springwasher (3). balancenut (4). drivewasher

(5)

wave washer

(6)

and

then removeretainingring(7) andwave washer

(8).

Still

grippingrandombalancebody(1

l),

tapoutmountingpadshaft(9)

assemblyat the rearendto removethe assembly fromtherandom

balance body with wave washer

(15).

Remove fixing

screw

(14)

from padmountingshaft (9) and tap this padmounting shaft

(9)

throughbearing (10).

Remove

two

screws

(38)

andtakeoff motor cover

(49).

Grip

body

(16)

in a vise fittedwith soft jaws and remove four rotor screws

(31) andtake off rotorcover (29). Fromthe frontendof thetool,tap

the

end

of rotorshaft (18) to drivethe motor assemblyout of the

body(16). Notehowthe slot inthe side of thecylindei(26) has to

line up with the portinthe body (16). Grip rearplate(28) andtap

the rearendof the rotorshaft

(18)

throughthe rearplate(28) and

bearing(24). Remove rotor blades (23), shims (20). and unscrew

set screw (22) from rotor (21) and remove rotor shaft (18). Note

locationof set screw (22) hole

in

rotor(21) inpositionwith flat on

rotorshaft (18) andremoveshims(20).Tap frontendof rotorshaft

(18)throughfrontplate(17)to removebearing(19)fromfrontplate

(17).

Unscrew cap screw (32) and take out throttle spring

(33).

pushrod(45). andO-ring(34). Do notremovevalve bodybushing

(46) frombody(16).Take off retainingring(35), removeplatewasher

(36)

andrubberwasher (37). Removescrew(44)andlockwasher

(43). Pulloff regulatorlever (42) andO-ring(41). Carefullypullout

regulator (40) with

two

O-rings (39). Unscrew bolt

(53)

from nut

(54)

andtake off safety lever (52). Take out two

screws

(50)

and

removeleverbracket (51). Remove handlegrip

(57)

andunscrew

handle(58) from body (16) and take off valve lever (55). Remove

muffler (47) and muffler element (48) trom motor cover (49).

Reassembly

Clean all parts andexamine for wear. Use only manufacturer or

authorizeddistributor supplied spare partsand replaceany worn

parts. Lookinparticularforwearonseals,

ball

bearingandblades.

Coatallparts inpneumatictoollubricatingoil, and reassemblein

the reverseorder carefully. Assure allparts are tight and letlever

and regulatormechanisms operate freely. With (ever depressed,

pour

5

miof a suitable pneumatic

tool

oil into inlet bushing and

release.Connect a suitableair supply and run this tool for

2

or

3

seconds to allow the oilto circulate.

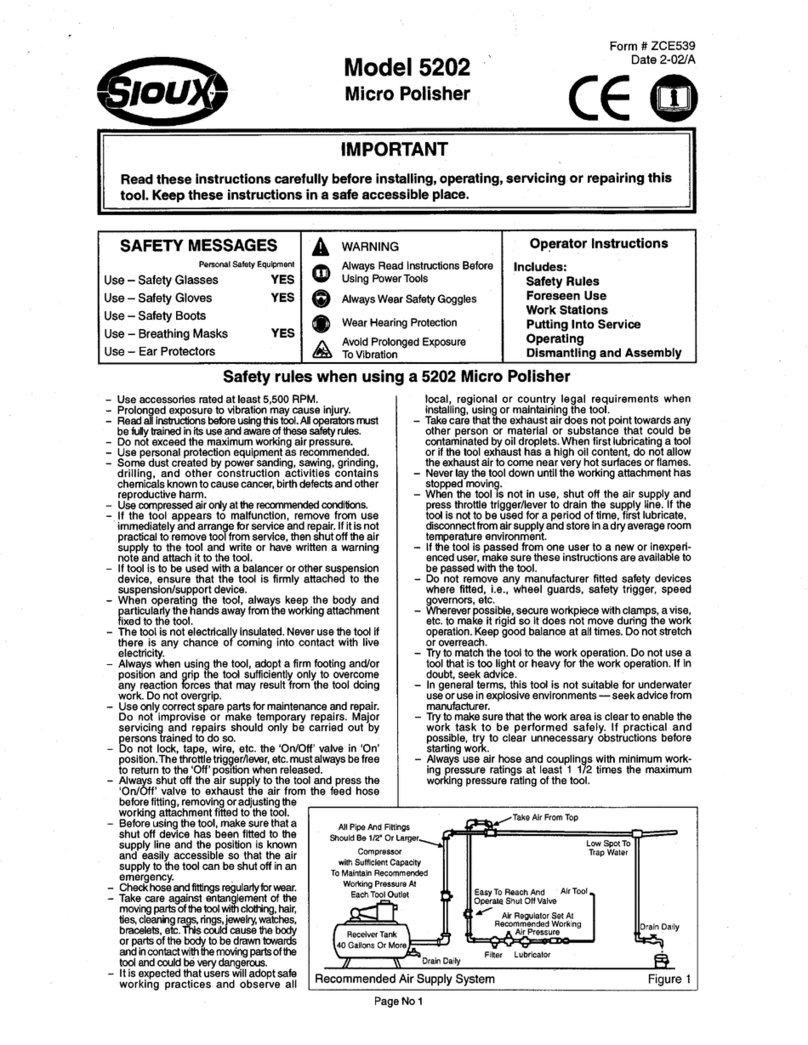

Operation Specification

AverageAir Consumption 4.0

dm

(28 scfm)

Air InletThread 114-18NPT

SpindleThread 5116-24UNF

t

Length

8"

(204mm)

Height 5.4" (136mm)

Pad

6"

(150mm)

I

at

60

PSIGl4.2 bar

1

Notes

I.

r

Declarationof Conformity

cc

SiouxTools Inc.

117

LeviDrive,Murphy,

NC

28906,

U.S.A.

declareunder our soleresponsibilitythat the product

Model5558A

6"

DualAction Sander, Serial Number

to which thisdeclaration relates isinconformity

with

thefollowingstandard(s) orother normativedocument(s)

EN792 (Draft), EN292 Parts

1

&

2,

IS08662 Parts

1

&

8, Pneurop PN8NTC1

followingthe provisionsof

89139ZEECas amended

by

91/368/EEC

&

93144fEEC Directives

&

fAL

G a

.

Seebeck (President)

Page

No

3