Content

1. Quick Start Guide...................................................................................................... 1

1.1 Front panel LCD display..........................................................................................1

1.2 Front panel key.........................................................................................................1

1.3 Key Description....................................................................................................... 2

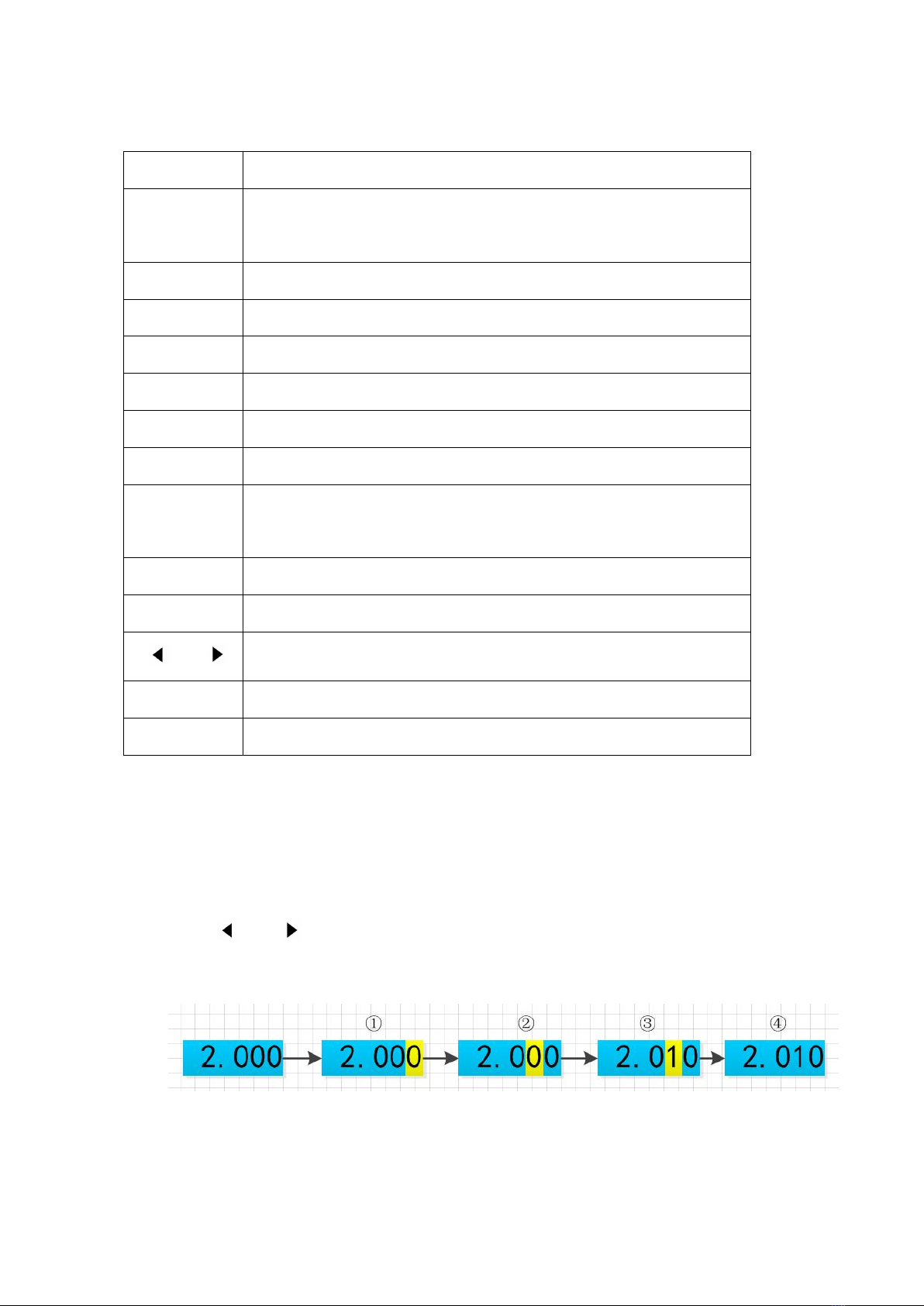

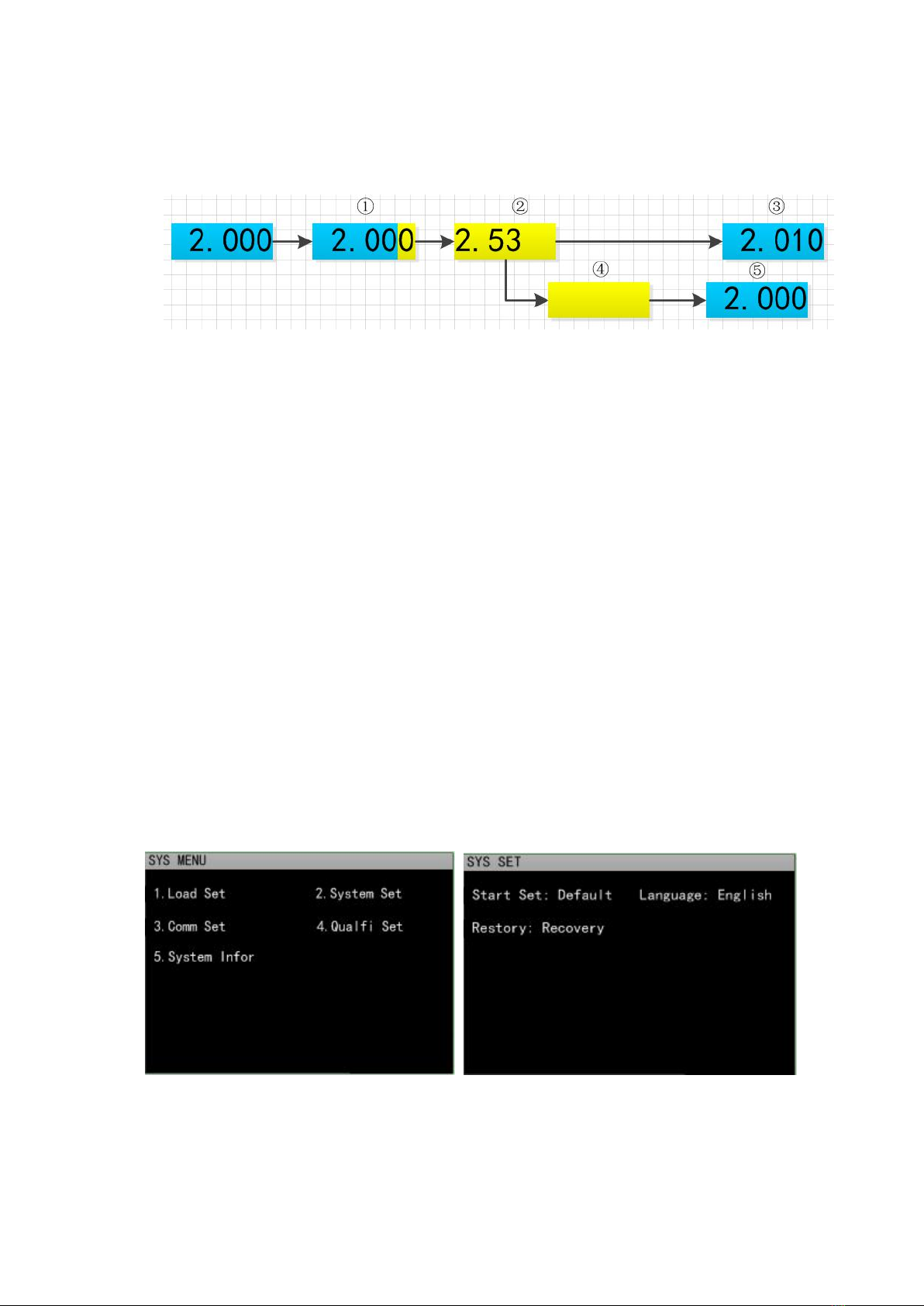

1.4 Numeric parameter settings......................................................................................2

2.Function operation................................................................................................... 3

2.1 Remote/local switching............................................................................................3

2.2 System Setup............................................................................................................3

2.3 Load Setup............................................................................................................... 4

2.4 Basic mode............................................................................................................... 4

2.4.1 Constant current mode.................................................................................. 4

2.4.2 Constant voltage mode..................................................................................5

2.4.3 Constant resistance mode..............................................................................5

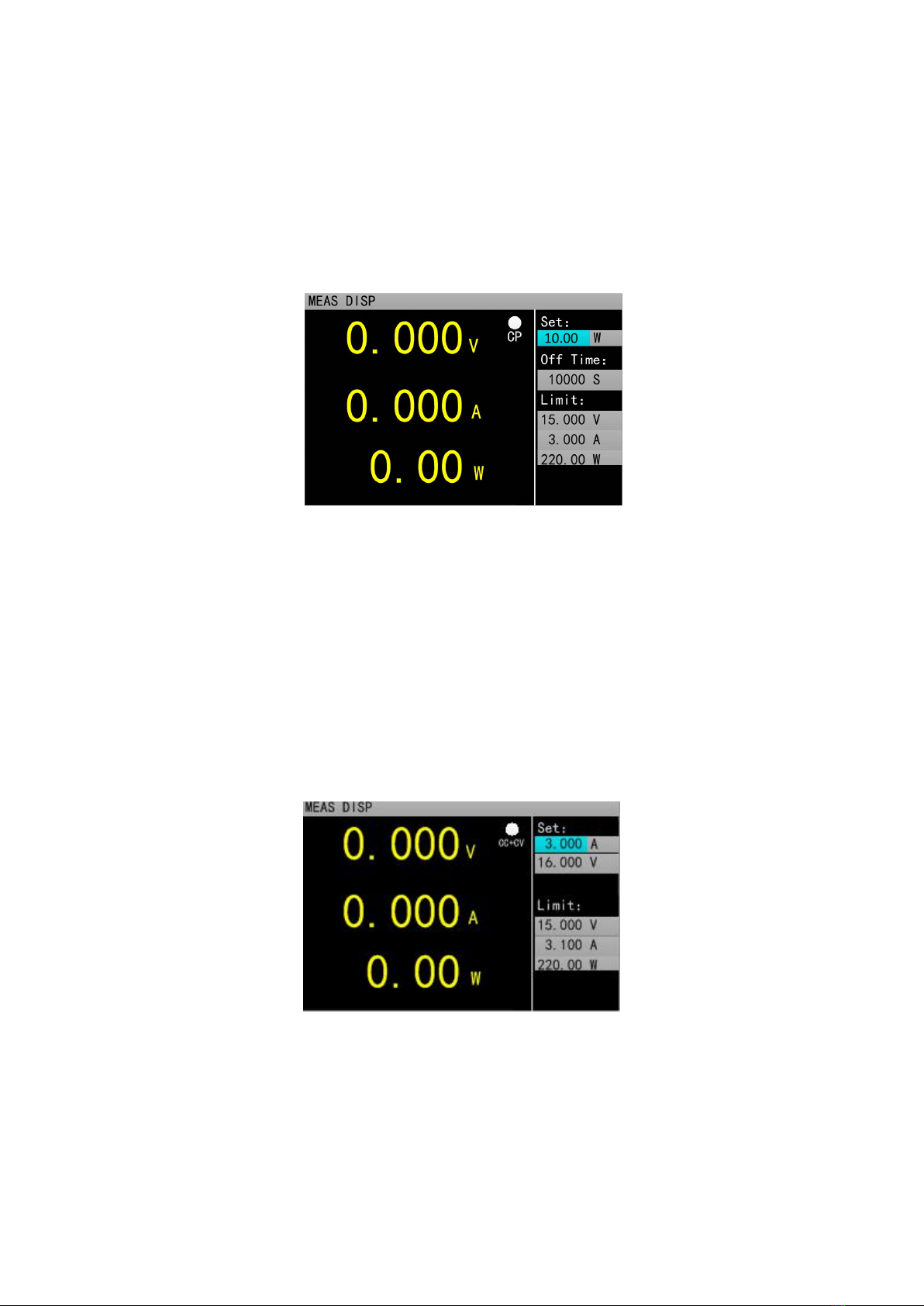

2.4.4 Constant power mode....................................................................................6

2.4.5 Constant current to constant voltage mode................................................... 6

2.4.6 Constant resistance to constant voltage mode...............................................6

2.5 Tran Test.................................................................................................................. 7

2.6 List Test....................................................................................................................8

2.7 Scan Test................................................................................................................ 11

2.8 Battery Test............................................................................................................ 12

2.9 LED Test................................................................................................................ 13

2.10 Short Circuit Test................................................................................................. 14

2.12 Protection function............................................................................................... 14

2.13 Trigger function................................................................................................... 14

2.14 Qualification test.................................................................................................. 14

2.15 Other system settings........................................................................................... 15

2.15.1 Key-Lock Function................................................................................... 15

2.16 Communication port and External expansion port...............................................15

2.16.1 Communication port..................................................................................15

2.16.2 Expansion port.......................................................................................... 16

2.16.3 Current monitoring terminal..................................................................... 16

Technical specifications............................................................................................... 17