Sino Instruments HS710 User manual

User manual

HS710

Hydraulic Comparator

2

The operating instructions are parts of the products and must be kept in

the immediate vicinity of the instrument and readily accessible to skilled

personnel at any time.

Skilled personnel must have carefully read and understood the operating

instructions prior to beginning any work.

The manufacturer's liability is void in the case of any damage caused

by using the product contrary to its intended use, non-compliance with

these operating instructions, assignment of insufciently qualied skilled

personnel or unauthorized modications to the instrument.

HUAXIN reserve the rights to change the contents or form of these

operating instructions at any time without prior notice having been given.

Claim

......warns you against actions that can cause injury to people or

damage to the instrument.

......points out useful tips,recommendations and information for

efcient and trouble-free operation.

In order to protect your products,your own and others safety,please read

this manual carefully before your operation,otherwise it may cause trouble.

Huaxin is not liable for any safety problems or damages caused by misuse

or incorrect operation.

Safety information

Symbol

Warning

The system must only be operated by trained and authorised personnel

who know the manual and can work according to them.

Any operation not included in the following instructions or outside the

specications must not be attempted.

Don’t use and disable the Product if it is damaged.

Operate by professional

Use the product only as specied

Please use non-damage goods

1

2

3

3

Disassembling may cause physical injury or equipment damage.Only

qualied technicians are allowed to x the equipment.Please call our

service staff for repair instruction and guidance if there would be

anything wrong.

No Disassembling

Only provide pressure for oil gauge.if you use the item to calibrate

water pressure gauges,maybe water will enter into it and that couldn’t

generate pressure anymore.Meanwhile that may pollute the gauges

under test.

If this equipment will be in idle for a long time, please shut off the relieve

valve and provide a little pressure.In order to avoid the air enter into the

item inside.that will affect the system stability when you use it nexe time.

Don’t calibrate water pressure gauge

Store the item with pressure

5

6

4

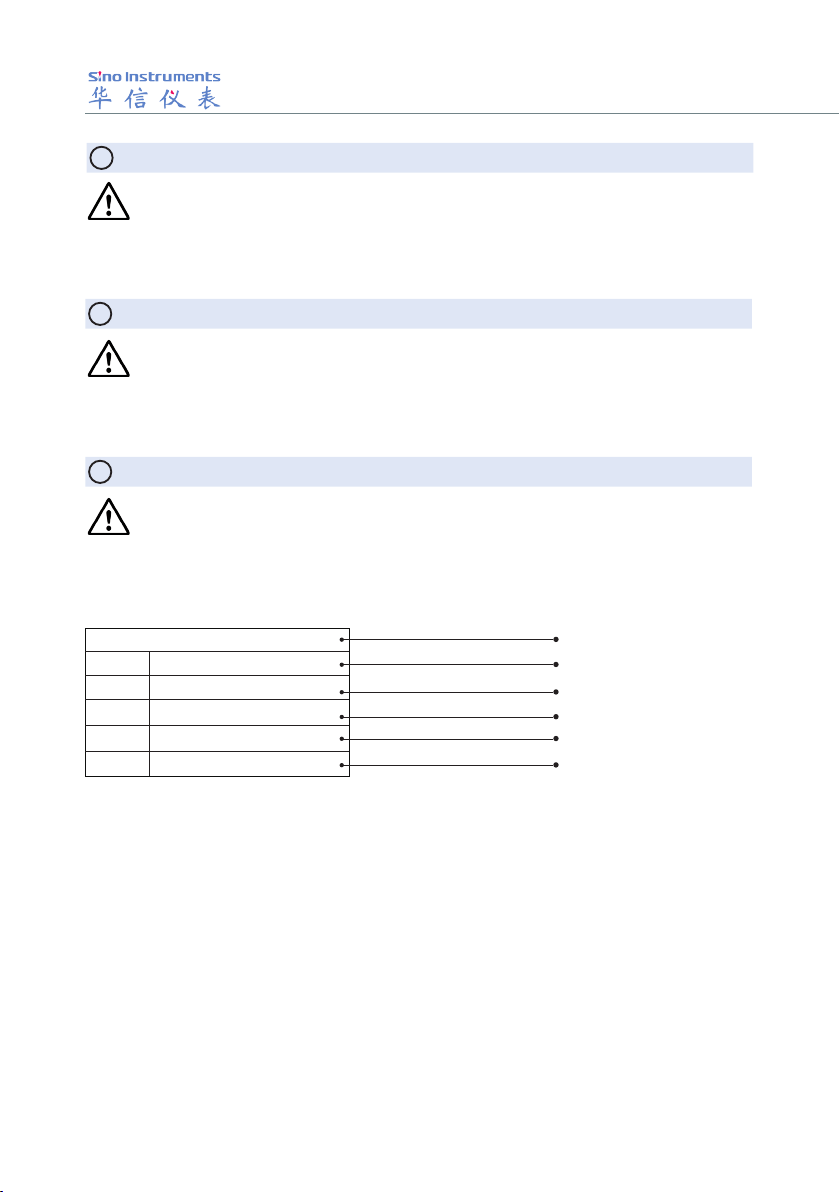

Labelling

Huxin Instrument(Beijing)Co.,LTD

Model

Range

Product

No.

Date

(0-700)bar

Hydraulic comparator

140865011

2014.08

HS710

Manufacturer

Model

Product name

Pressure range

Serial number

Date of manufacture

4

Claim

Safety

1.Summary 1

2.Technical Specication 1

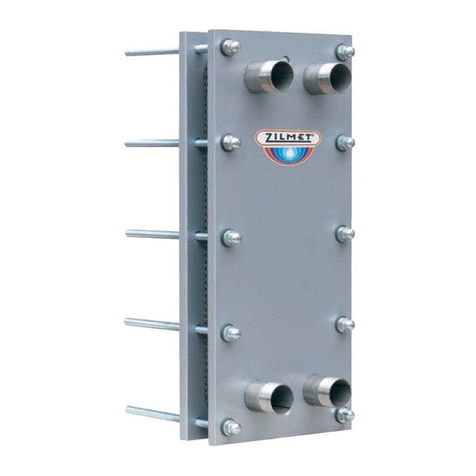

3.Components 2

4.Working principle 3

5.Operation 4

6.Troubleshooting 5

7.Maintenance 6

8.Support 6

1

1.Summary

2.Technical Specication

Model:HS710 Hydraulic comparator

Generated pressure range:(0~600)bar,(0~700)bar

Working media:25#transformer oil

Adjust resolution:0.001bar(0.1kPa)

Material:Body:Stainless Steel/Aluminium Seals:Buna-N

Output interface connection:M20×1.5Female

Output quantity:Three

Package: Specialized cartons and foam wrap

Dimensions:430L×330W×170H(mm)

Weight:14.9kg

HS710 Hydraulic comparator adopts advanced stainless steel,with bench-top

structure and designed to generate pressure range up to 700bar.The sliding block

structure for screw pump design makes the high pressure operation more easy

and save labor,and saves operation space without screw outside.The special

F-adjust valve adjusts the exact pressure value and calibrate 250kpa pressure

instruments.The detachable oil cup is easy to clean and maintenance,checking

work medium timely from outside.3pcs outputs with quick coupling makes

it calibrated pressure instruments together.The widely calibrates pressure

instrument in the laboratory.

HS710 provides pressure measurement for calibrating pressure (differential

pressure)transmitter,precision pressure gauge, general pressure gauge and

other pressure instruments. It can be extensively used in power,chemical,

petrol,metallurgy, metering,military industry,etc.

Adopts advanced stainless steel,bench-top structure

Detachable oil cup is easy to clean and maintenance

Fast connection,quick pressurizing and easy operation

It is used for calibrating all kinds of oil gauges

Characteristics

Functions

2

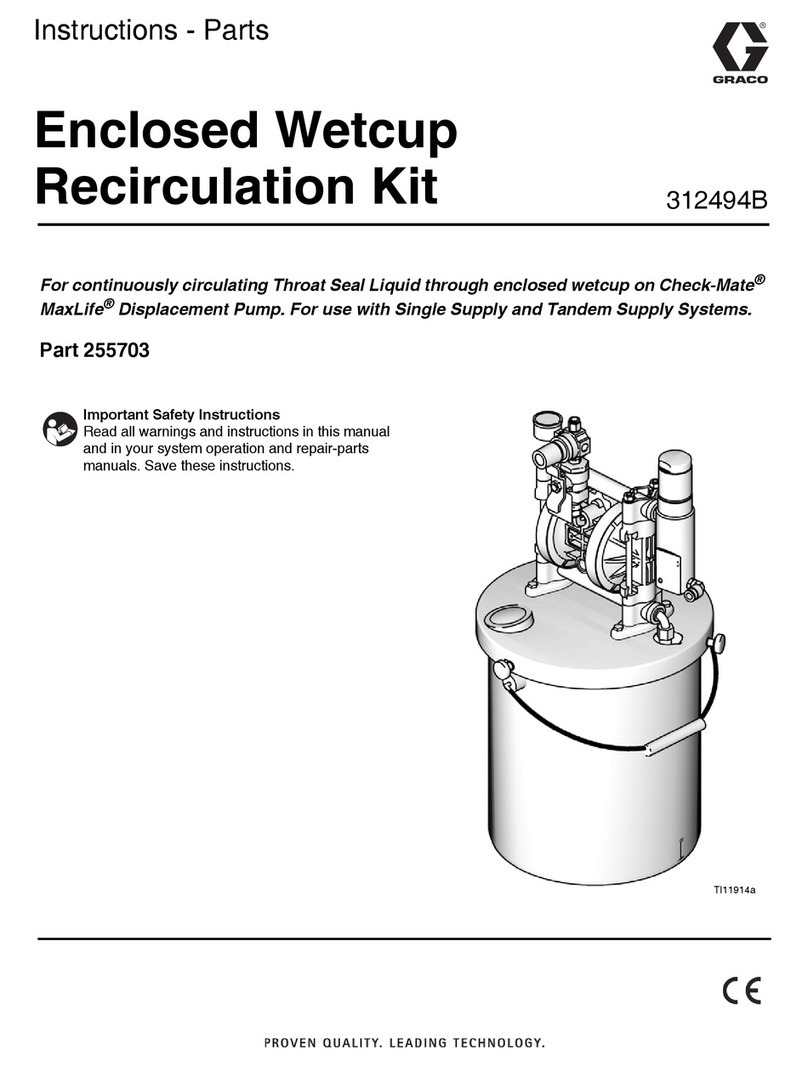

6

7

Output

There are three outputs.It could calibrate two gauges once time.

Ventilation nut

Unscrew the nut before use;tighten it up during storage and transport.

F-adjust valve

To realize the ne adjustment of pressure value.(clockwise to increase

pressure)

Lead Screw

Increase pressure by turning the lead screw clockwise,decrease pressure

by turning the lead screw anti-clockwise.

Plugs

Tighten it up when not in use,it could prevent oil-leaking by blocking

the output.

Hand pump

Generate pressure by running the handle up and down repeatedly, to

realize pre-pressure.

Relieve valve

Have to close before pressure generation(clockwise).Slowly open it to

relieve the pressure(anti-clockwise).

Oil cup

The container is used for the work medium, it can be take off anti-

clockwise from the hand pump.

Shut-off valve

Cut off the connection between hand pump & lead screw.Disconnect by

turning it clockwise,open up by turning it anti-clockwise.

1

2

3

4

8

9

5

3.Components

5

1

7

4

6

8

9

2

3

3

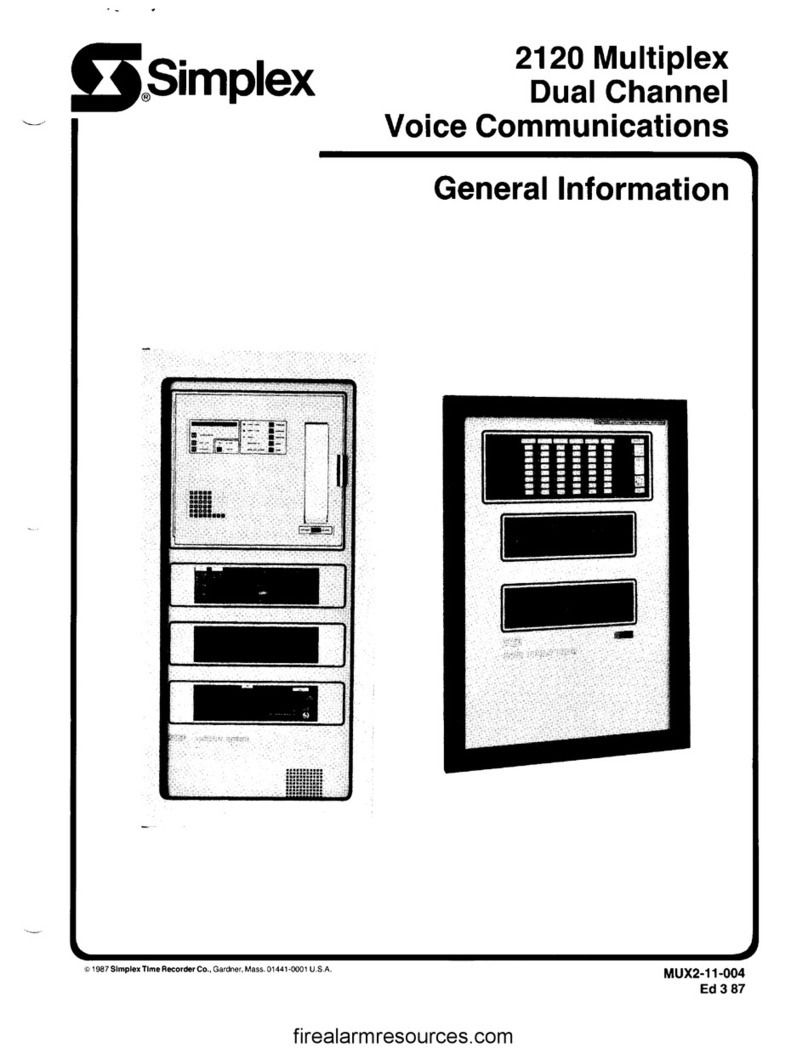

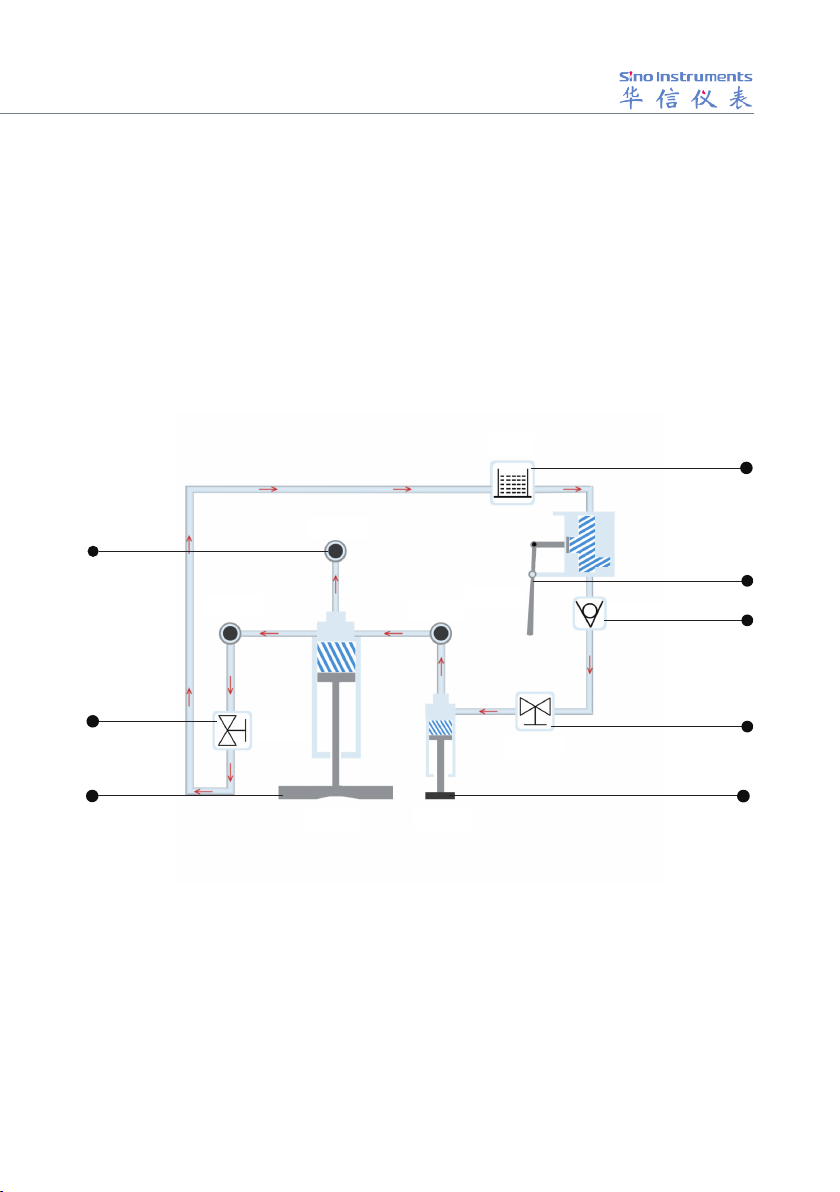

4.Working principle

Output

F-adjust valve

Check valve

Shut-off valve

Relieve

valve

Hand pump

Lead

screw

Oil cup

HS710 is composed of hand pump,lead screw,F-adjust valve,relieve valve,

shut-off valve,oil cup and outputs,etc.The pressure gauge can be installed

quickly,and easy to prepressurize by running hand pump up and down,

then compress the work medium by turning lead screw clockwise(anti-

clockwise),that could realize the pressure increasing(decreasing)secondary.

Fine adjust the F-adjust valve to reach desired point more accurately.

4

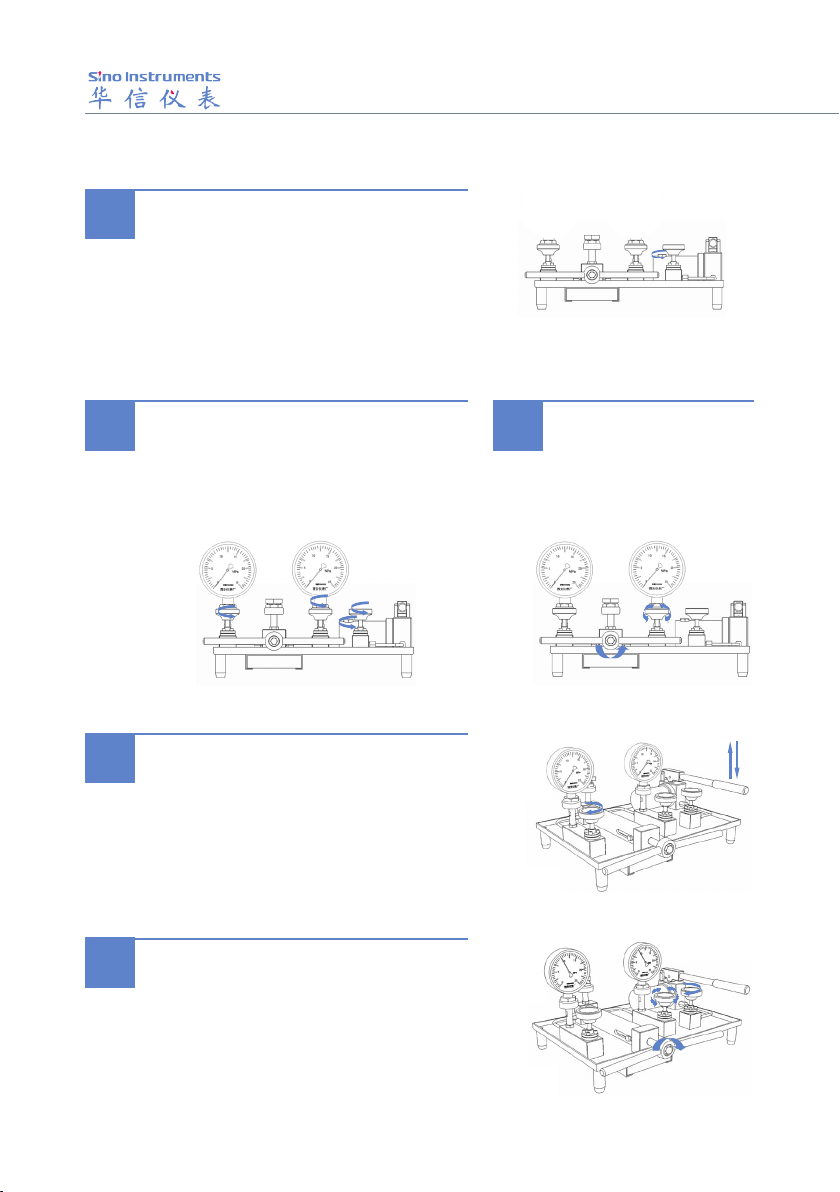

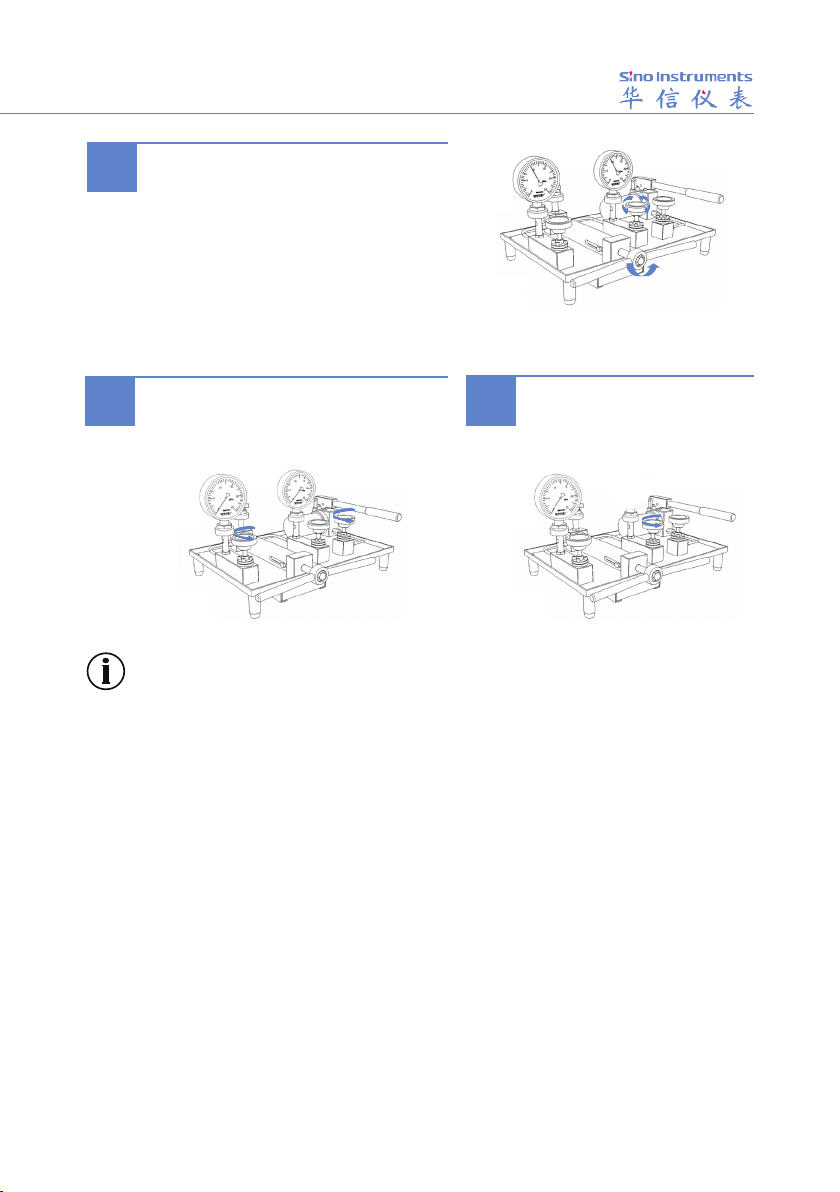

Record 0bar record ,and close the relieve

valve: Providing pressure 20bar by turning

hand pump up and down and stop pre-

pressure.

D

Put HS710 on the level. Turn the relieve valve

and shut-off valve anti-clockwise to open them,

unscrew ventilation nut.Remove the plug of

the outputs, connect the standard gauge and the

gauge under test to outputs.

Set F-adjust valve to the mid

position,and for lead screw,turn

all the way out.

B C

Close shut-off valve clockwise. Rotate the

Lead screw clockwise and adjust the F-adjust

valve to get exact values .Pressure rising &

stabilize to 50bar,100bar,150bar,200bar,250bar

in turn, meanwhile,record the data.

E

5.Operation

Take pressure gauge 250bar(25Mpa) as example.

(The standard points:0bar 50bar 100bar 150bar

200bar 250bar)

Please fill the work medium (25#transformer

oil) from vent before calibration .The oil position

should be at least 2/3 of the whole oil cup. Open

the ventilation nut as the PIC below.

AOpen

Open(anti-

clockwise)

Open(anti-

clockwise)

Turn all the way out

anti-clockwise

Pressurizing by

turn it clockwise

Turn it clockwise

until closed

In the mid position

Fine adjust Close

Up and down

Connect

Unscrew

5

6.Troubleshooting

There may be some faults of HS710 mentioned below after long term

use,the maintainer can analyse and eliminate problems by these methods.

Make sure to release all pressure of system.It is forbidden to disassemble

and repair the product with pressure.

Remark:

1.Hold the lead screw,turn in and out to complete ne adjustment.

2.Run the hand pump up-down slowly&slightly, to pre-pressurize(15~20)bar.

3.Please put on the plugs after all the tests have been nished.

4.Above pictures are just for reference.

NOTES:

1.There must be no pressure in the system when removing pressure gauge .

2.Replace the O-rings regularly.

3.The working media is oil.Pls don't mix with other liquid.

Change gauge under test and

calibrate next one.

H

Loop process: Decrease pressure by

turning lead screw anti-clockwise (or

together with relieve valve),and adjust the

F-adjust valve to get exact values. Record

the data when the pressure stabilize on

200bar,150bar,100bar,50bar and so on.

Finish the loop process and open the relieve

valve to release the pressure. Then open the

shut-off valve.

F

G

Depressurizing by turn

it anti-clockwise

Fine adjust

Open

Open Change gauge

6

8.Support

The product specications and other information contained in this manual

are subject to change without notice.if you have any questions,please call

our services hotline:400 611 3558 or Tel:+86-10-62392087

7.Maintenance

7.1.If this equipment will be in idle for a long time, please turn the lead

screw clockwise till it could not move anymore,shut off the relieve valve

and put on the plugs.Provide a little pressure by running the hand pump 2-3

times,then tighten the ventilation nut.

7.2.If HS710 needs to take a long distance transport,please put on all plugs

to prevent leakage of oil.It is necessary to pack with specialized cartons and

foam wrap.

7.3.Replace working medium regularly.

7.4.The working medium is 25#transformer oil or any oil that can be used

for calibrating gauges.

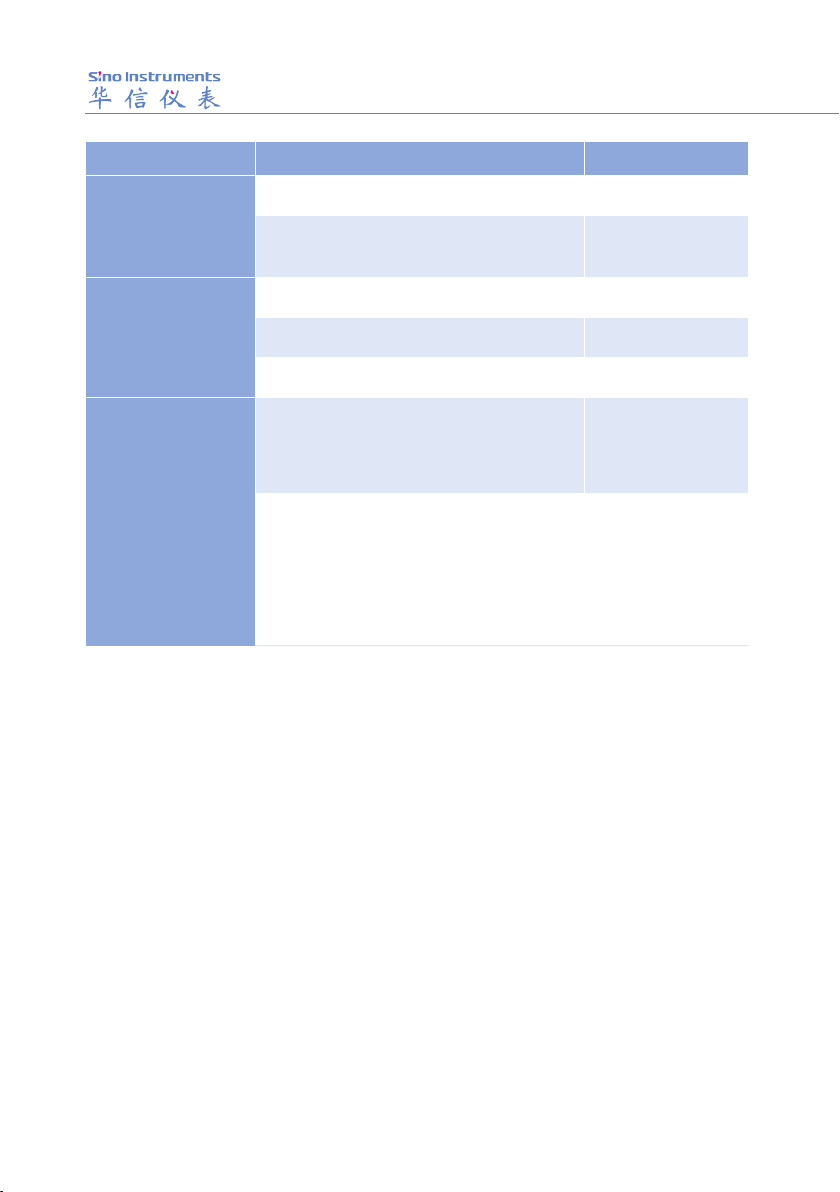

Faults Cause Solution

Oil leakage

The O-ring seal is loose or damaged Replace the O-ring

There is large damage on the sealing faces

of gauge under test Check the sealing

Hand pump couldn't

generate pressure

No enough medium in oil cup Add medium

The internal O-ring is damaged Replace the O-ring

The gauge under test has huge capacity Increase

prepressing times

The pressure is

instability,the

standard gauge

depressurized

quickly

Check the instrument to make sure there is

no leakage of oil.Otherwise the O-ring is

damaged or there is connection loosening

Replace O-ring,or

reassemble

Pressurize without gauge under test.if

the instrument doesn’t leak pressure,this

indicates gauge under test has problem.

Otherwise there is problem with device or

standard module.Check the module and

device separately

Replace standard

gauge or gauge

under test

Digital Pressure Gauge

HX601/HS108

Intelligent Pressure Calibrator

HS602

Pressure Comparator

HS700(-0.5-0.5)bar

HS701(-0.95-6)bar

HS702(-0.95-16/25)bar

HS703(-0.95-40/60)bar

HS720(0-140)bar

HS704(0-160/250)bar

HS705/HS705A(0-700)bar

HS710/HS710A(0-600/700)bar

HS706(0-1600)bar

Electrical Pressure Comparator

HS318L(0-600)bar 5pcs output

HS316L(0-25)bar 5pcs output

HS317L(0-60)bar 5pcs output

HS315(-0.95-0)bar 2pcs output

HS316(0-25)bar 3pcs output

HS318(0-600)bar 3pcs output

Automatic Pressure Calibrator

HS620(-0.1-1)bar, (-0.95-25)bar

Sphygomanometer Calibrator

ME01 & ME02

Temperature Calibrator

HS212 & HS213

HUAXIN Products series

Add:No.11,Chuangxin road,Changping,Beijing,102200,China.

Tel:+86-10-62392087/ Fax:+86-10-62345183

Web:http://www.sino-instruments.com

HUAXIN INSTRUMENT(BEIJING)CO.,LTD

E-mail:[email protected]/

Table of contents

Other Sino Instruments Industrial Equipment manuals