Sino Instruments HS711A User manual

1

User manual

Hydraulic Comparator

HS711A

2

Claim

The operating instructions are parts of the products and must be kept in

the immediate vicinity of the instrument and readily accessible to skilled

personnel at any time.

Skilled personnel must have carefully read and understood the operating

instructions prior to beginning any work.

The manufacturer's liability is void in the case of any damage caused by

using the product contrary to its intended use, non-compliance with these

operating instructions, assignment of insufficiently qualified skilled

personnel or unauthorized modifications to the instrument.

HUAXIN reserve the rights to change the contents or form of these

operating instructions at any time without prior notice having been given.

Safety information

Symbol

Warning

In order to protect your products,your own and others safety,please read this

manual carefully before your operation,otherwise it may cause trouble.

Huaxin is not liable for any safety problems or damages caused by misuse or

incorrect operation.

①Operate by professional

②Use the product only as specified

warns you against actions that can cause injury to people or damage to

the instrument.

points out useful tips,recommendations and information for efficient

and trouble-free operation.

The system must only be operated by trained and authorised personnel

who know the manual and can work according to them.

Any operation not included in the following instructions or outside

the specifications must not be attempted.

3

③Please use non-damage goods

④No Disassembling

⑤Don’t calibrate oil gauge

⑥Store the item with pressure

Labeling

Huaxin Instrument(Beijing) Co., Ltd.

Manufacturer

Model

Product Name

Pressure Range

Series Number

Date of Manufacture

Model

HS711A

Product

Hydraulic Comparator

Range

(0~600bar)

No.

17016038

Date

2017.01

Don’t use the product if it is damaged.

Disassembling may cause physical injury or equipment damage.

Only qualified technicians are allowed to fix the equipment. Please

call our service staff for repair instruction and guidance if there

would be anything wrong.

The item belongs to non-oil equipment, if you use the item to calibrate oil

gauge, there will be oil left behind in the system, and it will not provide

pressure anymore. Meanwhile that may pollute oil gauge.

If this equipment will be in idle for a long time, please close the relieve

valve and provide pressure about 2bar.In order to avoid the air enter into

the item inside. That will affect the system stability when you use it next

time.

4

Claim

Safety

1. Summary - - - - - - - - - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - 5

2. Technical Specification - - - - - - - - - -- - - - - - - - - - - - - - -- - - - - -5

3. Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - --6

4.Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- -- - - - - - - - - - -7

5.Troubleshooting -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- 8

6.Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - --- - - -8

7.Support - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - -- -- - - --- -- -- -- -9

5

1.Summary

HS711A Hydraulic comparator adopts special process with high quality aluminum alloy

and pining inside design, which make it high sealing quality, easy to clear. With the

advantage of fast connection ,easy generate pressure , quick pressurizing, long time keep

pressure, higher accuracy, it have been widely used in Lab and Field on the pressure

gauge calibration.

Functions

HS711A generate pressure for calibrating pressure gauges, such as pressure (different

pressure) transducers, precision pressure gauges, general pressure gauges and other

pressure gauges. It can be widely used in power, chemical, petrol, metallurgy, metering,

military industry, etc.

Features

Compact structure, light weight

Pressure range up to 600bar

Easy operation, saving time and energy

Fast connection, quick pressurizing

Easy increasing pressure, convenient maintenance

Simple and smart appearance

2.Technical Specification

Model:HS711A Hydraulic Comparator

Generated pressure range:(0~600)bar ; (0~700)bar

Working medium: Distilled water

Adjust resolution:0.001bar(0.1kPa)

Material: Stainless Steel/Aluminum for body; Stainless steel for outputs; Buna-N for

seals

Output interface connection:M20×1.5Female

Package: Carrying black bag. Specialized cartons and foam wrap(optional)

Dimensions:320L×240W×140H(mm)

Weight:5.0kgs

6

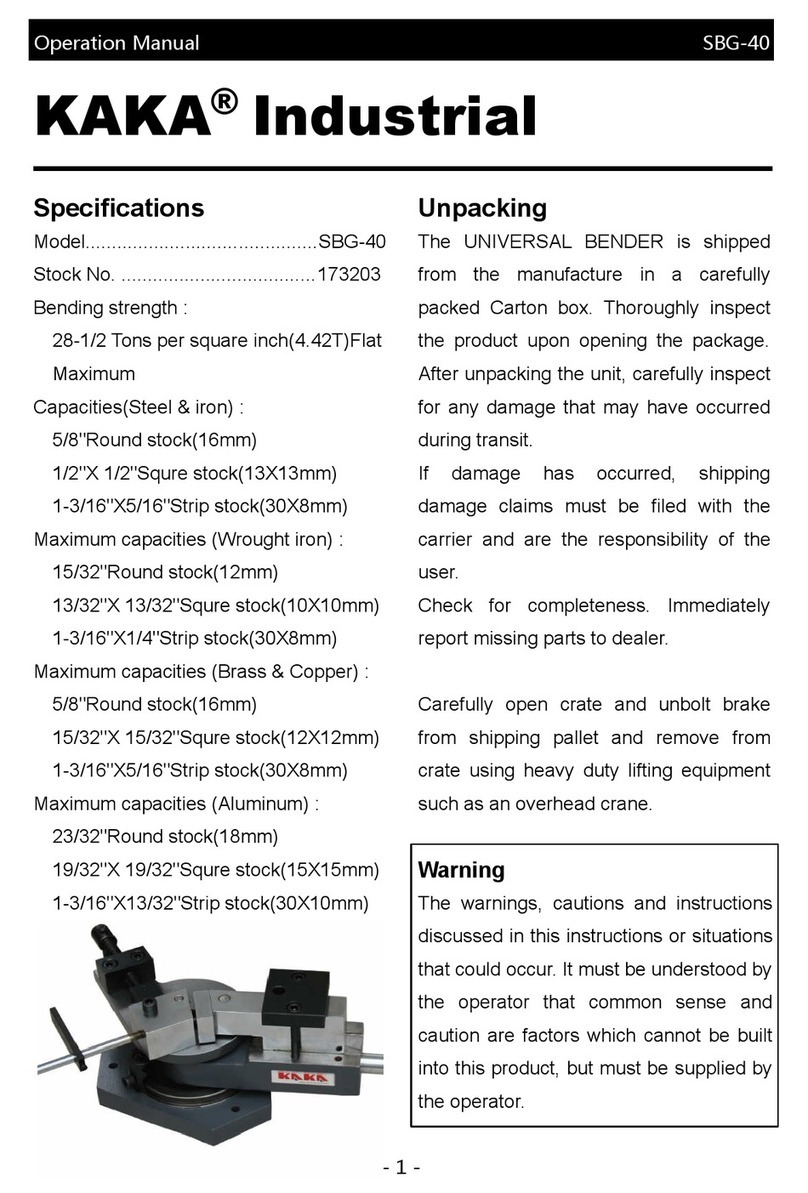

3.Components

Output

There are two output interface. one for standard gauge, the other for gauge under test.

Venting screw

Release the venting screw during operation ;otherwise be tightened.

Relieve

Clockwise rotate the relieve knot before generating pressure,slowly anti clockwise rotate

to release the inner pressure when finished calibration.

Lead screw

Clockwise rotate the lead screw to increase the pressure, anti clockwise rotate to decrease

the pressure (pressure range :0~600bar).

Hand pump

Clockwise rotate the hand pump to pre-generate the pressure (pre-generate pressure

range: 0~50bar ) before use lead screw to increase the pressure.

Water can

Store distilled water

Plug

relieve

plug

output interface

hand pump

Oil/water cup

venting screw

lead screw

7

Please fasten plug after calibration test, only release it during testing process.

4.Operation

Pressure gauge 250bar(25Mpa) as example.

(The calibration points:0bar 50bar 100bar 150bar 200bar 250bar)

A. Lay the HS711A on the test bench. anti-clockwise the relieve valve, unscrew venting

screw . Remove the plug of the outputs, connect the standard gauge and guage under test

on the two output interface

B. Please fill the work medium (distilled water) before calibration. The water position

should be at least 2/3 of the whole water can.

C. Anti-clockwise rotate the hand pump and lead screw till cannot rotated.

D. Record 0bar record, then close the ''relieve'' valve, clockwise rotate the lead screw to

generate the pressure till the standard gauge shows to about 20~30bar.

E. Then clockwise the hand pump to increase the pressure to calibration the normal

pressure gauge on the calibration points, then anti-clockwise rotate hand pump to

decrease pressure on the calibration points for calibration.

F. After finished calibration, anti-clockwise the relieve valve to release the pressure till

all the inside pressure have been released. then remove the standard gauge and gauge

under test. tighten the plug and venting screw. The whole calibration cycle have finished.

Remarks:

Please tighten the plugs after all the tests have been finished.

NOTES:

1.There must be no pressure in the system when removing pressure gauge.

2.Replace the O-rings regularly.

3.The working medium of item is water, please don’t mix any other liquid.

8

5.Troubleshooting

There are some main faults of HS711A mentioned below after long term usage, the

operator can analyze and eliminate problems by these methods.

Disassemble and repair the HS711A with pressure is prohibited.

Faults

Cause

Solution

Water leakage

The O-ring seal is loose or damaged

Replace the O-ring

There is large damage on the sealing faces

of gauge under test

Check the sealing faces

Lead screw couldn't

generate pressure

No enough medium in water cup

Add medium

The internal O-ring is damaged

Replace the O-ring

The gauge under test has huge capacity

Replace the gauge under test

The pressure is

instability, the

standard gauge

depressurized quickly

Check the instrument to make sure there is

no leakage of water. Otherwise the O-ring

is damaged or there is connection

loosening

Replace O-ring, or

reassembling

Pressurize without gauge under test. if the

instrument doesn’t leak pressure, this

indicates gauge under test has problem.

Otherwise there is problem with device or

standard gauge. Check the standard gauge

and device separately

Replace standard gauge or

gauge under test

5.Maintenance

7.1. Keeping about 2bar pressure inside, and tighten the venting screw and relieve valve,

if the HS711A will be out of work for long time,

7.2 Tighten and fasten all the valve and plug to prevent water leakage during the

transportation. , it is necessary to packed with special carton and foam wrap.

7.3.Replace working medium regularly.

7.4.The working medium is distilled water or any water that can be used for calibrating

gauges.

9

6.Support

The product specifications and other information contained in this manual are subject to

change without notice. If you have any questions, please call our services hotline:400

611 3558 or Tel:+86-10-62392087

Table of contents

Other Sino Instruments Industrial Equipment manuals