Stahlwille SmartCheck User manual

English version of original German

operating instructions

EN

SmartCheck torque tester

Status: 07/2017

Contents

Notes on the instructions and the manufacturer .......................... 5

Availability ...................................................................................... 6

Other applicable documents .......................................................... 6

Structural features ......................................................................... 6

Safety ............................................................................................. 7

Structural features of the warning notices ..................................... 7

Structural features of notices referring to material damage .......... 7

Proper use, operating area ............................................................ 8

Basic safety instructions ................................................................ 8

Avoiding material damage ............................................................. 9

Handling batteries and rechargeable batteries ........................... 10

Warranty and liability ................................................................... 11

Personnel training ....................................................................... 11

Personal safety equipment .......................................................... 11

Description ................................................................................... 12

Overview of the device ................................................................ 13

Environmental conditions ............................................................ 14

Type plate .................................................................................... 14

Technical data ............................................................................. 15

Transport, scope of delivery, storage ......................................... 16

Transporting the DPG ................................................................. 16

Scope of delivery ......................................................................... 16

Storing the DPG .......................................................................... 16

Fastening the DPG and preparing for operation ........................ 17

Fastening the DPG ...................................................................... 17

Aligning the display ..................................................................... 20

Establishing the current supply .................................................... 21

Operation ..................................................................................... 25

Operating module ........................................................................ 25

Switching the DPG on .................................................................. 26

Setting the mode .......................................................................... 27

Setting the torque unit .................................................................. 28

Setting the target torque .............................................................. 29

Setting the torque target zone ..................................................... 30

Resetting the display ................................................................... 32

Resetting the display prior to direction changes .......................... 33

Overload warning ......................................................................... 33

Switching the DPG off .................................................................. 34

Testing torque wrenches ............................................................. 35

Connecting a torque wrench to the DPG ..................................... 35

General measurement of torques ................................................ 37

Testing indicating torque wrenches ............................................. 38

Testing click type torque wrenches ............................................. 39

Eliminating faults or malfunctions .............................................. 41

Cleaning ....................................................................................... 43

Calibrating the DPG ..................................................................... 43

Disposal ....................................................................................... 44

EU declaration of conformity ...................................................... 45

Notes on the instructions and the

manufacturer

5

Notes on the instructions and the

manufacturer

These operating instructions help you to use the SmartCheck torque

tester, abbreviated to DPG in the following, properly, safely and

economically.

These instructions are aimed at each person who performs the

following activities with and on the DPG:

•Transportation

•Assembly

•Operation

•Cleaning

•Disposal

In particular, these instructions are aimed at trained specialist

personnel and qualified and authorised operating personnel.

Each of these persons must have read and understood the contents

of these instructions. Compliance with these instructions helps to

avoid dangers and to increase the reliability and service life of the

DPG. In addition to the notes contained in these instructions, also

always observe the legal and other regulations applicable at the

installation location, such as e.g.:

•Accident prevention regulations

•Regulations for safe and proper work.

Notes on the instructions and the

manufacturer

6

Availability

These instructions are part of the DPG. Always store these

instructions along with the documentation on the DPG. Make sure

that the instructions are available to the user. Enclose these

instructions if you sell the DPG or pass it on in any other manner.

Other applicable documents

Also observe and comply with the information in the other applicable

documents. Other applicable documents particularly include the

following document types:

•DPG factory calibration certificate

•Operating instructions of the torque wrenches to be tested

Structural features

Defined structural features are assigned to the various elements

within the operating instructions. You can therefore easily determine

the type of text which this involves:

Normal text,

"BUTTONS" on the DPG

•Lists, first level

−Lists, second level or

Action steps.

Tips. General information and information regarding the

economical use of the DPG is provided here.

Safety

7

Safety

Structural features of the warning notices

DANGER

Notices containing the word DANGER warn of hazards

which lead directly to severe or fatal injuries.

CAUTION

Notices containing the word CAUTION warn of hazards

which may possibly lead to minor to moderate injuries.

Structural features of notices referring to material

damage

ATTENTION

Notices containing the word ATTENTION warn of

hazards in which property damage may possibly occur.

Safety

8

Proper use, operating area

The SmartCheck type 10, 100, 400 and 800 torque testers are

suitable for testing tracking and click type torque wrenches as well as

for generally measuring torques.

The SmartCheck type 10S torque tester is exclusively suitable for

testing tracking and click type torque screwdrivers.

Use in explosive areas is prohibited.

Proper use also includes observing and compliance with all of the

data in these instructions. This particularly applies to observing and

compliance with all safety instructions and warning notices as well as

the technical limit values. The DPG must only be used by personnel

trained in using the DPG.

Any other, or more extensive, use is regarded as improper, and can

lead to material damage or personal injury

Basic safety instructions

Avoiding a risk of explosion

Risk of explosion due to use of the DPG in explosive areas.

Do not use the DPG in explosive areas.

Avoiding electric shock

There is a risk of fatal accident due to electric shock if you ignore the

following safety instructions:

Never open the DPG housing.

Use only the CE-conformant plug-in power supply unit included in

the scope of delivery, see Page 15.

Prior to cleaning work on the DPG, disconnect the plug-in power

supply unit from the DPG.

Safety

9

Avoiding hazards due to improper assembly

If the DPG is not assembled properly, there is a risk of losing the

balance weight during testing. This can result in broken bones,

bruises and crushing.

Mount the DPG firmly on a worktop

Avoiding injuries due to incorrect handling

A risk of dropping occurs if an unfastened DPG is handled

incorrectly. This can result in broken bones, bruises and crushing.

Only grip the DPG at the mounting bracket.

Wear safety shoes with steel toecaps.

Avoiding hearing damage

When testing click type torque wrenches, the triggering impact

causes a sound pressure level. This can cause noise-induced

hearing loss.

Wear ear protectors in this case.

Avoiding material damage

The DPG is precision test equipment, and must be handled with the

greatest of care. Avoid mechanical, chemical or thermal effects

which exceed the stresses involved in proper use.

Soiling or moisture can lead to material damage and influence the

measurement accuracy.

Safety

10

Avoid material damage on the DPG and the torque wrenches

through the following measures:

Make sure that the torque wrenches are not damaged.

Only test the torque wrenches in the manner described in these

operating instructions.

Do not overload the DPG.

Only use the DPG for testing in the measuring range intended for

this.

Handling batteries and rechargeable batteries

Children could swallow the batteries and rechargeable batteries and

choke on them.

Make sure that batteries and rechargeable batteries are kept out of

the reach of children.

Batteries and rechargeable batteries may contain poisonous

substances which pollute the environment.

Dispose of batteries and rechargeable batteries according to the

applicable legal regulations.

Leaking batteries and rechargeable batteries may cause damage to

the DPG.

If the DPG is not used for a long time, remove the batteries or

rechargeable batteries.

Replace weakening batteries or rechargeable batteries in good

time.

Do not charge batteries.

Only use batteries or rechargeable batteries according to the data

from Page 15.

Safety

11

Warranty and liability

Warranty and liability claims in the event of personal injury and

material damage are inadmissible if they are attributable to one or

more of the following causes:

•Improper use of the DPG.

•Improper assembly, operation and cleaning of the DPG.

•Non-observance of the notes in the DPG operating instructions.

•Unauthorised modification of the DPG's properties.

•Improperly performed repairs.

Personnel training

•Only personnel which has been trained in handling the DPG or has

been familiarised by a trained person may work with the DPG.

•The personnel must be familiar with the application and handling of

torque wrenches.

•Personnel undergoing on-the-job training may only work with the

DPG under the supervision of an experienced person.

Personal safety equipment

Crushing of feet possible due to a DPG being dropped during lifting

and carrying.

Wear safety shoes with steel toecaps.

Noise-induced hearing loss possible due to the triggering impact of a

torque wrench.

Wear ear protectors.

Description

12

Description

The SmartCheck type 10, 100, 400 and 800 torque testers are

suitable for testing tracking and click type torque wrenches as well as

for generally measuring torques.

The SmartCheck type 10S torque tester is exclusively suitable for

testing tracking and click type torque screwdrivers.

Use in explosive areas is prohibited.

The DPG has a stable plastic housing. The mounting bracket is

made of metal. The holes present in the mounting bracket enable

fastening in a vertical or horizontal position. STAHLWILLE

recommends fastening in a vertical position, see Page 18.

The transducer is integrated into the plastic housing. Refer to the

technical data for the respective measuring range.

The DPG's display deviation is ±1 %.

Current can be supplied using the power supply unit included in the

scope of delivery or with batteries or rechargeable batteries.

Diverse setting options are available to guarantee perfect reading of

the display.

Three modes are available:

•Track, for general measurement of torques

•Peak Hold, for indicating torque wrenches

•First Peak, for click type torque wrenches.

Description

13

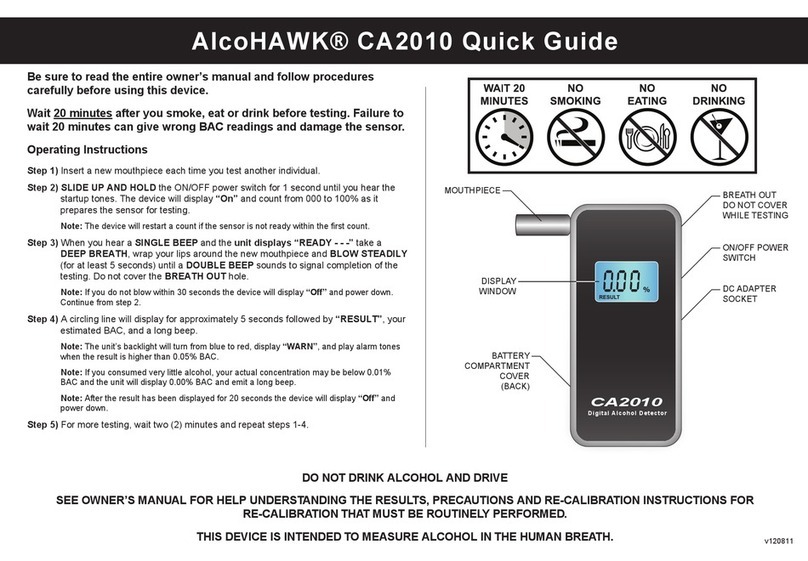

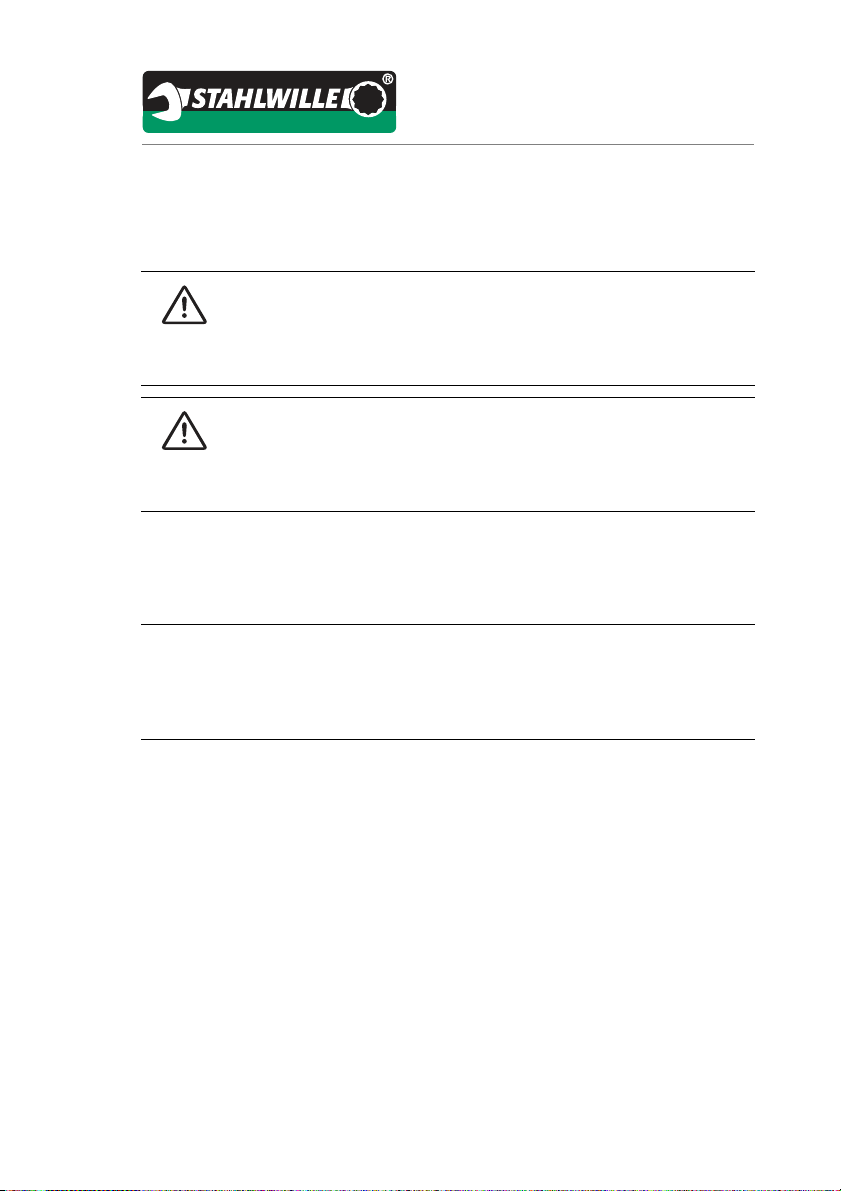

Overview of the device

1

2

5

3

4

No. Designation

1 Mounting bracket

2 Connection socket for power supply unit

3 Display, mounted for rotation

4 Battery compartment

5 Recessed square on transducer

Description

14

Environmental conditions

The ambient temperature during use must lie between –2 °C and

+60 °C.

Make sure that the DPG can adapt to the prevailing ambient

conditions for at least one hour prior to use.

Type plate

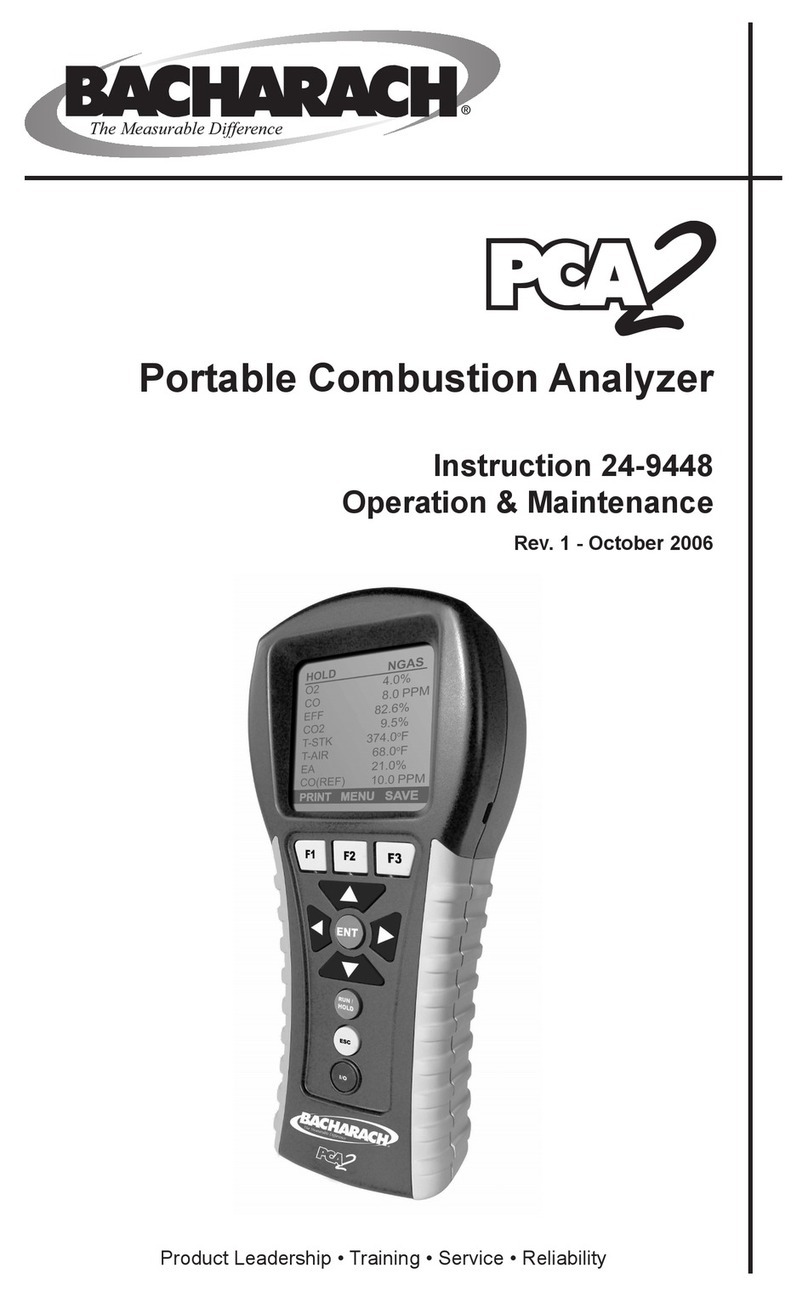

The type plate is attached to the DPG's housing. The DPG's nominal

value corresponds to the type. The figure shows a type plate for a

type 100 DPG (nominal value 100 N‧m).

N m

in.lb

ft.lb

www.stahlwille.de RoHS

MADE IN GERMANY

IP 20

>PA<

S/N XXXXXXXXX

10 - 100

89 - 885

7 - 74

SmartCheck

Description

15

Technical data

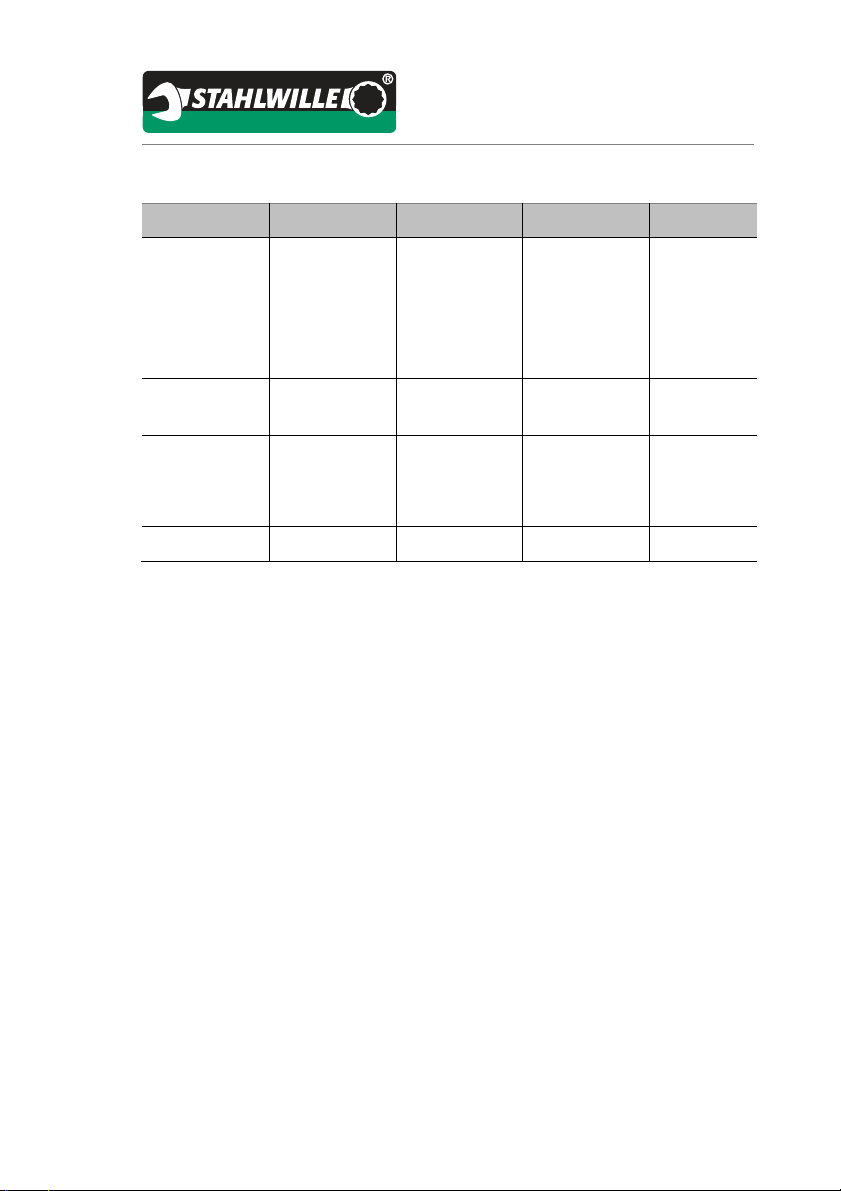

Type 10S*, 10 100 400 800

Measuring

range

N‧m

ft‧lb

in‧lb

1–10

0.74–7.4

8.9–88.5

10–100

7–74

89–885

40–400

30–295

354–3540

80–800

59–590

708–7081

Recessed

square

1/4" 3/8" 3/4" 3/4"

Width [mm]

Height [mm]

Depth [mm]

120

124

167

120

124

167

120

124

167

120

124

167

Weight [g] 5210 5310 5690 5690

* For checking torque screwdrivers

Plug-in power supply unit:

Input: 110–230 VDC, 50–60 Hz

Output: 9 VDC, jack plug 5 mm/2 mm with (+)

Batteries/rechargeable batteries:

9 V block battery or rechargeable battery or

Four 1.5 V AAA batteries or rechargeable batteries

Transport, scope of delivery, storage

16

Transport, scope of delivery, storage

Transporting the DPG

The DPG weighs 5 to 6 kg. Transport the DPG only in the

accompanying plastic case, and secure this sufficiently against being

dropped during transport.

Scope of delivery

The DPG's scope of delivery includes the following:

•Plastic case incl. inserts

•Torque tester

•Plug-in power supply unit incl. four adapters for different countries

•Factory calibration certificate

•Operating instructions

•Reduction adapter

−From 3/8" to 1/4" DPG type 100

−From 3/4" to 1/2" DPG type 400

Storing the DPG

Store the DPG only in the accompanying plastic case.

Ensure the following storage conditions:

•Relative humidity: 20–60%, non-condensing

•Temperature: –20 to +60 °C

Fastening the DPG and preparing for

operation

17

Fastening the DPG and preparing for

operation

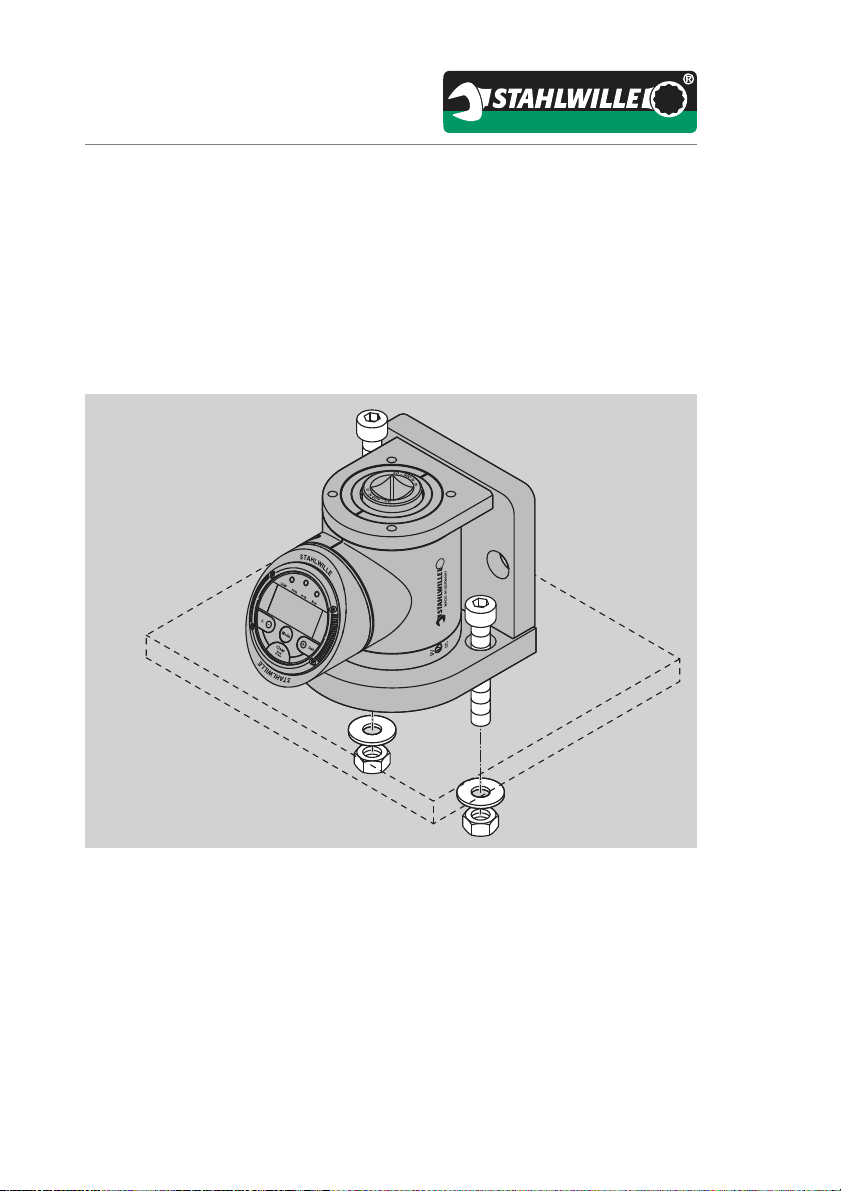

Fastening the DPG

The DPG is suitable for vertical or horizontal installation. Vertical or

horizontal refers to the position of the transducer axis.

STAHLWILLE recommends fastening

the DPG the vertical

transducer axis position.

To be able to work with the DPG, it must first be fastened securely.

The base must be sufficiently solid, e.g. a worktop. The worktop

must be approx. 30 to 50 mm thick.

Use the following for fastening:

•Two cheese head screws with hexagon socket M10 according to

ISO 4762, material strength 10.9

•Two washers

•Two hexagon nuts M10

CAUTION

Broken bones, bruises and crushing during assembly.

The DPG can fall down during handling.

Wear safety shoes with steel toecaps.

CAUTION

Risk of injury due to inadequate fastening of the DPG.

The DPG can fall down.

Fasten the DPG securely.

Wear safety shoes with steel toecaps.

Fastening the DPG and preparing for

operation

18

To fasten the DPG on a worktop, proceed as follows:

Drill clearance holes with a diameter of 12 mm in the worktop.

Bolt the DPG so firmly to the base (70 N‧m) using the intended

holes that it can absorb stresses caused by the torque values to be

tested.

Secure each of the hexagon socket head screws with a washer

and a nut.

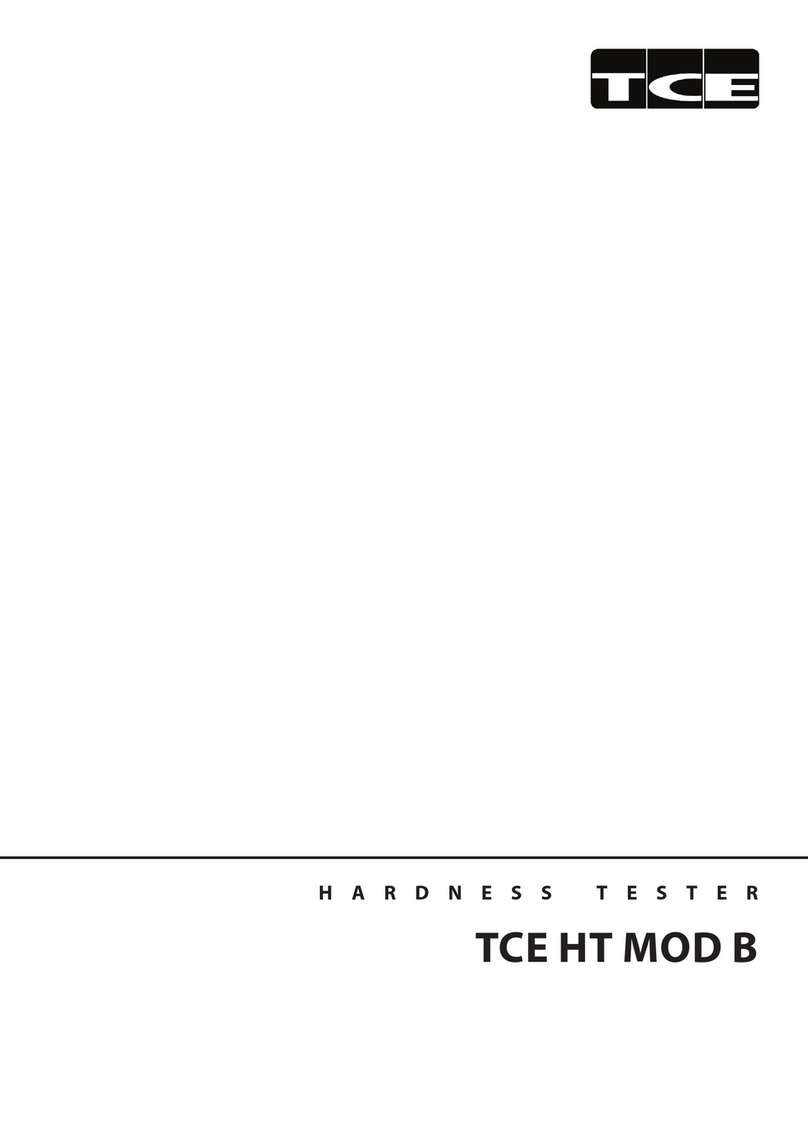

Example of vertical fastening:

Fastening the DPG a

nd preparing for

operation

19

Example of horizontal fastening:

Fastening the DPG and preparing for

operation

20

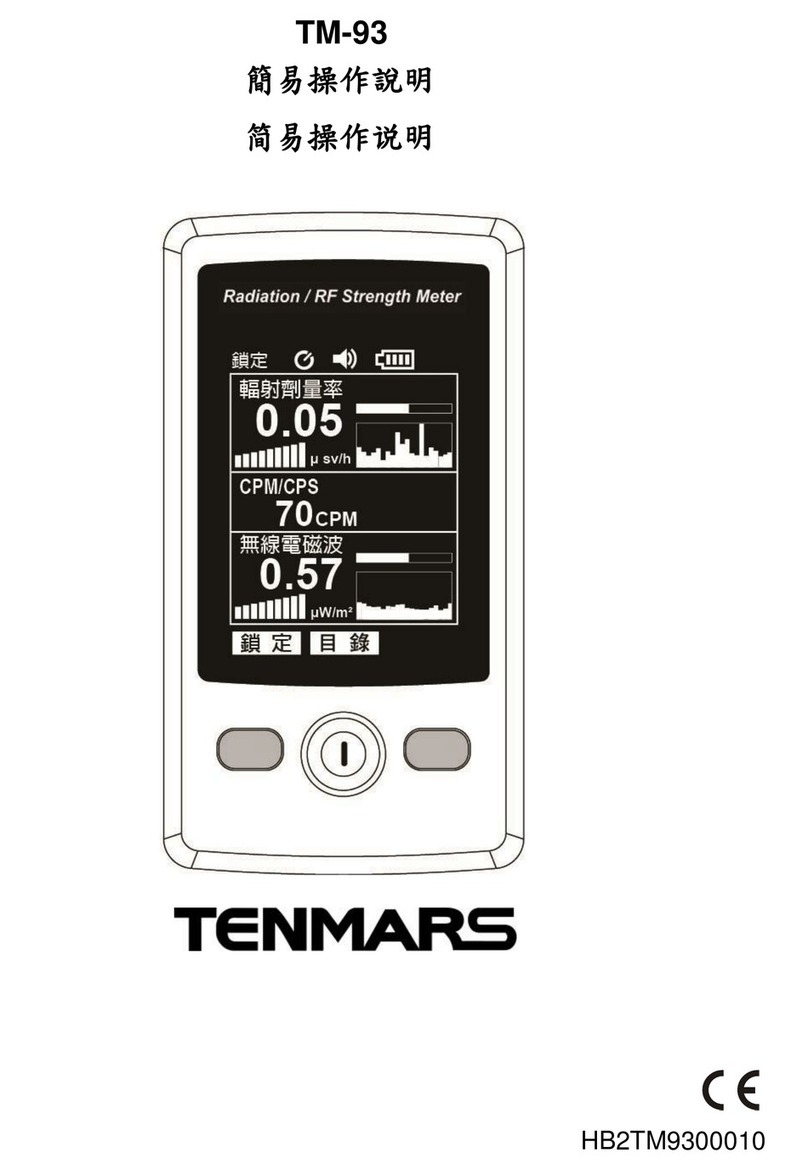

Aligning the display

To read the display clearly, it can be set as shown in the following for

your application.

180°

180°

180°

Table of contents

Other Stahlwille Test Equipment manuals

Popular Test Equipment manuals by other brands

Dräger

Dräger X-dock 5300 Instructions for use

Tektronix

Tektronix DPO3000 Series Installation

Gossen MetraWatt

Gossen MetraWatt METRALINE PAT operating instructions

Dwyer Instruments

Dwyer Instruments UHH Installation and operating instructions

Bosch

Bosch FSA 500 instructions

Sanxin

Sanxin EC5 Operation manual