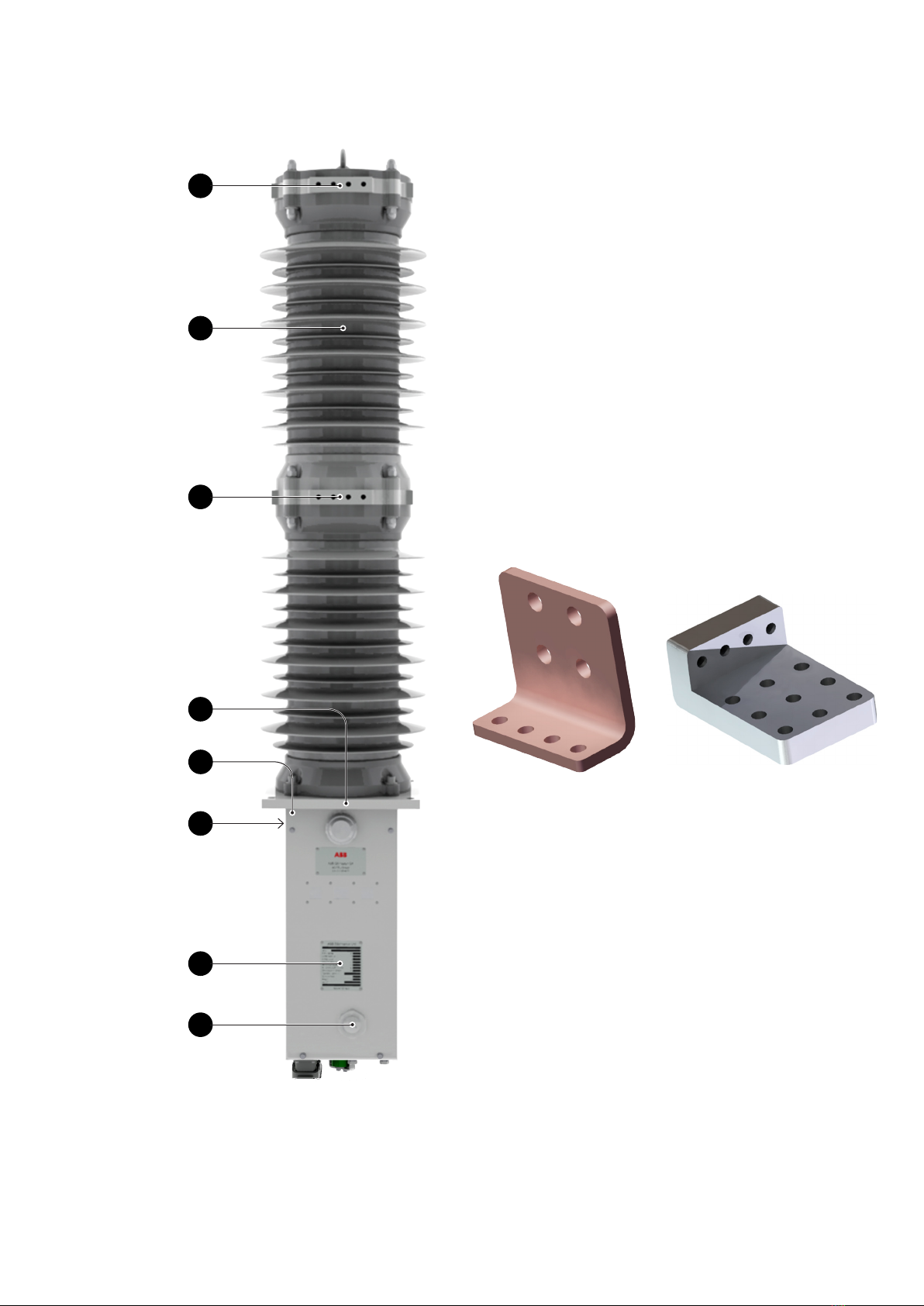

Binary

inputs

supply

Binary

inputs

Output

driver

Control unit

Control panel

Capacitor

banc Magnetic

Actuator

LED

I

O

ABB IN THE RAILWAYS – MEDIUM VOLTAGE PRODUCTS 7

ABB IN THE RAILWAYS – MEDIUM VOLTAGE PRODUCTS 7

1VSR630206EN – en – EDO-D0002852– Instruction manual – 2021.10 Design and specification are subject to change without notice

The operation of the CB takes place by means of a

current energy for “Open” and “Close” operations

by a capacitor bank. As a result, the auxiliary

of the pole. The MABS card analyses and indicates

sensor information and given operating orders.

The MABS card repeats this indication through

auxilliary relays so that it is available for external

use.

3.1.1. MABS Control Card

buttons or remote control signals. The MABS card

permanently monitors itself, the supply voltage,

the magnetic actuator, the position sensors, the

capacitor charge and the logic of the breaker

Malfunctions are detected and signalled

the “READY

according to customer requests. These settings

are factory set and not to be changed at a later

Capacitive energy storage (capacitor bank)

Position sensors

Push button panel

LOCAL, REMOTE, GLOBAL operating modes

(explanations in later chapters)

Interlock functions (blocked in open)

System monitoring

AC/DC (depending on card type)

consumption

Autonomy for apparatus operation in case of aux.