Sinclair ZX User manual

SERVICINGMANUAL

FOR

ZXPRINTER

.LISTOFCONTENTS

INTRODUCTION

SECTION1 GENERALINFORMATION

SECTION2 SYSTEMDESCRIPTION

SECTION3 FAULTDIAGNOSISANDREPAIR

SECTION4 REMOVALANDINSTALLATIONPROCEDURES

SECTION5 ILLUSTRATIONS

-LISTOFILLUSTRATIONS

FigNo.

1

2

3

4

5

6

7

LocationofComponents

LocationofComponents

TopCoverandBaseInsertAttachmentPoints

Setting-UpDriveTrain

PinchRollerSprings

LogicCircuitDiagram

CircuitDiagram

©SinclairResearchLtd.

(i)

SERVICINGMANUAL

FOR

ZXPRINTER

-INTRODUCTION-

ThismanualisforusebyauthorisedSinclair

dealers,engineersandrepresentativesasa guide

torectifyingfaultsontheSinclairZXPrinter.

Repair/renewalproceduresarelimitedtothose

which

are

specific

to

this

printer;

standard

proceduresfortherenewalofelectronic

componentsetc.,arenotincluded.

NOTE:

The

printer

uses

electro-sensitive

paper,thegradingandqualityof

which

are

critical

if

satisfactory

operationoftheprinteristobe

achieved.Onlypaperwhichis

suppliedandapprovedbySinclair

ResearchLtd.,ortheiragentsshould

beused.Ifadjustmentsaremadein

an

attempt

to

make

the

printer

functionwithotherpapers,excessive

wearoftheprintermechanismmay

result.

(11)

SAFETYMEASURES

1.Thisinstructionmanualcontainscertain

WARNINGandCAUTION

noticeswhichMUSTbefollowedbytheuserto

ensureSAFEoperationandtoretainthe

equipmentina SAFEcondition.

2.Allusersoftheequipmentdescribedinthis

manualMUSThavereceivedadequatetraining

initsuseandapplicationinordertoensure

SAFEANDPROPERUSE.

3.Anyadjustment,maintenanceandrepairofthe

openedapparatusundervoltageshallbe

carriedoutonlybya skilledpersonwhois

AWAREOFTHEHAZARDINVOLVED.

SECTION1

GENERALINFORMATION

Sub-SectionLISTOFCONTENTSPageNo.

1Introduction1.1

2PrincipleofOperation1.1

1.INTRODUCTION

1.1TheZXPrinterisdesignedforusewiththeSinclairrangeofmicro-

computers,andprovidesa permanentrecordofanycomputeroutput

whichmaybedisplayedontheTVscreen.Becauseofgraphicdisplays

always'joinup',longprograms,tablesofresults,elaboratepatterns

andgraphscanbeprintedoutascontinuousrecords,evenifcarried

outinseveralparts.

2.PRINCIPLEOFOPERATION

2.1Theprintingmechanismisunconventional,andconsistsoftwostyli

whichpasssuccessivelyacrossthesurfaceofthepaper.Eachpass

representsonerowofdots,andsixrowsofdotsformthematrixfora

singlelineofprint.A moderatelyhighvoltage(50V)isgeneratedin

theelectronicswithintheprinter,andisroutedtoa conductorstrip

inthetopcover.

2.2Eachstylusishairpin-shapedsothatoneendpassesoverthesurface

ofthepaperwhilsttheotherendcontactstheconductorstrip,thus

carryingthecurrenttothenatalliecoatingofthepaper.Thereturn

pathisthroughthecoatingtotheconductiverubberroller,which

alsofeedsthepaperthroughtheprinter,totheearthconnections

withintheelectroniccircuitry.Beforemakingcontactwiththe

paper,thestyluspassesoveran'L'-shapedinsulatingwafer;asthe

stylusleavesthewafer,ittouchesthepaperandtheelectrical

continuityissensedbythecontrolelectronicswhichthenpulsesthe

appliedvoltagetoprovidetheprintingaction.

2.3A descriptionofthecontrolcircuitisgiveninSection2.

1.1

SECTION2

SYSTEMDESCRIPTION

Sub-Section

LIST

OF

CONTENTS

Page

No.

1Introduction2.1

2TopCoverAssembly2.1

3BeltandStyli Assembly2.1

4MotorandGearTrainAssembly2.2

5ControlElectronicsBoard2.2

6BaseFrameAssembly2.2

7PaperReelCarrierAssembly2.2

8LogicDescription2.3

9CircuitDescription2.3

1.INTRODUCTION

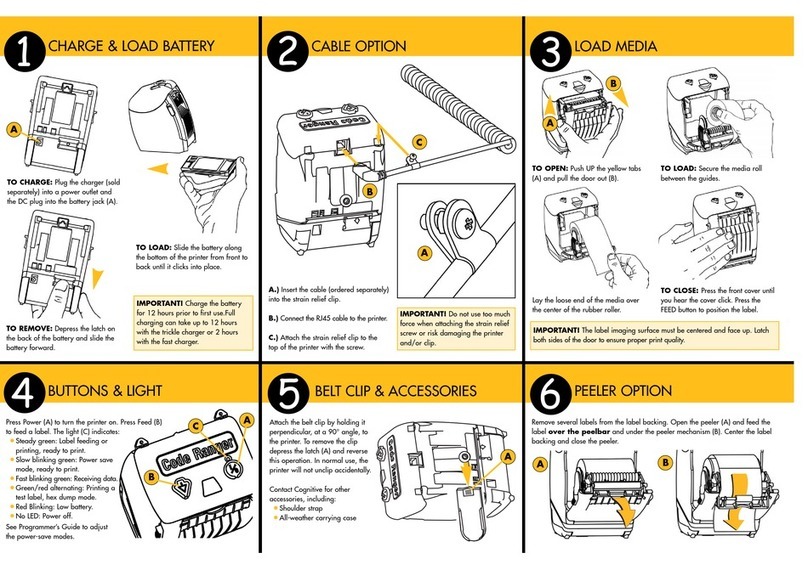

Theprintercomprisessixmainassemblies(seeFigures1 and2):

(a)TopCoverAssembly,

(b)BeltAssembly,

(c)MotorandGearTrainAssembly,

(d)ControlElectonics,LoomandEdge-ConnectorAssembly,

(e)BaseFrameAssembly,

(f)PaperReelCarrierAssembly.

2.TOPCOVERASSEMBLY

2.1Thetopcoverassemblyconsistsofa mouldedplasticcover,a metal

conductor

strip,

anda

serratedplastic

strip

which

forms

a

cutting

edgetofacilitatetearingoffthepaperprintout.Twobushesare

mouldedintotheundersideofthecovertohousetheupperendsofthe

driveandidlerpulleyshafts.Theassemblyissecuredtothebase

frame

by

four

screws

which

are

inserted

from

the

underside

ofthe

base

(seeFigure3).

3.BELTANDSTYLI ASSEMBLY

3.1Thisassemblycomprisesanendless,internally-toothedplasticbeltto

which

are

attached

two

hair-pin

styli.

Each

stylus

fits

over

a

spigot

onthe

upper

edge

ofthe

belt,

andis

retained

bya

push-on

cap.

The

beltislocatedontwosimilarpulleys,oneofwhichisdrivenbythe

motor

via

bevel

gearing,while

the

other

isan

idler.

2.1

4.MOTORANDGEARTRAINASSEMBLY

4.1Themotorandgeartrainassemblydrivesthefollowing:

(a)beltassembly,whichproducestheprintoutimage,

(b)

paperfeed

roller,

which

moves

the

paper

upwards

as

printing

proceeds,

(c)encodingdisc,whichfunctionsinconjunctionwiththecontrol

electronicsp.c.boardtoprovidetheprintoutsignalstothe

stylf onthebeltassembly.

4.2Thehorizontallymountedmotordrives,viabevelgearing,the

vertically

mounted

pulley

and

wormshaft

which

rotates

the

belt

assembly.Thiswormshaftdrivesa horizontallymountedwormshaft

which,inturn,drivesthepaperfeedrollerassembly.Atthelower

endofthepulleyandwormshaft,a spurgeardrivestheencoderdisc,

bothitemsbeingmountedwithintheundersideofthebaseframe.

5.CONTROLELECTRONICSBOARD

5.1Thecontrolelectronicsboardismountedontheuppersurfaceof

thebaseframe.Inconjunctionwiththeencodingdiscandthe

LED/photodiodecombination,theboardprovidessignalstodrivethe

motorandtheprintingsystem.Thep.c.boardisconnectedto

thedouble-sidededge-connectorbya shortloom;thep.c.board-end

oftheloomisclampedbetweenthetopcoverandthebaseframewhen

thecoverissecuredtothebase.

6.BASEFRAMEASSEMBLY

6.1Thebaseframeassemblycomprisesthebaseframeandthebaseframe

insert,

both

of

which

are

plastic

mouldings.

The

base

frame

provides

a

chassis

on

which

most

components

are

mounted;

the

base

frame

insert

isa removablesectionwhichfitsintotheundersideofthebase

frame.Theinsertcontainsthelowerbushesfortheshaftsofthe

drive

and

idler

pulleys,

as

well

asthe

mounting

forthe

LED.

Itis

securedtothebaseframebytwoofthefourscrewswhichretainthe

topcover,andbytwoshorterscrews(seeFigure3).

7.PAPERREELCARRIERASSEMBLY

7.1Thepaperreelcarrierassemblyconsistsofa plasitcmouldingwhich

housesthereelofelectro-sinsitivepaper,anda spring-loadedpinch

roller.Thepaperissupportedinthecarrierontwoplastic

spigotted

end-caps

which

are

inserted

into

the

ends

ofthe

tube

atthe

centreofthereel; theseend-capsshouldbetransferredtothenew

reel

when

the

reel

is

changed.

The

spring-loadedpinch

roller

forces

the

paper

into

contact

with

the

paperfeed

roller

to

provide

the

'grip'necessarytoenablethepapertobefedthroughtheprinter.

The

complete

assembly

slides

into

the

base

frame,

and

clips

into

place;itisreleasedbypressurebeingappliedtothepointmarked

PRESS

HERE

onthe

underside

ofthe

carrier.

2.2

7.2Normally,thepaperfeedsthroughtheprinterasprintingtakesplace.

However,

a

manually

operatedpaperfeedswitch

is

fitted

to

enable

the

papertobefedthroughwithoutprinting,forexample,toprovidea

tear-offmarginattheendofa print-out.Theoperatingbuttonfor

thisswitchprotrudesthroughthetopcover.

8.LOGICDESCRIPTION

8.1TheLEDandthephotodiodearepositionedonoppositesidesofan

aperturedencoder

disc.

Asthe

disc

rotates,

the

beam

of

light

from

theLEDisinterrupted,thusprovidinga pulsedsignal,thetimingof

whichisgovernedbythespeedofrotationofthedisc.This,pulsed

signalisappliedtooneinputofanAND-gatewhose1outPut1S

connected,viaa divide-by-fourcircuit,toa blockinputofa buffer

storeanddecoder(seeFigure6).

8.2Thebufferstoreanddecoderreceivesandstoresinformationrelating

toone

line

of

print,

i.e.

six

scanned

lines,

from

the

computer;

it

respondstoclockpulsesatitsclockinputtoselectivelyenablethe

high-voltage(50V)switchtopermitcurrenttoflowfromthepower

supply

tothe

conductor

strip

and

thence,

viathe

stylus

tothe

paper.

Thecircuitisearthedviatheconductingrubberrollerofthepaper

feed

anda

resistor.

Where

the50Vis

applied

tothe

surface

ofthe

paper,themetalliccoatingisburnedoff,leavingthedark

undercoatingexposedtoprovidethepermanentimage.Theconductor

strip

is

alsoconnected

tothe

paper

detect

circuit

which

detects

when

thestylushasrunofftheedgeoftheinsulatingwaferandhas

commencedtrackingacrossthesurfaceofthepaper.

8.3Theencoderdiscproduces1024pulsesacrosstheprintingwidthofthe

paper;theseareproducedto256bythedivide-by-fourcircuitto

ensurethattheregisterofeachlineofdotswithinthematrixis

maintainedtowithina quarterofthewidthofa dot.

9.CIRCUITDESCRIPTION

9.1TR1andTR2

form

a

self

regulating

50V

power

supply.

The50Vmaybe

measuredconvenientlyonC4(seeFigure7).

9.2

When

the

stylus

first

makes

contactwith

the

paper

atthe

left

hand

margin,TR5isswitchedonviaR8.Thisraisesthelevelatpin4 of

theULAandresultsintheencodersignalbeingpassedtothe

associatedmicrocomputer.C6andRllpreventcontactbeinglost

momentarily

andare

critical

in

value.

Many

problemshavebeen

experiencedwithdevicesgivingtoomuchgainandTR5whichonsome

early

printers

wasa

ZTX550

should

be

replaced

bya

ZTX551.

9.3TR3andTR4switchthe50Vtothestylusinordertogenerate

printing.

2.3

9.4ThephototransistorTR9issolderedtotheboard,whiletheLEDison

flyingleadsstuckintothebaseinsert.Theseitemsaresubjecttoa

lotoftolerancesbutthereshouldbegreaterthan200mVp-patpin2

oftheULAwhenoperating.Commonfaultsencounteredinclude,over-

etchedencoderdisc,encoderdiscworkingloose,incorrectlyformed

slotm thebaseframeinfrontofthephototransistor(somehave

metalshimswithphoto-etchedslots). Dirtintheencoderdiscorin

frontofthephototransistoralsogivemisleadingresults.The

operationoftransistorTR9canbereadilycheckedusingan

oscilloscopeprobeontheemitter.

9.5TransistorTR6switchesthemotoronandoff.Duringthelasttwo

linesofan'Lprint'themotorrunsslowly;thisisaccomplishedby

switchingTR6onandoff,usingthetimeconstantR13/C8in

conjunctionwiththephototransistoroutput.

9.6Themotorisfittedinternallywitha vanstorringsuppressor.

Withoutthisitwouldgeneratesomuchinterferencetomakeit

unusable.Itisunlikely,however,thatthiswouldoccur.

2.4

SECTION3

FAULTDIAGNOSISANDREPAIR

Thefollowingtableisintendedasa generalguidetothediagnosis

andrectificationofmostofthefaultswhichmayoccurafter

considerableusageoftheprinter.

FAULTPOSSIBLECAUSEREMEDY

1.Poorprintquality:

(a)Verticalzig-zag(a)Wornbelt.(a)Fitnewbelt.

usuallyworseon

right-handside.

(b)Horizontallines(b)Wornbelt.(b)Fitnewbelt.

unevenlyspaced.

(c)Printfadingout(c)Dirtonconductor(c)Cleanand

overpartoflinestripintoplubricate

cover.conductorstrip-

useElectrolube.

(d)'Noisy'Printin5-<d)W Excessive(d)/^FitZTX551in

gainonTR5.placeof

ZTX550

(ii)Insufficient(ii)FitnewULA.

signalfrom

encoder.

2.Noprint:(a)Ifprintisall(a)Ifdefective,

black,checkTR4.changeTR4.

(b)Ifnoimage,check(b)Connectwhitewire

thatwhitewiretoconductorstrip

isconnectedtoandcheck50Vis

conductorstrip.presentonstrip.

(c)Dirtonphoto-(c)Cleanphotodiode

diodeand/orLED.and/orLED.

{d}Defectivephoto-(d)Fitnewphotodiode

diodeand/orLED.and/orLED.

3.1

FAULTPOSSIBLECAUSEREMEDY

3.

Motor

not

operating:

(a)

Conductor

strip

(a)Fitnewtop

cover

hasbecomelooseassembly.

Intopcover.

(b)Motorbevel(b)Checktightnessof

piniontouchingscrewsandreset

motormountinggearmesh(see

screws.Figure4).

4.Motorrunning(a)Excessive(a)Slightlyslacken

slowly:frictiononbaseinsertscrew

encoderdisc.nearencoderdisc.

(b)Excessivegain(b)FitZTX551in

onTR5

place

of

ZTX550.

5.Inadequatepaper(a)Insufficient(a)Fitnew0.60mm

feed:springpressuredia.springs.

onpaperpinch

roller.

(b)Paperreelends(b)Ensurethatreel

jammed

against

is

wound

tightly

thecover.andnottouching

cover.

SECTION4

REMOVAL ANDINSTALLATIONPROCEDURES

Sub-SectionLISTOFCONTENTSPageNo.

1CleaningandLubrication4.1

2TopCoverAssembly4.1

3BeltandSty!i Assembly4.2

4MotorandGearTrainAssembly4.3

5PCBoard,LoomandEdgeConnectorAssembly4.4

6EncoderDisc4.5

7PaperFeedRollerAssembly' 4.6

8PaperReelCarrierPinchRollerSprings4.7

1.CLEANINGANDLUBRICATION

1.1A certainamountofdustfromthemetallizedcoatingofthepaperwill

accumulatewithintheprinterasprintingproceeds.Wheneverthe

printerisdismantledforanyreason,thedustshouldberemoved,

usinga gentleairblastand/ora softbrush.

-CAUTION

Neverusesolventsorotherfluidsasthey

may

attack

the

plastic

or

rubber

components

1.2Beforere-assemblyoftheprinter,bushesshouldbelightlylubricated

withMolycote44,butgears,wormshaftsetc.,mustnotbelubricated;

athincoatingofelectrolubeshouldbeappliedtotheconductorstrip

inthetopcoverassembly.

2.TOPCOVERASSEMBLY

2.1Toremovethetopcoverassembly:

(a)

Remove

the

paper

reel

carrier

assembly.

(b)Removethefourscrewsatthecornersofthebase(seeFigure3).

(c)Liftthecoverapproximately15mm,removethewhitewire

connector

from

the

spadeterminal

onthe

conductor

strip

inthe

undersideofthecover.

(d)

Withdraw

the

cover,

and

lift

offthe

operatingbutton

forthe

buttonfeedswitch.

4.1

(e)Iftheserratedtear-stripiswornordamaged,thiscanbe

removedbypushingoutthecentrelug(nearthespadeterminal),

liftingtheouteredgesofthetear-stripandmovingitawayfrom

thecovertodisengagetheretaininglugsfromtheslotsinthe

cover.

2.2Toinstallthetopcoverassembly:

(a)Ifa newtear-stripistobefitted,insertitsretaininglugs

intotheslotsinthetopcover,andpushdownonthetear-strip

untilitclipsintoposition;ensurethatthecentrelugis

engagedinitsslotinthecover.

(b)Positionthebeltassemblyonitspulleyssothatthestyliare

attheextremeleftandrightoftheprinter,thatis,theyare

onthepulleys.Ensurethatthestyliareinthetrailing

position- thebeltrotatesclockwise,viewedfromthetop.

(c)Placetheoperatingbuttononthespigotofthepaperfeed

switch,andensurethattheslopingfaceofthebuttonis

correctlyalignedwiththecontourofthetopcover.

(d)Placethetopcoverinposition,andconnectthewhitewireto

thespadeterminalontheconductorstrip.

(e)Gentlymanoeuvrethetopcoverintoposition,ensuringthatboth

pulleyshaftsengagetheirlocatingbushes,andthatthepaper

feedswitchoperatingbuttonlocatescorrectlyonthecut-outin

thetopcover.Checkthatthewirestotheswitcharenotcaught

betweenthecoverandthebaseframe.

NOTE:Careisneededtoavoiddamagetotheinsulatorstripon

theverticalwebofthebaseframe.

(f)Securethetopcovertothebaseframewiththefourscrews.

(g)Fitthepaperreelcarrierassembly.

3.BELTANDSIYLIASSEMBLY

3.1Toremovethebeltandstyliassembly:

(a)Removetopcoverassembly(seepara2.1).

(b)Liftoffthebeltandstyliassemblyfromthepulleys.

(c)Ifitisdesiredtoremovea stylus,pulloffthestylus

retainingcap,andliftthestylusfromitsmountingspigoton

thebelt.

4.2

3.2Toinstallthebeltandstyliassembly:

(a)ifa stylushasbeenremoved,placea newstylusoverits

mountingspigotonthe,belt.so,thatthelegofthestylus.which

hasthelonger'foot11Soutsidetliebelt-,securetliestYlus°?

pushingtheretainercapontothespigot.

(b)Placethebeltassemblyoverthepulleyssothatthestyliareat

theouteredgesofthepulleys,andthestyliareinthetrailing

positiononthebelt- thebeltrotatesina clockwisedirection,

viewedfromthetop.

{c}Installthetopcoverassembly(seepara2.2).

4.MOTORANDGEARTRAINASSEMBLY

4.1Toremovemotorandgeartrainassembly:

(a)Removetopcoverassembly(seepara2.1).

(b)Removebeltandstyliassemblyandidlerpulley(seepara3.1).

(c)Removethedrivepulleybypullingitupwards(itsshaftisa

pushfitinthelargespurgearwithinthebaseframe).

(d)Prisethewormshaftoutofitssupports,andremoveit.

(e)Prisethebevelpinionfromthemotorshaft,andremovethe

spacerfromtheshaft(iffitted).

(f)Unsolderthewiresfromthemotorterminals.

(g)Removethetwoscrewssecuringthemotortoitsmounting,and

withdrawthemotor.

NOTE:Onearlierprinters,themotorislightlygluedtoits

mounting,anditwillbenecessarytoprisethemapart

carefully.

4.2Toinstallmotorandgeartrainassembly:

Priortoinstallingthemotor,determinewhetherthebaseframeisof

theearlypatternorthelaterdesign.Ontheearlypattern,thereis

across-shapedslotinthemotormountingflange;thelaterdesignhas

averticalslotonly.

(a)Iftheprinterisoftheearlytype,applya thincoatof

suitableglue,suchasLoctite,tothefaceofthemotor.

4.3

(b)Positionthemotoronitsmountingflangewiththeorientation

mark(ontheterminalendofthemotor)attheoutside,and

insertthetwoattachmentscrews.Iftheprinterisofthelater

design,thescrewsmaybetightenedfullyatthisstage.Ifthe

printeris of theearlierpattern,theverticalheightof the

motormustbesetasshowninFigure4;itmaybeadvantageousto

manufacturethejigshowninFigure4 toensureaccuratesetting

ofthemotorbeforethescrewsaretightened.

(c)Fitthespacertothemotorshaft,andpushthebevelpinion

fullyontotheshaft.

NOTE:Onsomemotors,theendbearingisrecessedonitsouter

face.Thespacerforusewiththismotoris3.25mmlong,

whereasthespacerforusewiththeflush-facedend

bearingis2.92mmlong.Itisessentialtoensurethat

thecorrectspacerisfitted.

Ifa spacerisnotavailable,setthebevelpinionclearanceas

showninFigure4.

(d)Solderthewirestothemotorterminals- theredwireconnects

totheouterterminal,theblackwiretotheinnerterminal.

EnsurethatcapacitorC9isconnectedacrossthemotorterminals.

NOTE:Theblackwiremustpassoverthewhitewirewhich

connectstotheconductorstripinthetopcover.

(e)LightlylubricatetheendsofthewormshaftwithMolycote44,and

presstheshaftintoitssupportbushes.

(f)Supportthebaseinsertinthevicinityofthelargespurgear,

andpushthedrivepulleyshaftfullyhomeintothespurgear

bosswhichprotrudesupwardsthroughthebaseframe.

(g)Fittheidlerpulleyandbeltassembly.

(h)Fitthetopcoverassembly(seepara2.2).

5.PCBOARD,LOOMANDEDGECONNECTOR

5.1Toremovethep.c.board,loomandedge-connectorassembly:

(a)Removethetopcoverassembly(seepara2.1).

(b)Removethemotor(seepara4.1).

(c)Disconnectthegreenwireattheearthterminal.

(d)Removethetwoscrewssecuringthebaseinsert,andeaseitclear

ofthebaseframe.CarefullyeasetheLEDanditsleadsoutof

themountingclipsonthebaseinsert,andremovetheinsert.

4.4

(e)Removethetwoscrewssecuringthep.c.boardtothebaseframe.

(f)Gentlyeasethephotodiodeanditsleadsoutofthemounting

clipsonthebaseframe,andremovethep.c.board,loom,and

edge-connectorassembly- takecaretoavoiddamagetotheLED,

photodiodeandtheirleads.

5.2Toinstallp.c.board,loomandedge-connectorassembly:

(a)Carefullypositionthep.c.boardonthebaseframe,withtheLED

anditsleadspassingthroughthecut-outinthebaseframe.

(b)Clipthephotodiodeanditsleadsintoplaceonthe'baseframe

(ensuringthatthelensisfacingdownwards),andsecurethe

p.c.boardtothebaseframewithitstwoscrews.

(c)CarefullyinserttheLEDanditsleadsintotheclipsonthebase

insert,ensuringthatthelensfacesupwards.

(d)Securethebaseinserttothebaseframewithitstwoscrews.

(e)Connectthegreenwiretotheearthterminal.

(f)Installthemotor(seepara4.2).

(g)Installthetopcoverassembly(seepara2.2).

6.ENCODERDISC

6.1Toremovetheencoderdisc:

(a)Removethescrewssecuringthebaseinsert,andeasetheinsert

outofthebaseframe.

NOTE:AvoiddamagingtheLEDanditsleadswhichareclippedto

thebaseinsert.

(b)Carefullylifttheedgeoftheencoderdiscuntilitsspindleis

clearofthebushinthebaseframe,andslidethediscclear.It

isnotnecessarytoremovethelargespurgearwhichdrivesthe

encoderdisc.

6.2Toinstalltheencoderdisc:

(a)Applya traceofMolycote44tothebushfortheencoderdisc

spindle.

4.5

(b)Ensurethattheencoderdiscisclean,andcarefullyslideits

edgeunderthelargespurgearuntilthespiondlecanbeseated

initsbush.

NOTE:

Laterversions

ofthe

printer

have

a

modifiedspurgear

ontheencoderdiscanda flatspringfittedtothe

spindle,abovethespurgear.Theseverionsare

identifiedbythepalebluecolourofthesmallspurgear

(theearlierversionsarewhite).Thismodifiedgearand

flatspringcanonlybefittedtothelaterversionof

thebaseinsert- theymustNOTbefittedtotheearlier

versions.

(c)Carefullyfitthebaseinsertintothebaseframe,andsecureit

withitsscrews;avoiddamagetotheLEDanditsleads.

7.PAPERFEEDROLLERASSEMBLY

7.1Toremovethepaperfeedrollerassembly:

(a)Removethetopcoverassembly(seepara2.1).

(b)Disconnectthegreenwirefromtheearthterminal.

(c)Removethescrew,washerandnutwhichsecuretheearthterminal

tothebaseframe,andwithdrawtheterminal.

(d)Slidethepaperfeedrollerassemblysidewaysuntilitsend

disengages

from

its

worm

wheel,

and

withdraw

the

roller

assembly.

7.2To

install

the

paper

feed

roller

assembly:

(a)Inserttheroundendofthepaperfeedrollerassemblyintoits

mountinginthebaseframe.

(b)

Slide

the

square

endofthe

roller

assembly

into

the

worm

wheel,

andpushitfullyhome.

(c)Securetheearthterminaltothebaseframewiththescrew,

washerandnut,andensurethattheterminalcontactstheendof

therollerspindle.

(d)Connectthegreenwiretotheearthterminal.

(e)Installthetopcoverassembly(seepara2.2).

4.6

8.PAPERREELCARRIERPINCHROLLERSPRINGS

Aspringisfittedateachendofthepaperreelcarriertoforcethe

pinchrollerintocontactwiththepaper.Althoughthespringsare

identical,theymustbefittedinthecorrectmanner(seeFigure5)-

alwaysremoveandinstallonespringata time.Earlyprintersare

fitted

withsprings

made

from

0.55

mm

diameterwire;

later

printers

are

fitted

withsprings

made

from

0.60

mm

diameterwire.

Whenever

thesespringsaretobechanged,thethickerspringsshouldbefitted,

regardlessofwhethertheprinterisanearlyorlaterversion.

SECTION5

ILLUSTRATIONS

LISTOFCONTENTSFigNo.

LocationofComponents(1)1

LocationofComponents(2)2

TopCoverandBaseInsertAttachmentPoints3

Setting

Up

Drive

(Gear)

Train

4

PinchRollerSprings5

LogicCircuitDiagram6

CircuitDiagram7

5.1

Other manuals for ZX

2

Table of contents

Other Sinclair Printer manuals