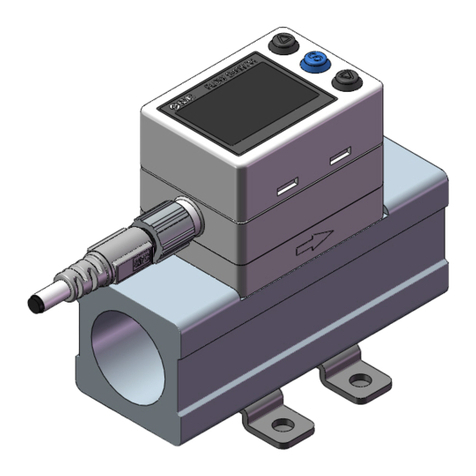

Specifications

Piping Specifications

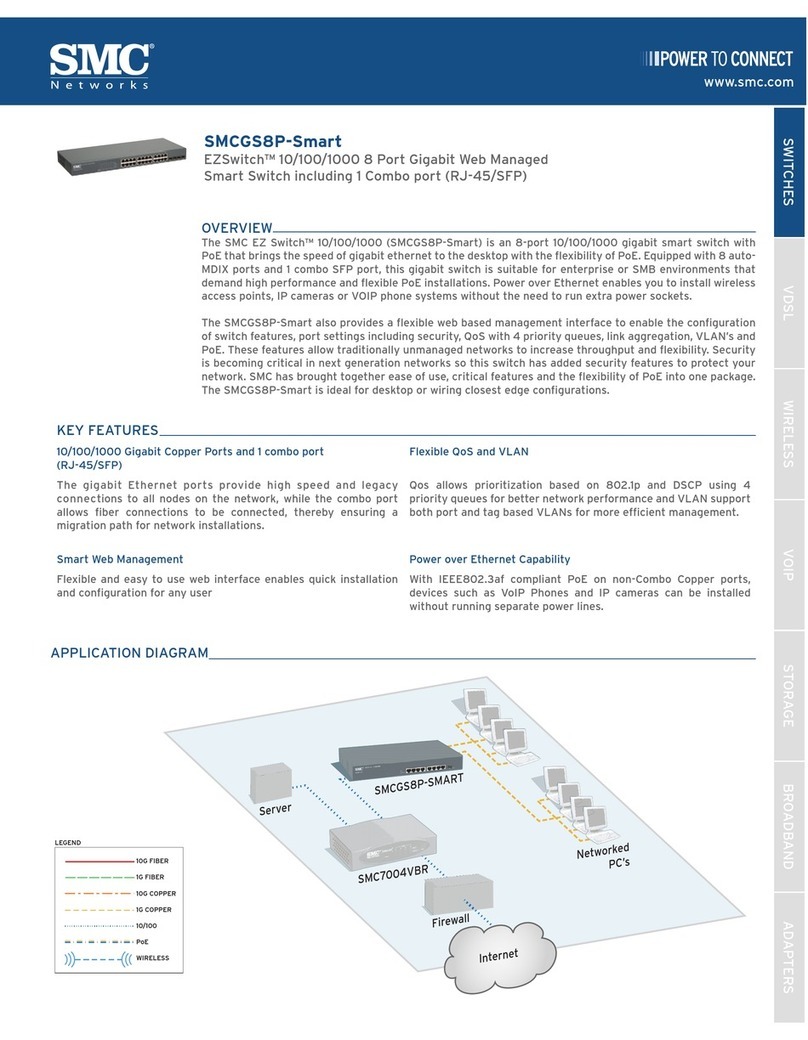

Part no. 01 N01 W1 WF1

78 g 79 g 97 g 104 g 101 g

M5 C4 C6

ø6 one-touch

fitting

ø4 one-touch

fitting

ZDC2, POM, Stainless steel 304,

C3604 (Electroless nickel plated)

O-ring: HNBR

M5 x 0.8

female thread

G1/8

Silicon

Rc1/8

ZDC2

O-ring: HNBR

NPT1/8

(With M5

female thread)

R1/8

(With M5

female thread)

C3602 (Electroless nickel plated)

O-ring: HNBR

Port size

Sensor pressure

receiving area

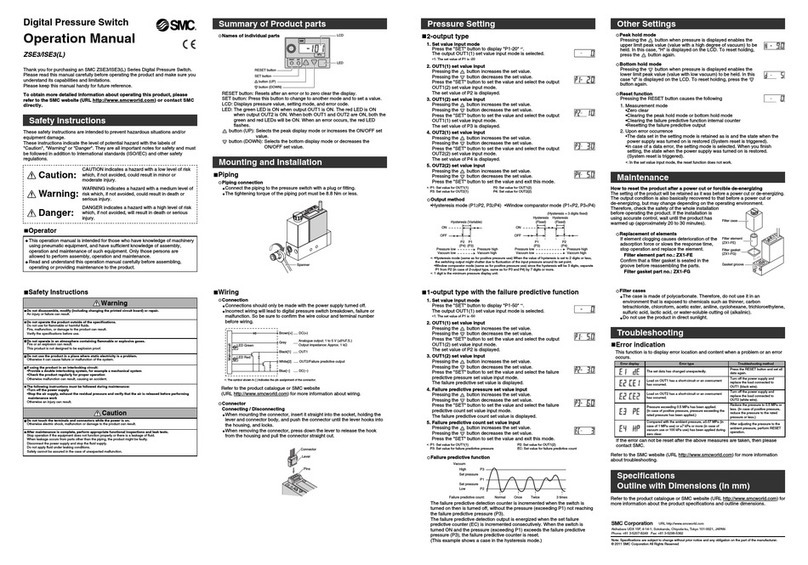

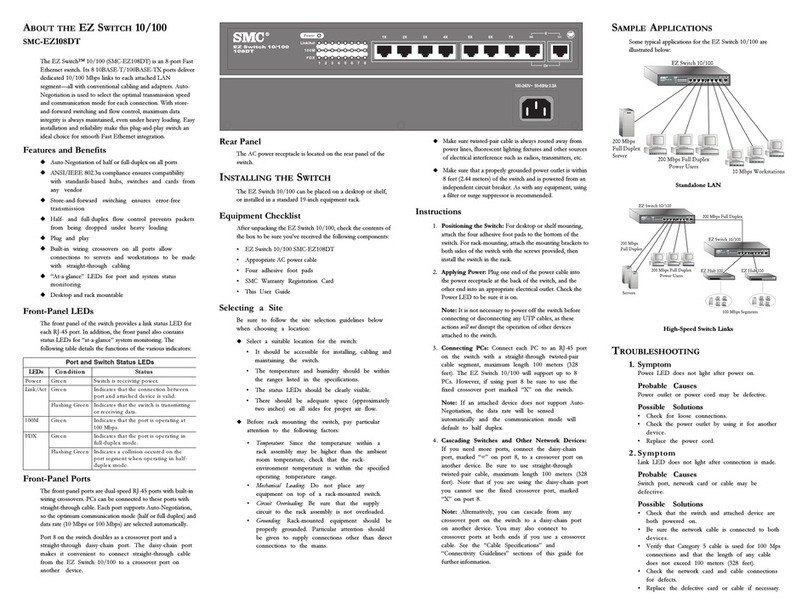

Model ZSE40A (vacuum pressure)

0.00 to –14.69 psi

1.45 to –15.23 psi

72.5 psi

0.01 psi

–14.50 to 14.50 psi

–15.22 to 15.22 psi

72.5 psi

0.02 psi

Air, Non-corrosive gas, Non-flammable gas

12 to 24 VDC ±10%, Ripple (p-p) 10% or less (with power supply polarity protection)

45 mA or less

NPN or PNP open collector 2 outputs (Selectable)

80 mA

28 V (at NPN output)

1 V or less

2.5 ms (with anti-chattering function: 20, 100, 500, 1000, 2000 ms)

Yes

±0.2% F.S. ±1 digit

Variable (0 or above) Note 1)

1 to 5 V ±2.5% F.S.

4 to 20 mA ±2.5% F.S.

Maximum load impedance: 300 Ω(Power supply voltage 12 V)

600 Ω(Power supply voltage 24 V)

Minimum load impedance: 50 Ω

Oilproof heavy-duty vinyl cable

ø3.5, 2 m Conductor area: 0.15 mm2(AWG26) Insulator O.D.: 0.95 mm

0.6 to 5 V ±2.5% F.S.

2.4 to 20 mA ±2.5% F.S.

–14.5 to 145.0 psi

–15.2 to 152.3 psi

218 psi

0.1 psi

Rated pressure range

Display/Set pressure range

Withstand pressure

Display/Minimum unit setting

Applicable fluid

Power supply voltage

Current consumption

Switch output

Repeat accuracy

Hysteresis

Maximum load current

Maximum applied voltage

Residual voltage

Response time

Short circuit protection

Hysteresis mode

Window comparator mode

Voltage

output

Analog

output

Current

output

Output voltage

(Rated pressure range)

Linearity

Output impedance

Output current

(Rated pressure range)

Linearity

Load impedance

Enclosure

Operating temperature range

Operating humidity range

Withstand voltage

Insulation resistance

Vibration resistance

Impact resistance

ZSE40AF

(compound pressure)

ISE40A (positive pressure)

Note 1) If the applied voltage fluctuates around the set-value, the hysteresis must be set to a value more than the fluctuating width, otherwise chattering will occur.

Note 2) When the analog voltage output is selected, the analog current output cannot be selected.

Note 3) When the analog current output is selected, the analog voltage output cannot be selected.

Note 2)

Note 3)

±1% F.S. or less

Approx. 1 kΩ

±1% F.S. or less

Non-voltage input (Reed or Solid state), Low level: 0.4 V or less, 5 ms or longer input

3 1/2-digit, 7-segment, 2-color LCD (Red/Green)

±2% F.S. ±1 digit (Ambient temperature of 77 ±5°F)

Lights up when output is turned ON. OUT1, OUT2: Orange

IP65

Operating: 23 to 122°F, Stored: 14 to 140°F (No freezing or condensation)

Operating/Stored: 35 to 85% RH (No condensation)

1000 VAC for 1 minute between live parts and case

50 MΩor more between live parts and case (at 500 VDC Mega)

10 to 150 Hz at whichever is smaller of 1.5 mm amplitude or 20 m/s2acceleration,

in X, Y, Z directions, for 2 hours each (De-energized)

100 m/s2in X, Y, Z directions, 3 times each (De-energized)

±2% F.S. (Based on 77°F)

CE marking, UL (CSA), RoHS compliance

Auto-shift input

Display

Display accuracy

Indicator light

Temperature characteristics

Lead wire

Standards

Environment

resistance

Material

of parts

in contact

with fluid

Weight

Piping port

2

Series ZSE40A(F)/ISE40A