Tennsmith LM1010 Guide

Model LM1010 Performance “R”

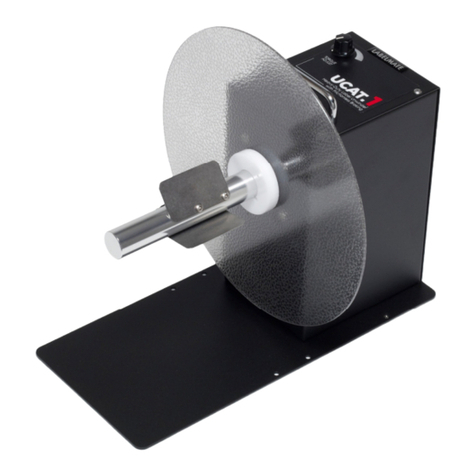

MODEL LM1010 POWER BACK GAUGE

MECHANICAL SHEAR

OPERATION, PARTS & MAINTENANCE MANUAL

Model: Purchased From:

Serial #: Date Received:

6926 Smithville Hwy., McMinnville, TN 37110

931-934-2211 / Fax: 931-934-2220

www.tennsmith.com

2

TABLE OF CONTENTS

SUBJECT PAGE NUMBERS

SHEAR SPECIFICATIONS 3

WARRANTY INFORMATION 3

SAFETY LABELING AND INSTUCTIONS 4-9

INSTALLATION 10

OPERATING INSTRUCTIONS 11-13

BLADE CLEARANCE/ADJUSTMENT 14

BLADE ROTATION/REPLACING 15-16

BACKGAUGE INFORMATION 17

HOLDDOWN INFORMATION 18

SHEET SUPPORT SYSTEM INFORMATION 19

MAINTENANCE 20-21

PARTS VIEW AND DESCRIPTIONS 22-29

ELECTRICAL DIAGRAM 30-31

MOTOR AND GEARBOX INFORMATION 32-43

3

LM SERIES SHEAR

LM1010

Maximum Shearing Capacity, Mild Steel

Mild Steel Rated Materials at 80,000 Tensile / 44,000 Yield

10 gauge / 3,5mm

Maximum Shearing Capacity, Stainless Steel

Stainless Shear Rated Materials at 90,000 Tensile / 55,000 Yield

14 gauge / 2,0mm

Maximum Cutting Length 121 in / 3073mm

Back gauge Range 30 in / 762mm

Strokes per Minute 35

Number of Hold downs 16

Motor-230/460v, 3-phase, 60Hz 12.5 hp

Overall Dimensions, Less Gauges, LxWxH 145 x 39 x 60 in

Floor Space, Gauges in Position 145 x 78 x 60 in

Shipping Weight 9,500 lbs.

3-YEAR LIMITED WARRANTY

TENNSMITH machinery and component parts are carefully inspected at various stages of production and

are tested and inspected prior to shipment. We agree that for a period of twelve (12) months from the date

of delivery from our authorized distributor to replace, at our option, any machine (or component part thereof)

proving defective within the above period. Additionally, we agree that for a period of thirty-six (36) months

from date of delivery to replace component parts proving defective within the stated period. All warranty

claims are made F.O.B. our plant, providing such machine (or component part) is returned freight prepaid to

our plant, or a designated service center of the undersigned, for our examination. This warranty does not

include repair or replacement required because of misuse, abuse, or because of normal wear and tear; or

electrical components which are warranty by their manufacturer. Further, we cannot be responsible for the

cost of repairs made or attempted outside our factory or designated service center without our authorization.

No claims for defects will be honored if the name and data place has been remove. This warranty is made

expressly in place of all other warranties or guarantees express or implied, with respect to fitness,

merchantability, quality or operative ness. This warranty becomes effective only when the accompanying

warranty card is fully and properly filled out returned to the factory within ten (10) days from date of delivery.

4

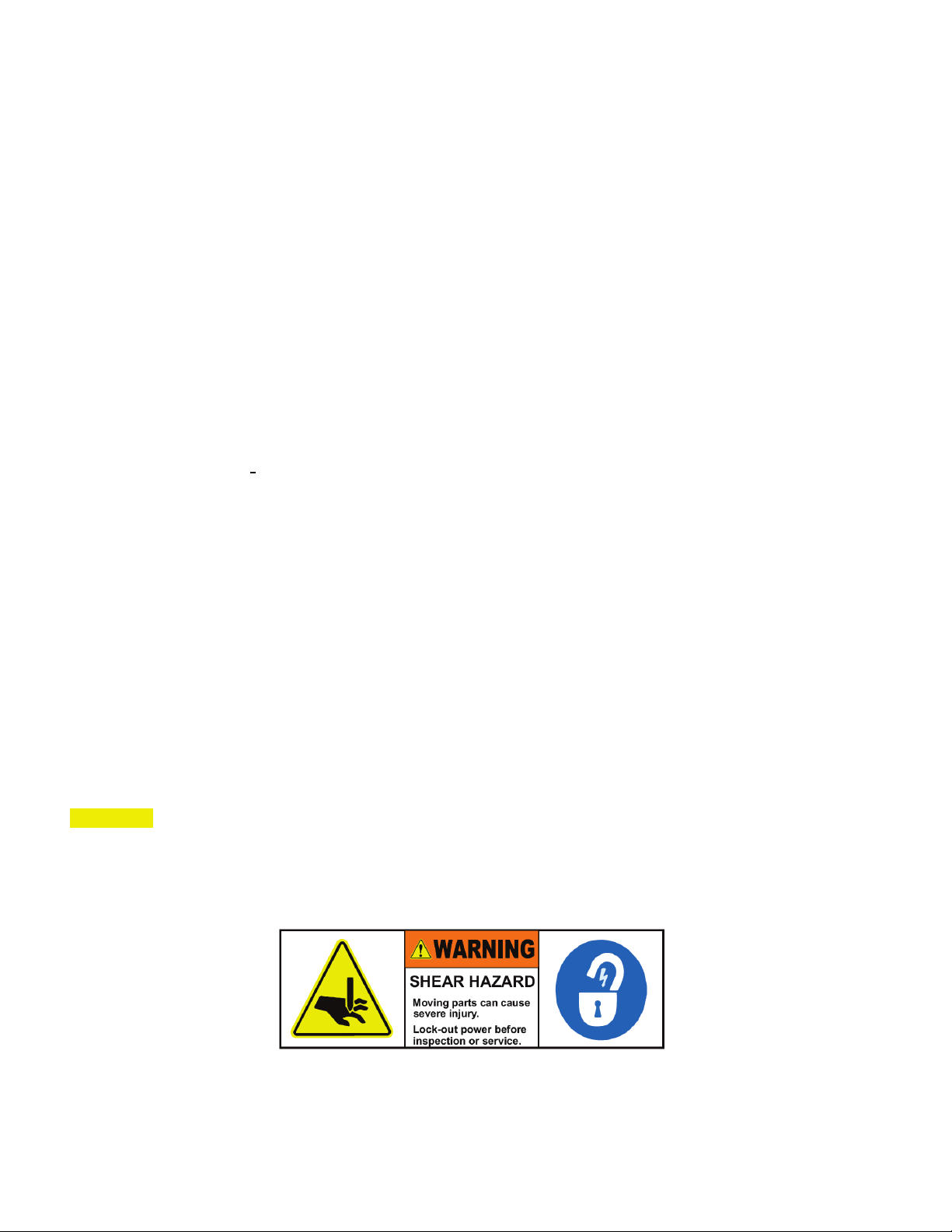

ATTENTION

Please verify that the following safety decals are attached to the LM Shear. If you do not locate all of

the decals, please contact Tennsmith to replace any missing or unreadable safety labels.

NEVER operate this machine without the proper safety labeling.

5

6

7

8

SAFETY INSTRUCTIONS

1. Do not operate service or perform maintenance prior to reading and understanding the

instruction manual. Become familiar with and understand the hazards and limitations of

your shear.

2. Wear approved eye protection and protective footwear while operating the machine.

3. Be certain this machine is properly wired and grounded to conform to the National Electric

Code. The connection of this machine to the power source should only be made by and

inspected by a qualified electrician.

4. Keep hands and body parts clear of the hold down, cutter head and blade area.

5. Do not exceed the rated capacity of the machine.

6. Never leave the machine in a power on condition when unattended.

7. Always disconnect the machine from the power source before attempting maintenance,

repairs or adjustments.

9

8. DANGER! Do not attempt to remove the hold down before inserting and bottoming out

the hold down compression bolts (71). The compression bolts were shipped with the

machine. When receiving the shear the bolts are located inside of the electrical box.

Please remove them and store them in a location to be accessible.

9. Do not remove guards unless required to service the machine. Replace all protective

covers prior to operation.

10. Always wear gloves to protect your hands when handling the shear blades.

11. Insure that the point of operation safeguarding is provided, used and maintained for any

applicable use or service which exposes bodily hazards. For more details please refer the

ANSI Standards for Shear Operations.

12. Keep the Work area around this machine clear and clean to avoid tripping or slipping.

10

INSTALLING THE SHEAR

The unit is shipped with a lifting bolt attached on the top of the cutter head. The shear should be lifted and

positioned by using a sling or chain passed through the lifting bolt.

CAUTION! The LM1010 shear weighs approximately 10,000 lbs. net. Be sure to verify the maximum load

permissible for a given chain or sling.

Locate the machine in a well lighted area on a solid level floor. Use lag screws or bolts with expandable

shields or similar holding devices through the mounting holes on each of the unit’s side panels (22,51) The

center line dimensions for the foundation holes can be found on the diagram supplied with the manual on

page ().

The shear must be securely anchored to the floor and leveled before operating. Check the level of the

shear with a machinist level both along the length and depth of the machine. Use the leveling screws (35)

provided with the machine to achieve proper level. It may be advisable to slip a small section of light

gauge sheet metal under the leveling screws so that their adjustment will not penetrate the floor.

ELECTRICAL SPECIFICATIONS

A wiring diagram is located in this manual and inside the electrical box (41). The connection of this

machine to the power source should only be made and inspected by a qualified electrician. This machine

should be properly grounded. Improper wiring may result in accidental shock which could cause grave

injury or death. Motor rotation should match the directional indicators found on the motor housing. The unit

is equipped with 230v/460v, 3 phase, 60Hz motor. The manufacture’s data on the motor will detail its

specifications.

11

LM Operator’s Control Panel

MODE OF OPERATION SWITCH:

1. CONTINUOUS

2. SINGLE or

3. JOG

PULL: TURN ON MACHINE (ILLUMINATED

RED WHEN ON)

PUSH: TURN OFF MACHINE PUSH:

EMERGENCY STOP

3-PHASE ELECTRICAL

POWER DISCONNECT SWITCH

12

LM1010 SHEAR CONTROL PANEL OPERATION

Please refer to the previous page which shows the 4 functions of the control panel box on your

LM1010 Shear

1. On/Off Push/Pull Switch:

This switch is located on the upper left corner of the box. It is labeled 1.on the previous page. To

operate the shear, turn the main disconnect power switch to the on position and pull the Push/Pull

switch to out position until the light illuminates the switch. The shear is now ready to operate.

Please note if your switch does not illuminate in the out position, you must immediately replace the

bulb located within the switch. It is unsafe to operate this shear without the illuminated switch.

Please contact Tennsmith if you need assistance replacing the bulb.

2. To the right of the Push/Pull Switch is the Jog/Run Switch:

This selector type switch is designated 2 on the previous page. In normal shearing operation this

switch should be in the Run position.

3. The Jog Button is located under the Push/Pull switch on the panel:

It is designated 3 on the previous page. The Jog function allows the operator to engage the motor

and move the cutter head of the shear up or down slowly and hold the cutter head at a particular

position. A secondary function of the Jog function is move the cutter head up if material is ever

wedged between the blades and stalls your machine. The primary use of the Jog function is to

check the clearance between the upper and lower blades at various points within the shearing

cycle.

To operate the Jog function, select Jog on the switch 2 in the upper right corner of the panel. Next, select

either Forward or Reverse on the switch designated 4 next to the Jog switch, and finally push the Jog

switch to move the cutter head of the shear.

CAUTION! If you are performing a check of the clearance or blade gap of the shear, the shear must be in

an off position at the Push/Pull switch 1 and at the main disconnect power switch located on the outside of

the box. In addition a lockout tag must be securely placed on the main electrical connection anytime you

are verifying the blade clearance.

If you have any questions on this procedure, please consult the factory prior to any adjustments

on your shear.

13

4. Stroke Selector Switch:

This switch is located towards the bottom of the panel and is designated 5 on the previous page.

The switch has two options:

a. Cont – This is for continuous operation of the cutter head of the shear. To engage the

continuous mode, select run on switch 2 (Jog/Run Switch) and select Cont. on the stroke

selector switch. With this mode the cutter head will repeat continuously a full cycle until the

operator releases his foot from the foot pedal of the shear. This mode is useful when cutting

short strips of material that is generally 2” or less.

b. Single – With this mode, the shear will make one complete down and up cycle each time the

foot pedal is pressed. This is the standard mode of operation on this shear.

Please contact the factory if you have any questions regarding the operation of this shear.

14

BLADE CLEARANCE

The blade clearance on the LM1010 was set at the factory to .004 in. on the ends of the blades with a .003

gap in the center of the machine. At this setting, your shear should provide satisfactory results over a

broad range of materials and thickness. However, when shearing lighter gauge materials a tighter blade

gap may be desired. Also, upon turning the blades to a new edge or after re-sharpening the blades, the

blade clearance must be reset.

CAUTION! Checking the blade gap will require removing the wire finger guard (80). Do not operate the

shear without the guard in place. To check the blade clearance, set the machine to the jog mode and jog

the cutter head down so that the blades just overlap at the point at which the inspection is to take place.

WARNING! Disconnect power to the machine prior to making the measurement. Use a feeler gauge to

make the measurement.

The blade clearance adjustment is made in the following manner:

1. Loosen the two table locking bolts (49) located near the mid-section of each side panel and then

retighten the bolts hand tight.

2. Loosen the four table bolts (43), again reasserting only a slight amount of pressure back to each

one.

3. The table positioning screws (20) located at both ends of the table are the means used to achieve

the proper blade clearance. The forward screw pushes the table and bottom blade toward the

cutter head. Likewise, the rear screw adjusts the blade back, thus increasing the clearance. To

set the clearance, place a feeler gauge of the same thickness as the desired clearance between

the two blades. Adjust the forward screw outward until the feeler gauge is locked between the

blades and cannot be removed. Then adjust the rear screw in the opposite direction until the

gauge stock is freed. The opposing actions of the screws serve to attain a tight, positive setting.

4. After setting the clearance on both ends of the machine, retighten the four table bolts and the two

locking bolts.

5. The blade clearance in the center of the machine controlled by adjusting the center truss located at

the rear of the cutter head. The blade clearance in the center of the shear should be set at least

.001 closer than the dimension chosen for the ends of the blade.

6. Reposition all protective guards and covers.

Please contact the factory if you have any question regarding this procedure.

15

REPLACING/ROTATING BLADES

The blades on the LM Series shears are four edged blades constructed of high carbon, high chromium

tool steel. Top and bottom blades are interchangeable. Upon utilizing all four edges of you blades, you

may return the blades to the factory for re-sharpening or to a qualified blade re-sharpener, such as a blade

manufacturer.

To remove and reposition the blades, the procedure is as follows:

1. DANGER!Disconnect the main electrical power source to the shear.

2. Removal of the hold down assembly (69)

A. DANGER! Never attempt to remove the hold down assembly without inserting and

bottoming out the hold down compression bolts (1/2” x 6” bolts shipped with the machine)

which are required to contain the spring pressure of the hold down pads while the assembly

is removed from the shear. Remove the top sheet metal cover from the top of the hold

down, and insert the compression bolts inside the hole mounts on top of the hold down until

each bolt bottoms out.

B. After bottoming out the compression bolts, remove the four hex head bolts (81) which

attach the hold down to the side panels on each end.

C. Use a sling and fork lift to remove the hold down after pulling the assembly free of the front

gib screw space collars located on the side frames of the shear.

3. Removal of the top blade.

CAUTION! Use gloves to handle the blade to protect your hands. Place a wood block wedge

between the upper and lower blades. Loosen the top blade bolts starting at the ends of the

blade working toward the center. Rotate the blade to a new cutting edge and reversing the

procedure, reinsert and snug the bolts working from the center out to each end.

16

4. With all bolts in place, securely torque the bolts while insuring that the blade is properly seated in

the machined blade slot of the cutter head by using either a brass or wood pry bar.

5. Repeat the above procedures similarly to reposition the bottom blade.

6. Use the procedures outlined in the BLADE CLEARANCE section of this manual to reset the

proper baled gap. CAUTION!Upon repositioning the shear blades, it is imperative that the bottom

blade be adjusted well clear of the top blade before attempting to jog the cutter head down to make

the blade clearance adjustment. Otherwise, crashing of the blades could result in severe damage

to the machine.

7. Reposition the hold down assembly.

BACKGAUGE INFORMATION

The LM1010 shear is fitted with a front operated powered back gauge as standard equipment. The gauge

was installed and calibrated at the factory and shipped intact mounted on the shear. Inspect the gauge

carefully to determine any possible movement or damage in transit.

The gauge has 30 inches of travel. To verify the back gauge was not disturbed during shipping, rotate the

hand wheel bringing the gauge into contact with the bottom blade. The display should now read zero. If

the display has a value other than zero and gauge is in fact in contact with the bottom blade, the unit must

be adjusted.

To move the back gage select on the control panel which direction to move: In to move the back gauge

towards the blade / out to move the back gauge away from the blade. Use the handle wheel attached to

the motor for exact measurement adjustments. The back gauge will measure to a thousandth of an inch.

ADJUSTING the BACKGAUGE

1. Power feed backgauge for quick in and out positioning.

2. Final position is set with hand wheel.

3. Large .71" LED display pre-programmed at factory.

4. 30” (in) backgauge travel.

5. Forward (IN) and reverse (OUT) over-travel switches to prevent backgauge crash.

6. Digital readout can be reset at any time.

7. Guarding to protect backgauge assembly.

17

USING THE DRO BACKGAUGE

To operate the backgauge:

1. Press and hold the “IN” button located on the control box to move backgauge in.

2. Press and hold the “OUT” button located on the control box to move backgauge out.

NOTE: FORWARD AND REVERSE OVER-TRAVEL SWITCHES ARE INSTALLED TO PREVENT

BACKGAUGE CRASHES.

3. Use the jog buttons to power the backgauge close to the desired position. Then reach the final position

by using the hand wheel located on the backgauge drive motor. When moving backgauge out to a

position always remember to take out any backlash by first moving past the final position and then

coming back in. This will result in the most accurate gauging.

WARNING: KEEP HANDS AWAY FROM HANDWHEEL WHEN BACKGAUGE IS MOVING.

WARNING: DO NOT PRESS ANY BUTTONS ON THE COUNTER UNLESS YOU INTEND TO RESET

THE READ OUT OR ADJUST THE SCALE FACTOR.

4. To “zero” or reset the digital read out: Manual reset to zero is accomplished by pressing the front panel

button marked “RST”. Also, be sure the backstop is all the way “home” to insure accurate gauging after

resetting. Backgauge is considered “home” when the backstop is flush against the lower blade.

5. To adjust the Scale Factor or Calibration (CAL): The Calibration, “CAL”, has been preset at the factory

to obtain optimum accuracy. However, due to physical variances some adjusting may be necessary

once the machine is set-up for use. Pressing & Holding the “PGM” push button in for several seconds

will change the display from Position value to "CAL". Release the "PGM" push button and the current

"CAL" value will be displayed. Pressing the "arrow right" push button will enter Edit mode and each

press of the same key will toggle between each of the digits which will blink when activated. To change

the blinking digit value, press the "down arrow" push button. Each press will decrease the value by one

(9,8,7,6,5,4,3,2,1,0,-) until the desired value is obtained. When finished changing all the digits press the

“PGM” push button to accept this new value. Hold "PGM" push button for several seconds to return to

Position display. Adjust the “CAL” value slightly up if counter position is short of actual cut length or

down if cut length is too short compared to counter position. Continue adjusting “CAL” value slightly

until desired accuracy is achieved.

NOTE: Value for “CAL” should fall in the range of 0.9600< CAL<1.0400 Always "HOME" backgauge

between adjustments.

18

Hold Down Adjustment

The following is the instructions to raise the hold down height to reduce the pressure (Hold down) on your

LM shear:

1. Using the jog mode, depress the jog button until the machine cutter head reaches the bottom

or its lowest position.

2. Disconnect the power to the machine.

3. Remove the sheet metal cover on the top of the hold down.

4. To raise the height of the hold down pad use two 7/8” wrenches unlock the two nuts that are

locked and positioned against the square tube. Turn the bottom nut against the tube for 1

complete turn. Lock the top nut against the bottom.

5. Replace the top sheet metal cover to the hold down.

6. Reconnect the power to the machine.

7. Verify the clearance or height has been raised.

19

SHEET SUPPORT SYSTEM

a. Single Stroke:

When the foot pedal is activated, the sheet support will drop down and remain down

until the cycle is complete and then return to the up position.

b. Continuous Stroke:

When the foot pedal is activated, the sheet support will drop down and stay down as

long as the foot pedal is activated. When the foot pedal is released the cutter head will

return to top of the stroke and the sheet support return to the up position.

c. Speed of the System:

The speed of the sheet support is regulated by the two flow controls on the sheet

support air valve. The pressure to the system is regulated by the Filter / Regulator unit

that the air supply connects to. Generally 80 psi on the regulator will give consistent

operation providing the incoming air supply is 90 psi or higher (max 150 psi). The

incoming air supply should also have a flow rate of at least 5 cfm with a 3 second

recovery time.

d. Dump Time:

Rear dump sheet support systems generally have this time set to 0 seconds. The sheet

support will drop as soon as the cutter head begins its down stroke.

Front dump sheet support systems have a slight delay (approximately .5 seconds)

before the system drops.

Please consult the factory for adjustments for sheet support system speed.

20

MAINTENANCE

On a monthly basis, remove the top cover (11) of each side panel and grease the gib plates (9, 10, 15).

This can be best accomplished by jogging the cutter head down to the extreme down-stroke position, thus

exposing a majority of the gib surface.

WARNING! MAKE SURE THE POWER TO THE MACHINE HAS BEEN TURN OFF WHEN APPLING

LUBRICATES.

Also each month, apply grease to the zerk fitting of the support bearings (53) of the drive linkage shaft

(55). Otherwise, periodic lubrication with a good grade of machine oil to the remaining moving parts such

as those associated with the linkage are of the self-lubricating, oil impregnated composition. Additionally,

the manufactures recommended maintenances schedule for the power unit of the shear is included in this

manual as an appendix.

Table of contents

Other Tennsmith Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Scheppach

Scheppach rs 350 Translation of original instruction manual

Maxcess

Maxcess FIFE D-MAXE 2 Quick reference guide

DeLaval

DeLaval MA200 Instruction book

Clarke

Clarke CSA10EP Operation & maintenance instructions

Doka

Doka Shifting wheel KS operating instructions

Reflex

Reflex Fillcontrol Auto operating manual