Form

#

ZCE539

Model

5202

Date2-02/A

Micro Polisher

IMPORTANT

Readthese instructionscarefully before installing,operating, servicingor repairingthis

tool.

Keep

these instructionsin a safe accessibleplace.

Personal

Safety

Equipment

YES

I

0

Always Read InstructionsBefore Includes:

1

Use

-

Safety Glasses UsingPowerTools

1

Safety Rules

1

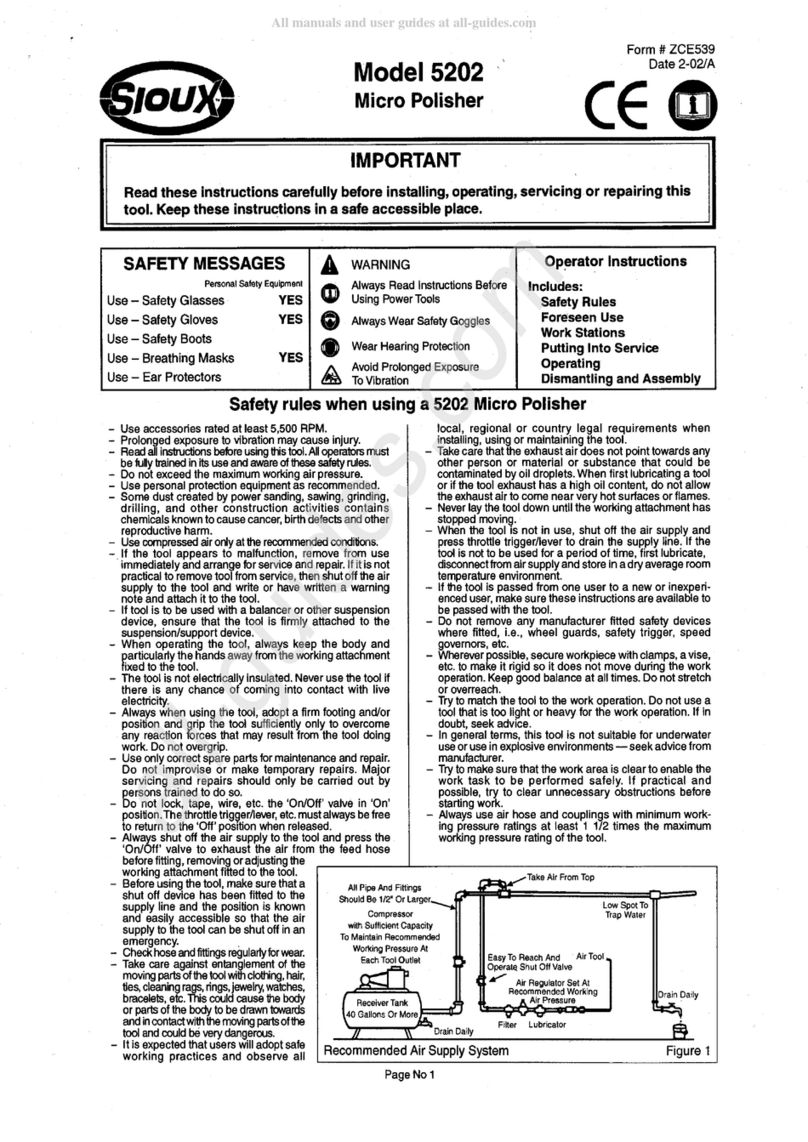

SAFETY MESSAGES

1

A

WARNING

Operator Instructions

Safety ruleswhen using a

5202

Micro Polisher

Use

-

Safety Gloves YES

Use

-

Safety Boots

Use

-

Breathing

Masks

YES

Use

-

Ear Protectors

-

Useaccessoriesratedat least

5,500

RPM.

-

Prolongedexposuretovibration may cause injury.

-

Readallinstructionsbeforeusingthistool. All operatorsmust

befullytrainedinitsuseandaware

of

these safety rules.

-

Donotexceedthe maximumworkingair pressure.

-

Use personalprotectionequipmentas recommended.

-

Somedustcreatedby power sanding, sawing, grinding,

drilling, and other construction activities contains

chemicalsknowntocausecancer,birthdefectsandother

reproductive harm.

-

Usecompressedair only atthe recommendedconditions.

-

If the tool appears to malfunction, remove from use

immediatelyandarrangefor serviceandrepair. If itisnot

practicalto removetoolfromservice,thenshutofftheair

supply to the tool and write or have written a warning

noteandattach ittothetool.

-

If tool is to be usedwith a balanceror other suspension

device, ensure that the tool is firmly attached to the

suspensionlsupportdevice.

-

When operating the tool, always keep the body and

I'

articularlythe handsawayfromthe workingattachment

ixedto the tool.

-

Thetool isnot electricallyinsulated.Never usethetool if

there is any chance of coming into contact with live

electricity.

-

Always when usingthe tool, adopt a firm footing and/or

position and rip the tool sufficiently only to overcome

any reactionkrcesthat may result from the tool doing

work. Do not overgrip.

-

Useonly correctspare partsfor maintenanceandrepair.

Do not improvise or make temporary repairs. Major

servicing and repairs should only be carried out by

personstrainedto do so.

-

Do not lock, tape, wire, etc. the 'OnIOff' valve in 'On'

position.Thethrottletriggerllever,etc. mustalwaysbefree

to returnto the 'Off' positionwhen released.

-

Always shut off the air supply to the tool and press the

'OnlOff valve to exhaust the air from the feed hose

beforefitting, removingoradjustingthe

working attachmentfittedto the tool.

-

Beforeusingthetool,makesurethat a

shut off device has been fitted to the

supply line and the position is known

and easily accessible so that the air

supply to the tool canbeshut off inan

emergency.

-

Checkhoseandfittingsregularlyforwear.

-

Take care against entanglement of the

movingpartsofthetoolwithclothing,hair,

ties,cleaningrags,rings,jewelry, watches,

bracelets,etc.This couldcausethe

body

or partsof the bodyto be drawn towards

andincontactwiththemovingpartsofthe

toolandcould

be

very

dangerous.

-

Itisexpectedthat userswill adoptsafe

working practices and observe all

@

Always Wear Safety Goggles

@

Wear HearingProtection

Avoid ProlongedExposure

ffs^

To Vibration

local, regional or country legal requirements when

installing, usingor maintainingthe tool.

-

Takecare thattheexhaustair does not pointtowardsany

other person or material or substance that could be

contaminatedbyoil droplets.Whenfirstlubricatinga tool

or if the tool exhaust has a highoil content, do notallow

theexhaustairtocomenearvery hotsurfacesor flames.

-

Never lay thetool down untilthe workingattachmenthas

ores seen

Use

Work

Stations

Putting

Into

Service

Operating

Dismantling

and

Assembly

stoppedmoving.

-

When the tool is not in use, shut off the air supply and

pressthrottle triggerllever to drain the supply line. If the

tool isnot to be usedfor a oeriodof time. first lubricate.

disconnectfromairsupplyandstore in

a

dryaverageroom

temperatureenvironment.

-

If the tool ispassedfrom one user to a new or inexperi-

enceduser, makesurethese instructionsareavailableto

be passedwith the tool.

-

Do not remove any manufacturer fitted safety devices

where fitted, i.e., wheel guards, safety trigger, speed

governors, etc.

-

Wherever possible,secureworkpiece withclamps,avise,

etc. to make it rigidso it does not move during the work

operation. Keepgood balanceat all times. Donotstretch

or overreach.

-

Try to matchthe tool to the work operation.Do not use a

tool that is too light or heavyfor the work operation. If in

doubt, seek advice.

-

Ingeneral terms, this tool is not suitable for underwater

useoruseinexplosiveenvironments-seek advicefrom

manufacturer.

-

Try tomakesurethatthe work areaisclearto enablethe

work task to be performed safely. If practical and

possible, try to clear unnecessary obstructions before

startingwork.

-

Always use air hose and couplings with minimumwork-

ing pressure ratings at least

1

112 times the maximum

workingpressure ratingof the tool.

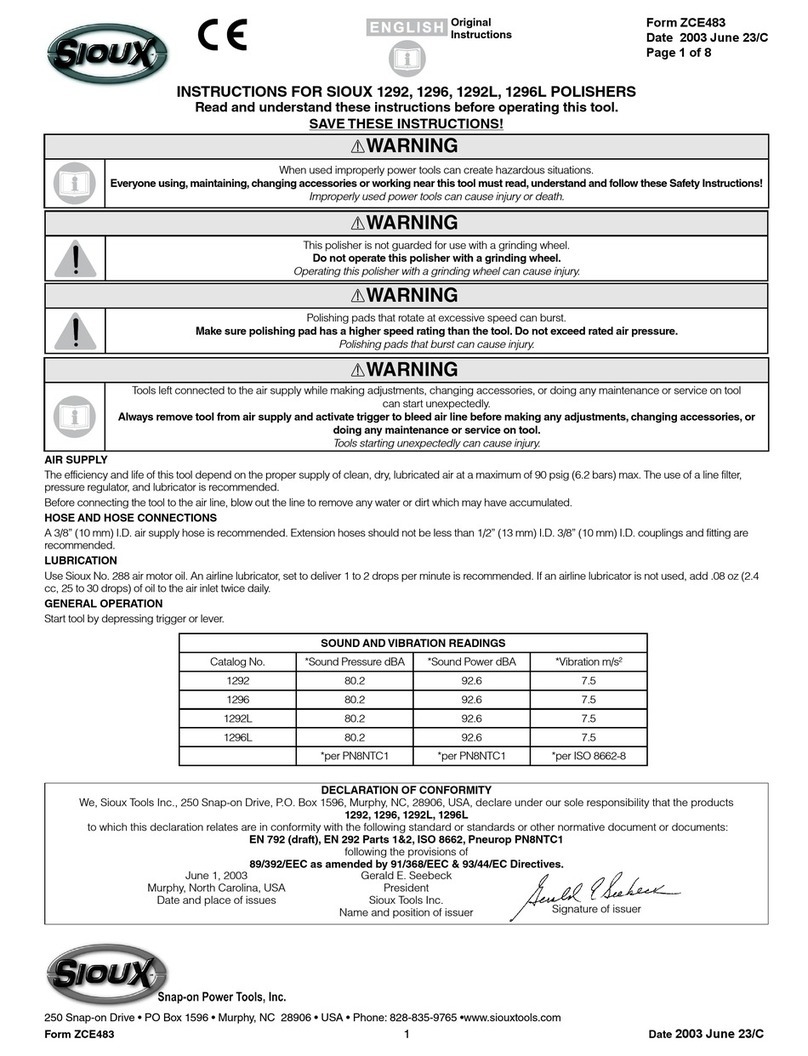

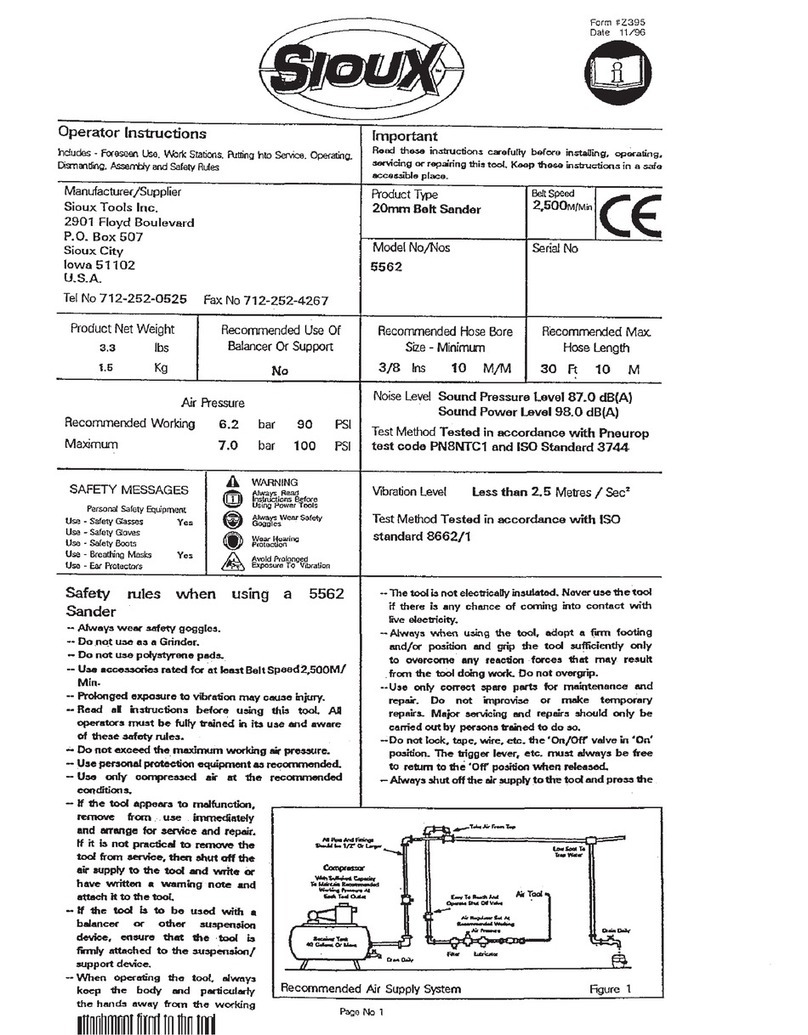

Take

Air

From

Top

All

PipeAnd

Fittings

-

Should

Be

112"

Or

Larger

A

Low

Spot

To

Compressor

Trap

Water

with

SufficientCapacity

To

Maintain

Recommended

11

11

Working

Pressure

At

Drain

Daily

L

Recommended Air Supply System Figure

1

PageNo

1