E2E2

1-12-2 Kawana, Fujisawa

Kanagawa 251-8522 Japan

URL

: https://www.azbil.com

(11)

Specifications are subject to change without notice.

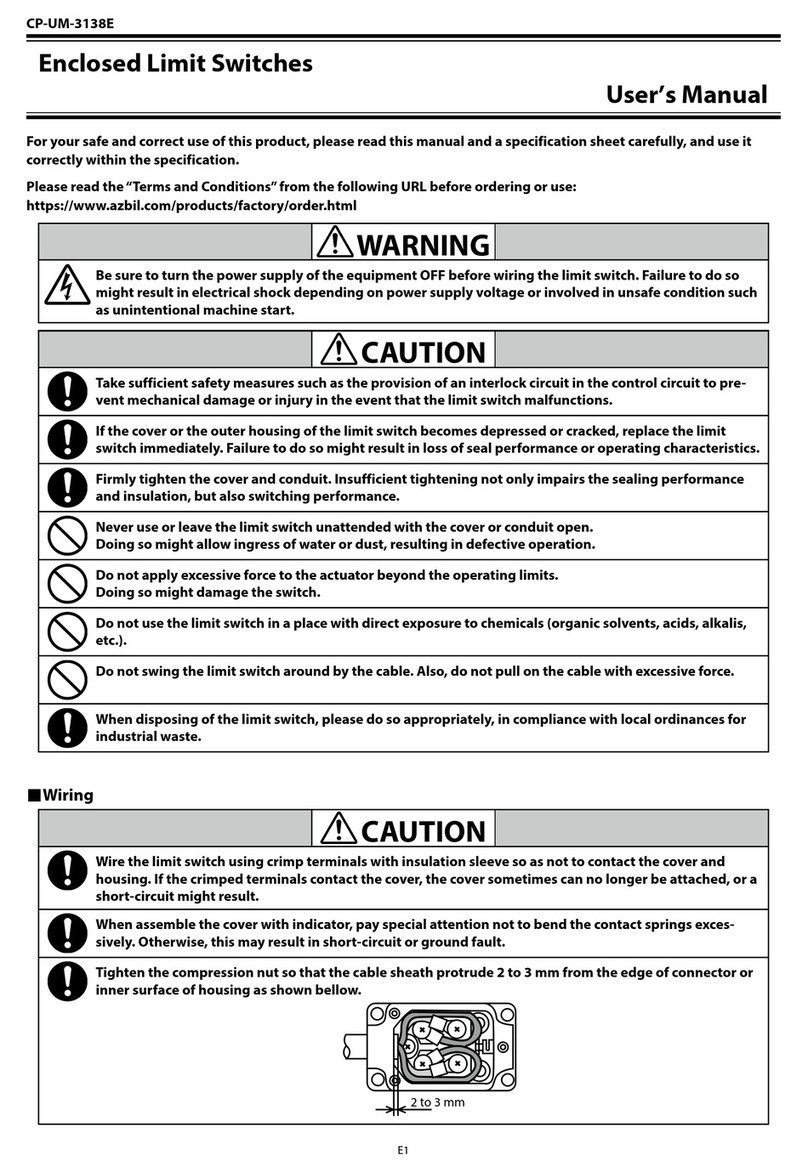

CAUTIONS FOR USE

• Use the included mounting screws for installation. The recommended

tightening torque is 1.6 to 2.1N·m. If screws other than the included

ones are used, be sure that they extend into this product at least 5mm.

Also, note that the use of stainless steel screws with this product can

lead to corrosion.

• Note that if this product is exposed to a corrosive environment such as

salt water (but not cutting oil), galvanic corrosion may result.

• Although the cable is oil-resistant, watch for hardening of the cable

outer sheath or loss of seal that can be caused by some kinds of oil

(such as non-watersoluble cutting oil or machine oil). Also, do not

allow water or oil to be splashed on the end of the cable.

• The lens cover is made of glass and can be damaged by a direct shock.

Do not use this product in an application where broken glass might

create a dangerous state.

• Do not connect this switch to AC power. Doing so might cause rupture

or burnout.

• Approx. 60ms is necessary after power on to reach stable operation.

•

Place a switch in the case to avoid sunlight or rain when used in outdoors.

• Avoid usage with big vibration or shock which may cause misalign-

ment of light axis.

• To avoid malfunction, install a shielding plate, etc., so that the lens is

not exposed to water or oil.

• Do not use in an atmosphere with chemicals (organic, acid, alkali).

• Confirm the stable operation by shielding or changing mounting di-

rection if ambient light is very strong.

• Keep dust away from lens by using sealed case and air purge.

• Put the protective cover on the switch if it is likely to be struck by an

object or person.

• Do not bend the part of the cable nearest to the switch with minimum

radius of 30mm and also avoid continuous bending stress.

• Cable cut may occur when cable is pulled with over 50N.

• Please wipe the reflector with soft cloth (dry or with a little water). Do

not use a organic solvent such as alcohol, benzine, acetone or thinner.

• Be careful of mutual interference when several switches are applied in

close proximity. Handle the switch with care.

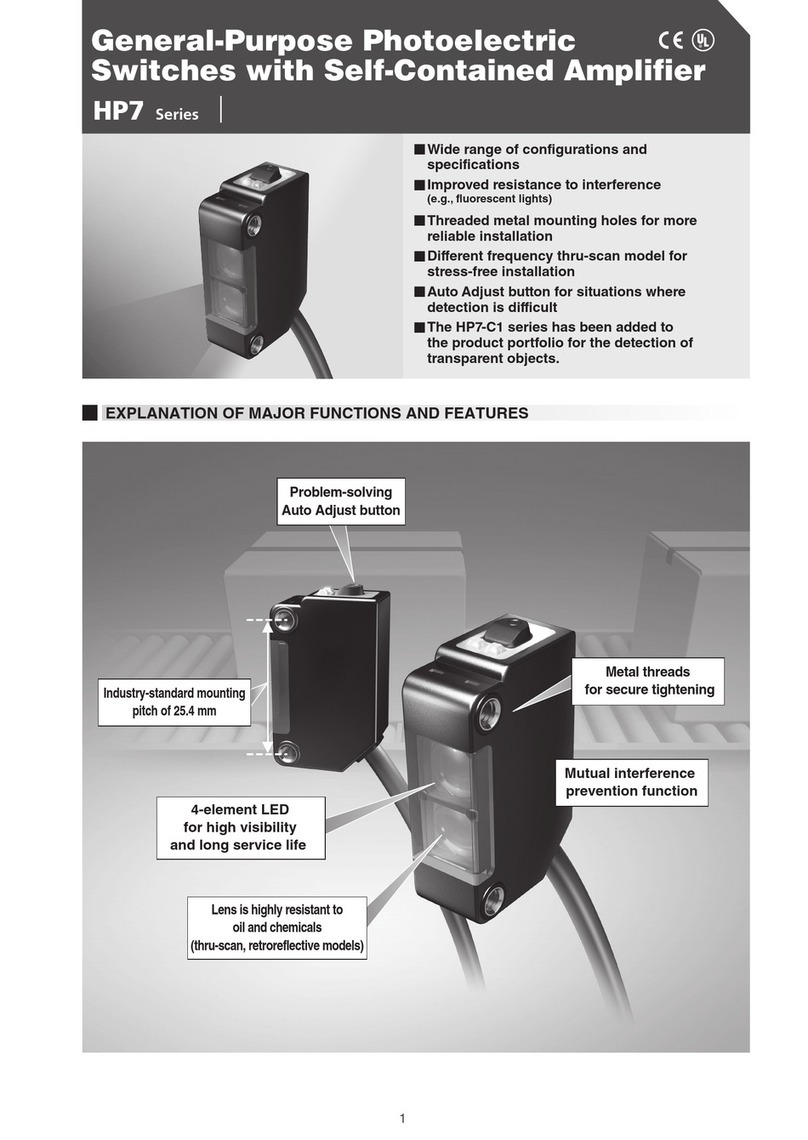

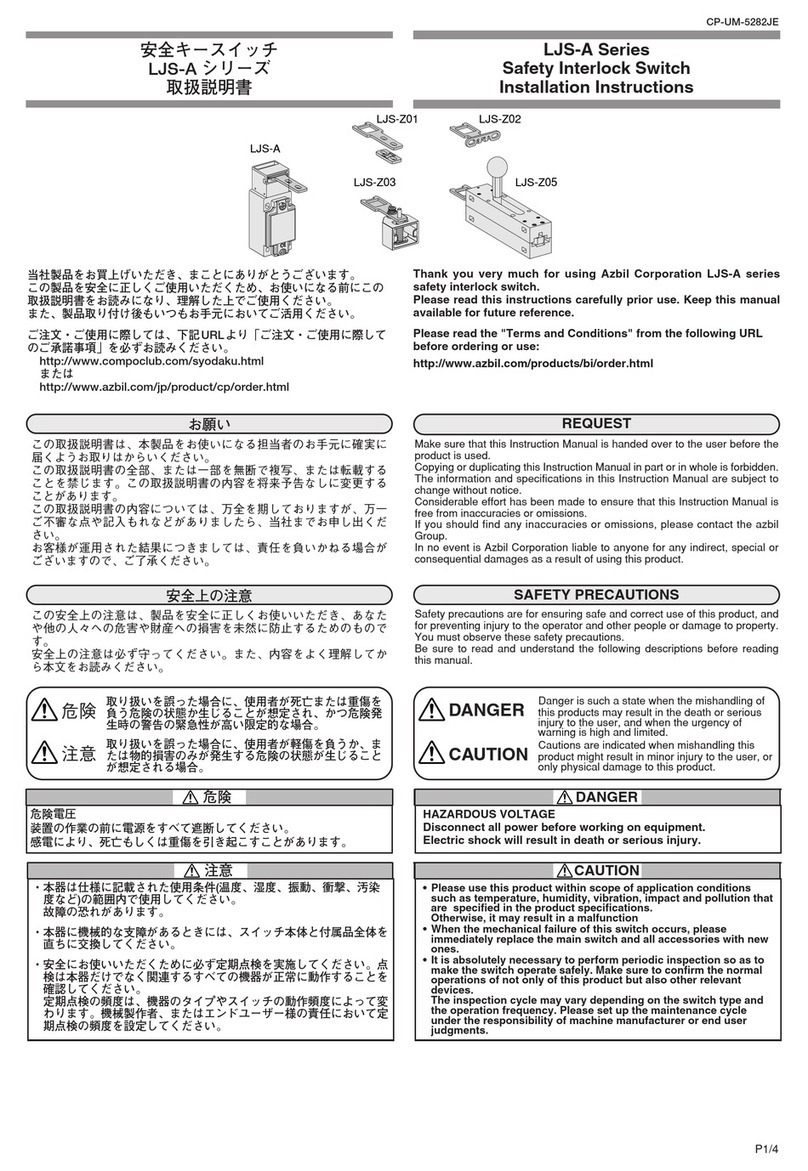

• For retroreflective-scan models, the optical axis of the emitter is in-

clined about 1 degree in order to prevent malfunctions caused when

detecting highly reflective objects or objects that disturb polarization

(transparent folding container, shrink wrap material, etc.).

Light-receiving axis

Light-emitting axis

Inclined about 1 degree

About one-third of the emitted light area (light spot) overlaps at the

top with the light-receiving area.

Light-receiving area

(invisible)

Reector

Emitted light area

(visible red light)

• If a retroreflective-scan is used to detect highly reflective objects or ob-

jects that disturb polarization, unreliable detection may result.

In such a case, take the following countermeasures:

Examples of target objects that might cause faulty operation:

• Objects covered with transparent film

• Translucent objects (such as a semitransparent case)

• Mirrors or highly reflective mirrorlike objects

Countermeasures to improve detection reliability

• Mount the switch at an angle to the target object.

• Increase the distance between the switch and the target object.

• It can be expected that cables will become stiff at low temperatures

(below 0°C). In such a case, avoid bending cables or subjecting them

to vibration or impact.

• Note that the operation button will become stiff at low temperatures

(below 0 °C).

WIRING CAUTIONS

• If cable extension is necessary, use at least 0.3mm2wire, and keep the

total cable length to no more than 100 m.

• Route the cables of the switch separately from power lines or through

an exclusive conduit, otherwise the electrical noise or surge may cause

incorrect operation or damage.

• When using a commercially available switching regulator, ground the

FG (frame ground) and G (ground) terminals. Otherwise the switch-

ing noise may cause incorrect operation.

• When using a load which generates a transient current, connect a cur-

rent limiting resistor between the load and the output terminal.

Otherwise the short-circuit protection may function.

DISPOSAL

Do not incinerate this product. It contains fluorocarbon resin and PVC

substances that expel poisonous gases when burned. When discarding

the H2B, dispose of it properly as industrial waste in accordance with

local regulations.

DIFFUSE-SCAN MODEL SETUP

Step1

The operation mode (Light-ON: LO, Dark-ON: DO) set when the

product is shipped is given in the model selection on page E1.

To switch between LO and DO, follow the instructions in

SWITCHING LO/DO. If no switching is necessary, go to Step 2.

Step2

After beam alignment, use a workpiece to check operation when

light is received and blocked. If the target is detected successfully, the

switch is set correctly. If not, follow the instructions in CHECKING

LO/DO .

Note: To check the LO/DO setting, see“CHECKING LO/DO.”

SWITCHING LO/DO

Press the button 5 times consecutively.

↓

LO

LO

↓

Orange LED only blinks rapidly

(about 10 Hz).

Green LED only blinks rapidly

(about 10 Hz).

Setup is complete.

Normal operation will be restored automatically (in about 2 seconds).

TUNING (no workpiece)

The orange LED blinks

rapidly

(about 10 Hz).

Hold down the button until the orange

LED starts blinking (about 2 seconds), and

release it.

↓

Both LEDs turn OFF.

Without a workpiece, give the button a short

press.

↓

Setup is complete.

If the switch does not work: when the sensing distance is too short (less

than 100 mm), the switch may not work due

to low light level. Increase the distance from

the background.

If LEDs Blink After Tuning (no workpiece)

LED indicators Status Solution

Orange LED only blinks

slowly.

Setup is not possible.

Background reflection is

too strong.

Pressing the button

once resumes normal

operation with the pre-

vious settings.

Reduce the background

reflection.

Both LEDs blink slowly

at the same time.

Setup is complete but

the amount of light

reflected is too large

to ensure a suffcient

margin.

If the button is pressed

once, settings are ad-

justed according to the

Tuning results.

If adjustment is needed,

reduce the reflection

from the background.

If the LEDs blink after 2-point tuning, contact the local azbil office.

When confused, or to restore the default setting

(max. sensitivity)

The green LED blinks

rapidly

(about 10 Hz).

Hold down the button until the green LED

starts blinking (about 7 seconds).

↓

Setup is complete.

Normal operation will be restored auto-

matically (in about 2 seconds).

The default setting (maximum sensitivity)

is restored.

2-POINT TUNING

For 2-point tuning, set the operating point halfway between the incom-

ing light levels with a workpiece and without a workpiece.

The orange LED blinks

rapidly

(about 10 Hz).

Hold down the button until the orange LED

starts blinking (about 2 seconds),

and release it.

↓

Both LEDs blink rapidly

together

(about 10 Hz).

Without a workpiece, hold down the but-

ton until both LEDs start blinking (about 2

seconds),

and release it.

↓

Both LEDs turn OFF.

With a workpiece in place, give the button a

short press.

↓

Setup is complete.

Normal operation will be restored automatically. If the LEDs blink, con-

tact the local azbil office.

CHECKING LO/DO

Press the button 3 times consecutively.

About 2 seconds later

Orange LED only blinks rapidly

(about 10 Hz).

Green LED only blinks rapidly

(about 10 Hz).

©2019–2020 Azbil Corporation. All Rights Reserved.

1st edition: July 2019 (V)

2nd edition: Feb. 2020 (V)