W100-200

WING E100-200

WING C100-200

6. SERVICING

6.1. PROCEDURE IN CASE OF DEFECTS

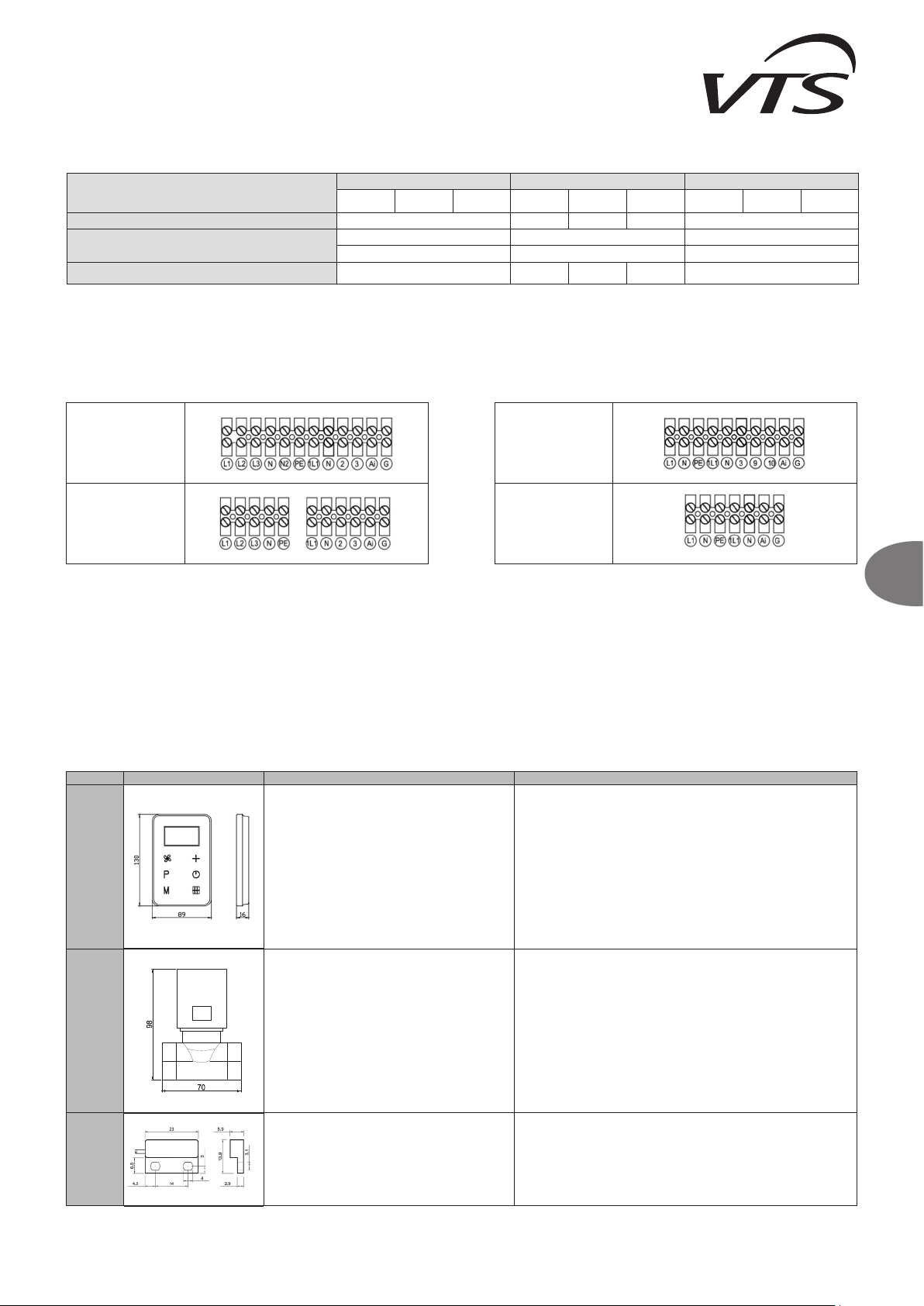

WING W100-200/EHN

Symptoms What to check Description

Leakage in the WING

W100-200 heat

exchanger

● Fitting of the heat exchanger terminals, using two keys acting in two opposite

directions (apply the keys on each terminal), which protects against the possibility

of internal breaking of the collecting pipes.

● Relation between the leaking and a potential mechanical damage to the

exchanger.

● Leaking of vent valve elements or drain plug.

● Parameters of the heating medium (pressure and temperature) should not

exceed the permissible values.

● Correctness of the draining of the exchanger.

● type of agent (it cannot be any aggressive substance Al or Cu active),

● Circumstances in which leaking occurred (e.g. during the trial/initial start-up of

the system; after having drained the heating medium, followed by the lling of

the system) and the external ambient temperature at the moment of the defect

taking place (freezing hazard to the exchanger).

● Potentially aggressive atmosphere (air) in the place of work (e.g. high

concentration of ammonia in the sewage-treatment plant).

● Pay particular attention to the possibility of the freezing of the heat

exchanger in the winter. 99% of leaks occur during start-up/pressure

checks. The rectifying of the defect consists in the pulling back of the

vent/drain valve.

The fan of the device

works too loudly WING

W100-200, EHN

● Installation of the device, according to the guidelines in the Operation and

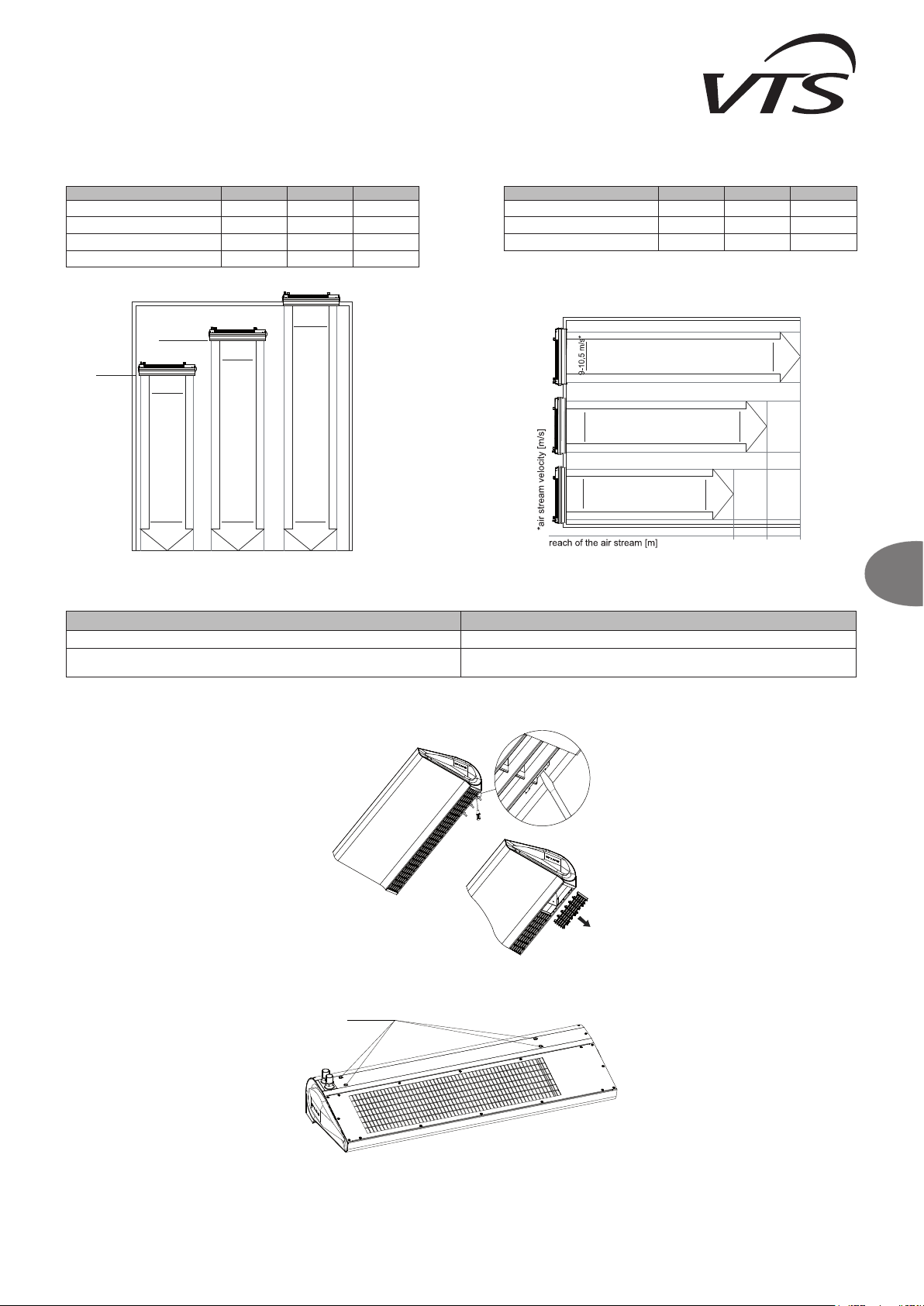

Maintenance Documentation (among others, the distance from the ceiling). ● Minimum distance: 10 cm from the ceiling

● Correctness of the horizontal alignment of the device.

● Correctness of electrical connections and qualications of

● Parameters of the supply current (among others: voltage, frequency).

● Incorrect covering of the curtain in the suspended ceiling.

● Noise in lower speeds (damaged winding).

● Noise present only in the higher speeds – blocking of the air outlet.

● Type of other equipment working in the facility (e.g. exhaust fans) – increasing

noise may be a result of several pieces of equipment working simultaneously.

● Louder operation of WING devices may be a result of inappropriate place

of assembly : e.g. choking the fan or the acoustic specics of a room.

The fan in the device

is not operational

WING W100-200, EHN

● Correctness and quality of electrical connections and qualications of the tter.

● Parameters of the supply current (among others: voltage, frequency) on the

terminal block of the fan’s engine.

● Operational correctness of other pieces of equipment present in the facility.

● Correct tting of the conduits on the engine side – information available from VTS

Service Department.

● Voltage on the PE conductor (if present, it may indicate a breakdown).

● The electrical connection of the device must be carried out, according to

the diagrams found in the Operation and Maintenance Documentation.

● Damage, incorrect connecting or tting of a wall-mounted controller, other than the

DX contro ller

● It is recommended to check the device by means of connecting the curtain

directly to the power supply and forcing the electric motor's operation

by shorting appropriate clips of the device's terminal strip and then the

terminal strip in the controller.

Damaged casing of the

device

WING W100-200, EHN

● Circumstances in which the defect occurred: remarks on the bill of lading,

inventory issue, condition of cardboard).

● Should the casing be defective, it is required to present photos of the

cardboard and device, as well as photos that conrm the compliance

between the serial number on the device and cardboard. If the damage

was done in transport, it is necessary to prepare a proper statement by the

driver/forwarder that delivered the goods.

Actuator does not open

the valve

● Correctness of electrical connections and qualications of the tter.

● Operational correctness of the thermostat (the characteristic “ticking” when

switching the device).

● Parameters of the supply current (among others: voltage).

● The most important step is to check whether the actuator has reacted

to the electrical impulse. When actuator damage is claimed, a complaint

must be submitted for the damaged element, and the actuator must be

deinstalled from the valve to open the valve mechanically (permanently).

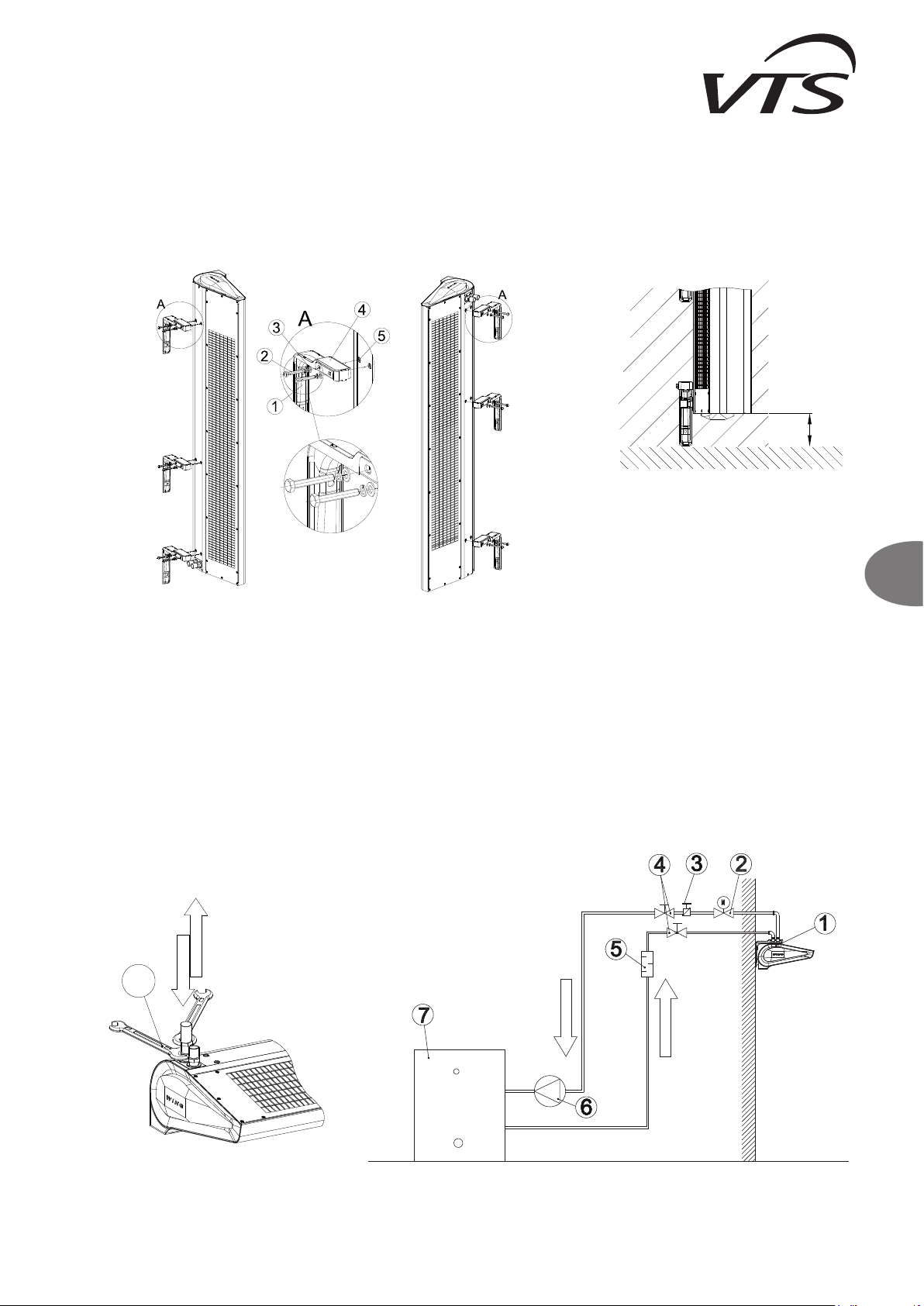

5. START-UP, OPERATION, MAINTENANCE

5.1. START-UP/PUTTING INTO OPERATION

● Prior to the commencing of any installation or maintenance work, disconnect power supply and secure it against unintentional reactivation.

● It is recommended to use lters in the hydraulic system. It is recommended to clean/rinse the system, draining a few litres of water, prior to the connecting of hydraulic conduits (the supply conduits,

in particular).

● It is advised to use vent valves in the highest point of the system.

● It is recommended to install shut-off valves directly after the device, should the disassembly of the device be necessary.

● All protective equipment is to be installed before the pressure increases, according to maximum the permissible pressure rating of 1.6MPa.

● Hydraulic connection should be free of any stresses and loads.

● Check the correctness of hydraulic connections (leak-tightness of the vent, collecting pipes, correctness of ttings installation), prior to the initial start-up of the device.

● It is recommended to check the correctness of electrical connections (of automatics, power supply), prior to the initial start-up of the device. It is advised to use an additional, external residual-

current protection.

IMPORTANT! All connections should be carried out, according to this technical documentation and the documentation delivered with automation equipment.

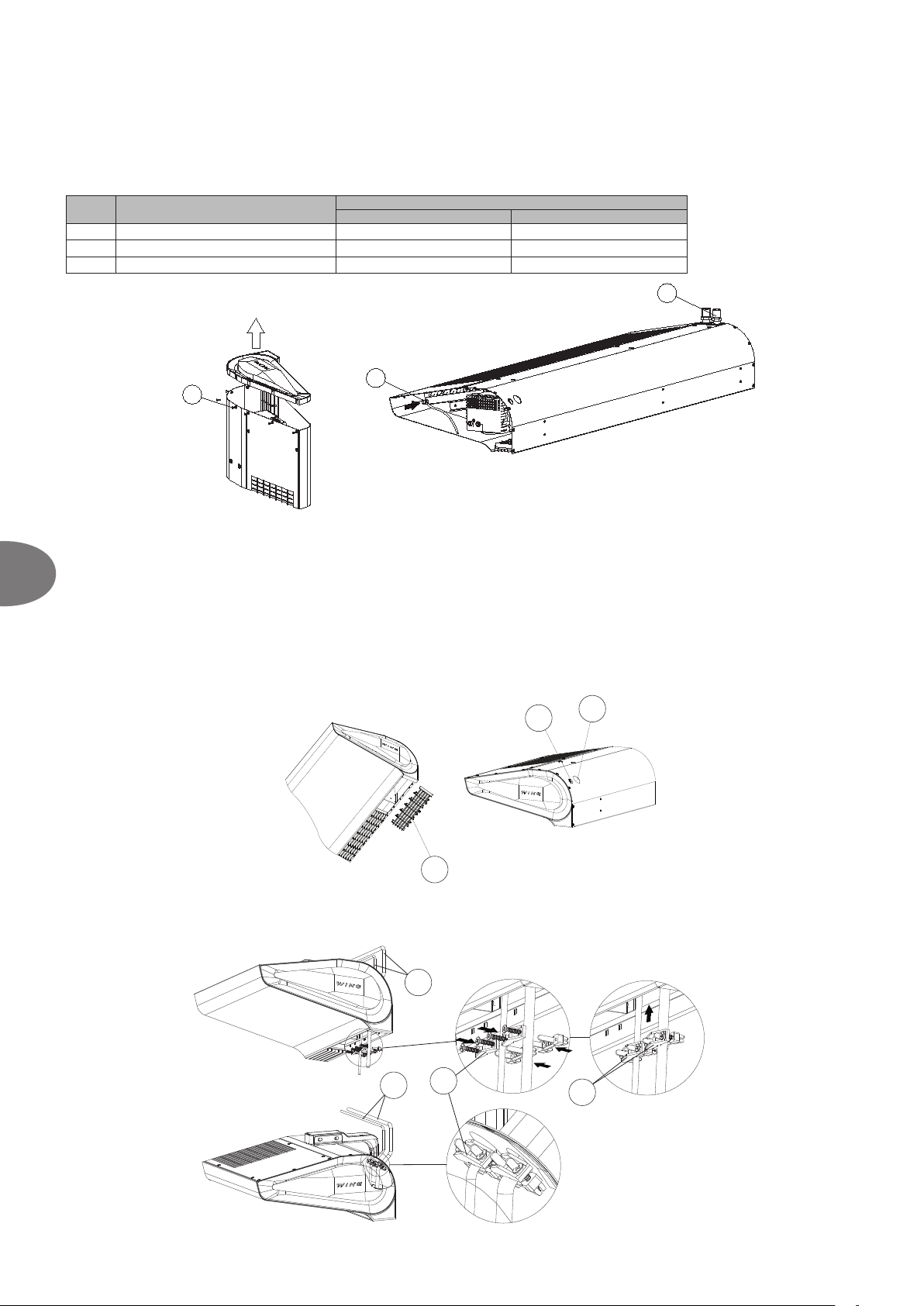

5.2. OPERATION AND MAINTENANCE

● It is advised to carefully analyse all the operational and assembly guidelines listed in chapter 3 and 4.

● The casing of the device does not require maintenance.

● The heat exchanger should be cleaned on a regular basis from dust and fat deposit. It is especially recommended to clean the exchanger before the heating season with the use of compressed air

from the air intake side (after removing the inlet grid). You should pay special attention to the exchanger's lamellae which are very delicate.

● Should the lamellas be deformed (bent), straighten them with a special tool.

● The fan's motor does not require any exploitation service, the only service activities that may be necessary concern cleaning the air intakes from dust and fat deposit.

● Disconnect phase voltage, if the device is shut down for longer periods of time.

● The heat exchanger does not have any anti-freezing protections.

● It is recommended to provide a periodical purging of the heat exchanger, preferably using compressed air.

● Should the temperature in the room drop below 0°C, with a simultaneous drop of the heating medium temperature, there is a risk that the heat exchanger might freeze (crack).

● The level of air pollutants should meet the criteria allowable concentrations of pollutants in indoor air, for non-industrial areas, the level of dust concentration up to 0.3 g/m³.

● It is forbidden to use device for the duration of the construction works except for the start-up of the system.

● The equipment must be operated in rooms used throughout the year, and in which there is no condensation (large uctuations in temperature, especially below the dew point of the moisture

content). The device should not be exposed to direct UV rays.

● The device should be operated at the supply water temperature up to 90°C with working fan.