Simlatus HD-212 User manual

Simlatus Corporation

175 Joerschke Drive, Suite A

Grass Valley, CA 95945

hone: 530-205-3437 Fax: 530-273-8482

sales@simlatus.com

www.simlatus.com

HD

HDHD

HD-

--

-212

212212

212

2 x

2 x 2 x

2 x 2

22

2

Digital

Digital Digital

Digital rotection

rotectionrotection

rotection

Switch

SwitchSwitch

Switch

Statement of Warranty

Statement of WarrantyStatement of Warranty

Statement of Warranty

Simlatus Corporation warrants its products for a period of three (3) years from

the date of shipment to be free from defects in materials and workmanship and

meets applicable published specifications. Equipment which has been operated

within its ratings and has not been sub ected to mechanical or other abuse or

modification by the purchaser, its agents, and/or employees, will, at the option of

Simlatus, be replaced or repaired if it is returned, freight prepaid, to Simlatus.

Equipment that fails under conditions other than described herein will be repaired

at the price of components and labor in affect at the time of repair.

This warranty is in lieu of all other warranties, expressed or implied, with respect

to the condition or performance of any Simlatus product, its merchantability or

fitness for a particular purpose. Simlatus Corporation is not liable for any

consequential damages.

FCC Compliance

FCC ComplianceFCC Compliance

FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area could cause

harmful interference in which case the user will be required to correct the

interference at his own expense.

Copyright

CopyrightCopyright

Copyright

© 2016 Simlatus Corporation

Contents of this publication may not be reproduced in any form without the

written permission of Simlatus Corporation. Reproduction or reverse engineering

of copyrighted software is prohibited.

May 2016

Part Number 71

7171

71-

--

-00

0000

003

33

38

88

8

Table of Contents

Table of ContentsTable of Contents

Table of Contents

Introduction

IntroductionIntroduction

Introduction

Important Safeguards and Notices ............................................................................i

Important Warnings and Cautions ............................................................................ ii

Warnings ............................................................................................................ ii

Cautions ............................................................................................................ iii

North American Power Supply Cords ................................................................ iv

Section I

Section ISection I

Section I

eneral Description ................................................................................................ 1

Section II

Section IISection II

Section II

Specifications .......................................................................................................... 3

Section III

Section IIISection III

Section III

Installation ............................................................................................................... 4

Switches and jumpers ....................................................................................... 4

Ethernet Processor reset ................................................................................... 5

Section IV

Section IVSection IV

Section IV

Circuit Description ................................................................................................... 6

Video Path ......................................................................................................... 6

Logic ................................................................................................................. 6

Status Output .................................................................................................... 6

Power Supply/Regulators .................................................................................. 7

Section V

Section VSection V

Section V

Diagrams ................................................................................................................. 8

External Control Connector Pin Assignment ...................................................... 9

Section VI

Section VISection VI

Section VI

Ethernet Interface .................................................................................................. 10

i

Important Safeguards and Notices

Important Safeguards and NoticesImportant Safeguards and Notices

Important Safeguards and Notices

Information on the following pages provides important safety

guidelines for both Operator and Service personnel. Specific

warnings and cautions will be found throughout the manual

where they apply, but may not appear here. Please read and

follow the important safety information, noting especially those

instructions related to risk of fire, electric shock or injury to

persons.

ARNING

ARNINGARNING

ARNING

Any instructions in this manual that require opening the

Any instructions in this manual that require opening the Any instructions in this manual that require opening the

Any instructions in this manual that require opening the

equipment cover or encl

equipment cover or enclequipment cover or encl

equipment cover or enclosure are for use by qualified service

osure are for use by qualified service osure are for use by qualified service

osure are for use by qualified service

personnel only. To reduce the risk of electric shock, do not

personnel only. To reduce the risk of electric shock, do not personnel only. To reduce the risk of electric shock, do not

personnel only. To reduce the risk of electric shock, do not

perform any servicing other than that contained in the

perform any servicing other than that contained in the perform any servicing other than that contained in the

perform any servicing other than that contained in the

operating instructions unless you are qualified to do so.

operating instructions unless you are qualified to do so.operating instructions unless you are qualified to do so.

operating instructions unless you are qualified to do so.

Symbols and Their Meaning in This Man

Symbols and Their Meaning in This ManSymbols and Their Meaning in This Man

Symbols and Their Meaning in This Manual

ualual

ual

The lightning flash with arrowhead symbol, within an

equilateral triangle, alerts the user to the presence of

“dangerous voltage” within the product’s enclosure that may be

of sufficient magnitude to constitute a risk of electric shock to

persons.

The exclamation point within an equilateral triangle alerts the

user to the presence of important operating and maintenance

(servicing) instructions in the literature accompanying the

appliance.

This symbol represents a protective grounding terminal. Such

a terminal must be connected to earth ground prior to making

any other connections to the equipment.

The fuse symbol indicates that the fuse referenced in text must

be replaced with one having the ratings indicated.

ii

Important arnings and

Important arnings andImportant arnings and

Important arnings and

Cautions

CautionsCautions

Cautions

arnings

arningsarnings

arnings

•Heed all warnings on the unit and in the operating instructions.

•Do not use this product in or near water.

•Disconnect ac power before installing any options.

•This product is grounded through the grounding conductor of

the power cord. To avoid electrical shock, plug the power cord

into a properly wired receptacle before connecting the product

inputs or outputs.

•Route power cords and other cables so that they are not likely

to be damaged.

•Disconnect power before cleaning. Do not use liquid or aerosol

cleaners; use only a damp cloth.

•Dangerous voltages exist at several points in this product. To

avoid personal injury, do not touch exposed connections and

components while power is on.

•Do not wear hand jewelry or watches when troubleshooting high

current circuits, such as the power supplies.

•During installation, do not use the door handles or front panels

to lift the equipment as they may open abruptly and injure you.

•To avoid fire hazard, use only the specified correct type, voltage

and current rating as referenced in the appropriate parts list for

this product. Always refer fuse replacements to qualified service

personnel.

•To avoid explosion, do not operate this product in an explosive

atmosphere unless it has been specifically certified for such

operation.

•Have qualified personnel perform safety checks after any

completed service.

iii

arnings (continued)

arnings (continued)arnings (continued)

arnings (continued)

•If equipped with redundant power, this unit has two power

cords. To reduce the risk of electrical shock, disconnect both

power supply cords before servicing.

•This equipment may employ laser(s). If it does, they comply

with the current construction requirements of the code of

Federal regulations, title 21, chapter I, subchapter J, sections

1010.2 and 1010.3 and sections 1040.10 and 1040.11.

•Do not attempt to view light output of the laser transmitter, eye

damage may result. Always use an optical power meter to verify

laser output.

•To prevent injury:

Never install telephone wiring during a lightning storm.

Never install telephone jacks in wet locations unless the jack is

specifically designed for wet locations.

Never touch uninsulated telephone wires or terminals unless the

telephone line has been disconnected at the network interface.

Use caution when installing or modifying telephone lines.

Cautions

CautionsCautions

Cautions

•hen installing this equipment, do not attach power cord to

building surfaces.

•To prevent damage to equipment when replacing fuses, locate

and correct the trouble that caused the fuse to blow before

applying power.

•Verify that all power supply lights are off before removing power

supply or servicing equipment.

•Use only specified replacement parts.

•Follow static precautions at all times when handling this

equipment.

iv

Cautions (continued)

Cautions (continued)Cautions (continued)

Cautions (continued)

•Leave the back of the frame clear for air exhaust cooling and to

allow room for cabling. Slots and openings in the cabinet are

provided for ventilation. Do not block them.

•Front door is part of fire enclosure and should be kept closed

during normal operation.

•This product should be powered on as described in the manual.

To prevent equipment damage select the proper line voltage at

the ac input connector as described in the Installation

documentation.

•To prevent damage to this equipment read the instructions in

this document for proper input voltage range selection.

•To reduce the risk of electric shock, ensure that the two power

supply cords are each plugged into a separate branch circuit.

•Circuit boards in this product are densely populated with surface

mount and ASIC components. Special tools and techniques are

required to safely and effectively troubleshoot and repair

modules that use SMT or ASIC components. For this reason,

service and repair of RJM products incorporating surface mount

technology are supported only on a module exchange basis.

Customers should not attempt to troubleshoot or repair modules

that contain SMT components. RJM assumes no liability for

damage caused by unauthorized repairs. This applies to both

in- and out-of-warranty products.

North American Power Sup

North American Power SupNorth American Power Sup

North American Power Supply Cords

ply Cordsply Cords

ply Cords

This equipment is supplied with molded grounding plug (NEMA 5-

15P) at one end and molded grounding connector (IEC 320-C13) at

the other end. Conductors are CEE color coded, light blue (neutral),

brown (line) and green/yellow (ground).

Operation of this equipment at voltages exceeding 130 VAC will

require power supply cords which comply with NEMA

configurations.

v

Note:

Note:Note:

Note:

This equipment has been tested and found to comply with the limits

for a class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference, in which case the user will be required to correct the

interference at his own expense.

SECTION 1

HD-212

General description

The Simlatus HD-212 functions as an input transfer system that can switch

between two high definition or SDI digital video input signals, and B. This is

accomplished automatically using the internal signal detect, or manually using

either the local or remote select /B switch. transfer module occupies one-half

of a 1RU frame. The 1RU frame is designed to house a maximum of two RTU

units. Each unit operates independently from the other. They do share a common

power supply.

The frame has space for two power supplies for redundancy, with the output of

the supply voltage diode OR’d on the main module with the output of the other

supply. Each supply has its own C line connection. If either supply fails or its

C line fails, then the other supply will keep the unit running.

The switchover is determined by the presence of video on the in-use video input.

If video is interrupted on the selected (in-use) input and if video is present on the

non-selected input, then a switch to the non-selected input will occur. If no video

is present on the non-selected input then no switch will occur. In the digital HD-

212 loss of video is not the loss of the data stream, but actually the loss of the

SMPTE TRS (E V-S V). The presence/absence detector can be set to SD-only,

HD-only or UTO detection of either. When in the UTO mode, the unit will also

detect DVB- SI.

toggle switch is provided on the module to allow the unit to operate in either

automatic or manual mode. The unit can be operated manually at any time by

pushing the red button located inside the hole in the front cover, or by providing

an external GPI closure to ground.

Once a switchover has been completed from one input to the other, the system

will not automatically return to the first input upon restoration of signal. If it is

desired that the unit be operated from that first source, then the return must be

accomplished manually. This is true if the switch has occurred from the B input to

the input. If the switch has occurred from input to input B, then there is an

additional feature that allows the unit to return-to- upon re-activation of the

signal.

Upon loss of power to the changeover unit or the removal of the processor

module, relays are provided that will allow the Input signal to be re-routed to

the #1 On-Line output, thereby bypassing the changeover function.

The video inputs terminate in 75 ohms.

2

When power is applied, the signal input is selected as the default mode.

The output of the HD-212 can be either the or B input. There are three 75Ω

BNC connectors for the On-Line output and one BNC connector for the Off-Line

output.

There is an EXT CONTROL connector, which is a female 9 pin ‘D’. The External

Control provides for external /B transfer and also /B signal and power supply

health monitoring of the HD-212. Refer to page 9 for the proper pinout.

second EXT CONTROL connector is provided, which is an RJ-45. This

connector is only utilized if the optional Ethernet Interface module is included.

The connector provides a path from the interface module to an external network

connection.

3

SECTION II

SECTION IISECTION II

SECTION II

HD

HDHD

HD-

--

-212

212212

212

Specifications

SpecificationsSpecifications

Specifications

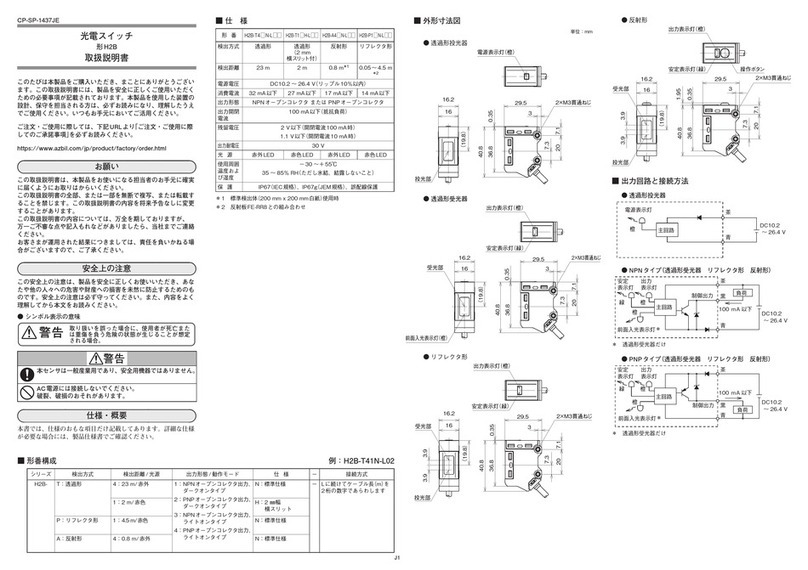

Video:

Video:Video:

Video:

Inputs:

Number 2

Input type 75Ω, BNC per IEC 169-8

Signal level 800mV ±10%

Return loss >13dB at 270Mb

Data rate 270Mb or 1.485Gbps

Equalization utomatic

>300 meters Belden 1694 @270Mb

>100 meters Belden 1694

@1.485Gbps

Outputs:

Number 3 – On-line

1 – Off-line

Impedance 75Ω, BNC

Signal level 800mV ±10%

Return loss >15dB at 270Mb

Specifications:

Jitter HD – 125ps

SDI – 150ps

Temperature:

Temperature:Temperature:

Temperature:

Performance 0 to 40 degrees centigrade

Operating 0 to 50 degrees centigrade

Humidity 90% non-condensing

Power requirements

Power requirementsPower requirements

Power requirements:

::

:

115/230V C, 50/60 Hz, 20W

Size

SizeSize

Size:

::

:

1.75” x 19” x 10”

Weight

WeightWeight

Weight:

::

:

≈7 lbs 3 kg

* Specifications and design are subject to change without notice.

4

SECTION III

SECTION IIISECTION III

SECTION III

HD

HDHD

HD-

--

-212

212212

212

Installation

InstallationInstallation

Installation

The HD-212 input transfer unit is a one rack-unit frame designed to be mounted

in a standard 19” equipment rack. There are no special cooling requirements

though care should be taken to ensure that extremely hot equipment not be

installed directly beneath. It is also recommended that, if possible, one rack-unit

of space be left above the unit.

Unless specified at the time of order, the HD-212 is shipped from the factory for

nominal 117V C 60Hz power. The unit comes shipped with a 120V type C

plug. If it is desired to operate at 230V C 50Hz, a selector switch must be set on

the power supply. The supply is removed from the frame, the switch set to

230V C, and the supply replaced in the frame.

The two HD/SDI video inputs and B are internally terminated at 75Ω. The On-

Line and Off-Line outputs are 75Ω. Unused outputs should be terminated with

precision 75Ω terminations.

Switches and jumpers

Switches and jumpersSwitches and jumpers

Switches and jumpers

When the unit is in the automatic mode, if the signal fails on the input the unit

switches to the B input. rotary switch (SW4)

(SW4)(SW4)

(SW4) is provided on the module to allow

the user to define whether the unit returns to the input upon return of the

signal or that the unit remains on the B input until it is manually returned to the

input. The return-to- -signal mode can be delayed by an adjustment of this

switch from position 1 to 5 to allow from 1 to 5 seconds after the return of the

signal before the unit switches back to the input. The zero (0) position of the

switch defeats the return function and dictates that the signal remain-on-B after a

switchover. The switch is set at the factory for 0 (do not return) operation.

toggle switch (SW2)

(SW2)(SW2)

(SW2) is located near the front of the module. This switch

permits selection of the unit in either the automatic ( UTO) or manual (M N)

mode of operation. Placing the switch in the DOWN position places the module

in the UTOM TIC mode of operation. Placing the toggle switch in the UP

position places the module in the M NU L mode.

5

The HD-212 can automatically detect whether the input signals are HD or SDI.

4-pin jumper

(JP1)

(JP1) (JP1)

(JP1) is provided to

allow the unit to automatically or manually set

the standard. If the jumper is placed between pins 1 & 2, the standards detection

will be automatic. Placing the jumper between pins 2 & 3 will set the unit to SD

only and placing the jumper between pins 3 & 4 will set the unit to HD only. The

jumper is set at the factory to UTO.

The 6-pin header (JP2)

(JP2)(JP2)

(JP2) is for factory use only.

LED lamps are provided on the module to provide certain operating indications.

Each LED block contains three lamps. In all cases the center lamp is not used.

D301 indicates the presence of the signal and the B signal. It can be viewed

through light pipes in the front cover of the frame. D302 indicates whether the

input or the B input is on-line. This also can be viewed through light pipes in the

front cover of the frame. Elements of D303 indicates the presence of +5 volts

from each of the two on-board +5V regulators. The front cover must be removed

to observe these LEDs.

Reset Default Settings

Reset Default SettingsReset Default Settings

Reset Default Settings

The Ethernet Processor module can be restored to factory default settings. To

accomplish this, proceed as follows:

1. Remove the RTU module from the frame.

2. long the left-hand side of the module, locate the black jumper at JP1

JP1JP1

JP1.

3. Remove the jumper.

4. Just to the left of the Ethernet Processor sub-module, locate a 2-pin

header JP3

JP3JP3

JP3.

5. Place the black jumper on JP3

JP3JP3

JP3.

6. Re-insert the RTU module in the frame and allow it to power up.

7. Remove the module and remove the jumper from JP3

JP3JP3

JP3.

8. Replace the jumper on JP1

JP1JP1

JP1.

9. Replace the RTU module in the frame.

10. The IP address will return to the default number. The processor must be

re-programmed with the appropriate IP address.

6

SECTION

SECTIONSECTION

SECTION

IV

IVIV

IV

HD

HDHD

HD-

--

-212

212212

212

Circuit Description

Circuit DescriptionCircuit Description

Circuit Description

Video Path:

Video Path:Video Path:

Video Path:

Each of the two inputs ( & B) connects to an automatic cable equalizer (U101 &

U201), which compensates for high frequency cable attenuation. Each equalizer

output connects to the input of two Gennum 1560 de-serializers (U103 & U203).

Each 1560 has two inputs; one from each of the equalizers. The 1560 locks an

oscillator (U102 & U202) to the input data stream, and also detects and locks to

SMPTE TRS framing words in the signal. It then outputs a LOCK signal when a

valid input signal is present. The 1560 also re-clocks the serial data and outputs

a regenerated serial stream.

One 1560 drives the on-line output drivers (U1 & U2) and the other drives the off-

line output driver (U3).

Logic:

Logic:Logic:

Logic:

Xilinx CPLD (U205) contains all logic to switch the Gennum 1560 inputs to the

proper output, based on the LOCK (video present) signals. The CPLD outputs

status information to the front panel LEDs, the remote control connector and the

Ethernet interface, if installed.

Status Outputs:

Status Outputs:Status Outputs:

Status Outputs:

Status is available for different functions on the External Control GPI connector.

Each output is an open collector output. There are five such outputs. The first

one is input health and video present, which will go to a high state if input

health is bad or video is not present. The second output is the same as the first

but for the B input health and B video present. The third output indicates the

health of the power supplies in the frame. If either supply goes down then the

output goes high. The fourth status output is for switch selection status. low on

this output indicates that the input is selected and a high indicates that the B

input is selected. The final output indicates that a switchover has occurred. It

provides a momentary low. n external alarm can be connected to this output.

7

Power Supply / Regulators:

Power Supply / Regulators:Power Supply / Regulators:

Power Supply / Regulators:

The unregulated voltage to the voltage regulators on the main board comes from

either of two power supplies that can be removed at the front of the RTU frame

for service and replacement. Each unregulated supply has an input fuse and a

115/230V C selector switch, and contains the circuitry that monitors the positive

output. dual color LED on the front of the power supply displays its health.

Green indicates normal operation, or healthy condition. Red indicates either no

C present, or a problem with that supply. The output of the supply is diode OR’d

to its respective supply bus.

There are four regulators on the main board. U401 regulates the +5 volts from

power supply , U402 the +5 volts from power supply B. The two outputs are

diode OR’d to provide the main +5 volts to the module. U403 regulates the +3.3

volts and U404 regulates the +1.8 volts.

The outputs of U401 and U402 are fed to separate voltage monitors, U405 and

U406. The outputs of these monitors are connected together and provide the PS

Health signal to the External Control connector.

8

SECTION V

SECTION VSECTION V

SECTION V

HD

HDHD

HD-

--

-212

212212

212

Diagrams

DiagramsDiagrams

Diagrams

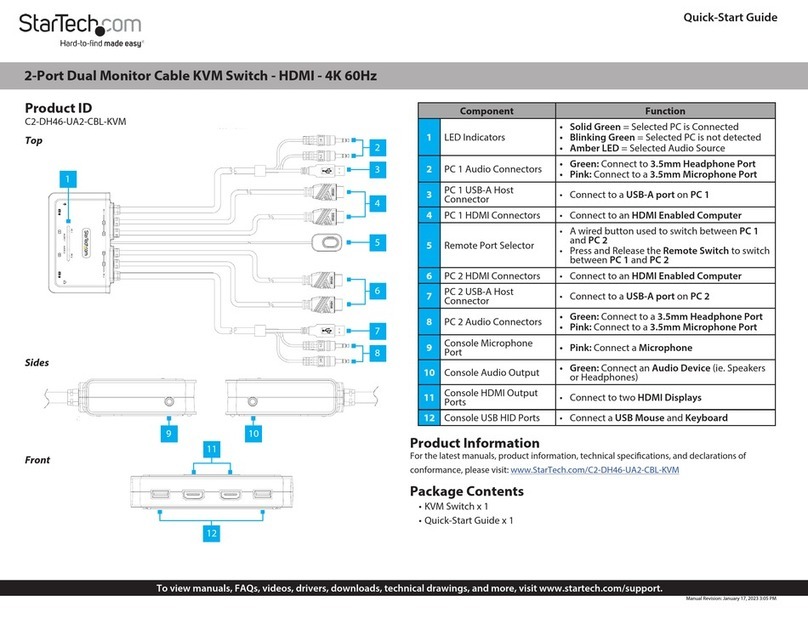

External Control Connector Pin ssignments

9

HD

HDHD

HD-

--

-212

212212

212

EXTERN L CONTROL CONNECTOR

EXTERN L CONTROL CONNECTOREXTERN L CONTROL CONNECTOR

EXTERN L CONTROL CONNECTOR

9

99

9-

--

-PIN ‘D’

PIN ‘D’PIN ‘D’

PIN ‘D’

1 Power Supply Health (Low = Healthy)

2 Input B Video Present/Input Health

(Low = Video Present and Input Healthy)

3 Switch-occurred larm (Momentary Low)

4 Select Input ( ctive Low, Momentary Pulse)

5 GND

6 Input Video Present/Input Health

(Low = Video Present and Input Healthy)

7 Input Selection Status (Low = Input Selected)

8 n/c

9 Select Input B ( ctive Low, Momentary Pulse)

10

SECTION VI

SECTION VISECTION VI

SECTION VI

HD

HDHD

HD-

--

-212

212212

212

Ethernet Interface

Ethernet InterfaceEthernet Interface

Ethernet Interface

core processor is included to allow the HD-212 to communicate through an

Ethernet interface to an external control device. This communication allows for

status monitoring and switchover control.

The installation consists of installing the processor sub-module into the mating

connector on the HD-212 with the RJ-45 facing forward. Then connect the

supplied cable between the RJ-45 connector on the processor sub-module and

the RJ-45 connector on the HD-212.

The jumper (JP3)

(JP3)(JP3)

(JP3) is provided to reset the processor to the default parameters.

To reset, remove the module from the frame, short the two pins on JP3 and plug

the module into the frame. This will reset the processor. Remove the module and

remove the short to return to normal operation.

Table of contents