Simpson 42145 User manual

www.simpsongroup.com

Operating Instructions

Electronic Scratch Hardness Tester

Model 42145

www.simpsongroup.com

Type:

Electronic Scratch Hardness Tester

Model No.:

42145

Part No.:

0042145

Serial No.:

Name and Address of Manufacturer:

Simpson Technologies Corporation

751 Shoreline Drive

Aurora, IL 60504

For other Simpson Technologies offices around the world and for our

contact information please visit us on the internet at

www.simpsongroup.com on the Contacts page.

This document is strictly confidential.

This document is protected under the copyright laws of the United States and other countries as an

unpublished work. This document contains information that is proprietary and confidential to

Simpson Technologies Corporation or its subsidiaries which shall not be disclosed outside or

duplicated, used or disclosed in whole or in part for any purpose other than to evaluate Simpson

Technologies for a proposed transaction. Any use or disclosure in whole or in part of this information

without the express written permission of Simpson Technologies Corporation is prohibited.

© 2021 Simpson Technologies Corporation. All rights reserved.

Table of Contents

man-stc-42145-V17-22 Electronic Scratch Hardness Tester i

Table of Contents

1Introduction 1

1.1 Application and Designated Use ...................................................1

1.2 Organizational Measures................................................................1

2Safety 2

2.1 Safety Alert Symbols ......................................................................2

3Short Description & Specifications 4

3.1 Description.......................................................................................4

3.2 Software Functions.........................................................................4

3.3 Specifications..................................................................................4

4Unpacking and Installation 6

4.1 Unpacking and Parts List...............................................................6

4.2 Preparation - Battery Status...........................................................7

4.3 Installing Software and Connection to PC ...................................7

5Operating Instructions 9

5.1 Description.......................................................................................9

5.2 User Information Screens ............................................................11

5.2.1 User Name Screen Description ............................................11

5.2.2 Current Scale Type Screen Description................................11

5.2.3 Last Calibration Screen Description......................................11

5.2.4 Actual Date/Time Screen Description...................................12

5.3 Setup Description..........................................................................12

5.3.1 Editing User Name................................................................13

5.3.2 Editing Mold Identification Name ..........................................13

5.3.3 Calibration Points..................................................................14

5.3.4 Timer and Battery Status ......................................................14

Table of Contents

ii Electronic Scratch Hardness Tester man-stc-42145-V17-22

5.3.5 Viewing Memory Status - Setup Description ........................15

5.3.6 Exiting Setup Mode...............................................................15

5.4 First Use.........................................................................................16

5.5 Working Modes Screen Description ........................................... 17

5.5.1 Store Data Into Tester Memory ............................................18

5.5.2 Point Mode............................................................................18

5.5.3 Link Mode .............................................................................20

5.6 Input Data to Excel Spreadsheet.................................................21

6Calibration, Maintenance and Warranty 23

6.1 Daily Maintenance.........................................................................23

6.2 When Required..............................................................................23

6.3 Setting Calibration Points............................................................24

6.4 Care for Your Electronic Scratch Hardness Tester...................26

6.5 Warranty, Service and Support ...................................................26

7Parts List / Ordering Parts / Returns 27

7.1 Spare Parts List.............................................................................27

7.2 Ordering Replacement / Spare Parts ..........................................27

7.3 Returned Goods Policy ................................................................ 27

8Decommissioning 30

Introduction 1

man-stc-42145-V17-2 Electronic Scratch Hardness Tester 1

1 Introduction

Congratulations, you have just purchased an extremely reliable sand

testing instrument that is backed by the professional technical support

and years of proven sand technology experience of Simpson

Technologies Corporation.

This laboratory equipment is constructed of quality materials and is

the result of unsurpassed craftsmanship. The Electronic Scratch

Hardness Tester (Model 42145) should be operated only when it is in

perfect condition, in accordance with its designed purpose and being

aware of possible hazards. Observe the safety instructions in Section

2 and operating instructions in Section 5.

1.1 Application and Designated Use

The Electronic Scratch Hardness Tester (Model 42145), is intended

exclusively for measuring the hardness of the core or mold present in

foundry molding sands. Usage of other materials may be possible

upon consultation with the Service department of Simpson

Any other application outside the intended usage will be regarded as

use not in accordance with its purpose, and, therefore, the

manufacturer/supplier will not be held liable for any damage that

might arise thereunder. The risk in this case will be exclusively that of

the user.

1.2 Organizational Measures

The operating instructions should be readily available at the place of

operation. In addition to the operating instructions, the general legal

regulations or other mandatory rules for prevention of accidents and

environmental protection should be made known and be observed!

The personnel instructed to use this apparatus, before beginning

work, should have studied and fully understood these Operating

Instructions, in particular the “Safety” chapter.

No modifications, extensions or changes of design of the device that

would impact safety requirements should be put into effect without

prior consent of the supplier! Spare parts must conform to the

technical specifications defined by the manufacturer. This is always

guaranteed when using original spares.

2 Safety

2Electronic Scratch Hardness Tester man-stc-42145-V17-22

2 Safety

The following Safety Instructions must be studied by

the responsible personnel before commissioning

and adhered to when operating the machine.

2.1 Safety Alert Symbols

This Manual does not imply any guarantee, but just has the intention

of conveying technical information. We reserve the right to modify the

contents of these Operating Instructions.

To facilitate quick comprehension and secure handling the symbols

used in the publication are shown below.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. OBEY all safety messages

that follow this symbol to avoid possible injury or death.

Indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

The safety alert symbol used without a signal word

to call attention to safety messages indicates a

potentially hazardous situation which, if not avoided,

could or may result in death or minor injury.

NOTICE indicates information used to address

practices not related to personal injuries but may

result in property damage.

This symbol indicates information containing important instructions

concerning the use of the machine or directions for further

procedures. Ignoring this information can lead to malfunction of the

machine.

Safety 2

man-stc-42145-V17-2 Electronic Scratch Hardness Tester 3

Use only the battery specified for the tester.

Always safely dispose of the battery according to local regulations.

Never expose battery to direct heat or dispose of it by

incineration!

Improperly using the battery can cause it to leak and damage

nearby items and may cause the risk of fire or personal injury.

We reserve the right to all modifications which do not affect the

technical content of these Operating Instructions.

3 Short Description & Specifications

4Electronic Scratch Hardness Tester man-stc-42145-V17-22

3 Short Description & Specifications

3.1 Description

The scratch hardness of a mold or core is determined using the

Simpson Electronic Scratch Hardness Tester (Model 42145). The

instrument incorporates a four point cutter that penetrates a finished

core or mold surface when rotated. The depth of penetration of the

cutter into the specimen determines the hardness of the core or mold.

The use of advanced electronics increases the accuracy of the

instrument. The Electronic Scratch Hardness Tester is lightweight,

portable and engineered for foundry use.

The instruction will automatically record the hardness number every 360

degrees of cutter rotation. This instrument will display, for a defined

time, the resultant scratch hardness value in the LCD.

3.2 Software Functions

•Store and display date of last calibration

•Store and display user name

•Point to Point mode

•Store up to 900 data points

•Identify up to 32 molds

•Digital calibration of displacement

•Infrared data transfer to computer

3.3 Specifications

Requirements

Electronic Scratch Hardness Tester (42145)

Power

AAA Rechargeable NiMH Battery

(Battery Charger not included)

Software

IBM Compatible, Windows Software

Short Description & Specifications 3

man-stc-42145-V17-2 Electronic Scratch Hardness Tester 5

Dimensions/Weights

Electronic Scratch Hardness Tester (42145)

Length

140 mm (5.5 in.)

Width

64 mm (2.5 in.)

Height

32 mm (1.25 in.)

Weight

Tester only - .25 kg (.55 lbs.)

4 Unpacking and Installation

6Electronic Scratch Hardness Tester man-stc-42145-V17-22

4 Unpacking and Installation

4.1 Unpacking and Parts List

Check the package for transport damages upon receipt and complete-

ness of the order in accordance with the Packing List. Any transport

damages or missing parts should be reported immediately to both the

carrier and equipment supplier.

Protect the device from atmospheric conditions that may be harmful.

Failure to follow this instruction may nullify any claims under warranty.

The following equipment should be included in the package:

(Figure 1)

» Electronic Scratch Hardness Tester Unit

» Infrared IR receiver unit, USB cable

» AAA Battery (Ni-MH rechargeable is included)

» Calibration assembly; including mounting fixture, micrometer and,

aluminum foot (for use in manufacturer’s calibration; call Simpson

for details)

» USB thumb drive (including instructions and drivers to download

data)

» Holster

Figure 1

Unpacking and Installation 4

man-stc-42145-V17-2 Electronic Scratch Hardness Tester 7

4.2 Preparation - Battery Status

The unit comes complete with a rechargeable Ni-MH AAA battery that

can be charged in any standard battery charger (not included). The Ni-

MH battery that comes with the unit should be fully charged according

to the OEM's battery charger (not included) before use. The battery has

a life of 8+ hours and may be recharged a total of 500 times before it

must be replaced.

Use only the battery specified for the tester in this manual.

Always ensure that the positive (+) and negative (-) ends of the

battery are facing correctly when loading battery into the tester.

Always safely dispose of the battery according to local regulations.

Never expose battery to direct heat or dispose of it by

incineration!

Improperly using the battery can cause it to leak and

damage nearby items and may cause the risk of fire or

personal injury.

Figure 2

4 Unpacking and Installation

8Electronic Scratch Hardness Tester man-stc-42145-V17-22

4.3 Installing Software and Connection to PC

1. Insert supplied USB thumb drive into your computer’s USB port and

copy the file Simpson eLab x86 x64 r1 to a convenient location on

your hard drive. If you wish, you can make a shortcut Icon on your

desktop for quick access.

2. Follow the instructions included on the enclosed thumb drive to

transfer the data.

a. Process to verify if PC recognized the USB cable

b. Process to allow to open macros in excel.

c. Process to collect data from the equipment.

3. Save the USB thumb drive as your master for the program file. Do

not link any data to the supplied thumb drive.

4. If you have trouble installing the software, see the back cover for

contacting us.

5. Assemble the cord (Figure 3). The “USB” connector plugs into the

USB port of the PC. Position the IR receiver facing to the Infrared

Data Port from the Tester.

Figure 3: USB Cable and Infrared IR Receiver

Operating Instructions 5

man-stc-42145-V17-2 Electronic Scratch Hardness Tester 9

5 Operating Instructions

For more information on how to use and care for your

Simpson Analytics equipment and accessories visit our

Simpson Technologies channel on YouTube and search

our library of videos. Subscribe to our channel to keep

updated on new releases.

5.1 Description

Scratch hardness of a mold the measurement of the surface hardness

of the mold. This is accomplished by removing material on the surface

of the mold and measuring the depth of penetration.

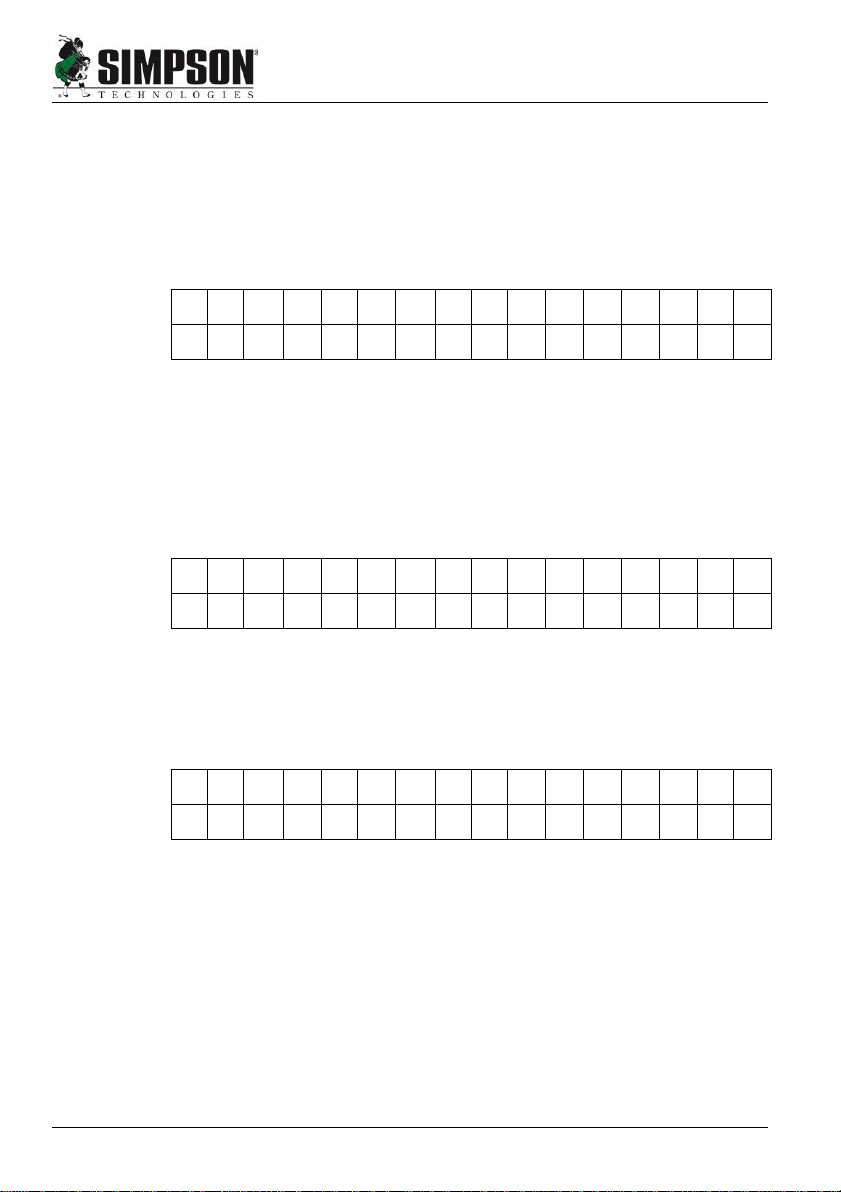

•Refer to Figures 4-6 for location of the various components while

following this instruction manual:

Figure 4

Item

Description

1

Penetrator Head

2

LCD Screen

3

MENU Button

4

UP Button

5

RIGHT Button

6

ENTER Button

5Operating Instructions

10 Electronic Scratch Hardness Tester man-stc-42145-V17-22

Figure 5

Item

Description

1

Battery Compartment

2

Infrared Data Port

3

Covered Spring Port

(DO NOT REMOVE RUBBER COVER)

Figure 6: Collar (1) Penetrator (2) and Body (3)

Operating Instructions 5

man-stc-42145-V17-2 Electronic Scratch Hardness Tester 11

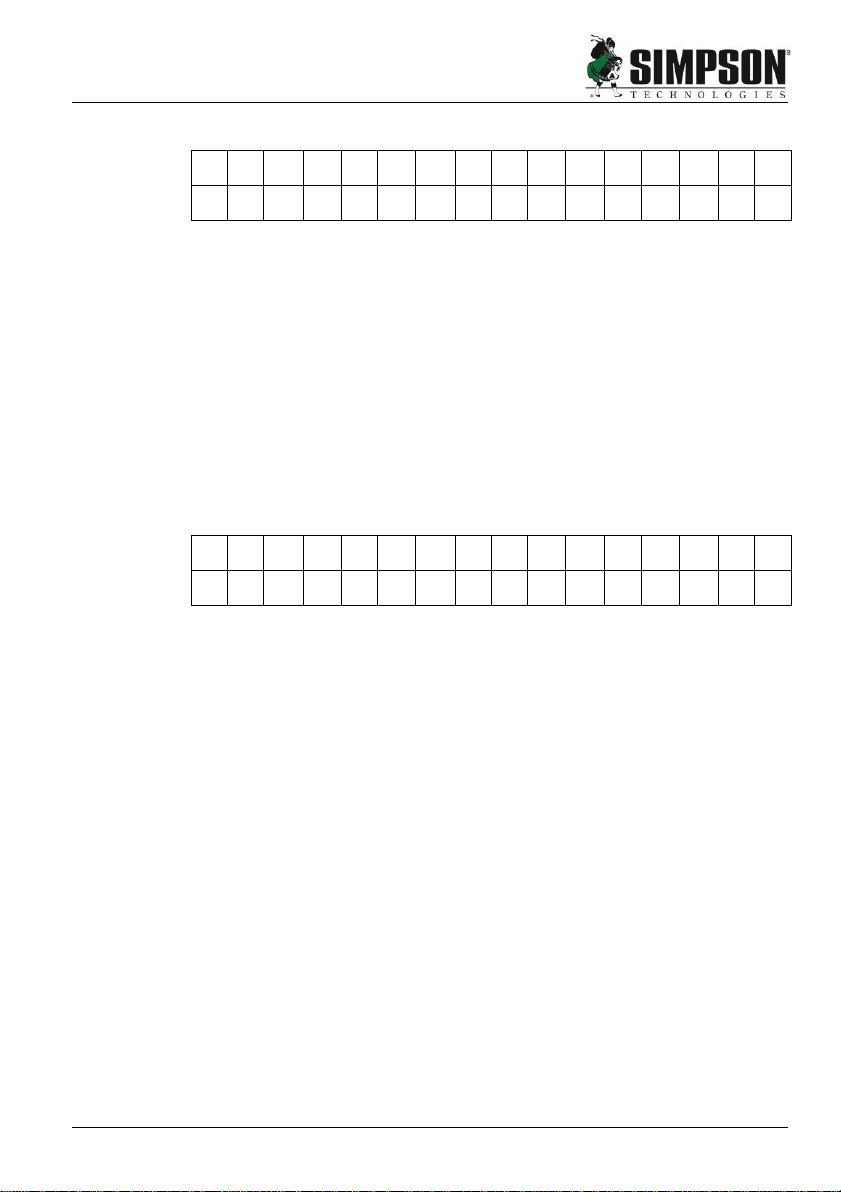

5.2 User Information Screens

There are five information screens in addition to the work mode screen

(USER NAME-SCALE-CALIBRATION-DATE-WORK). Cycle through

the beginning screens by pressing MENU from the working modes

screen.

5.2.1 User Name Screen Description

S

I

M

P

S

O

N

-

G

E

R

O

S

A

U

s

e

r

N

a

m

e

Figure 7

1. This screen shows the current user name (Figure 7). The only

function available in this screen is a key combination to enter the

SETUP MODE, see the section on Setup Screens.

2. Press MENU to switch to the next screen.

5.2.2 Current Scale Type Screen Description

H

A

R

D

N

E

S

S

T

E

S

T

E

R

C

o

r

e

Figure 8

This screen shows the current scale type (Figure 8). No other function

is available on this screen. Pressing MENU will change to next screen.

5.2.3 Last Calibration Screen Description

L

A

S

T

C

A

L

I

B

R

A

T

I

O

N

0

4

/

2

6

/

2

0

1

0

1

5

:

3

0

Figure 9

This screen shows when the hardness displacement sensor was last

calibrated (Figure 9). No other function is available on this screen.

Pressing MENU will change to next screen.

5Operating Instructions

12 Electronic Scratch Hardness Tester man-stc-42145-V17-22

5.2.4 Actual Date/Time Screen Description

A

C

T

U

A

L

D

A

T

E

/

T

I

M

E

0

4

/

2

6

/

2

0

1

0

1

5

:

3

0

Figure 10

1. This screen shows the actual time and date (Figure 10). A clock is

embedded into the instrument; its operation is shown by the

flashing colon. Using this screen you may set the date.

2. Press ENTER, a cursor will appear in the left of the screen, under

the month. The UP arrow will increment the number, and the

RIGHT arrow will advance the cursor position.

3. To exit the editing mode, simply press ENTER again.

4. Pressing MENU will return you to work mode screen.

5.3 Setup Description

S

I

M

P

S

O

N

-

G

E

R

O

S

A

U

s

e

r

N

a

m

e

Figure 11

1. Setup has 5 option screens:

USER NAME - MOLD IDENTIFICATION NAME - CALIBRATION -

TIMER AND BATTERY STATUS - MEMORY). You may cycle

through these by pressing the MENU button.

2. Enter setup mode by returning the USER NAME screen (Figure 11).

Hold the UP arrow for four seconds, then hold the RIGHT arrow for

four seconds until the screen changes as below (Figure 12).

Operating Instructions 5

man-stc-42145-V17-2 Electronic Scratch Hardness Tester 13

5.3.1 Editing User Name

E

D

I

T

U

S

E

R

N

A

M

E

U

s

e

r

N

a

m

e

Figure 12

1. To enter the Edit mode, press ENTER and a cursor will appear

(Figure 13).

Figure 13

3. Advance the cursor by pressing the RIGHT arrow.

4. To change the characters, press UP arrow. The characters will

increment by one character, in a cyclical fashion.

5. To increment backwards, press MENU. This will advance in the

reverse direction in a cyclical fashion.

5.3.2 Editing Mold Identification Name

E

D

I

T

M

O

L

D

N

A

M

E

m

o

l

d

0

1

:

0

0

0

0

0

0

Figure 14

1. This screen is available to edit the name given to a particular mold

or pattern number (Figure 14). First, choose a mold number to edit

the name of. There are 32 (00-31) mold numbers to choose from.

2. To increment the current mold number, simply press the UP arrow.

3. In the same way, to decrement the mold number, press the RIGHT

arrow.

E

D

I

T

M

O

L

D

N

A

M

E

m

o

l

d

0

1

:

0

0

0

0

0

0

Figure 15

E

D

I

T

U

S

E

R

N

A

M

E

_

U

s

e

r

N

a

m

e

5Operating Instructions

14 Electronic Scratch Hardness Tester man-stc-42145-V17-22

4. After you choose a mold number, press ENTER to edit a mold

number's name. The cursor should appear under the first character

of the name (Figure 15). To edit the name, proceed as with the

USER NAME screen. You have six characters with which to name a

mold number.

5. Advance the cursor by pressing the RIGHT arrow.

6. To change the characters, press the UP arrow. The characters will

increment by one character, in a cyclical fashion.

7. To increment backwards, press MENU. This will advance in the

reverse direction in a cyclical fashion.

8. Once you enter the complete name, press ENTER again to quit.

9. Pressing MENU will change to next screen.

5.3.3 Calibration Points

See 6.3 of the Calibration and Maintenance.

5.3.4 Timer and Battery Status

A

O

F

T

A

S

T

O

B

A

T

T

3

0

.

0

0

2

0

0

1

.

6

1

Figure 16

1. This screen allows you to adjust two things, AOFT and ASTO.

BATT refers to the battery power left (Figure 16).

2. AOFT is the automatic offset reading. Changing this will clear the

display in more or less time. It is measured in seconds. You can

change the time by pressing ENTER. This cycles the time by 0.5

seconds from 18.0 to 0.0.

3. ASTO is the number of the minimum reading before the timer is

activated. Increase the value by pressing the UP button. Decrease

the value by pressing the RIGHT button. There is one decimal

point in the number, for example 0200 is 20.0. This is your

minimum reading.

Operating Instructions 5

man-stc-42145-V17-2 Electronic Scratch Hardness Tester 15

4. BATT shows the remaining battery power. The battery may be

recharged up to 500 times; after this, it must be replaced. This

allows you to monitor the battery’s charge.

5. Press MENU to change to next screen.

5.3.5 Viewing Memory Status - Setup Description

M

E

m

o

r

y

U

S

e

d

0

3

2

0

M

E

m

o

r

y

L

E

f

t

7

3

6

0

Figure 17

1. This shows the amount of memory used, and how much memory is

free (Figure 17). The total amount of memory is 7680 bytes (960

readings!) for intensive sampling.

If you press RIGHT, you reset the memory. This will erase the sample

information stored in the onboard memory. Use extreme care not to

reset the memory, unless you purposely intend to clear the memory.

2. REMEMBER!!! If you press RIGHT, like the SERIAL IRED LINK,

you will be given a prompt warning that the memory will be lost.

Therefore, use extreme care not to reset the memory unless you

purposely intend to clear the memory (Figure 18).

M

e

m

o

r

y

U

S

e

d

0

0

0

0

M

e

m

o

r

y

L

E

f

t

7

6

8

0

Figure 18

5.3.6 Exiting Setup Mode

To exit the SETUP MODE, you must cycle through all of the setup

screens. After you have reached the memory screen, pressing MENU

once more will get the screen out of setup and to the User Name screen

and the instrument will return to normal operation.

5Operating Instructions

16 Electronic Scratch Hardness Tester man-stc-42145-V17-22

5.4 First Use

S

I

M

P

S

O

N

-

G

E

R

O

S

A

U

s

e

R

N

a

m

e

Figure 19

1. Turn the instrument on by pressing the ENTER button. Hold

ENTER for at least 3 seconds to stabilize the power supply.

If the unit does not seem to respond to a button, hold it in for a

moment.

2. The unit will display a series of screens, beginning with the one

shown in Figure 19 above and changing at a rate of about 2

seconds. It will cycle through these until it reaches the fifth screen;

that is the work mode screen.

If you press any key before the cycle is done, the cycle will stop, press

MENU until you reach the work mode screen. Begin when the cursor

is flashing. On the LCD screen, only the option above the flashing cur-

sor may be edited.

3. Button operation: In order to complete any operation, a button

should be held until the operation is performed.

The hardness tester will turn itself off, except when the work mode

flag is on Wk, after five minutes of inactivity for conserving battery

power. The charge can be monitored in the Setup mode, Timer and

Battery Status. The tester will not turn itself off in the Timer and

Battery Status mode.

Table of contents

Other Simpson Test Equipment manuals

Popular Test Equipment manuals by other brands

Klein Tools

Klein Tools HVNCVT1 instruction manual

TIS

TIS 851 instruction manual

WIKA

WIKA CEP6500 operating instructions

Würth

Würth PRO II LCD Translation of the original operating instructions

Industrial Test Systems

Industrial Test Systems eXact iDip quick start guide

Rigol

Rigol MSO2000A Series user guide