Form

#

Z409

Model

5265

Date

2-02lA

5"

Dia. Angle Sander

IMPORTANT

Readthese instructionscarefully before installing,operating,servicingor repairingthis

tool. Keepthese instructionsina safe accessible place.

SAFETY MESSAGES

Personal SafetyEquipment

Use

-

Safety Glasses

YES

Safety ruleswhen usinga

5265

Sander

Use

-

Safety Gloves

YES

Use

-

Safety Boots

Use

-

Breathing Masks

YES

Use

-

EarProtectors

YES

-

Donot useas a grinder.

-

Do not use polystyrene pads.

-

Useaccessories ratedabove

7,000

RPM.

-

Prolongedexposureto vibrationmay causeinjury.

-

Readallinstructionsbeforeusingthis

tool.

All

operators

must

befullytrained

in

its

use

and

aware of thesesafety rules.

-

Donot exceedthe maximumworking air pressure.

-

Usepersonalprotectionequipment

as

recommended.

-

Some dust createdby powersanding, sawing, grinding,

drilling, and other construction activities contains

chemicalsknowntocausecancer, birthdefectsandother

reproductive harm.

-

Usecompressedaironlyattherecommendedconditions.

-

If the tool appears to malfunction, remove from use

immediatelyandarrangefor serviceandrepair. Ifitisnot

practicaltoremovetoolfrom service,then shutoff the air

supply to the tool and write or have written a warning

noteandattachitto thetool.

-

Iftoolis to beusedwith a balanceror other suspension

device, ensure that the tool is firmly attached to the

suspension/support device.

-

When operating the tool, always keep the body and

particularlythe handsawayfromtheworkingattachment

fixedto the tool.

-

Thetool isnotelectricallyinsulated.Never usethetool if

there is any chance of coming into contact with live

electricity.

-

Always when usingthe tool, adopt a firm footingandlor

position and grip the tool sufficiently only to overcome

any reactionforces that may result from the tool doing

work. Donot overgrip.

-

Useonly correctspare partsfor main-

7

A

WARNING

Always ReadInstructionsBefore

0

UsingPowerTools

tenance and repair. Do not improvise

Operator Instructions

Includes:

Safetv Rules

@

AlwaysWear Safety Goggles

@

Wear HearingProtection

Avoid ProlongedExposure

W^

TOVibration

or make temporary repairs. Major

servicing and repairs should only be

carriedoutbypersonstrainedtodoso.

-

Donotlock,tape, wire, etc.the'On/Off'

valve in 'On' position. The throttle

trigger/ lever, etc. must always be free

to return to the 'Off' position when

ores seen

Use

Work Stations

Putting Into Service

Operating

Dismantlingand Assembly.

released.

-

Alwaysshutofftheairsupplytothetool

andpressthe'On/Offlvalveto exhaust

the air from the feed hose before

fitting, removing or adjusting the

workingattachment fittedto the tool.

-

Before usingthe tool, make sure that a shut off device

hasbeenfittedtothesupplylineandthepositionisknown

andeasilyaccessiblesothattheairsupplytothetoolcan

beshutoff inan emergency.

-

Check hoseandfittings regularlyfor wear.

-

Take care against entanglement of the moving parts of

the tool with clothing, hair, ties, cleaning rags, rings,

jewelry, watches, bracelets, etc.This couldcausethebody

or partsof the body to bedrawntowards and incontact

with the moving parts of the tool and could be very

dangerous.

-

Itisexpectedthat users will adopt safe workingpractices

andobserve

all

local,regionalor countrylegalrequirements

when installing,usingor maintainingthetool.

-

Take carethatthe exhaustairdoesnotpointtowards any

other person or material or substance that could be

contaminatedby oildroplets.Whenfirst lubricatinga tool

or if the tool exhaust has a highoil content, do not allow

the exhaust airtocome nearvery hotsurfacesorflames.

-

Never lay thetooldown untiltheworkingattachment has

stoppedmoving.

-

When the tool is not inuse, shut off the air supply and

pressthrottle triggerllever to drainthe supply line. Ifthe

toolisnotto be used for a periodof time, first lubricate,

disconnectfromairsupplyandstoreinadryaverageroom

temperatureenvironment.

-

If the tool is passedfrom one user to a new or inexperi-

enceduser, makesuretheseinstructionsareavailableto

bepassedwith the tool.

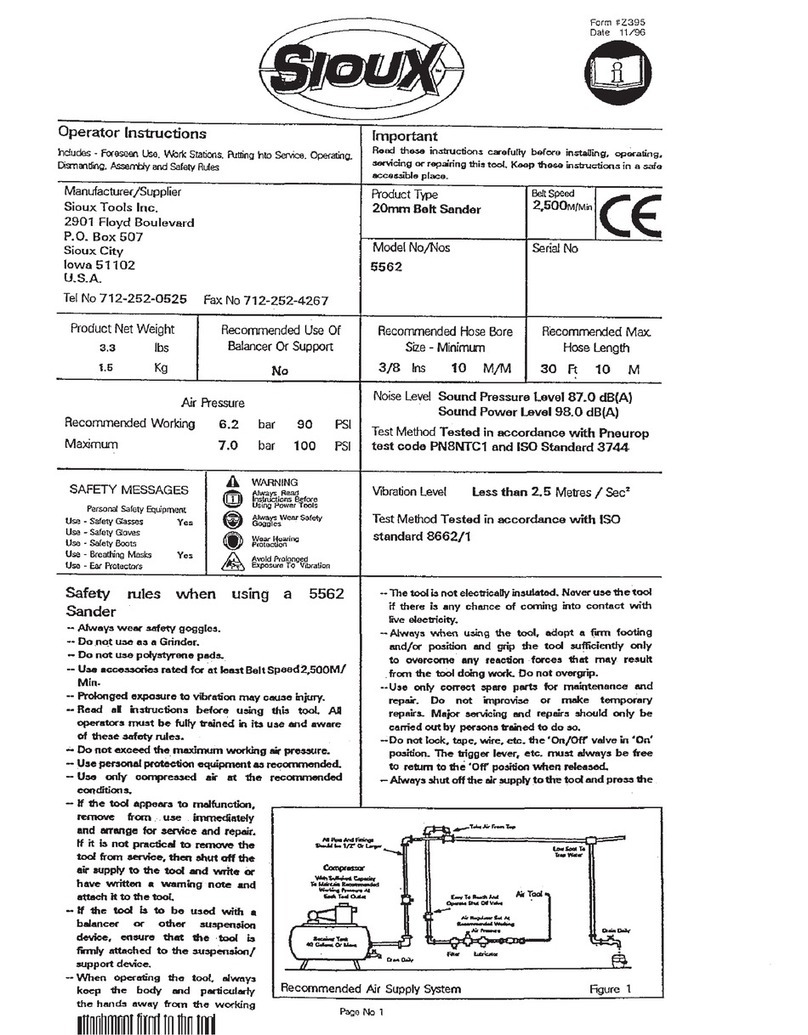

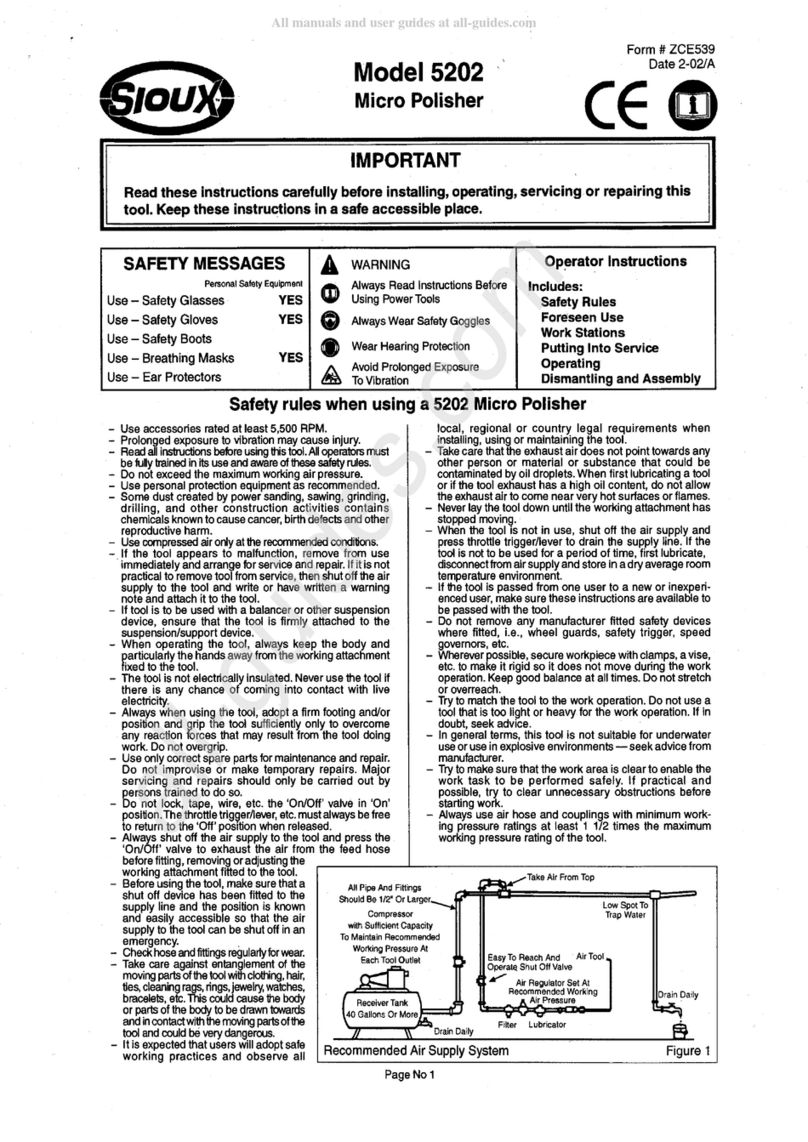

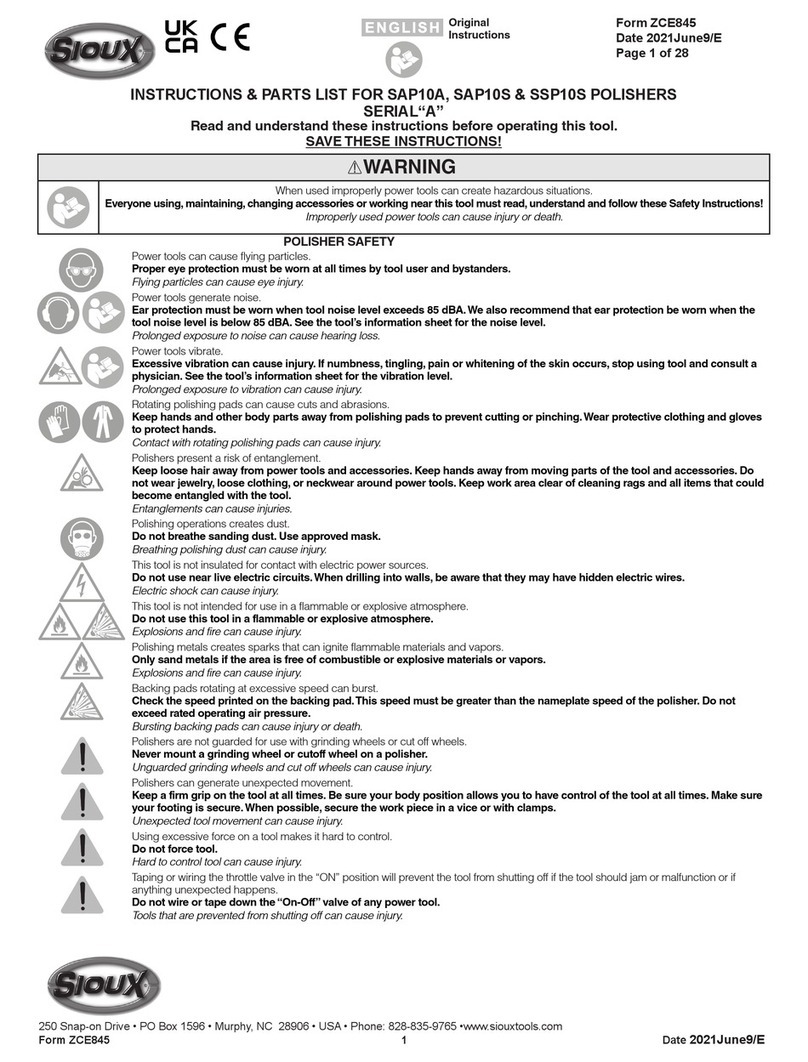

Take Air From Top

-

a

Low Spot To

TrapWater

with

Sufficient Capacity

To Maintain Recommended

11

11

11

Working PressureAt

11

11

EachTool Outlet

Easy

To Reach

And

Air Tool

Operate.Shut OftValve

\

Filter Lubricator

Drain Daily

L

Recommended Air Supply System Figure

1

Page No

1